APPLYING SUB-POPULATION MEMETIC ALGORITHM FOR

MULTI-OBJECTIVE SCHEDULING PROBLEMS

Yen-Wen Wang

Department of Industrial Engineering and Management, Chin Yun Tech. University

229 Chien-Hsin Rd., Taoyuan, Taiwan. R.O.C.

Chin-Yuan Fan

Department of Industrial Engineering and Management

Yuan-Ze University, Taoyuan, Taiwan, R.O.C.

Chen-Hao Liu

Department of Information Management, Kainan University

Taoyuan Taiwan, R.O.C.

Keywords: Flowshop scheduling problem, Multi-objective scheduling, Memetic Algorithm.

Abstract: Memetic Algorithm is a population-based approach for heuristic search in optimization problems. It has

shown that this mechanic performs better than traditional Genetic Algorithms for some problem. In order to

apply in the multi-objective problem, the basic local search heuristics are combined with crossover operator

in the sub-population in this research. This approach proposed is named as Sub-population with Memetic

Algorithm, which is applied to deal with multi-objective Flowshop Scheduling Problems. Besides, the

Artificial Chromosome with probability matrix will be introduced when the algorithm evolves to certain

iteration for injecting to individual to search better combination of chromosomes, this mechanism will make

faster convergent time for evolving. Compares with other three algorithms which are MGISPGA, NSGA-II

and SPEA2, the experiments result show that this algorithm possess fast convergence and average scatter of

Pareto solutions simultaneously for solving multi-objective Flowshop Scheduling Problems in test

instances.

1 INTRODUCTION

In the operations research literature, Flowshop

scheduling is one of the most well-known problems

in the area of scheduling. Flowshops are useful tools

in modeling manufacturing processes. A

permutation Flowshop is a job processing facility

which consists of several machines and jobs to be

processed on the machines. In a permutation

Flowshop all jobs follow the same machine or

processing order and job processing is not

interrupted once started. Our objective is to find a

sequence for the jobs so that the makespan or the

completion time is a minimum.

In this research, we take a close look at the

evolutionary process for a permutation Flowshop

scheduling problems and come out with the new

idea of generating artificial chromosomes to further

improve the solution quality of the genetic

algorithm. To generate artificial chromosomes, it

depends on the probability of each job at a certain

position. The idea is originated from Chang et

al.(2005) which propose a methodology to improve

Genetic Algorithms (GAs) by mining gene

structures within a set of elite chromosomes

generated in previous generations. Instead of

replacing the crossover operator and mutation

operator due to efficiency concern, the proposed

algorithm is embedded into simple GA (SGA) and

non-dominated sorting genetic algorithm-II (NSGA-

II). The probability model acquired from the elite

chromosomes will be integrated with the genetic

376

Wang Y., Fan C. and Liu C. (2009).

APPLYING SUB-POPULATION MEMETIC ALGORITHM FOR MULTI-OBJECTIVE SCHEDULING PROBLEMS.

In Proceedings of the 6th International Conference on Informatics in Control, Automation and Robotics - Intelligent Control Systems and Optimization,

pages 376-379

DOI: 10.5220/0002208603760379

Copyright

c

SciTePress

operators in generating artificial chromosomes, i.e.,

off-springs which can be applied to enhance the

efficiency of the proposed algorithm. Apart from our

previous researches, Harik (1999), Rastegar (2006),

Zhang (2005) have discussed and proved the genetic

algorithm which is based on the probability models.

For a complete review of the relative algorithms

discussed above, please refer to Larranaga (2001),

Lozano (2006), and Pelikan (2002). In most recent

works of evolutionary algorithm with probability

models, they all concentrate on solving continue

problems rather than discrete problems. There are

only few researches in applying evolutionary

algorithm with probability models to resolve discrete

problems.

2 METHODOLOGY

A new approach is developed in this research which

is called SPMA. The method is proposed to solve

Flowshop scheduling problems and will be

compared with SPGA, NSGA-II and SPEA-II.

Through literature reviews, we find that SPGA has

very good diffusivity when solving multi-objective

problems; however, as for convergence, there still

remains room for improvement. Thus, the research

tries to strengthen the solution convergence of

SPGA by mining gene structures and local search

heuristic. Except for the original mining gene

structures (Chang 2005), we called Artificail

chromosomes (AC).

2.1 Generating Artificial Chromosomes

During the evolving process of the GA, all the

chromosomes will converge slowly into certain

distribution after the final runs. If we take a close

look at the distribution of each gene in each assigned

position, we will find out that most the genes will be

converged into certain locations which means the

gene can be allocated to the position if there is a

probabilistic matrix to guide the assignment of each

gene to each position. Artificial Chromosomes (AC)

are developed according to this observation and a

dominance matrix will record this gene distribution

information. The dominance matrix is transformed

into a probability matrix to decide the next

assignment of a gene to a position. Consequently,

AC is integrated into the procedure of genetic

algorithm and it attends to improve the performance

of genetic algorithm. The primary procedure is to

collect gene information first and to use the gene

information to generate artificial chromosomes.

Before collecting the gene information, AC collects

the chromosomes whose fitness is better by

comparing the fitness value of each chromosome

with average fitness value of current population.

Then artificial chromosome is embedded into the

genetic algorithm. The detailed steps are described

in the following:

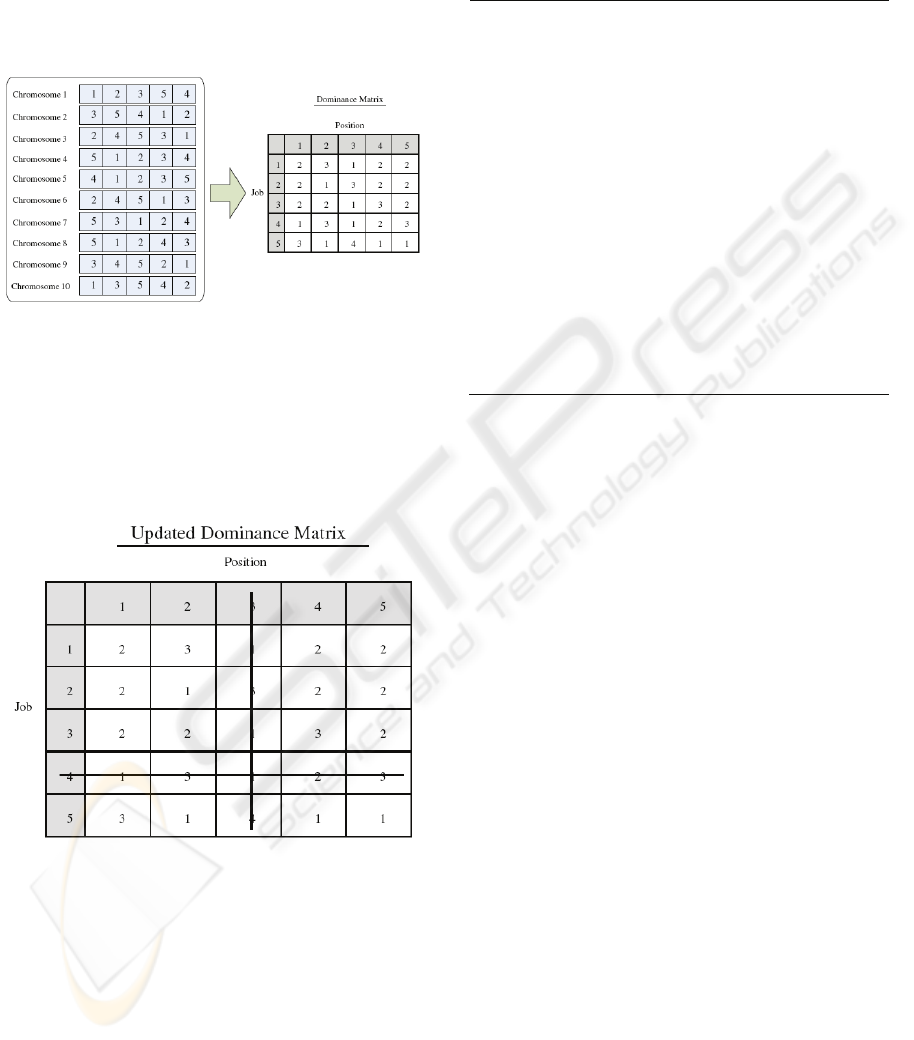

1. To convert gene information into dominance

matrix:

Before we collect gene information, selection

procedure is performed to select a set of

chromosomes. Then, for a selected chromosome,

if job i exists at position j, the frequency is added

by 1. To demonstrate the working theory of the

artificial chromosome generation procedure, a 5-

job problem is illustrated. Suppose there are ten

sequences (chromosomes) whose fitness is better

than average fitness. Then, we accumulate the

gene information from these ten chromosomes to

form a dominance matrix. As shown in the left-

hand side of Figure 1, there are two job 1, two job

2, 2 two 3, one job 4, and three job 5 on position

1. Again, there are 3 job 1, 1 job2, 2 job3, 3 job4,

and 1 job5 on position 2. The procedure will

repeat for the rest of the position. Finally, the

dominance matrix contains the gene information

from better chromosomes is illustrated in the

right-hand side of Figure 1.

2. Generate artificial chromosomes:

As soon as we collect gene information into

dominance matrix, we are going to assign jobs

onto the positions of each artificial chromosome.

The assignment sequence for every position is

assigned randomly, which is able to diversify the

artificial chromosomes. After we determine the

assignment sequence, we select one job assigned

to each position by roulette wheel selection

method based on the probability of each job on

this position. After we assign one job to a

position, the job and position in the dominance

matrix are removed. Then, the procedure

continues to select the next job until all jobs are

assigned. Assume the first job is to be assigned at

position 3 in the beginning. The frequency of each

job at position 3 is [1, 3, 1, 1, and 4] starting from

job 1 to job 5. Because the number of total

frequency is 10, the corresponding probability for

job 1 is 1/10; job 2 is 3/10, and so on. Then, we

accumulate the probability from job 1 to 5 and

roulette wheel select is able to apply this

accumulated probability. If a random probability

0.6 is generated, then job 4 is assigned to position

3.

3. Replacement strategy:

APPLYING SUB-POPULATION MEMETIC ALGORITHM FOR MULTI-OBJECTIVE SCHEDULING PROBLEMS

377

After embedding artificial chromosomes into

the population, we use l + k strategy, which

combines previous parent population and artificial

chromosomes. Then, we select better l

chromosomes from the combined population.

Consequently, better solutions are preserved to the

next generation.

Figure 1: To collect gene information and converted into a

dominance matrix.

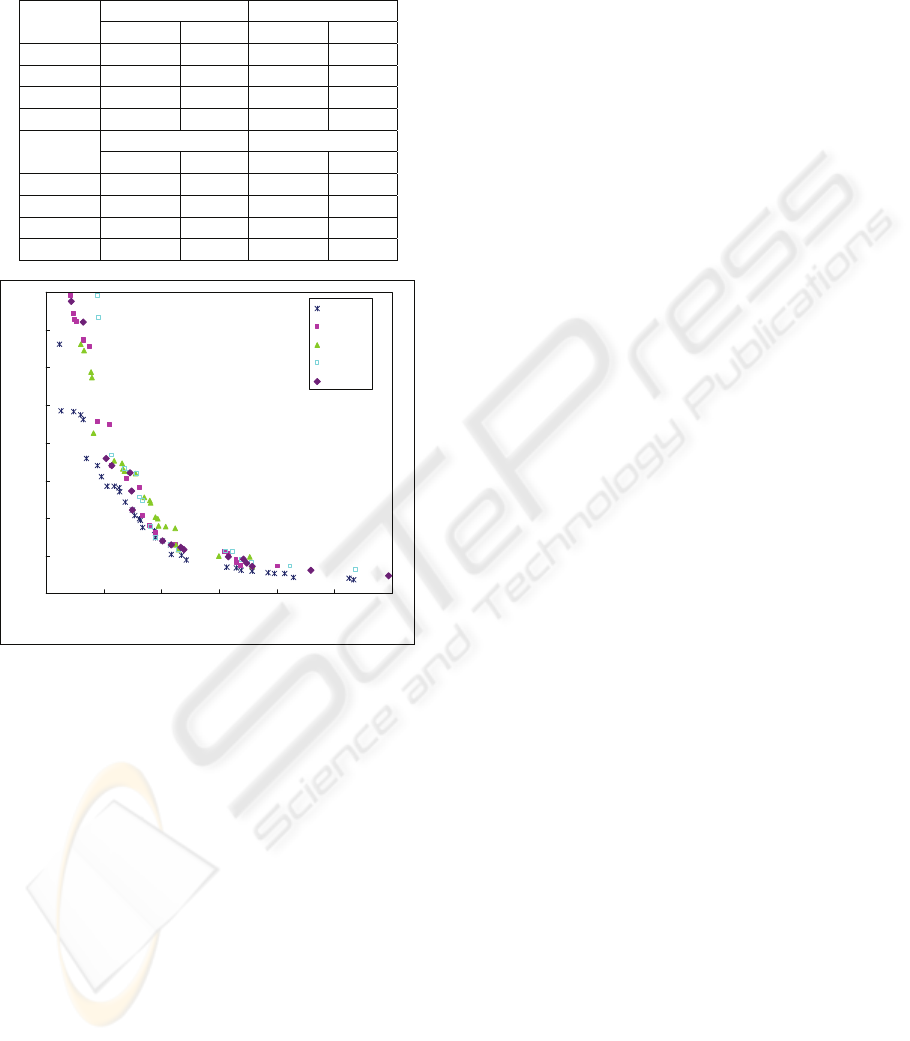

During the assignment of each job to a specific

position, the dominance matrix will be updated

continuously. For example, after assigning job 4 at

position 3 and suppose position 2 is the next one to

be assigned. An updated dominance matrix is shown

in Figure 2.

Figure 2: The updated dominance matrix after assigning

job 4 at position 3.

Next, the probability of each job is recalculated

as well as the accumulated probability. Then, a

roulette wheel selection method will select a job

based on the probability of each job. Consequently,

the algorithm iteratively assigns jobs to vacant

positions until all jobs are assigned.

2.2 The procedure of SPMA

The detailed procedure of SPMA is shown as the

following:

(Ns is the number of sub-populations; g is the

number of generations; k is the interval number of

artificial chromosomes’ generations.)

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

Initialize();

DividePopulation();

AssignWeightToEachSubGroup();

for i=1 to Iterations

for j=1 to Groups

if i % k == 0

ArtificialChromosome(j);

<GenerateArtificialChromosome(j);

LocalSearch(j);

SurvivalofThefittest(j);>

else

GeneAlgorithm(j);

<Selection(j);

Crossover(j);

Mutation(j);

LocalSearch(j);

SurvivalofThefittest (j);>

FindPareto(Groups);

UpdatePareto(Groups);

Compared with SPGA, this approach is different

in that it has the mechanism of creating AC, local

search heuristic and the sorting information of

chromosomes in each mutation is recorded for the

use of creating AC and placing them in the mating

pool for evolution. In the end,

R

D1

is a metric

which considers the convergence and diversity

simultaneously (Knowles, 2002) and it is adopted in

this research to evaluate the solution quality. Its

main concept is to calculate the shortest distance

between each solution in the Pareto-Solution set and

the set to be compared with, and then calculate the

mean value. The smaller

R

D1 is the better.

3 EXPERIMENTAL TESTS

The research uses the Flowshop scheduling case

study by Ishibuchi (2003) in which four types were

included in the bi-objective flow-shop problems;

they were 20 jobs in 20 machines, 40 jobs in 20

machines, 60 jobs in 20 machines and 80 jobs in 20

machines. Two objectives are the total completion

time (Cmax) and maximum tardiness (Tmax). The

processing and completion time are the same as used

in Ishibuchi et al. (2003). The experimental results

will be compared with those of SPGA, NSGA-II and

SPEA-II. The testing result of this sample problem is

depicted in Table 1 and Figure 3. It is obvious that

SPMA performs better in the small and medium size

problem (job = 20, 40, 60). And it deserve to be

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

378

mentioned is the Std. of SPMA is much less than

other models.

Table 1: The algorithm comparison with other methods.

Instance

(job)

NSGA II SPEA II

Ave. Std. Ave. Std.

20 43.05 14.42 37.35 14.22

40 146.36 28.71 138.6* 19.9

60 321.12 57.86 291.02 52.78

80 424.96 93.92 394.14 63.79

Instance

(job)

SPGA SPMA

Ave. Std. Ave. Std.

20 38.62 9.44 22.46* 8.89

40 146.21 21.09 142.40 20.03

60 341.86 94.15 261.24* 34.49

80 344.45* 99.12 515.34 75.72

0

100

200

300

400

500

600

700

800

2250 2300 2350 2400 2450 2500 2550

Cmax

Tmax

Reference

NSGAII

SPEAII

MGISPGA

SPMA

Figure 3: The plot of algorithms with reference Pareto set

of SPMA.

According to the above-mentioned four testing

results, we find that when solving more complex

problems, it is harder to find the improving

effectiveness of SPMA. Along with the increasing

number of jobs, the problems become more complex

and thus the improving effectiveness of SPMA can’t

be obviously noticed.

4 CONCLUSIONS

Through this study, we can verify that by combining

AC and local search heuristic with SPGA, multi-

objective scheduling problems can be solved more

effectively, especially in the small and medium size

problem. In the future, SPMA can be further

extended to three objectives or multidimensional

continuous problems. And the procedures of SPMA

might be improved to deal with large size problem.

Further investigation will be carried out to

examine whether it is possible to generate elite

chromosomes through better mining algorithms. It is

also suggested that different objectives of Flowshop

scheduling problems can be further tested such as

the arrival time of job is considered, and those with

more complex requirements such as sequence

dependent setup times.

REFERENCES

Chang, P. C., Chen, S. H., and Lin, K. L., 2005, Two

phase subpopulation genetic algorithm for parallel

machine scheduling problem, Expert Systems with

Applications, 29(3), 705–712.

Harik, G.R., Lobo, F.G., and Goldberg, D.E., 1999, The

compact genetic algorithm, IEEE Transactions of

Evolution Computing, 3 (4), 287–297.

Ishibuchi, H., Yoshida, T. and Murata, T., 2003, Balance

between Genetic Search and Local Search in Memetic

Algorithms for Multi-objective Permutation Flowshop

Scheduling, IEEE Trans on Evolutionary

Computation, 7(2), 204-223.

Larranaga, P., and Lozano, J.A., 2001, Estimation of

Distribution Algorithms: A New Tool for

Evolutionary Computation, Kluwer, Norwell.

Lozano, J.A., Larranaga, P., Inza, I., and Bengoetxea, E.,

2006, Towards a New Evolutionary Computation,

Springer.

Pelikan, M., Goldberg, D.E., and Lobo, F.G., 2002, A

survey of optimization by building and using

probabilistic models, Computational Optimization

and Applications, 21 (1), 5–20.

Rastegar, R., and Hariri, A., 2006, A step forward in

studying the compact genetic algorithm, IEEE

Transactions of Evolution Computing, 14 (3), 277–

289.

Zhang, Q., Sun, J., and Tsang, E., 2005, An evolutionary

algorithm with guided mutation for the maximum

clique problem, Evolutionary of Computing, 9 (2), 192

–200.

APPLYING SUB-POPULATION MEMETIC ALGORITHM FOR MULTI-OBJECTIVE SCHEDULING PROBLEMS

379