SOL

VING THE FEEDER ASSIGNMENT ON A REVOLVER-HEAD

GANTRY MACHINE

Py

¨

otti

¨

al

¨

a Sami, Knuutila Timo

Department of Information Technology, University of Turku, FI-20014 Turun yliopisto, Finland

Johnsson Mika

Valor Computerized Systems (Finland) Oy, Ruukinkatu 2, 20540 Turku, Finland

Nevalainen Olli S.

Department of Information Technology, University of Turku, FI-20014 Turun yliopisto, Finland

Keywords:

Printed circuit boards, Electronics assembly, Multi-spindle placement machines, Revolver-head, Nozzle,

Gantry machines, Optimization, Production control.

Abstract:

Revolver-head gantry machines are nowadays very popular because of their flexibility, accuracy and high

enough placement speed. In the optimization of this machine type the selection of nozzles into the placement

head, the order of the component reels in feeder slots, and the pick-up and placement sequences have to be

considered.

In this article, it is assumed that the selection of nozzles and the pick-up and placement sequences are fixed and

the feeder assigment is to be solved. The problem statement is formed by analysing the operation properties

of a real placement machine. Contrarily to previous literature dealing with this problem, in this work each

component can be picked up only by a certain type of nozzle. Finally, four algorithms for solving the problem

are proposed and tested. In the experimental tests with realistic data the algorithms performed equally.

1 INTRODUCTION

Electronic devices having at least one printed circuit

board (PCB) inside have become more common in

the last 20 years. The PCBs are used not only in the

consumer electronics but also for example in cars and

as parts of other bigger products. It is typical that a

great number of PCBs of the same type are produced

in batches and their manufacturing is done in assem-

bly lines which normally comprise of multiple place-

ment machines.

Research on optimisation problems of placement

machines dates to late 80’s (Ball and Magazine, 1988;

Leip

¨

al

¨

a and Nevalainen, 1989) and it has continued

actively through years to these days. There are cur-

rently several different types of placement machines

in use. They all have their own technical properties

and are suitable for different types of assembly tasks,

see e.g. (Ayob and Kendall, 2008) for thorough re-

view of different machines, their features and occur-

ring problems in every machine context.

There is a lot of literature that concerns the optimi-

sation of the operations of different types of machines

except for revolver-head gantry machines. However,

this machine type is very popular in industry at the

moment. In particular, this deals with the feeder as-

signment and pick-up-and-place scheduling problems

of this machine type. One can find two main trends in

the literature on the subject. While there are methods

using an evolutionary approach and solving the feeder

assignment and plamecent sequence at the same time

(Ho and Ji, 2004; Kulak et al., 2007), the others ap-

proach these two problems using hierarchic methods,

see (Grunow et al., 2004; Lee et al., 1999; Sun et al.,

2004; Ho et al., 2007).

In this article, controlling of revolver-head gantry

machines is discussed. These machines are known

with several names: multi-spindle gantry place-

ment machines, a revolver-head gantry machines, a

revolver-head machines and collect-and-place ma-

chines. See (Ayob and Kendall, 2008) for an illustra-

tion of the parts of this machine type. Note, that the

placement head of the collect-and-place-machine can

also be organised in different way so that the place-

75

Pyöttiälä S., Knuutila T., Johnsson M. and Nevalainen O. (2009).

SOLVING THE FEEDER ASSIGNMENT ON A REVOLVER-HEAD GANTRY MACHINE.

In Proceedings of the 6th International Conference on Informatics in Control, Automation and Robotics - Intelligent Control Systems and Optimization,

pages 75-80

DOI: 10.5220/0002213000750080

Copyright

c

SciTePress

ment head is a linear array of spindles.

In the revolver-head gantry machine the PCB to

be manufactured is kept on the table at a fixed loca-

tion. The placement head of the machine moves in

the (x, y)-plane on the PCB and the feeder unit. The

placement head is also called revolver-head or even

an arm. It picks up the neccessary components from

the feeder unit that is located on the side (or sides) of

the machine and then mounts them on the PCB.

The placement head is moved by three step mo-

tors which run independently. The first one moves

the whole gantry on its rails (in x-direction). The sec-

ond motor moves the revolver-head on the gantry (in

y-direction) and the third motor is used to rotate the

revolver-head.

The revolver-head is equipped with multiple spin-

dles, typically 6-12. Each spindle can hold a noz-

zle which can grab a component. There are many

different types of component nozzles. Each compo-

nent type requires a compatible nozzle. The shape of

a component defines what type of nozzle should be

used for grabbing it. It is also possible that a certain

nozzle type is compatible with several different com-

ponent types.

The feeder unit is divided into a set of feeder slots

of fixed width (typically 8 mm). The slots are loaded

with component tapes in which the components are

stored one after the other. There are only components

of the same type in each tape. Usually, the dimen-

sions of the components are notably smaller than 8x8

mm and they fit a 8 mm tape. However, there are also

wider components which are supplied in wider tapes,

for example 16 mm. These tapes occupy more than

one feeder slots but their use is similar to that of nar-

row tapes.

At a high abstraction level, revolver-head gantry

machines operate in cycles of four phases:

1. pick-up-phase

2. travel onto the PCB -phase

3. placement-phase

4. travel onto the feeder -phase

While there are slight differences in the opera-

tion principles of different machines, we consider a

case, where the design of the machine includes the

following details: In the first phase, the revolver-head

moves on the feeder unit and collects one component

after the other from the right feeder slots keeping the

component tapes. Between two pick-up events the

revolver-head has to rotate at least one step to get

an empty nozzle operable. It is also possible that the

revolver-head has to move in the x-direction (which is

parallel to the length of the feeder unit) onto a correct

feeder slot. The revolver can rotate while it is mov-

ing to the next pick-up location. In the pick-up-phase,

we suppose that the revolver never rotates more than

360

◦

and it can leave one or more nozzles empty by

skipping them during the pick-ups.

After at least one component has been picked up

the placement head moves onto the PCB area. This

is called travel onto the PCB -phase. During this

movement, the revolver rotates so that the component

which was picked up first in the pick-up-phase can

be placed immediately after the head has reached the

placement location.

In the placement-phase, the collected components

are placed onto the PCB in their correct locations in

the same order as they were picked up. The rotation

limit of 360

◦

concerns this phase, also. Finally, the

empty revolver-head is moved back onto the feeder

unit and rotated so that the suitable nozzle for the next

component to be picked up is operable again.

If for example 180 components have to be placed

on a single PCB the gantry machine with revolver

spindle count of 12 makes at least 15 tours described

above. However, this requires that all the nozzles are

loaded in every single tour. In practice, it is usually

impossible to get full loads because of component-

nozzle incompatibilities. If the next nozzle in the re-

volver is not compatible with the next component that

should be picked up, the revolver is rotated more than

one step forward.

There are placement machines that can change

nozzles automatically during the manufacturing pro-

cess but in many cases the change-process takes

too much time and it is therefore avoided. On the

otherhand, in some placement machines the nozzle

changes can be done only manually and the placement

process has to be stopped for doing that.

A setup operation (i.e. change of component tape

reels, conveyor belt adjustment etc.) of the placement

machine must be performed before the machine can

manufacture any new PCB types. At least the follow-

ing decicions have then to be made:

1. assign the component types into the slots of the

feeder unit,

2. define the set of component nozzles and their or-

der in the revolver-head, and

3. define the sequence and tours in which compo-

nents are picked up and placed.

It has been commonly assumed in previous liter-

ature that each nozzle can grab any type of compo-

nent exist, so there has not been a need to solve the

nozzle selection for the revolver-head. However, the

situation is often more complicated in practice. The

consideration of the nozzle-component compatibility

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

76

is one of the aspects which tends to make the design

of the machine control more difficult. If it is assumed

(as it is often done) that every nozzle can pick up any

type of component in a single machine then we also

have to assume that there are (even for narrow compo-

nent types) multiple machines in the production line

and components are divided among them so that uni-

versal nozzle compatibility is achieved in every ma-

chine. Algorithms for deciding the nozzle selection of

the revolver are proposed in (Py

¨

otti

¨

al

¨

a et al., 2006).

The goal of this article is to find such a feeder

setup that minimizes the assembly cycle time (ACT)

of the single multi-spindle gantry machine. We sup-

pose that sequence of component placements and the

assignment of nozzles for the head are fixed. We thus

consider a subproblem of the total machine control

problem. It is assumed that a significant number of

PCBs of the same type are manufactured. This set of

PCBs is called a batch. Here, ACT is the time required

to manufacture a single PCB in the batch. Clearly,

minimizing ACT minimizes also the time requirement

of the whole batch.

We formulate the Optimal Feeder Assignment

problem (OFA) in Section 2. The formulation is then

used in four heuristics to solve the problem in Sec-

tion 3. In this formulation we omit the possibility

of duplicate compoment tapes in the feeder unit and

the delays caused by camera inspections. Further, we

suppose that the nozzle-to-arm assignment is fixed for

the whole PCB job and revolver rotations can be done

in parallel with the head movements. Results of the

heuristics are compared with a lower bound in Sec-

tion 4.

2 PROBLEM STATEMENT

2.1 Notation and Terminology

The discussion of the previous section leads to the fol-

lowing notation which can be used to describe the de-

termination of ACT.

• the set of component types CT = {ct

1

, . . . , ct

m

}

• the recipe of a PCB i.e. the set of components

and their locations C = {c

1

, . . . , c

n

}, where c

i

=

(t, (x

i

, y

i

)) such that t ∈ CT and (x

i

, y

i

) ∈ R

2

• the set of nozzle types NT = {nt

1

, . . . , nt

l

}

• for convenience, the location of a component on

the PCB is also given by function cl : C 7→ R

2

• the type of component is given by function ct :

C 7→ CT

• the location of the component of a certain type in

the feeder is given by function f l : CT 7→ R

2

• the nozzle requirement of a certain component

type is given by function nt : CT 7→ NT

• the nozzle sequence of the revolver-head i.e. an

arm is α = (n

1

, . . . , n

k

), where n

i

∈ NT

• distance (Chebychev) between two locations is

given by function d : R

2

× R

2

7→ R so that

d((x

1

, y

1

), (x

2

, y

2

)) = max(|x

1

− x

2

|, |y

1

− y

2

|)

• time required by the revolver-head to travel a cer-

tain distance is given by function tt : R 7→ R

• function re : C × α 7→ N gives the number of ro-

tation steps required to rotate the revolver-head so

that the next suitable empty nozzle can pick up a

certain component

• function r f : C × α 7→ N gives the number of ro-

tation steps required to rotate the revolver-head so

that the next nozzle that holds a component can

place it

• time required by the revolver-head to rotate cer-

tain steps forward is given by function rt : N 7→ R

• pt is a constant time that a single pick-up or place-

ment takes

A permutation of PCB recipe C is called a job and

it determines an order in which the components can be

placed on the PCB. Each component of set C occurs

exactly once in a permutation. Often, we use sym-

bol W for a job and it can be partitioned into p sep-

arate subjobs such that W = W

1

·W

2

···W

p

. (The par-

titioning is discussed for example in (Knuutila et al.,

2007).)

Definition 1.1 Given arm α of size k and any par-

tition of job W

i

= (c

i

1

, c

i

2

, . . . , c

i

s

), where s ≤ k. We say

that α can pick up W

i

if and only if W

i

is a subsequence

of α.

Definition 1.2 Given arm α and job W = W

1

·

W

2

···W

p

. We say that α can execute W if and only

if α can pick up each W

i

.

2.2 Assembly Cycle Time

Suppose that job W of length n, arm α of size k and

functions as above in section 2.1 are given. Further,

let us assume that α can execute W in p separate pick-

up and placement tours and the revolver-head (arm) is

initially located at the park position (x

pp

, y

pp

). The

assembly cycle time can then be defined as follows

ACT (W, α) = cost

1

+

p−1

∑

i=2

µ

cost

i

¶

+ cost

p

,

SOLVING THE FEEDER ASSIGNMENT ON A REVOLVER-HEAD GANTRY MACHINE

77

where cost

1

is the time consumed in travelling

from park position to the location of the feeder slot of

the first component type, cost

i

is the time that passes

in the ith tour of the process and cost

p

is the time of

the last tour and travel time from last placement loca-

tion to the park position. We denote by

cost

1

= tt(d((x

pp

, y

pp

), f l(ct(c

1

1

)))),

cost

i

= pt +

|W

i

|−1

∑

j=1

(cost

pickup

i, j

) + cost

travel PCB

i

+ pt

+

|W

i

|−1

∑

j=1

(cost

place

i, j

) + cost

travel f eeder

i

,

and

cost

p

= pt +

|W

p

|−1

∑

j=1

(cost

pickup

p, j

) + cost

travel PCB

p

+ pt

+

|W

p

|−1

∑

j=1

(cost

place

p, j

) +tt(d(cl(c

p

|W

p

|

), (x

pp

, y

pp

))),

furthermore,

cost

pickup

i, j

= max

Ã

tt

µ

d

µ

f l(ct(c

i

j

)), f l(ct(c

i

j+1

))

¶¶

,

rt

µ

re(c

i

j+1

, α)

¶

!

+ pt,

cost

travel PCB

i

= tt(d( f l(ct(c

i

|W

i

|

)), cl(c

i

1

)),

cost

place

i, j

= max

Ã

tt

µ

d

µ

cl(c

i

j

), cl(c

i

j+1

)

¶¶

,

rt

µ

r f (c

i

j+1

, α)

¶

!

+ pt,

and

cost

travel f eeder

i

= tt(d(cl(c

i

|W

i

|

), f l(ct(c

i+1

1

)).

Note, that revolver-head rotations and (x, y)-

travels are simultaneous operations and one has there-

fore considered which one of these takes longer time

(c.f. formulae for cost

pickup

i, j

and cost

place

i, j

).

We still summarize the assumptions relating the

operation principle of the placement machine.

• Placement head may rotate at most 360

◦

in a sin-

gle pick-up phase. This concerns also the place-

ment phase.

• The nozzle setup of arm α has at least one nozzle

of each type that the executing of job W requires.

• There can be multiple nozzles of the same type in

the arm.

• Note, that in our model the number of nozzle

types required by W is ≥ 1 instead of being = 1.

(This makes a difference from earlier literature on

revolver-head gantry machines.)

Now, the main problem of this work can be stated

as

Optimal Feeder Assignment Problem (OFA).

Given recipe C, job W and its partition W = W

1

·

W

2

···W

p

, arm α of size k and functions as above (ex-

cept f l). Assign component types to feeder slots so

that ACT (W, α) is minimized.

3 SOLVING OFA

In this section four different strategies to solve the

OFA problem are proposed. The first strategy eval-

uates simply a set of random feeder assignments. In

the second strategy, the neighborhood of the compo-

nents on the PCB is analysed and the feeder assign-

ment rests on that analysis. This method has been

proposed before in (Grunow et al., 2004). The last

two strategies are based on the frequencies of the dif-

ferent component types in a PCB recipe. The four

methods are described in more detail in the following

subsections.

3.1 Random Sample Feeder Assignment

The random strategy (random) to decide the feeder

assignment is straightforward: a constant number (in

our case 10000) of suitable random feeder assign-

ments are formed and their ACTs are calculated. The

feeder assignment with the lowest ACT is the result of

the search process.

3.2 MST-based Feeder Assignment

Grunow et al. (Grunow et al., 2004) used a minimum

spanning tree (MST) for the analysis of the neigh-

bourhood of components on the PCB. Here, the same

idea is applied in algorithm mst.

At the beginning, a fully connected graph of all

component placement points on the PCB is formed

and the MST of this graph is solved. In the next phase

the number of the neighbours in the MST is calculated

for each component type. Then the different compo-

nent types are put in a priority queue using the num-

ber of the neighbours as a priority index. Finally, the

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

78

component type with the highest priority index gets

the feeder slot which is at the center of the feeder unit.

The component type with the second highest index is

then put on the left side of the first one and the third

goes to the right side of the first. This dealing process

is iterated until all component types in the queue have

been assigned to some feeder slot.

3.3 Frequency-based Feeder

Assignment

In this method (freq), the frequencies of the compo-

nent types of the PCB recipe are calculated and used

as priority indices. The feeder slots are then occupied

in the same way as in 3.2.

3.4 Frequency-based Balanced Feeder

Assignment

Frequency based feeder assignment of subsection 3.3

may lead into a very unbalanced configuration if there

are big differences in the number of every second

component type. For example, the left half of the

feeder unit may feed a significant amount of the com-

ponents. This can be avoided if the next component

type in the priority queue is always assigned on the

side which has less components to feed at the mo-

ment. This heuristic (freq bal) implements the bal-

ancing property which leads to a more balanced out-

come in terms of feeded components. However, the

other parts of this method follow the heuristic of sub-

section 3.3 closely.

4 EXPERIMENTAL TESTS

In this section, the results of a set of numerical test

with the four heuristics of section 3 are discussed.

There are 43 different PCB recipes based on genuine

products but they differ from originals slightly. All of

them are parts of the actual PCBs because the original

PCBs were assembled in a production line of four dif-

ferent placement machines and this article concerns

the production control of a single machine. The mod-

ifications of the PCBs were done by deleting random

periods from the original recipies so that the require-

ments of different nozzles and the number of feeder

slots needed met the limits of a single gantry machine.

The characteristics of the test PCB-recipe set are

shown in Table 1. The technical properties of the

placement machine are presented in Table 2 and they

mainly follow those used in (Kulak et al., 2007).

Table 1: Dimensions and number of components and com-

ponent types in the tests with 43 PCBs.

min number of comp. on PCB 34

max number of comp. on PCB 199

smallest board size (mm) 125.5 x 127.8

largest board size (mm) 400 x 255.2

min number of comp. types on PCB 1

max number of comp. types on PCB 40

During the tests, the nozzle selection of the

revolver-head and the placement sequence were fixed.

The feeder assignment was then solved using the

heuristics and ACT was calculated for each of the so-

lutions. A theoretic lower bound (described below)

was also calculated using the written software.

The average values of ACTs of the 43 test cases

are shown for the heuristics in Table 3. The table also

shows an average ACT for the theoretic lower bound

(theoretic) in which the ACT has been calculated for

the case where all components are picked up from the

center of the feeder unit and placed onto a placement

point which is closest to the center slot of the feeder.

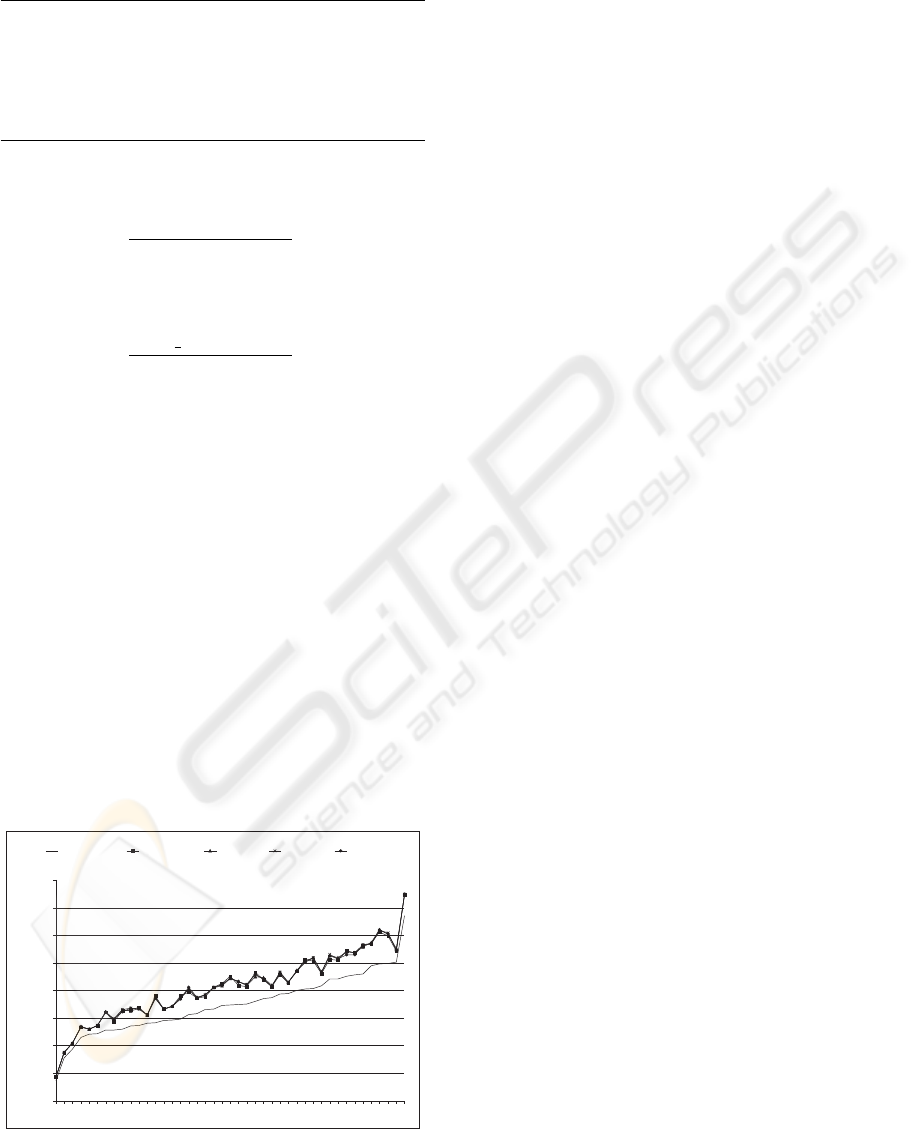

The ACTs for all 43 test cases are presented graphi-

cally in Figure 1. The figure shows that there is no

statistically significant difference (tested in Excel, t-

test) in the efficiency of the different heuristics.

However, the ACTs calculated from the results of

heuristics were clearly longer than the theoretic lower

bound yielded which was naturally expected.

Because the test results of the different methods

are equal it can be asked if the optimization of the

placement process of the revolver-head gantry ma-

chines should be focused more on the placement se-

quencing and on selecting a suitable combination of

nozzles into the revolver-head than on the feeder as-

signment.

Heuristics proposed in this article give a feasible

enough solution for the feeder assignment problem

and the placement sequence can be solved for a feeder

assignment which has been determined by OFA. (Of

course, it is also possible to solve these problems at

the same time, for example using genetic approach,

see (Kulak et al., 2007).) Even the trivial sampling

method (in section 3.1) that randomly generates dif-

ferent solutions produced as good results as the more

advanced heuristics. This encourages to think that be-

cause the rotation of the revolver takes time anyway

between two pick-ups, the order of the component

types in the feeder is not so critical when it comes

to ACT.

SOLVING THE FEEDER ASSIGNMENT ON A REVOLVER-HEAD GANTRY MACHINE

79

Table 2: Technical properties of the placement machine in

simulations.

velocity in x- and y-axis 800 mm/s

step rotate time 0.05 s

single component placement time 0.04 s

single component pick-up time 0.04 s

feeder slot sizes 8.0, 12.0, 16.0 mm

number of spindles 12

feeder slot capacity 40

Table 3: Average of ACTs for four heuristics and the value

of the theoretic lower bound.

theoretic 34.85

random 41.29

mst 41.46

freq 41.50

freq bal 41.43

5 CONCLUSIONS

In this article, the control of a revolver-head gantry

machine was discussed and its properties were de-

scribed. A mathematical model for the assembly cy-

cle time was given for the machine type and the op-

timal feeder assignment problem (OFA) was formu-

lated.

Four heuristics were proposed for solving OFA

of the revolver-head gantry machine. The heuristics

were tested and the test results were compared to each

other and a the theoretic lower bound. The heuristics

performed equally when tests were done with realistic

PCB assembly data. Since the different methods yield

different solutions to OFA and it still does not have a

significant affect on ACT, the other problems in the

0,00

10,00

20,00

30,00

40,00

50,00

60,00

70,00

80,00

test case PCB

ACT (seconds)

theoretic

random mst freq freq_bal

Figure 1: Assembly cycle times of heuristics and theoretic

lower bound for all 43 test PCB-recipies.

placement machine control context may be more im-

portant objects for optimization. For example, select-

ing a good nozzle combination into the revolver-head

and pick-up- and place-sequencing seems to be such

a problem.

REFERENCES

Ayob, M. and Kendall, G. (2008). A survey of surface

mount device placement machine optimisation: Ma-

chine classification. In European Journal of the Oper-

ational Research, vol. 186, pp. 893-914.

Ball, M. and Magazine, M. (1988). Sequencing of inser-

tions in printed circuit board assembly. In Operations

Research 36(2), pp. 192-201.

Grunow, M., G

¨

unther, H.-O., Schleusener, M., and Yilmaz,

I. (2004). Operations planning for collect-and-place

machines in pcb assembly. In Computers & Industrial

Engineering, Vol. 47, pp.409-429.

Ho, W. and Ji, P. (2004). A hybrid genetic algorithm for

component sequencing and feeder arrangement. In

Journal of Intelligent Manufacturing, 15, pp. 307-315.

Ho, W., Ji, P., and Wu, Y. (2007). A heuristic approach for

component scheduling on a high-speed pcb assembly

machine. In Production Planning & Control, Vol. 18,

No. 8, pp. 655-665.

Knuutila, T., Py

¨

otti

¨

al

¨

a, S., and Nevalainen, O. (2007). Mini-

mizing the arm movements of a multi-head gantry ma-

chine. In Proceedings of 4th International Conference

on Informatics in Control, Automation and Robotics

(ICINCO 2007).

Kulak, O., Yilmaz, I., and G

¨

unther, H.-O. (2007). Pcb as-

sembly scheduling for collect-and-place machines us-

ing genetic algorithms. In International Journal of

Production Research, Vol. 45, pp. 3949-3969 No. 17.

Lee, S., Lee, H., and Park, T. (1999). A hierarchical method

to improve the productivity of a multi-head surface

mounting machine. In Proc. of the IEEE International

conference on Robotics and Automation.

Leip

¨

al

¨

a, T. and Nevalainen, O. (1989). Optimization of the

movements of a component placement machine. In

European Journal of Operational Research, 38, pp.

167-177.

Py

¨

otti

¨

al

¨

a, S., Knuutila, T., and Nevalainen, O. (2006).

The selection of nozzles for minimizing the num-

ber of pick-ups on a multi-head placement machine.

In GTCM2006 Conference, Groningen, The Nether-

lands.

Sun, D.-S., Lee, T.-E., and Kim, K.-H. (2004). Component

allocation and feeder arrangement for a dual-gantry

multi-head surface mounting placement tool. In In-

ternational Journal of Production Economics 95 pp.

245-264.

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

80