PARAMETER IDENTIFICATION OF A HYBRID REDUNDANT

ROBOT BY USING DIFFERENTIAL EVOLUTION ALGORITHM

Yongbo Wang, Huapeng Wu and Heikki Handroos

Department of Mechanical Engineering, IMVE, Lappeenranta University of Technology, Lappeenranta, Finland

Keywords: Calibration, Parameter Identification, Parallel Robot, Differential Evolution.

Abstract: In this paper, a hybrid redundant robot IWR (Intersector Welding Robot) which possesses ten degrees of

freedom (DOF) where 6-DOF in parallel and additional redundant 4-DOF in serial is proposed. To improve

the accuracy of the robot, the kinematic errors caused by the manufacturing and assembly processes have to

be compensated or limited to a minimum value. However, currently, there is no effective instrument which

capable of measuring the symmetrical errors of the corresponding joints and link lengths after the structure

has been assembled. Therefore, calibration and identification of these unknown parameters is utmost

important and necessary to the systematic accuracy. This paper presents a calibration method for identifying

the unknown parameters by using differential evolution (DE) algorithm, which has proven to be an efficient,

effective and robust optimization method to solve the global optimization problems. The DE algorithm will

guarantee the fast convergence and accurate solutions regardless of the initial conditions of the parameters.

Based on the inverse kinematic error model of the robot, the simulation of the actual robot is achieved by

introducing random geometric errors and measurement poses which representing their relative physical

behavior. Moreover, through computer simulation, the validity and effectiveness of the DE algorithm for the

parameter identification of the proposed application has also been examined.

1 INTRODUCTION

It is widely believed that parallel robot has high

stiffness, low inertia, high speed and accuracy but

small workspace compared to its counterpart serial

robot. To take advantage of the benefits (bigger

workspace and higher stiffness) of both types of

robotic structures, a compromised hybrid redundant

robot which can be used to perform the welding,

machining and remote handling is developed in

Lappeenranta University of Technology (Wu, 2005).

In order to satisfy the required accuracy of the robot,

the calibration and identification of the real structure

parameters is essential and necessary. Generally,

calibration can be classified into two types: static

and dynamic. The static or kinematic calibration is

an identification of those parameters which

influence primarily the static positioning

characteristics of a robot, such as the errors caused

by length of the links and joints. Whereas the

dynamic calibration is used to identify parameters

influencing primarily motion characteristics, such as

the deflection of mechanisms caused by temperature,

and the compliances of joints and links. This paper

will be concentrated on the static calibration to

identify the geometric parameters of the proposed

hybrid redundant robot. At present, there exist two

kinds of static or kinematic calibration methods, one

is self or autonomous calibration method based on

inner information or restrictions of the kinematic

parameters of joints (Ryu, 2001; Zhuang, 1996;

Khalil, 1999; Zhuang, 2000; Ecorchard, 2005), and

another is exterior or classical calibration method by

using accurate instruments to measure the pose of

the moving platform directly (Gao, 2003; Besnard,

1999; Prenaud, 2003). For these calibration methods,

most of them are focused on the kinematic

calibration and parameter identification of the pure-

serial or pure-parallel mechanisms. Moreover, many

calibration models are based on the identification

Jacobian matrix which formulates a linear

relationship between measurement residuals and

kinematic parameter errors, then the parameter

errors are evaluated by using least square algorithm.

However, this kind of method is subject to break

down in the vicinity of singular robot configurations

due to the iterative inversion of the robot Jacobian

(Zhong, 1996). Instead of the Jacobian matrix based

287

Wang Y., Wu H. and Handroos H. (2009).

PARAMETER IDENTIFICATION OF A HYBRID REDUNDANT ROBOT BY USING DIFFERENTIAL EVOLUTION ALGORITHM.

In Proceedings of the 6th International Conference on Informatics in Control, Automation and Robotics - Robotics and Automation, pages 287-292

DOI: 10.5220/0002214202870292

Copyright

c

SciTePress

calibration approaches, the non-parametric

calibration method was introduced by Shamma and

Whitney (Shamma, 1987), in which the actual

kinematic parameters which drive the robot to

minimize the end-effector deviations can be found

by using non-linear least-square optimization

without explicit evaluation of the Jacobian. Based on

the non-parametric calibration method, some

evolutionary computing algorithms, such as genetic

algorithm (GA) (Liu, 2007; Zhuang, 1996), artificial

neural networks (NN) (Zhong,1996) and genetic

programming (GP) (Dolinsky, 2007), have been

successfully employed to calibrate serial or parallel

robot. Differential evolution (DE) is a simple but

effective evolutionary algorithm for solving non-

linear, global optimization problems. It has

demonstrated superior performance in both widely

used benchmark functions (Vesterstrom, 2004) and

practical applications (Wu, 2000). In this work,

based on the static and non-parametric calibration

method, DE will be adopted to identify the real

kinematic parameters of the proposed hybrid

redundant robot.

The paper is organized into five main sections.

The first section serves as an introduction. The

second section reviews the kinematic model of the

proposed robot, which includes the inverse

kinematic equations and the error models of the

robot. Section 3 presents the calibration equations

and the implement of DE optimization method.

Simulation results are presented in section 4, and

conclusions are drawn in section 5.

2 IDENTIFICATION MODELS

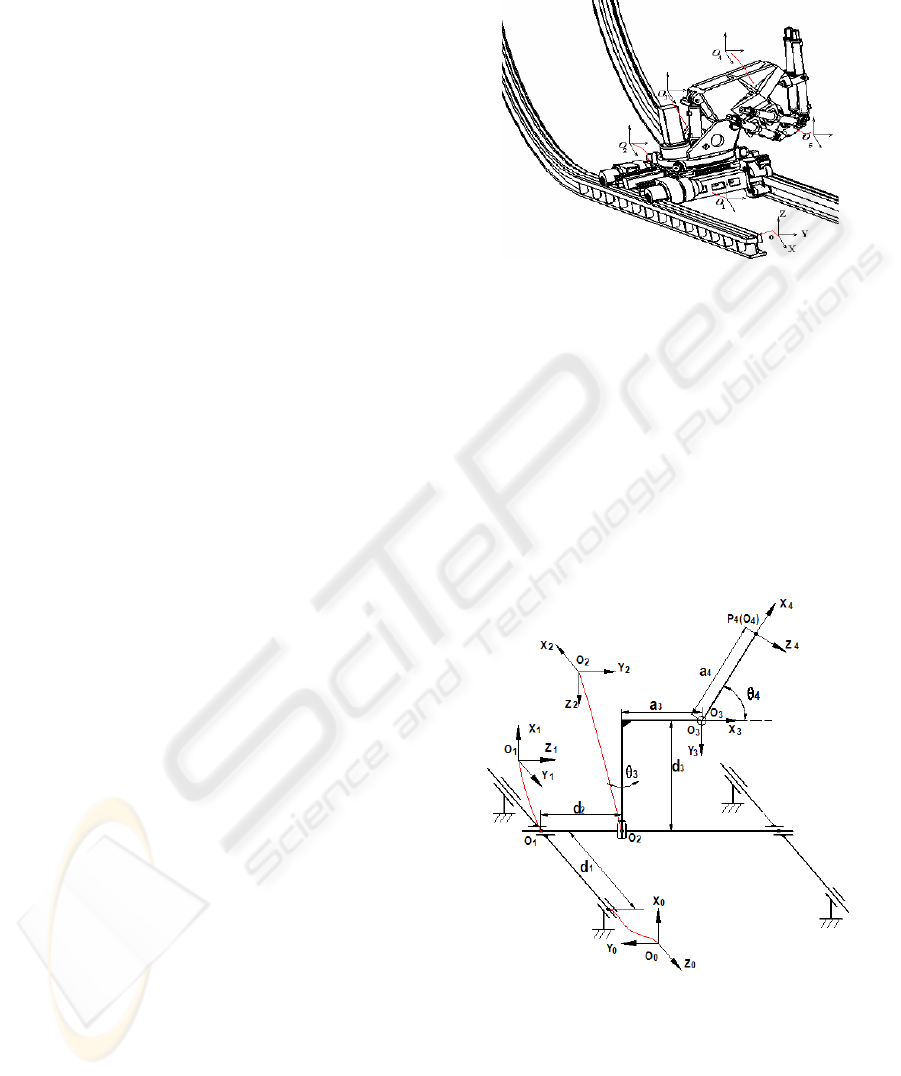

The kinematics of the proposed hybrid robot as

shown in Fig.1 is a combination of a multi-link

serial mechanism (here named as Carriage) and a

standard Stewart parallel manipulator (here named

as Hexa-WH). To simplify its analysis, the two parts

will be first carried out separately, and then

combined them together to obtain the final solutions.

According to Shamma and Whitney (Shamma,

1987), the calibration also can be classified into

forward calibration and inverse calibration. Forward

calibration involves finding the actual location in the

world space for a given joint configuration, while

inverse calibration involves finding exact joint

values for given locations in the world space. As we

all know that the inverse kinematics of the parallel

robot is simple than forward kinematics and vice

versa for the serial robot, so we decide to identify

the kinematic parameters of the parallel part based

on inverse calibration method and the serial part

based on forward solutions

Figure 1: 3D model of IWR.

2.1 Forward Kinematics

To study the kinematics of the serial multi-link

mechanisms, the convention of Denavit-Hartenberg

(Craig, 1986) is commonly adopted. Based on this

convention, the principle of the 4-DOF Carriage

mechanism can be established as shown in Fig.2,

which provides four degrees of freedom to the

transient end-effector (O

4

), including two

translational movements and two rotational

movements.

Figure 2: Coordinate system of Carriage.

Using the coordinate systems established in Fig.

2, the corresponding link parameters are given in

Table1. Substituting the D-H link parameters into

(1), we can obtain the D-H homogeneous

transformation matrices .

4

3

3

2

2

1

1

0

,,, AAAA

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

288

Table 1: Nominal DH parameters of Carriage.

Joint

i

α

i

a

i

d

i

θ

1

/2

π

0

1

d

0

2

/2

π

0

2

d

/2

π

3

/2

π

3

a

3

d

3

θ

4

/2

π

−

4

a

0

4

θ

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎣

⎡

−

−

=

−

1000

0

1

iii

iiiiiii

iiiiiii

i

i

dcs

sacsccs

cassscc

αα

θθαθαθ

θθαθαθ

A

(1)

where

c

i

θ

denotes

i

θ

cos

, and

i

s

θ

denotes

i

θ

sin

.

The resulting homogeneous transformation

matrix, i.e. the forward kinematics of the Carriage,

can be obtained by multiplying the matrices

of and

3

2

2

1

1

0

,, AAA

4

3

A

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎣

⎡

++−−

−−−−−

++

=

=

1000

0

43433143343

43433243343

443144

4

3

3

2

2

1

1

0

4

0

θθθθθθθθ

θθθθθθθθ

θθθ

ccacadscscc

csasadssccs

sadacs

AAAAA

(2)

From (2) we can get the rotation matrix and

position vector of the frame {4} with respect to

frame {0} as follows:

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

−−

−−=

43343

43343

44

4

0

0

θθθθθ

θθθθθ

θθ

scscc

ssccs

cs

R

(3)

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

++

−−−

++

=

434331

434332

4431

4

0

θθθ

θθθ

θ

ccacad

csasad

sada

P

(4)

In reality, the above D-H parameters will deviate

from their nominal values because of the

manufacturing and assembly errors. Since each joint

provides four parameters, therefore, the four links

will produce 16 identified parameters for the robot.

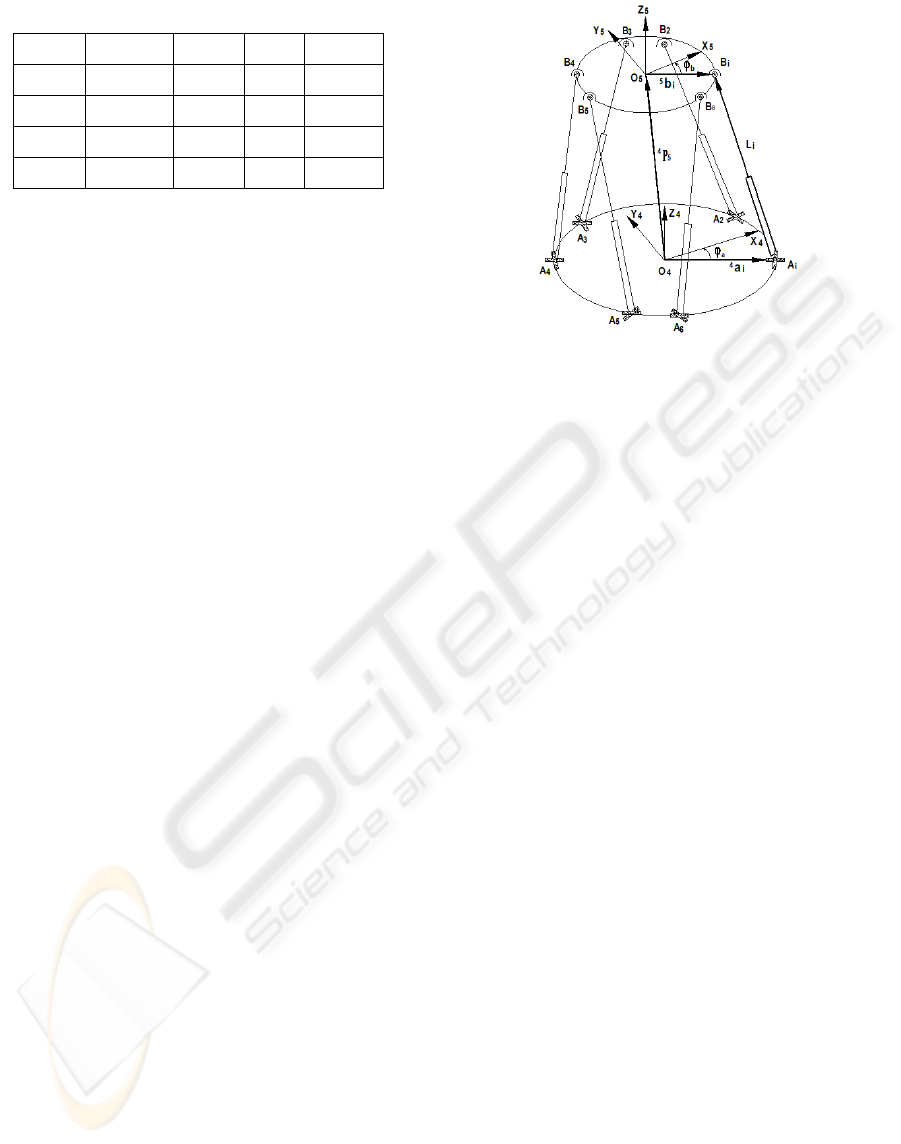

2.2 Inverse Kinematics of Hexa-WH

Fig. 3 shows a schematic diagram of hexapod

parallel mechanism, for the purpose of analysis, two

Cartesian coordinate systems, frames O

4

(X

4

, Y

4

, Z

4

)

and O

5

(X

5

, Y

5

, Z

5

) are attached to the base plate and

the end-effector, respectively. Six variable limbs are

connected with the base plate by Universal joints

and the task platform by Spherical joints.

Figure 3: Norminal model of the Hexapod parallel

mechanism.

For the designed kinematics parameters, let be

the unit vector in the direction of , and denote

the magnitude of the leg vector , then the

following vector-loop equation will represent the

inverse kinematics of the

ith limb of the

manipulator.

i

l

ii

BA

i

A

i

l

i

B

)6,2,1(

45

5

4

5

4

L=−+= il

iiii

abRPl

(5)

where denotes the position vector of the task

frame {5} with respect to the base frame {4}, and

is the Z-Y-X Euler transformation matrix

expressing the orientation of the frame {5} relative

to the frame {4},

5

4

P

5

4

R

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

−

−+

+−

=

λβγββ

γαγβαγαγβαβα

γαγβαγαγβαβα

ccscs

sccssccsssss

sscsccsssccc

5

4

R

(6)

and the , represent the position vectors of

U-joints and S-joints in the coordinate

frames {4} and {5} respectively. In practice, due to

the manufacturing and assembly errors, the

coordinate and will deviate from their

nominal values and will also have an initial

offset, altogether there will be 42 identified

parameters provided by Hexa-WH.

i

a

4

i

A

4

i

b

5

i

A

i

a

i

B

i

b

5

i

l

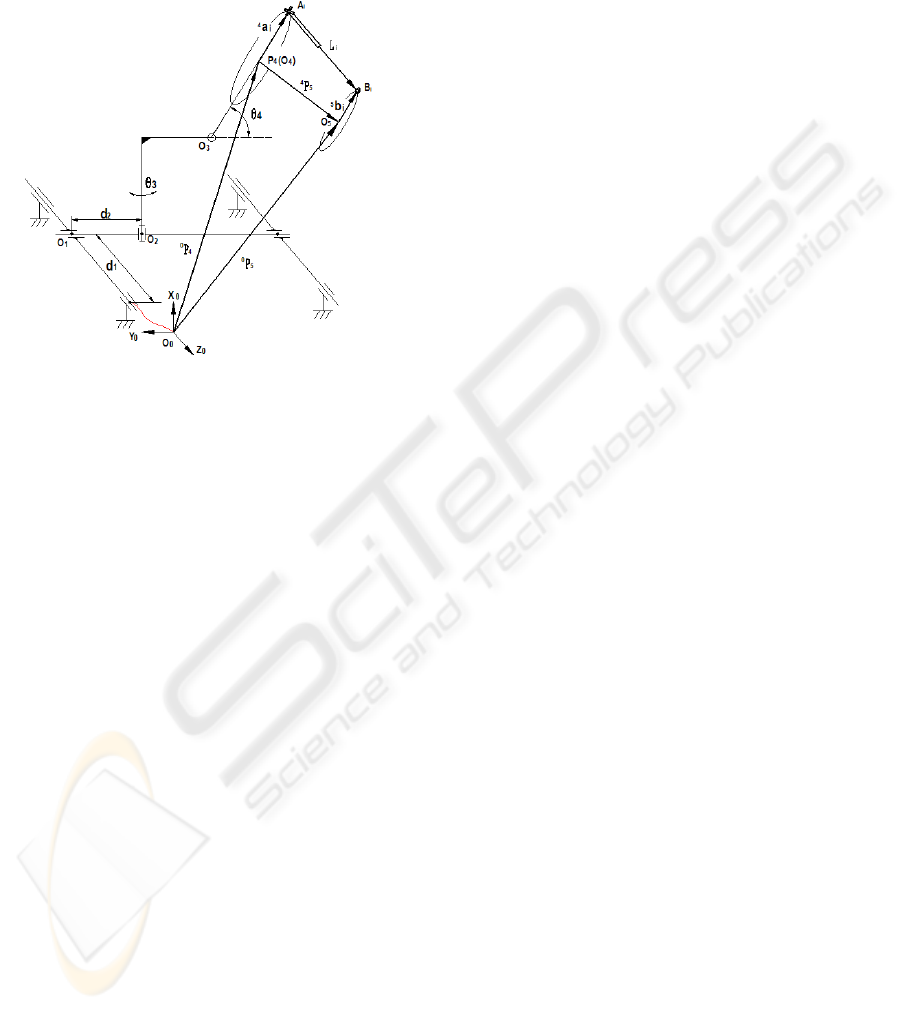

2.3 Kinematics and Identified Error

Model of the Hybrid Manipulator

The schematic diagram of the redundant hybrid

manipulator is shown in Fig. 4, which consists of

PARAMETER IDENTIFICATION OF A HYBRID REDUNDANT ROBOT BY USING DIFFERENTIAL EVOLUTION

ALGORITHM

289

Carriage and Hexapod manipulator as mentioned

above. The base plate frame {4} of Hexa-WH is

coincided with the end task frame of Carriage. The

global base frame {0} is located at the left rail of

Carriage.

()

2

,

1

6

1

,

)(,,,,,,min

m

ji

N

ij

jihhhcccc

llFun −=

∑∑

==

lbaθadα

δδδδδδδ

(10)

where

hhhcccc

lbaθadα

δ

δ

δ

δ

δ

δ

δ

,,,,,,

m

ji,

jth

denote the 58

identified parameter vectors, among which 16

parameters are from Carriage and 42 parameters

from Hexa-WH.

N

is measurement number,

and

l

respectively represent the calculated value

and measured value of the leg in the

ith

measurement point.

ji

l

,

3 DIFFERENTIAL EVOLUTION

Differential Evolution (DE), which introduced by

Price and Storn (Storn, 2005), has been proven to be

a promising candidate for minimizing real-valued,

non-linear and multi-modal objective functions. It

belongs to the class of evolutionary algorithms and

utilizes the same steps as Genetic Algorithm, i.e.

mutation, crossover and selection. Individuals in DE

are represented by D-dimensional

vectors ,

Gi,

x

},,2,1{ NPi L

∈

∀

, where D is the

number of optimization parameters and NP is the

population size. There are several variants or

strategies of DE, but the DE scheme which classified

by notation DE/rand/1/bin is the most commonly

used one. The optimization process of this classical

DE can be summarized as follows:

Figure 4: Schematic diagram of IWR.

According to the geometry, a vector-loop

equation can be derived:

(

)

iiii

iiii

l

l

bRaRlRP

bRalRPPRPP

5

5

04

4

0

4

0

4

0

5

5

44

4

0

4

0

5

4

4

0

4

0

5

0

−++=

−++=+=

(7)

From (7), we can obtain the nominal leg length,

i.e. the inverse solution of the robot as:

()(

iiii

l bRaRPPRl

5

5

04

4

0

4

0

5

0

1

4

0

+−−=

−

)

(8)

3.1 Initialization

where and is the position vector and

rotation matrix of the task frame {5} (or end-

effector) with respect to the fixed base frame {0}.

5

0

P

5

0

R

To establish a starting point for the optimization

process, an initial population must be created.

Typically, each decision parameter in every vector

of the initial population is assigned by a randomly

chosen value from its feasible bounds:

Let represent the whole leg length which

made up of the measured leg length with the inner

sensor and the fixed initial leg length offset.

Therefore, if parameter errors are not be taken into

account, there is the following relation.

m

i

l

)()1,0[

,,,0,,

L

ij

U

ijj

L

ijGij

xxrandxx −⋅+=

=

(11)

where

Dj ,,2,1 L

=

is parameter index, and

NP,Li ,2,1

=

is population index, and

are the lower and upper bound of the decision

parameter, respectively. After the initial population

has been created, it evolves through the following

operations of mutation, crossover and selection until

the terminal condition satisfied.

L

ij

x

,

jth

U

ij

x

,

m

ii

ll =

(9)

As a matter of fact, since geometrical errors and

other error sources exist, two sides of (9) will never

be equal, even if their geometrical parameters are

properly corrected. Consequently, if we get enough

measurement point data from the inner sensors of

the parallel Hexa-WH legs and the Carriage

actuators, then our identified kinematic error model

can be expressed as an optimization function given

as follows:

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

290

3.2 Mutation

For each vector , a mutant vector is

generated according to

Gi,

x

Gi,

m

)(

,3,2,1, GrGrGrGi

F xxxm −

⋅

+=

(12)

where randomly selected

integers , ,

1

r

2

r

{}

irrrNPr

≠

≠

≠∈

3213

,,2,1 L

0>F

,

and mutation scale factor .

3.3 Crossover

The trial vector is generated as follows:

),,,(

1,,1,,21,,11, ++++

=

GiDGiGiGi

uuu Lu

⎩

⎨

⎧

=∨<

=

+

+

+

,

))1,0[(

1,,

1,,

1,,

otherwisex

jjCRrandifm

u

Gij

rjGij

Gij

(13)

where denotes generation index, the

index is chosen randomly from the set

, which is used to ensure that vector

gets at least one parameter from , and

is known as a crossover rate constant which is a

user-defined parameter within the range

[]

.

max

,,2,1 GG L=

r

j

},D

1+

,2,1{ L

,, Gij

u

CR

Gi,

m

1,0

3.4 Selection

To decide whether or not the trail vector should

become a member of the next generation, the trail

vector is compared to the target vector

by evaluating the cost or objective function. A

vector with a minimum value of cost function will

be allowed to advance to the next generation. That

is,

1, +Gi

u

Gi,

x

⎩

⎨

⎧

≤

=

++

+

,

),()(

,

,1,1,

1,

otherwise

funfunif

Gi

GiGiGi

Gi

x

xuu

x

(14)

Using this selection procedure, all individuals of

the next generation are as good as or better than the

individuals of the current population.

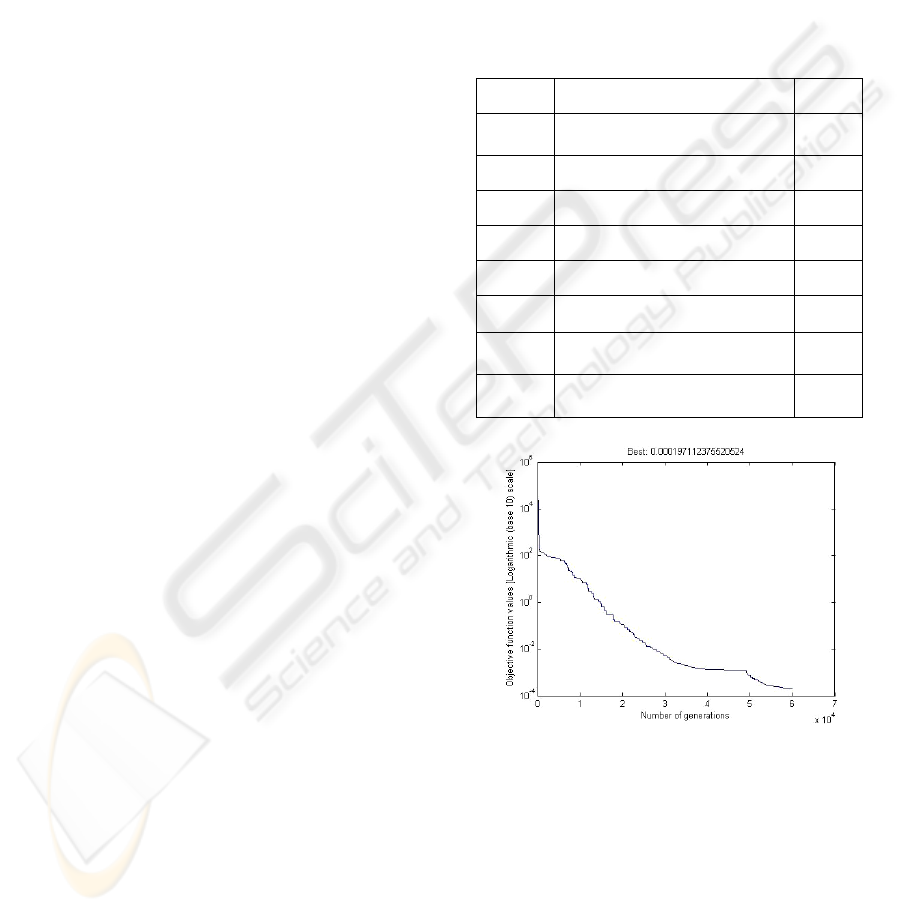

4 SIMULATION RESULTS

To simulate the above process, we randomly

generate 100 measurement poses within the robot

workspace to form the measured input values. As

stated above, we can take (10) as our fitness

function, among which, we assume a set of fixed

geometric errors for the identified parameter to

represent the actual measurement values of the

robot, and at the same time suppose these error

parameters to be our simulation variables. Through

enough evolution generations, the simulated

identification parameter will finally approximate to

the assumed parameter errors. Table 2 shows the

constant parameters we have chosen and the best

objective function values of each generation are

plotted in Fig. 5.

Table 2: Parameters of DE.

Symbol Parameter

Value

D

Number of parameters

(Variables)

58

NP Number of population

600

F Scale or difference factor

0.9

CR Crossover control constant

1.0

N Measurement number

100

max

G The maximum generations

60000

L

ij

x

,

Lower bound of identified

error parameters

-0.5

U

ij

x

,

Upper bound of identified

error parameters

0.5

Figure 5: Best objective function values of 60000

generations.

From the above tables and the figure of

evolutionary process, we can see that the objective

function values decrease dramatically at the

beginning, but with the advance of evolution

process, they tend to be calm and the convergence

speed also become slow. After 60000 generations,

most of the identified errors are approximated to the

assumed errors, and the final best object function

value reach to the accuracy of 10

-4

. Of course, if we

PARAMETER IDENTIFICATION OF A HYBRID REDUNDANT ROBOT BY USING DIFFERENTIAL EVOLUTION

ALGORITHM

291

increase the maximum generation number and add

more measured poses, then the identification

accuracy will be improved and the identified

parameters will infinitely approach to the actual

values.

5 CONCLUSIONS

In this paper, a hybrid redundant robot used for both

machining and assembling of Vacuum Vessel of

ITER is introduced. Furthermore, a parameter

identification model which has the ability to account

for the static error sources is derived. Due to the

redundant freedom of the robot, we first divide the

robot into two parts according to its mechanism,

then formulate the parameter identification model

respectively, and finally combine them together to

get the final optimization identification model.

Based on the DE algorithm and the derived

identification model, the 58 kinematic error

parameters of the robot were identified by computer

simulations. According to the simulation results, we

can see that DE has a very strong stochastic

searching ability, which is reliable and can be easily

used to identify the high non-linear kinematic error

parameter models.

REFERENCES

Ecorchard, G.; Maurine, P, 2005. Self- calibratrion of

delta parallel robots with elastic deformation

compensation, 2005 IEEE/RSJ International

Conference on Intelligent Robots and Systems, 2-6

Aug. 2005, pp, 1283 – 1288.

Gao, Meng, Li Tiemin, Yin Wensheng, 2003. Calibration

method and expriment of stewart platform using a

laser tracker, IEEE International Conference on

Systems, Man and Cybernetics, Vol. 3, 5-8 Oct. 2003

pp. 2797 – 2802.

Hanqi Zhuang, Jie Wu et al., 1996. Optimal Planning of

Robot Calibration Experiments by Genetic

Algorithms, Proceedings of the 1996 IEEE

International Conference on Robotics and

Automation, Minneapolis, Minnesota, April 1996, pp.

981-986.

Hanqi Zhuang, Lixin Liu, 1996. Self-calibration of a class

of parallel manipulators, Proceedings of the 1996

IEEE international conference on robotics and

automation, Minneapolis, Minnesota, April

1996,pp.994-999.

Hanqi Zhuang, Lixin Liu, Oren Masory, 2000.

Autonomous calibration of hexapod machine tools,

ASME transactions on Journal of Manufacturing

Science and Engineering, February 2000, Vol. 122,

pp. 140-148.

Huapeng Wu, Heikki Handroos, 2000. Utilization of

differential evolution in inverse kinematics solution of

a parallel redundant manipulator, IEEE conference on

knowledge-based intelligent engineering systems &

allied technologies, 30 Aug. – 1 Sept. 2000, Brighton,

UK, pp.812-815.

Huapeng Wu, Heikki Handroos et al. 2005. Development

and control towards a parallel water hydraulic

weld/cut for machining processes in ITER vacuum

vesse. Int. J. fusion Engineering and Design, Vol. 75-

79, pp. 625-631.

J. Craig, 1986. Introduction to Robotics: Mechanics and

Control , Addison-Wesley Publishing Co., Reading,

MA.

J.Vesterstrom, R.Thomsen, 2004. A comparative study of

differential evolution, particle swarm optimization,

and evolutionary algorithms on numerical benchmark

problems, Evolutionary computation, Vol. 2. pp. 1980-

1987.

J.U. Dolinsky, I.D.Jenkinson et al., 2007. Application of

Genetic Programming to the Calibration of Industrial

Robots, Journal of Computers in Industry, 58 (2007),

pp. 255-264.

Jeha Ryu, Abdul Rauf, 2001. A new method for fully

autonomous calibration of parallel manipulators using

a constraint link. 2001 IEEE/ASME international

Conference on advanced intelligent mechatronics

proceedings 8-12 July, 2001 Como, Italy, pp. 141-146.

Prenaud and N. Andreff et al, 2003. Vision-based

kinematic calibration of a H4 parallel mechanism,

Proc. IEEE Int. Conf. on Robotics and Automation,

Taipei, Taiwan, pp.1191-1196.

R. Storn and K. Price, 2005. Differentila Evolution – a

Practical Approach to Global Optimization, Springer,

Germany.

S.Besnard,W.Khalil, 1999. Calibration of parallel robots

using two inclinometers, Proceedings of the 1999

IEEE int. Conference on Robotics & Automation,

Detroit, Michigan, pp.1758-1763.

Shamma J.S. and Whitney D.E., 1987. A mehod for

inverse robot calibration, J. of Dynamic Systems,

Measurement and Control. Vol, 109,pp.36-43.

W. Khalil and S. Besnard, 1999.

Self calibration of

Stewart-Gough parallel robots without extra sensors,

IEEE transactions on robotics and automation,

Vol.15, No.6, December 1999. pp.1116-1121.

Xiaolin Zhong, John Lewis etc., 1996. Inverse Robot

Calibration Using Artificial neural Networks, Engng

Applic. Artif. Intell. Vol. 9, No. 1, pp. 83-93.

Yu Liu, Bin Liang et al., 2007. Calibration of a Steward

Parallel Robot Using Genetic Algorithm, Proceedings

of the 2007 IEEE International Conference on

Mechatronics and Automation, August 5-8, 2007,

Harbin,China. pp. 2495-2500.

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

292