BUILDING TRAINING PATTERNS FOR MODELLING MR

DAMPERS

Jorge de-J. Lozoya-Santos, Javier A. Ruiz-Cabrera, Vicente Diaz-Salas

Ruben Morales-Menendez and Ricardo Ramirez-Mendoza

Tecnol´ogico de Monterrey, Av. Garza Sada 2501, Monterrey, NL, M´exico

Keywords:

Pattern validation, Modelling, Magneto-rheological damper, Identification.

Abstract:

A method for training patterns validation for modelling MR damper is proposed. The method was validated

with two models based on black-box and semi-phenomenological approaches. An input pattern that allows a

better identification of the MR damper model was found. Including a frequency modulated displacement and

increased clock period in the training pattern, the MR damper model fitting is improved. Also, the designed in-

put pattern minimizes of training phase and reduces of the number of experiments. Additionally, incorporation

of the electric current in the MR models outperforms the modelling approach.

1 INTRODUCTION

A Magneto-Rheological (MR) damper is a device

which allows the dissipation of energy in a automo-

tive suspension. Its principal components are: piston,

housing, accumulator, coil and MR fluid. The me-

chanical structure is the unchangedof passivedamper.

The MR fluid is a suspension of micrometer-sized

magnetic particles in an oil. In the area of piston

where the oil is transfered between housing chambers,

a magnetic field is applied via electric current. The

later varies the damping properties of the device. The

interaction of the several aforementionedmechanisms

and the magnetic field variations results in highly non

linear behavior with hysteretic patterns of the gener-

ated force.

The power generated and energy dissipated by this

device are defined by the piston displacement and ve-

locity multiplied for the force, respectively. In the

control system of a semi-active automotive suspen-

sion, the precision on the generated power and dis-

sipated energy of MR damper is crucial. This pre-

cision depends on the accuracy of the MR damper

model. Therefore, a good MR damper model is a key

issue. Having a good MR damper simulation demands

a good mathematical equation of the damper, a good

training phase and a good learning phase of the model

(coefficients). The training phase must find out the

main characteristics of the MR damper through the

training patterns. This requires a specific Design of

Experiments (DoE).

The role that the input patterns plays in the MR

damper identification process was analyzed with two

models. The hypothesis is that there exists experi-

mental input patterns that allows the best learning of

the coefficients of the model, regardless the chosen

model structure. This paper is organized as follows.

Section 2 presents a literature review. In section 3,

several input patterns were implemented in order to

validate the proposal. Section 4 discusses the results.

Section 5 concludes the paper.

2 LITERATURE REVIEW

2.1 Input Patterns

The training patterns of the most representative mod-

eling approaches were reviewed. In some research

works the Design of Experiments (DoE) and the MR

damper model were not clearly associated. The de-

velopment of a MR damper model, its parameteriza-

tion and its final application were not integrally per-

formed.

A training pattern for modelling of a MR damper

consists of signal that includes a displacement (x) and

electric current (I). The velocity is considered as a

rate of change of the displacement. Table 1 summa-

rizes some important works. This table is divided in

three sections according to the training patterns.

Section one (SSS+C). The displacement is a

156

de-J. Lozoya-Santos J., Morales-Menendez R., A. Ruiz-Cabrera J., Diaz-Salas V. and Ramirez-Mendoza R. (2009).

BUILDING TRAINING PATTERNS FOR MODELLING MR DAMPERS.

In Proceedings of the 6th International Conference on Informatics in Control, Automation and Robotics - Signal Processing, Systems Modeling and

Control, pages 156-161

DOI: 10.5220/0002215501560161

Copyright

c

SciTePress

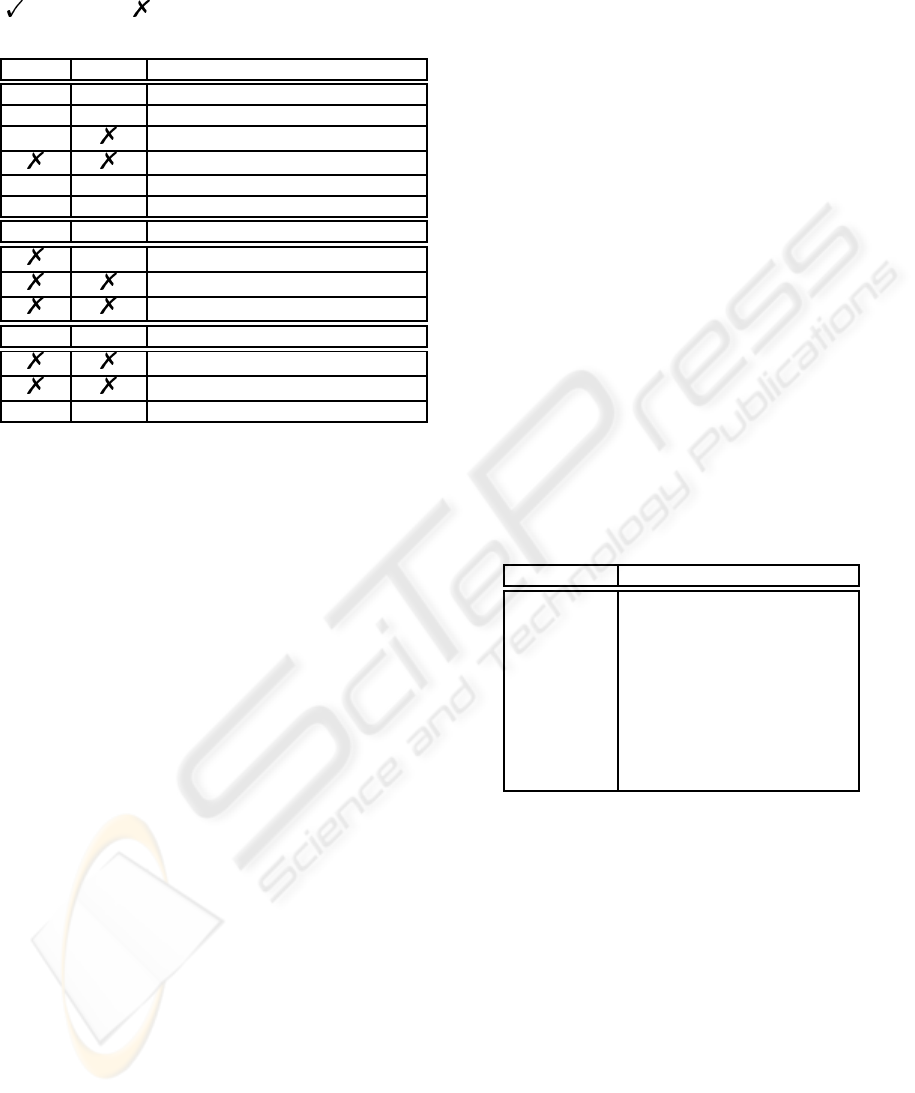

Table 1: Comparison of MR damper models. Power col-

umn shows if the research work studied the generated power

(

), or did not ( ). Energy column same meaning as

power column. Finally, the reference are cited.

Power Energy SSS+C training patterns

X X (Spencer et al., 1996)

X X (Li et al., 2000)

X (Wang and Kamath, 2006)

(Shivaram and Gangadharan, 2007)

X X (Guo et al., 2006)

X X (Nino-Juarez et al., 2008)

Power Energy BWN+C training patterns

X (Burton et al., 1996)

(Wang and Liao, 2001)

(Savaresi et al., 2005)

Power Energy BWN+BWN training patterns

(Wang and Liao, 2001)

(Chang and Zhou, 2002)

X X (Du et al., 2006)

Sinusoidal Sweep Signal (SSS) with specific fre-

quency and a Constant electric current. This is a typ-

ical training input for MR damper models. Exploiting

this pattern, both Energy (E) and Power (P) are suc-

cessfully simulated. The number of experiments is

high. The obtained model accuracy is high (5% er-

ror). There are not electrical current transients, this

compromises the use of the model. Table 1 shows six

representative works with this type of training inputs.

Section two (BWN+C). The displacement is a

bandwidth BandWidth Noise (BWN) pattern and a

Constant electric current (C). This training input pat-

terns has the same features as SSS+C signals. How-

ever, the information richness due to the magnitude of

displacement is decreased. Power and Energy simu-

lation are not achieved.

Section three (BWN+BWN), both displacement

and electric current follow a bandwidth noise BWN

pattern. Power and energy simulation are not

achieved, except if a displacement greater than 10 mm

is generated, (Du et al., 2006). The pattern requires

shorter training inputs. The fitting error this pattern is

low (3%).

The BandWidth (BW) in all the reviewed works

was lower than 6 Hz, except in (Savaresi et al., 2005)

and (Nino-Juarez et al., 2008). Hence, the MR damper

response to high frequency has not been explored.

Neither, hard non-linearities due to the broken mag-

netic bounds of metallic particles (because of high

frequency and displacements). There are missing

analysis of power and energy responses in automo-

tive applications for frequencies around 10-15 Hz and

displacement greater than 10 mm.

There are research works with other type of pat-

terns, such as, Amplitude Pseudo Random Binary

Signal APRBS in electric current (Savaresi et al.,

2005). (Wang and Liao, 2005). explored electric cur-

rent with sinusoidal wave signals.

There are not a standard definition of training pat-

terns in order to identify the power and energy fea-

tures. The overuse of the MR damper due to long ex-

perimental exploration at electric current greater than

3 amperes could give a skewed model. Therefore,

more research of training patterns for MR damper

modelling is needed.

2.2 Modeling Approaches

Several models have been developed with differ-

ent approaches. These models could be: phe-

nomenological (P), semi-phenomenological (SP) and

black-box (BB) (neural network, fuzzy, non-linear

ARX, polynomial among others). The training pat-

tern will be tested with both non-linear with Auto

Regressive eXogenous inputs (NARX) and a Semi-

Phenomenological models. A brief review of these

models will be included for completeness.

Table 2: Description of variables for DoE.

Variable Description

x

k

or x Damper piston displacement

I

k

or I Electrical current

˙x

k

or ˙x Damper piston velocity

f

MRk

or f

MR

Damping force

a

j

j-esime modeling coefficient

d time delays

q

1

, q

2

Electrical current exponents

ESR Error-Signal-to-noise Ratio

k Discrete sample, discrete time

j Subindex

The MR damper model based on a non-linear

ARX structure is a lineal combination of a vector

of delayed inputs multiplied for their parameters. If

electric current is not an input, all the parameters have

a polynomial dependence on it.

In (Nino-Juarez et al., 2008), a non-linear ARX

model of nine parameters (1) achieves high precision

simulation of power and energy. Table 2 defines the

parameters of this equation.

f

MRk

= a

1

f

MRk−1

+ a

2

f

MRk−2

+ a

3

f

MRk−3

+a

4

x

k−1

+ a

5

x

k−2

+ a

6

x

k−3

+a

7

˙x

k−1

+ a

8

˙x

k−2

+ a

9

˙x

k−3

(1)

By the side of Semi-Phenomenological (SP) ap-

proaches, the bi-viscous and hysteretic behavior are

shaped with smooth and concise forms. The instanta-

neous force is delivered without taking into account

BUILDING TRAINING PATTERNS FOR MODELLING MR DAMPERS

157

the transients, and consequently at high frequency,

dynamic features are not well emulated. Transients

can be omitted at both low frequencies and small dis-

placements. The coefficients are related to energy and

power features of MR dampers but they are not linked

to components. The SP model has a good balance be-

tween simulation capability and easy to fit model.

(Guo et al., 2006) (2) have well defined parame-

ters for the dynamic yield force, the post-yield and the

pre-yield proportions. The the MR damper response

is simulated using hyperbolic tangents.

f

MR

= a

1

tanh

a

3

˙x+

a

4

a

5

x

+ a

2

˙x+

a

4

a

5

x

(2)

The non-linear ARX model has less than 1% error

prediction; while the SP approach has less than 4%

error prediction.

3 EXPERIMENTS

The specimen tested was a DELPHI Gabriel MR

damper. It is a standard mono-tube configuration with

36 mm piston and MR fluid. This damper is part of the

Delphi MagneRide

TM

commercial system. The con-

figuration of the experimental system was a MTS

TM

which can deliver enough force and time response

with respect to the maximum force and bandwidth of

the MR damper.

The monitored variables were the damping force

f

MR

, displacement x, and electric current I. The

data acquisition system was Software Testlink

TM

and

Testware

TM

II). Thanks to Metalsa

1

for using its fa-

cility.

The DoE considered a displacement that fol-

lows this signal 0.0125· sin(ω·

k

512

), where the

sampling frequency was 512Hz, ω = 2π f, f =

{1, 1.5, . . . , 13.5, 14} Hz. The absolute resultant range

for the displacement was [0, 25] mm. The absolute re-

sultant range for the force was (0, 2.850] N. The cur-

rent was kept constant.

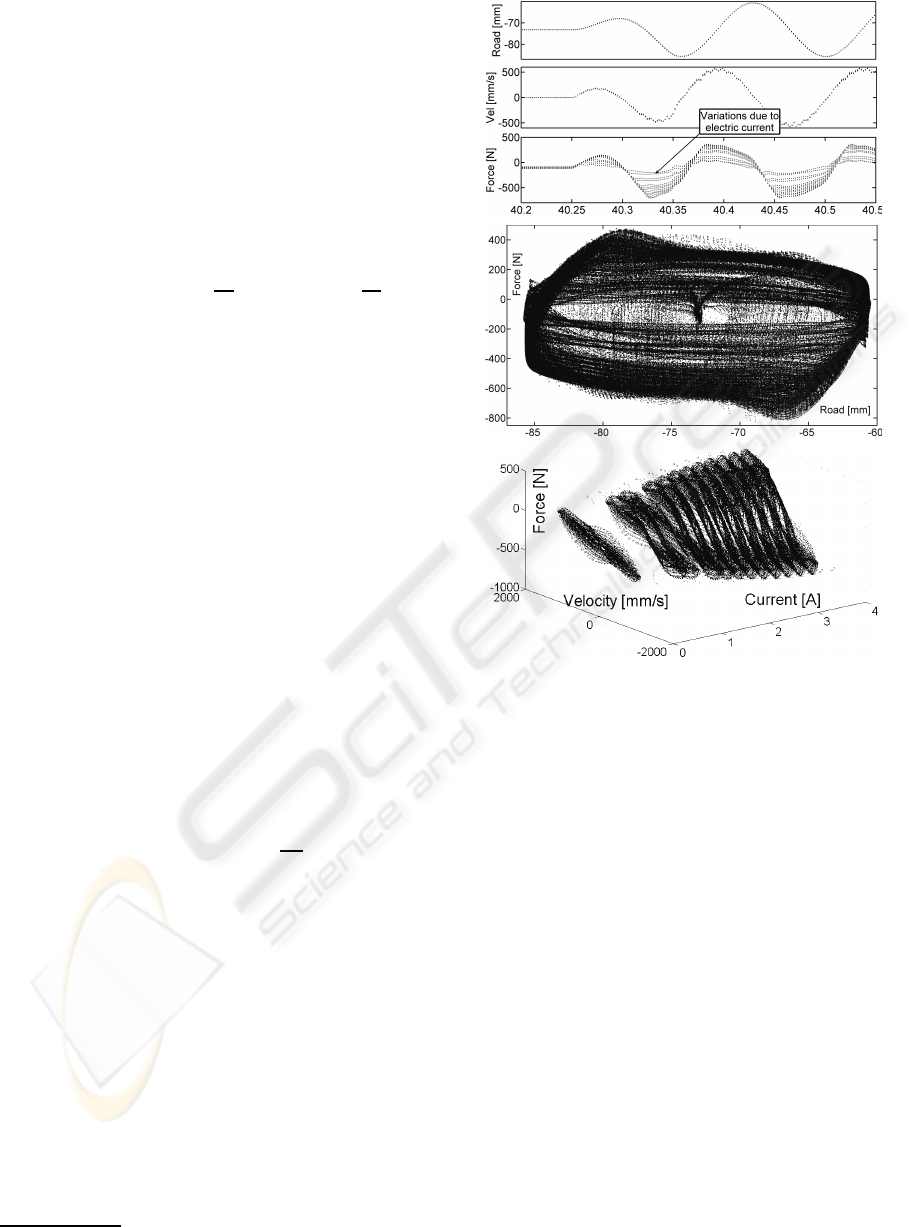

The displacement signal was replicated 12 times.

At each replicate, the current was increased in 0.25 A

from 0 to 4 A. Figure 1 shows an example of these

experimental results.

All the experimental data sets were identified

with a semi-phenomenological model obtaining a MR

damper simulator (Guo et al., 2006).

In order to generate several datasets, eleven train-

ing patterns were designed. The Table 3 shows

two example of this. The displacement follows a

1

www.metalsa.com.mx

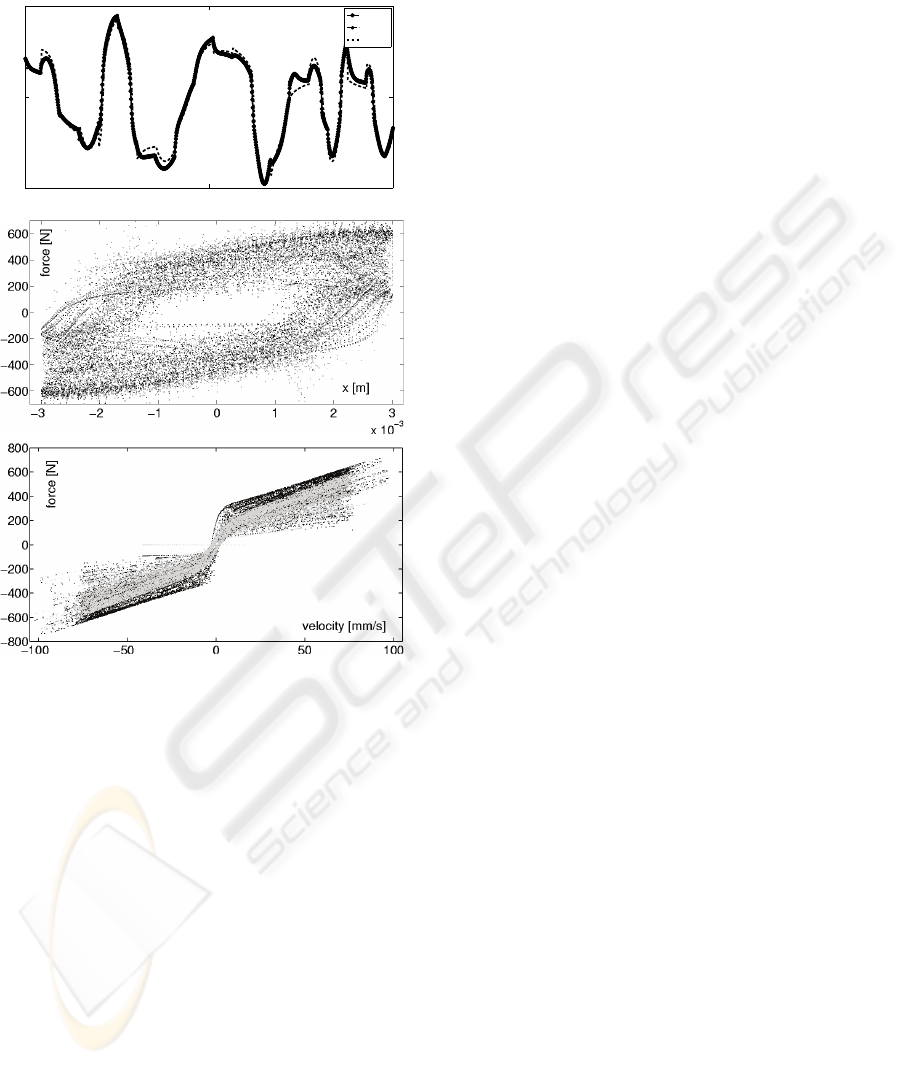

Figure 1: Experimental data for 4.5 − 14.5 Hz (high fre-

quency). Top plot. Time versus displacement, velocity and

force response. Middle and bottom plots show the experi-

mental energy and power. These plots include several force

responses according to applied electric currents.

Frequency Modulated FM signal with fixed ampli-

tude and a BW from 0.5 to 14.5 Hz. This signal was

generated by a Voltage Controlled Oscillator (VCO).

The VCO’s input was an ICPS with values between

0 and 1. Each ICPS step had a time length of 100ms

which means that the frequencies in signal were con-

stant over same time. The magnitude of displacement

was held constant in 3 mm. Two different signals of

electric current were evaluated: an Increased Clock

Period Signal (ICPS) and a Pseudo Random Binary

Sequel (PRBS). The length of time was 30 seconds.

All the experiments were piecewise designed, assur-

ing the invariance of conditions during all the exper-

iment. The signals were fed through the simulator in

order to retrieve the force.

For the displacement, the several DoE forms were:

Sinusoidal Stepped Frequency (SFS), Sinusoidal

CHirp Signal (CHS), Road Profile (RP) and (FM).

For the electric current, the DoE shapes were:

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

158

Stepped increment at electrical Current (SC), Ramp

Periodic positive slope Current (RC), Ramp with pos-

itive and negative slope Current (ADRC), ICPS, and

PRBS.

With later defined signals the DoEs were:(1)

(SFS,SC), (2)(SFS,RC), (3)(SFS,ADRC),

(4)(CHS,ICPS), (5)(CHS,PRBS), (6)(SFS,ICPS),

(7)(SFS,PRBS), (8)(FM,ICPS), (9)(FM,PRBS),

(10)(RP,ICPS) and, (11)(RP,PRBS). The precedent

number will identified the training patterns in the rest

of the paper. For rich details, see (Lozoya-Santos

et al., 2009).

Table 3: Design of experiments.

Displacement

PTIC

τ(vco) Time

Current

PTIC(I)

PTIC(x)

FM,ICPS 0.10s 30 τ

kIk

= 0.10s 1

FM,PRBS 0.10s 30 min

τ

= 0.05s 1

Equation Description

τ(vco) Time constant for VCO

PTIC(I)

PTIC(x)

How many PTIC(I) utilized each PTIC(x)

min

τ

Minimum clock period in PRBS

τ

kIk

Amplitude Period in ICPS

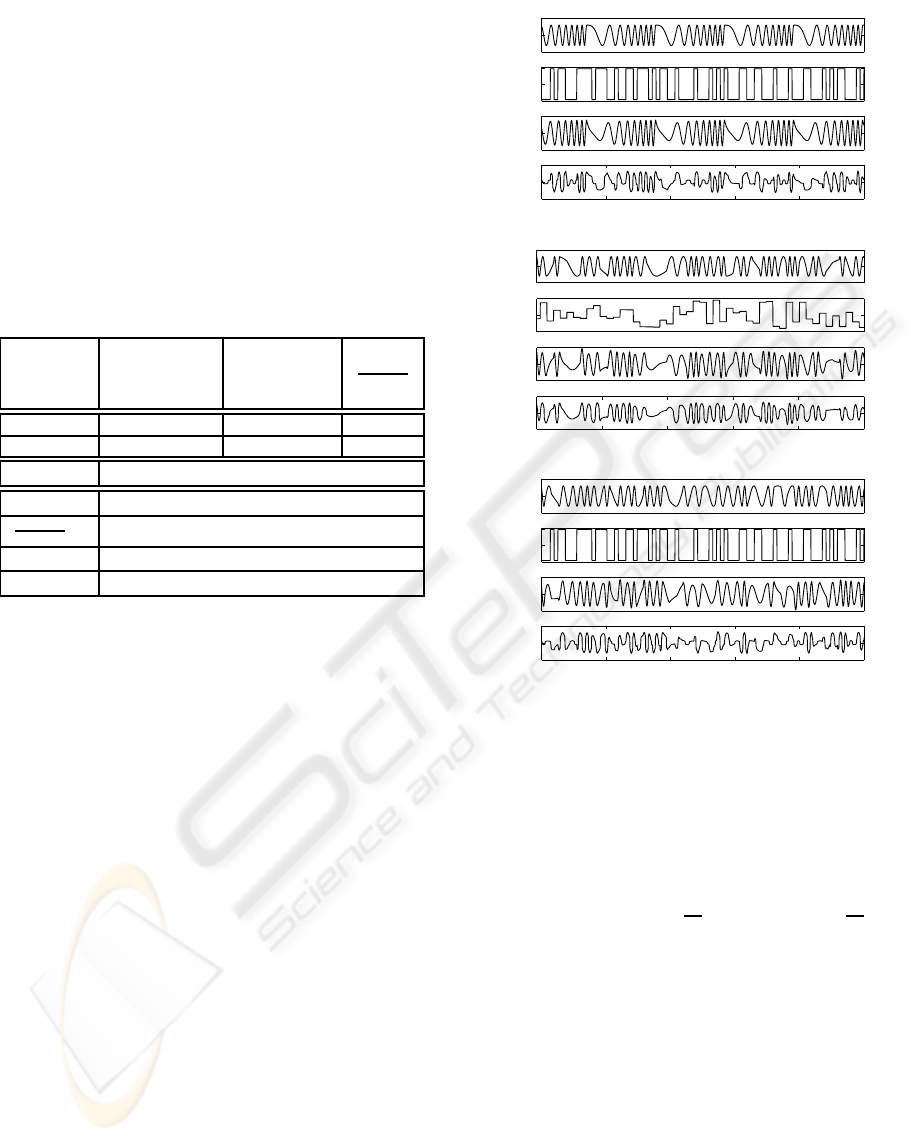

The Figure 2 shows three computed experiments.

These training pattern exhibit fixed amplitude for dis-

placement and persitent signals in frequency.

4 RESULTS

Performing an analysis of the models (1) and (2)

and a-priori knowledge of MR damper dynamics, the

modified models and its degree of freedoms were pro-

posed. The Degree of Freedom (DoF) of the model

represents a main variation in the original structure of

the model

Then, for the given experimental data sets, the two

MR damper models were trained. The first trained

model was the modified version of (1). The new

model has added regressors of the current. Each de-

layed value of current is raised to power two. Thus,

the augmented regressors structure were:

a

10

·I

2

k−1

+ ··· + a

{10+d−1}

·I

2

k−(1+d)

(3)

The resultant model could have from 11 to 14 param-

eters, then its DoF is the number of parameters for

I. The second trained model was the modified SP

model (4). The modification consisted of the incorpo-

ration of the factor I

q

j

as direct input on both terms,

where j={1,2} is the j-esime model term. The DoFs

−5

0

5

x 10

−3

meters

0

2

4

A

−100

0

100

mm/s

10 11 12 13 14 15

−1000

0

1000

newtons

−5

0

5

x 10

−3

meters

0

2

4

A

−100

0

100

mm/s

10 11 12 13 14 15

−1000

0

1000

newtons

−5

0

5

x 10

−3

meters

0

2

4

A

−100

0

100

mm/s

10 11 12 13 14 15

−1000

0

1000

newtons

Figure 2: Experimental training patterns. Top plot shows a

(CHS,PRBS). Middle plot shows a (FM,ICPS). Bottom plot

describes a (FM,PRBS).

of model (4) were the power q

j

, where its possible

values were {0.5, 0.33, 0.25, 0.2}. The parameters

number remains the same.

f

MR

= a

1

·I

q

1

tanh

a

3

˙x+

a

4

a

5

x

+ a

2

·I

q

2

˙x+

a

4

a

5

x

(4)

Finally, the modified models were identified by

nonlinear curve fitting using the non-linear least

squares algorithm. Based on these models, the DoEs

were validated.

The training patterns have persistent signals with

richness frequency content for each signal (x, ˙x, I,

f

MR

). For each experiment, the model was fitted at

each defined DoF. Then a validation of the model via

ESR was performed with the rest of the experiments

and the ESR average was computed.

This process was repeated until all the possible

values of DoF were varied and the resultant model

BUILDING TRAINING PATTERNS FOR MODELLING MR DAMPERS

159

was fitted.

After obtaining all the fit measures per DoF for

experiment data sets, a sort process from lowest to

highest ESR was done. This step did include all the

experiments. The combination of DoF and experi-

ment with the lowest error-to-noise ratio was selected

as the best.

Identification and validation were performed for

all the experiments and models. Therefore pro-

posed NARX model was submitted to the variation in

number of coefficients. The semi-phenomenological

model always maintained five coefficients along DoF

variations. The models include the electric current as

natural input. The validation process confirmed that

the emulation of bi-viscous and hysteretic features by

the proposed models are dependent on the design of

experiments.

Table 4: Comparison of ESR results for different training

patterns. M is the type of model. E is the number of training

pattern, ESR AVG is the average ESR. BEST ESR is the

best obtained ESR.

M E ESR AVG BEST ESR

BB 8 0.002 0.0009

9 0.003 0.0009

5 0.0011 0.0010

11 2139 2232

6 2.0582 3.6940

7 1.1010 1.9761

SP 8 0.0239 0.0212

1 0.0235 0.0202

4 0.0240 0.0205

10 0.1916 0.1055

3 0.1002 0.1094

11 0.2132 0.0979

In Table 4, general approach results are shown.

BB and SP correspond to the modified model (1) and

the model (4) respectively. E column sorts the ex-

periments by the top 3 performance and the worst

3 for the same DoF. The next columns ESR AVG

and SD shows the overall ESR statistical behavior, in

other words, for all DoF variations and for all valida-

tions with a specific experiment. For example, the

first row specifies that EXP 8 for NARX proposed

model has an average ESR = 0.0002 when the coef-

ficients obtained by experiment 8 are used to validate

others patterns. For this row, the best model has a

DoF = 2. An analysis of the full table demonstrates

that the best performing E is the number 8 because

it has the lowest ESR values. For completeness, the

values for DoFs have been included into the Table 4.

The best performing DoF were: number of regres-

sors of electric current equal to 2 for NARX model

and q

1

= 0.5, q

2

= 0.2 for electric current dependent

semi-phenomenological model.

By other side, the experiments 11, 6 and 7 used

to fit BB and the experiments 10, 3 and 11 used to fit

SP have big ESRs (i. e. lack of fit). The experiment

11 is repeated for both worst cases, hence the use of

road profiles could generate skewed models. Thus,

the configuration of input patters has high significa-

tion on the learning of model parameters.

Based on the results, a frequency modulated dis-

placement, with the same spectral frequency content

as road profile and an electrical current excitation with

ICPS shaping can recreate the dynamical force re-

sponse of MR Damper devices, regardless of the MR

damper model’s structure.

Moreover, coefficients are robust when model is

tested with other patterns (cross validation), obtaining

lows ESRs. The ESR span intervals were for NARXs

(6.17x10

−5

, 0.00026), for SP (0.00635, 0.05687) and

for P (0.02234, 0.06917), respectively. The experi-

ments 5, 7, 9 y 12 (current equal to PRBS) for mod-

ified SP always offer an ESR ≥ 0.15 which means

that discontinuous values of current are not proper for

model.

4.1 Discussion

The classic DoE has poor frequency content in elec-

tric current and excessive repetitions in displacement.

Hence, the number of experiments are a multiple of

the values of the tested electric current plus the repli-

cates for each experiment. The lengths of time of the

eleven DoEs in this work were between 30-60 sec-

onds. The maximum number of experiments will be

30, including the replicates. The realistic nature of

exogenous and actuation variables allows a safe test.

The best learning of the coefficients in each tested

model was successfully with the training pattern

FM+ICPS. The frequency modulated displacement

implies a continuous changes of slope implying the

persistence of the effect of the velocity over MR

damper. Therefore, with a short and continuous test,

the uniform coverage of the semi-active zone, (the

exploration of energy and power capabilities) in MR

damper is achieved.

5 CONCLUSIONS

A comparative analysis of training pattern for identi-

fication of MR damper models was done. Two mod-

els were exploited to validate the proposal: non-linear

ARX and Semi-phenomenological models. The key

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

160

variables in training patterns are the frequency band-

width and the electric current.

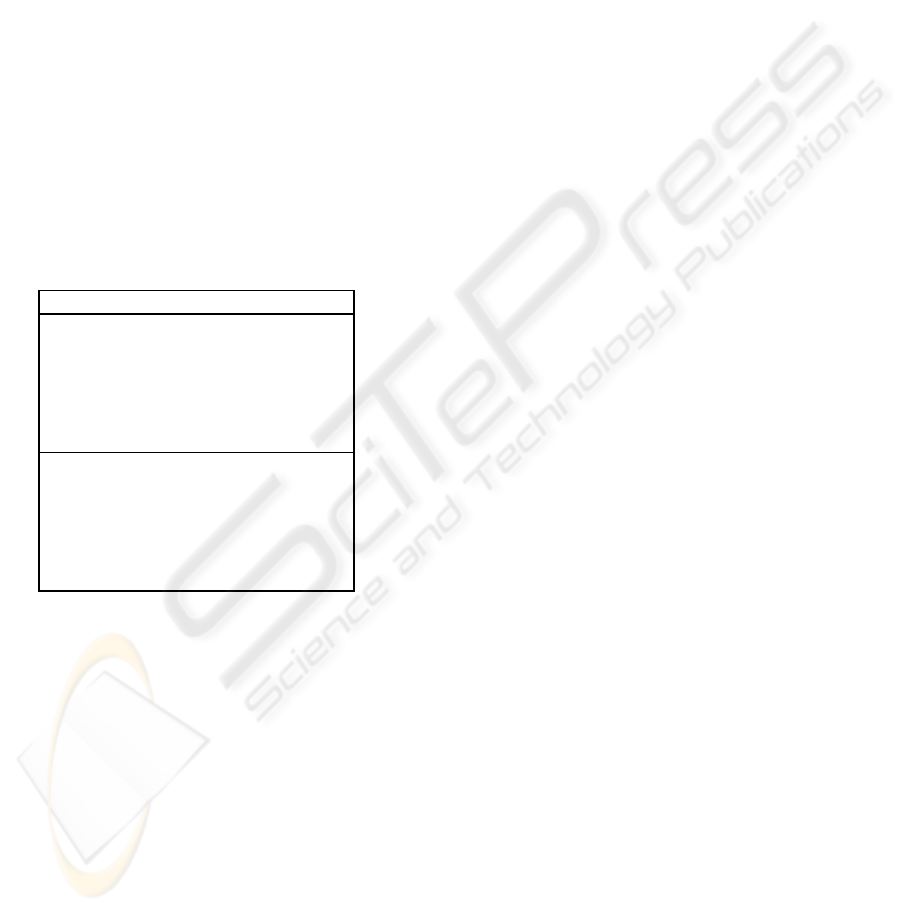

1.15 1.2 1.25

x 10

4

−500

0

500

Samples

Force [N]

Real

NARX

Shuqi

Figure 3: Top plot. Comparison of simulated responses ver-

sus experiment 8. Middle and bottom plots show the power

and energy extraction using the experiment 8. The black

dots are experimental data. The gray dots are emulated data

by SP proposed model with a q

1

= 0.5, q

2

= 0.2.

I was validated that the configuration of the train-

ing patterns has a high impact over the model fitting.

Features as short duration, continuity, uniform cov-

erage of electric current and displacement ranges are

needed. Also, the use of the model must be consid-

ered into the DoE.

REFERENCES

Burton, S., Makris, N., Konstantopoulos, I., and Antsak-

lis, P. (1996). Modeling the Response of ER

Damper: Phenomenology and Emulation. Eng.

Mech., 122:897–906.

Chang, C. and Zhou, L. (2002). Neural Network Emulation

of Inverse Dynamics for a MR Damper. Struct. Eng.,

128:231–239.

Du, H., Lam, J., and Zhang, N. (2006). Modelling of

a Magneto-Rheological Damper by Evolving Radial

Basis Function Networks. Eng. Apps. of Art. Intell.,

19(8):869–881.

Guo, S., Yang, S., and Pan, C. (2006). Dynamical Model-

ing of Magneto-rheological Damper Behaviors. Int.

Mater, Sys. and Struct., 17:3–14.

Li, W. H., Yao, G. Z., and Chen, G. (2000). Testing and

Steady State Modeling of a Linear MR Damper un-

der Sinusoidal Loading. Smart Materials Structures,

9:95–102.

Lozoya-Santos, J. J., Morales-Menendez, R., and Ramirez-

Mendoza, R. (2009). Design of Experiments for MR

Damper Modelling. To appear in Neural Netwotks,

Int. Joint Conf. on, IEEE Proc.

Nino-Juarez, E., Morales-Menendez, R., Ramirez-

Mendoza, R., and Dugard, L. (2008). Minimizing the

Frequency in a Black Box Model of a MR Damper.

In 11th Mini Conf on Vehicle Sys. Dyn., Ident. and

Anomalies.

Savaresi, S. M., Bittanti, S., and Montiglio, M. (2005).

Identification of Semi-Physical and Black-Box Non-

Linear Models: the Case of MR-Dampers for Vehicles

Control. Automatica,, 41(1):113–127.

Shivaram, A. C. and Gangadharan, K. V. (2007). Statisti-

cal Modeling of a MR Fluid Damper using the Design

of Experiments Approach. Smart Mater. and Struct.,

16(4):1310–1314.

Spencer, B., Dyke, S., Sain, M., and Carlson, J. (1996). Phe-

nomenological Model of a MR Damper. ASCE J of

Eng Mechanics.

Wang, D.-H. and Liao, W.-H. (2001). Neural Network Mod-

eling and Controllers for Magneto-Rheological Fluid

Dampers. In Fuzzy Sys.. The 10th IEEE Int. Conf. on,

volume 3, pages 1323–1326.

Wang, D. H. and Liao, W. H. (2005). Modeling and Control

of Magnetorheological Fluid Dampers using Neural

Networks. Smart Mater. Struct., 14:111–126.

Wang, L. X. and Kamath, H. (2006). Modelling Hysteretic

Behaviour in MR Fluids and Dampers using Phase-

Transition Theory. Smart Mater. Struct., 15:1725–

1733.

BUILDING TRAINING PATTERNS FOR MODELLING MR DAMPERS

161