FAULT DETECTION AND DIAGNOSIS IN A HEAT EXCHANGER

Juan C. Tudon Martinez, Ruben Morales-Menendez and Luis E. Garza Casta˜non

Tecnol´ogico de Monterrey, Av. E. Garza Sada 2501, 64849, Monterrey N. L., M´exico

Keywords:

Dynamic principal component analysis, Diagnostic observers, Fault detection, Fault diagnosis.

Abstract:

A comparison between the Dynamic Principal Component Analysis (DPCA) method and a bank of Diagnostic

Observers (DO) under the same experimental data from a shell and tube industrial heat exchanger is presented.

The comparative analysis shows the performance of both methods when sensors and/or actuators fail. Different

metrics are discussed (i.e. robustness, quick detection, isolability capacity, explanation facility, false alarm

rates and multiple faults identifiability). DO showed quicker detection for sensor and actuator faults with

lower false alarm rate. Also, DO can isolate multiple faults. DPCA required a minor training effort; however,

it cannot identify two or more sequential faults.

1 INTRODUCTION

Early detection and diagnosis of abnormal events in

industrial processes represent economic, social and

environmental profits. Generally, the measuring and

actuating elements of a control system fail causing ab-

normal events. Thus, when the process has a great

quantity of sensors or actuators, the Fault Detection

and Isolation (FDI) task is very difficult.

Most of the existing FDI approaches for Heat Ex-

changers (HE), are based on quantitativemodel-based

methods. In (Ball´e et al., 1997), fuzzy models are

used to generate residuals; since each fault has an

unique residual incidence, it is possible the fault iso-

lation. Similarly, a residual generator is proposed to

create fault signatures in (Krishnan and Pappa, 2005).

Generalized Likelihood Ratio is frequently used to es-

timate the fault magnitude from a residual generation

(Aitouche et al., 1998). On the other hand, a particle

filtering approach for predicting the probability dis-

tribution of different heat exchanger states (faults) is

proposed in (Morales-Menendez et al., 2003).

A comparative analysis between two FDI systems

in an industrial HE is proposed. One of them is

based on the Dynamic Principal Component Analy-

sis (DPCA) and another one on a bank of Diagnostic

Observers (DO).

Some researches are related to this work. Re-

cently, DPCA and correspondence analysis (CA) have

been compared (Detroja et al., 2005). CA shows a

greater efficiency of fault detection in terms of the

shorter detection delay and lower false alarm rates;

however, CA needs a greater computationaleffort. An

adaptive standardization of the DPCA has been pro-

posed for MIMO systems (Mina and Verde, 2007);

simulation results allow to detect faults and avoid nor-

mal variations in process signals.

An adaptive observer of a nonlinear discrete-time

system with actuator faults is proposed in (Caccavale

and Villani, 2004). Using process linear models, a dy-

namic observer detects malfunctions caused by mea-

surement and modeling errors (Simmani and Patton,

2008). In order to detect multiple faults in a process,

a set of unknown input-observers can be used, each

one of them is sensitive to a fault while insensitive to

the remaining faults (Verde, 2001).

The aforementioned works were implemented un-

der different types of faults and processes; then, a

comparison under same experimental data in an in-

dustrial HE is considered.

This paper is organized as follows: Section 2 for-

mulates the DPCA approach. Section 3 describes the

steps for designing a set of DO. Section 4 describes

the experimental system. Section 5 discusses the re-

sults. Finally, conclusions of this work are presented.

2 DPCA

Let X be a matrix of m observations and n variables

collected from a real process. This data set repre-

sents the normal operating conditions.

¯

X is the scaled

data matrix and ¯x is a vector containing mean (µ)

265

C. Tudon Martinez J., Morales-Menendez R. and E. Garza Castañón L. (2009).

FAULT DETECTION AND DIAGNOSIS IN A HEAT EXCHANGER.

In Proceedings of the 6th International Conference on Informatics in Control, Automation and Robotics - Intelligent Control Systems and Optimization,

pages 265-270

DOI: 10.5220/0002216402650270

Copyright

c

SciTePress

of each variable. Such that ¯x = (

1

m

)X

T

1 and

¯

X =

(X −1¯x

T

)D

−1

where D is a diagonal matrix contain-

ing standard deviation (σ) of each variable and 1 is a

vector of elements equal to 1.

When the system has a dynamic behavior,the data

present a serial and cross-correlation among the vari-

ables. This violates the assumption of normality and

statistical independence of the samples. To overcome

these limitations, the column space of the data matrix

X must be augmented with a few past observations for

generating a static context of dynamic relations.

¯

X

D

= [X

1

(t)X

1

(t −1),.. .,X

1

(t −w),...

X

n

(t)X

n

(t −1), ..., X

n

(t −w)]

(1)

where w represents the quantity of time delays. By

performing PCA on the augmented data matrix, a

multivariate auto regressive model is extracted di-

rectly from the data (Ku et al., 1995). For a multi-

variate system, the process variables can have differ-

ent ranges of values, thus the data matrix X

D

[m×(n×w)]

must be standardized. With the scaled data ma-

trix, a set of a smaller number (r < n) of variables

is searched through the process of decomposing the

variance in the data. r must preserve most of the in-

formation given in these variances and covariances.

The dimensionality reduction is obtained by a

set of orthogonal vectors, called loading vectors (p),

which are obtained by solving an optimization prob-

lem involving maximization of the explained variance

in the data matrix by each direction (j) with t

j

=

¯

Xp

j

;

the maximal variance of t

j

must be computed from:

max(t

T

j

t

j

) = max(p

T

j

¯

X

T

¯

Xp

j

) = max(p

T

j

Ap

j

) (2)

Such that p

T

j

p

j

= 1. Solving the optimization problem

through the Singular Value Decomposition (SVD),

the eigenvalues λ

j

of the matrix A are computed from,

(A −λ

j

I)p

j

= 0 for j=1,...,n

(3)

where, A represents the correlation matrix of the data

matrix

¯

X, and I is a n ×n identity matrix. Using the

new orthogonal coordinate system, the data matrix

¯

X

can be transformed into a new smaller data matrix T,

called scores matrix.

T

[m×r]

=

¯

X

[m×n]

P

[n×r]

(4)

where, P represents the obtained loading vectors of

the SVD with the most significant eigenvalues λ

j

.

As this transformation is a rotation matrix, it holds

P

T

P = I. Therefore also

¯

X = TP

T

is valid. Thus,

PCA decomposes the matrix

¯

X as,

¯

X = t

1

p

T

1

+ t

2

p

T

2

+ ... + t

r

p

T

r

(5)

The matrix T can be back-transformed into the

original data coordination system as,

X

∗

[m×n]

= T

[m×r]

P

T

[r×n]

(6)

2.1 FDI using DPCA

The normal operating conditions can be characterized

by T

2

-statistic (Hotelling, 1993). Equation (7) allows

to generate online the T

2

-statistic based on the first r

loading vectors (principal components).

T

2

= x

T

[1×n]

P

[n×r]

Λ

−1

[r×r]

P

T

[r×n]

x

[n×1]

(7)

where, x is a new measurement vector taken online

and Λ is a diagonal matrix which contains first r

eigenvalues of the correlation matrix (A). If the value

of T

2

-statistic stays within its control limit then, the

status of the process is considered normal (Ku et al.,

1995). Thus, a fault occurs, when a value of T

2

-

statistic is greater than its control limit (T

2

α

).

T

2

α

=

(m−1)r

(m−r)

F

α

(r,m−r) (8)

where, F

α

(r,m −r) is the F-distribution with r and

m−r degrees of freedom with 100α% of confidence.

Due T

2

-statistic only detects variation in the di-

rection of the first r principal components, Jackson et

al. (Jackson and Mudholkar, 1979) propose to mon-

itor the variation in the residual space (components

associated with the smallest singular values) using Q-

statistic for helping to fault detection. Both statis-

tics must detect a fault, however they have not the

same resolution in the deviation when the fault oc-

curs. Similarly to T

2

-statistic, when a value of Q-

statistic is greater than its threshold (Q

α

) indicates the

occurrence of a fault. The values of Q-statistic and its

control limit can be calculated through the equations:

Q = [(I −PP

T

)x]

T

[(I −PP

T

)x] (9)

Q

α

= θ

1

h

0

c

α

√

2θ

2

θ

1

+ 1+

θ

2

h

0

(h

0

−1)

θ

2

1

1

h

0

(10)

where, θ

i

=

∑

n

j=r+1

(λ

j

)

2i

, h

0

= 1−

2θ

1

θ

3

3θ

2

2

and c

α

is the

normal deviation corresponding to (1−α) percentile.

Once a fault is detected, the next step is the isola-

tion. In order to determine which variable is the most

relevant to cause the fault, the use of contribution

plots has been proposed (Miller et al., 1998). Con-

tribution plots quantify the error of each process vari-

able when the process is not in normal operating con-

ditions. The variable which shows the highest contri-

bution (Con

i

) to the error is isolated and associated as

the most relevant to the fault which has occurred.

Con

i

=

R

2

i

∑

r

j=1

R

2

j

(11)

where, R

i

represents the residue in the residuals space

(Isermann, 2006). The residue R can be calculated by

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

266

subtracting the back-transformation data (equation 6)

to scaled data matrix (

¯

X),

R

[m×n]

=

¯

X

[m×n]

−T

[m×r]

P

T

[r×n]

(12)

where P contains the loading vectors corresponding

to components with the smallest singular values.

3 DESIGN OF A BANK OF DO

As the state observer compute the error between the

process states and adjustable model states, it can be

used as a further alternative for model-based fault de-

tection. The discrete state space model which can de-

scribe the process dynamic is,

x

p

(k+ 1) = Gx

p

(k) + Hu(k)

y(k) = Cx

p

(k)

(13)

A state observer for unmeasurable state variables

can be represented as

˜x

o

(k+ 1) = G ˜x

o

(k) + Hu(k) + K

e

[y(k) − ˆy(k)]

ˆy = C ˜x

o

(k)

(14)

where, K

e

is the observer feedback matrix.

3.1 FDI using a Bank of DO

The error of the observer can be computed as:

x

p

(k+ 1) − ˜x

o

(k+ 1) = (G −K

e

C)[x

p

− ˜x

o

] (15)

Defining e(k) = x

p

− ˜x

o

as the error vector, the pre-

dicted error can be calculated as

e(k+ 1) = (G −K

e

C)e(k) (16)

The dynamic behavior of the error e(k) is deter-

mined by the eigenvalues of G-K

e

C. If the matrix G-

K

e

C is a stable matrix, the error vector will converge

to zero for any initial error e(0).

When an unknown input (fault) changes the pro-

cess normal operation, the error signal called residual,

should be different to zero. Therefore, if the residual

is close to zero (i.e. noise with µ = 0 and σ = 1), the

process variableis into its normal operating condition,

called nominal behavior.

If the process is affected by several faults, it is pos-

sible to use a bank of DO for identification of different

faults. All DO are designed from different fault mod-

els and they are sensitive to any fault except the used

fault for their design.

Water Outlet

Water Inlet

Steam Inlet

Condensed

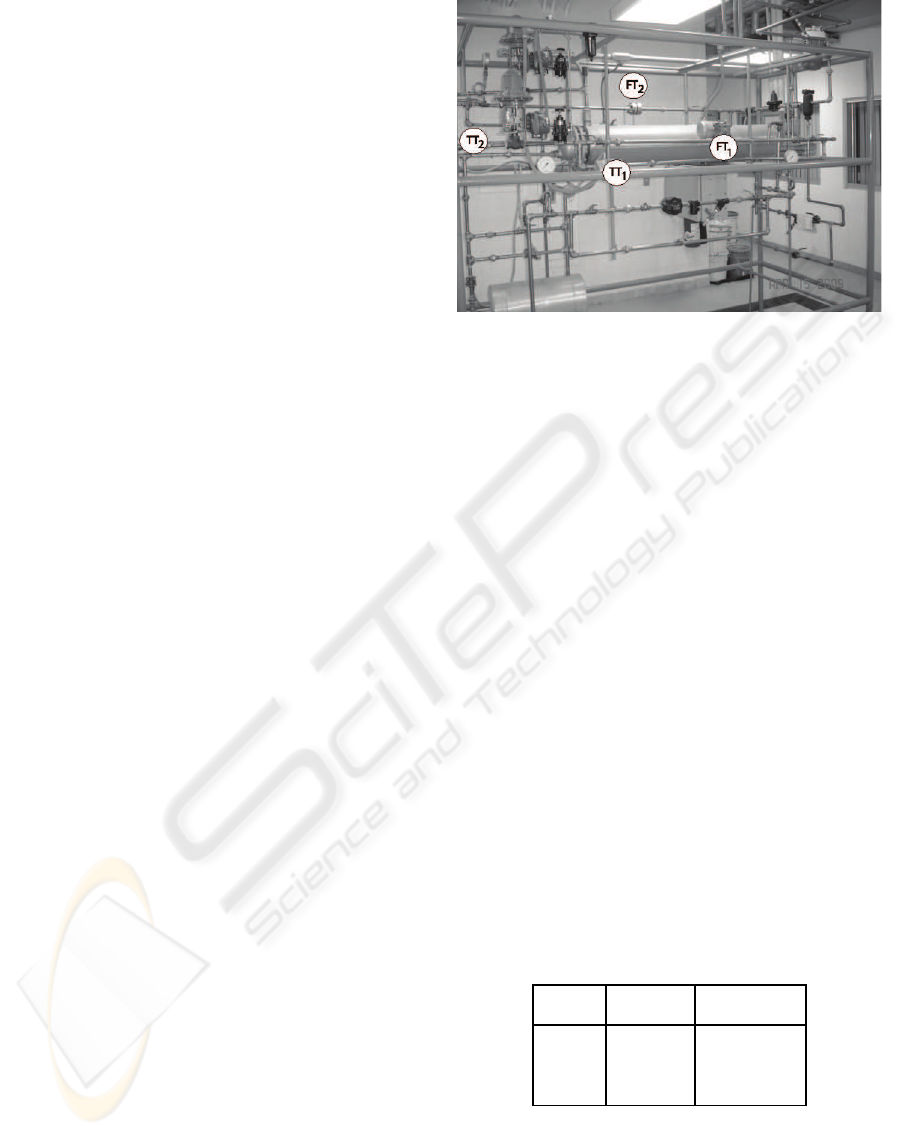

Figure 1: Experimental System.

4 EXPERIMENTAL SYSTEM

An industrial shell-tube heat exchanger is used,

whose characteristics of non-linearity and slow tran-

sient response are the most relevant, see Figure 1.

Faults in sensors and actuators, called soft faults,

have been implemented in additive form. Also, the

process always was free of disturbances.

DPCA used 1 second as sample time delay; and

1900 measurement data of each sensor were taken.

x(t) = [FT

2

(t) FT

1

(t) TT

1

(t) TT

2

(t)] (17)

where, FT

1

and FT

2

are flow transmitters and TT

1

and

TT

2

are temperature transmitters.

In case of diagnostic observers, 5 seconds of sam-

ple time are used to obtain the state space models for

each faulty condition. The observer feedback matrix

in each observer is designed via pole placement with

closed loop poles close to origin in the discrete space.

Four types of additive soft faults will be imple-

mented: abrupt fault in sensors, gradual fault in sen-

sors, abrupt faults in actuators and multiple faults in

sensors, Table 1.

Table 1: Types of faults in the sensors.

Sensor Abrupt Gradual

fault fault (slope)

FT

1

6% (5σ) 0.1%/sec

FT

2

8% (5σ) 0.1%/sec

TT

1

2

◦

C (8σ) 0.1

◦

C/sec

TT

2

2

◦

C (8σ) 0.1

◦

C/sec

Five types of faults were implementedin the steam

and water control valves, Table 2.

FAULT DETECTION AND DIAGNOSIS IN A HEAT EXCHANGER

267

Table 2: Types of faults in actuators.

Case Status of the steam valve Status of the water valve

0 normal (70%) normal (38%)

1 low pressure (60%) normal (38%)

2 high pressure (80%) normal (38%)

3 normal (70%) low pressure (28%)

4 normal (70%) high pressure (48%)

5 RESULTS

5.1 DPCA Approach

Taking one sample time delay of each measurement,

it is possible to explain a high quantity of variance in-

cluding the possible auto and cross correlations. The

normal operating conditions can be explained with 5

principal components (99.95%).

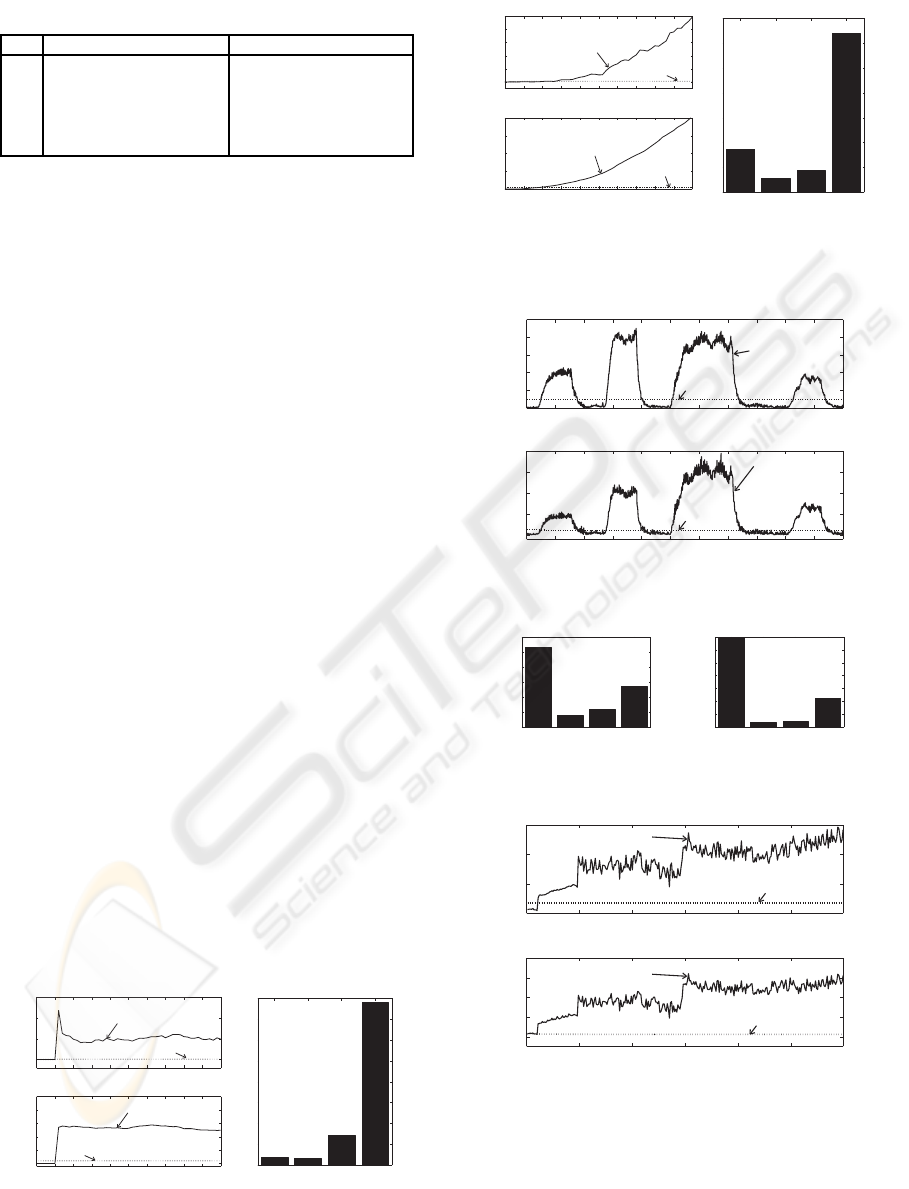

When an abrupt fault was implemented in the TT

2

sensor at time 105, the Figure 2(left plot) showsthat Q

and T

2

statistics clearly overshoot their control limits.

Figure 2(right lot) shows how the contribution plot

helps correctly with the fault isolation. The 78% of

total error corresponds to outlet temperature signal.

Figure 3 (left plot) shows a gradual fault in the

TT

2

sensor at time 200. Q and T

2

statistics overshoot

their control limits and indicate the fault detection af-

ter 14 and 10 seconds respectively once the fault has

occurred. Figure 3(right plot) shows that 64% of total

error corresponds to outlet temperature signal.

For actuator faults, independently if the bias is

positive or negative, there is a reaction in both statis-

tics. When T

2

and Q statistics overshoot their control

limits, the fault is detected (Figure 4).

Using contribution plots, for the cases 1 and 2, the

steam flow signal has the greatest error contribution

followed by the outlet temperature signal (Figure 5).

This result is right because the faults are associated

to changes in the pressure of steam valve (negative

and positive respectively). Similarly, the water flow

signal has the greatest contribution to the error when

the water valve is affected by a pressure change.

0

10

20

30

40

50

60

70

80

0

5

10

15

100 105 110 115 120 125 130 135 140 145 150

0

50

100

150

200

250

Hotelling ‘s T2 statistic

Threshold

Analysis in the Q statistic

Analysis in the Hotelling’s statistic

Fault Contribution Analysis

% of contribution to the fault

Steam

Flow

Water

Flow

Inlet

Temp.

Outlet

Temp.

100 105 110 115 120 125 130 135 140 145 150

Q statistic

Threshold

Figure 2: FDI analysis for an abrupt fault in the outlet tem-

perature sensor using DPCA.

200 205 210 215 220 225 230 235 240 245 250

0

2

4

6

8

10

0

100

200

300

400

Analysis in the Q statistic

Analysis in the Hotelling’s statistic

200 205 210 215 220 225 230 235 240 245 250

Hotelling ‘s T2 statistic

Threshold

Q statistic

Threshold

Fault Contribution Analysis

% of contribution to the fault

Steam

Flow

Water

Flow

Inlet

Temp.

Outlet

Temp.

0

10

20

30

40

50

60

70

Figure 3: FDI analysis for a gradual fault in the outlet tem-

perature sensor using DPCA.

0 100 200 300 400 500 600 700 800 900 1000 1100

0

50

100

150

200

250

0 100 200 300 400 500 600 700 800 900 1000 1100

0

50

100

150

200

Time (seconds)

Q statistic

Threshold

Hotelling T2 statistic

Threshold

Case 1

Case

3

Case

2

Case 4

Analysis in the Q statistic

Analysis in the Hotelling’s statistic

Case 1

Case

3

Case 2

Case

4

Figure 4: Fault detection for actuator faults using DPCA.

Fault Contribution Analysis

% contribution to the fault

Steam

Flow

Water

Flow

Inlet

Temp.

Outlet

Temp.

0

10

20

30

40

50

60

0

10

20

30

40

50

60

70

Fault Contribution Analysis

% contribution to the fault

Steam

Flow

Water

Flow

Inlet

Temp.

Outlet

Temp.

Figure 5: Results in actuators: case 1(left), case 2(right).

0 50 100 150 200 250

0

100

200

300

0 50 100 150 200 250

0

100

200

300

400

Time (seconds)

Q statistic

Threshold

Hotelling T2 statistic

Analysis in the Q statistic

Analysis in the Hotelling’s statistic

Fault

(FT1 :10s)

1

Fault

(TT1 : 48s)

2

Fault

(FT2 : 147s)

3

Fault

(TT2 : 250s)

4

Fault

(FT1 :10s)

1

Fault

(TT1 : 48s)

2

Fault

(FT2 : 147s)

3

Fault

(TT2 : 250s)

4

Threshold

Figure 6: Fault detection using DPCA under multiple faults.

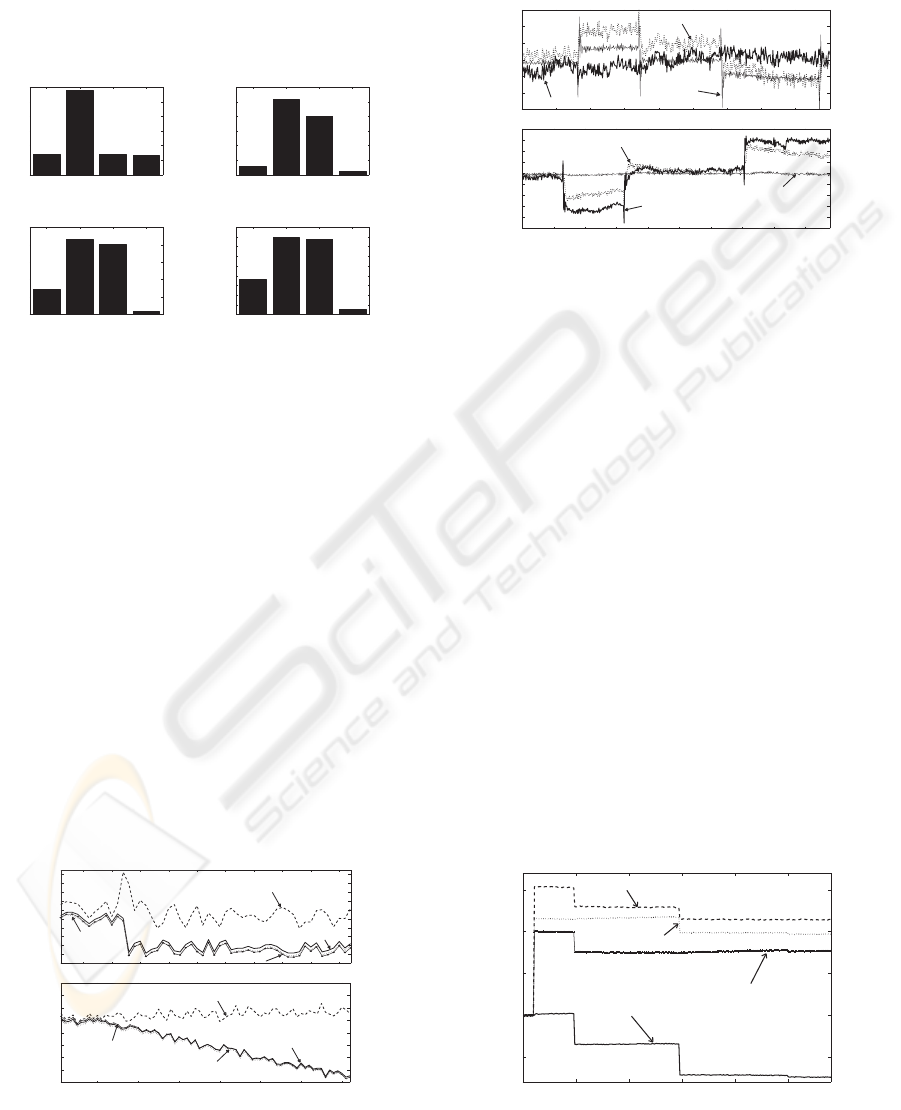

Finally, multiple faults have been activated se-

quentially at different times. Figure 6 shows the per-

formance of DPCA; each fault presents its activation

time. Both statistics overshoot their control limits

when the fault 1 has occurred at time 10. When the

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

268

remainder of the faults were introduced, the statistics

stay inside their control limits; however, they move

more away from their thresholds. None of the statis-

tics comes back to its normal status since none of the

faults was deactivated. Figure 7 shows that it is not

possible to isolate multiple faults since contribution

plots can not associate the error to a specific variable.

0

10

20

30

40

50

60

Fault Contribution Analysis (Fault 1)

% contribution to the fault

0

10

20

30

40

50

60

Fault Contribution Analysis (Fault 1−2)

% contribution to the fault

0

10

20

30

40

50

Fault Contribution Analysis (Fault 1-2-3)

% contribution to the fault

% contribution to the fault

Steam

Flow

Water

Flow

Inlet

Temp.

Outlet

Temp.

0

10

20

30

40

Steam

Flow

Water

Flow

Inlet

Temp.

Outlet

Temp.

Steam

Flow

Water

Flow

Inlet

Temp.

Outlet

Temp.

Steam

Flow

Water

Flow

Inlet

Temp.

Outlet

Temp.

Fault Contribution Analysis (Fault 1-2-3-4)

Figure 7: Diagnostic result for multiple faults in all sensors.

5.2 DO Approach

In order to distinguish different fault conditions, a

bank of four DO was designed (i.e. water flow, steam

flow, outlet temperature and inlet temperature).

When an abrupt fault is implemented in the TT

2

sensor, the outlet temperature residue is the unique

signal which does not change its nominal behavior

whereas the remainder of the residues are deviated

negatively 1.5 units at time 10 when the fault is ac-

tivated, Figure 8(top plot). Thus, it is possible to as-

sociate the fault to the TT

2

sensor. Same FDI result is

obtained when a gradual fault is implemented in the

TT

2

sensor. Figure 8(bottom plot) shows the fault de-

tection after 5 seconds once the fault has occurred.

Figure 9 shows the performance of DO for faults

in actuators Table 2. When is implemented a fault

in the water control valve, independently of the bias

direction, the water flow residue does not change its

5 10 15 20 25 30 35 40 45 50

−2.5

−2

−1.5

−1

−0.5

0

0.5

1

1.5

2

2.5

Residual Analysis (Abrupt fault)

10

20 30 40 50

60 70

−5

−4

−3

−2

−1

0

1

2

3

Time (seconds)

Residue

Water Flow Residue

Steam Flow Residue

Outlet Temperature Residue

Inlet Temperature Residue

Residual Analysis (Gradual fault)

Residue

Water Flow Residue

Steam Flow Residue

Outlet Temperature Residue

Inlet Temp.

Residue

Figure 8: FDI analysis for an abrupt fault (top plot) and

gradual fault (bottom plot) in the TT

2

sensor using DO.

behavior from its nominal value; whereas, the remain-

der of the residues are deviated. Similarly, when is

implemented a fault in the steam control valve, the

steam flow residue does not change its behavior.

500

550

600 650 700 750 800 850 900 950

−10

−8

−6

−4

−2

0

2

4

6

8

Case 1

0

50 100 150 200 250 300 350 400 450

−3

−2

−1

0

1

2

3

Residual Analysis (Faults in the water control valve)

Residual Analysis (Faults in the steam control valve)

Time (seconds)

Residue

Residue

Case 2

Case 4

Case 3

Water Flow Residue

Steam Flow Residue

Water Flow Residue

Steam Flow

Residue

Outlet and Inlet Temp. Residue

Outlet and Inlet Temp. Residue

Figure 9: FDI analysis for actuator faults using the DO.

Figure 10 shows the FDD result using a set of DO

when multiple faults have been activated sequentially

at different time instants. It is important to note that

only one signal is not deviated from its behavior when

is introduced any abrupt sensor fault. The residual

signal which does not change its behavior is associ-

ated to the occurred fault.

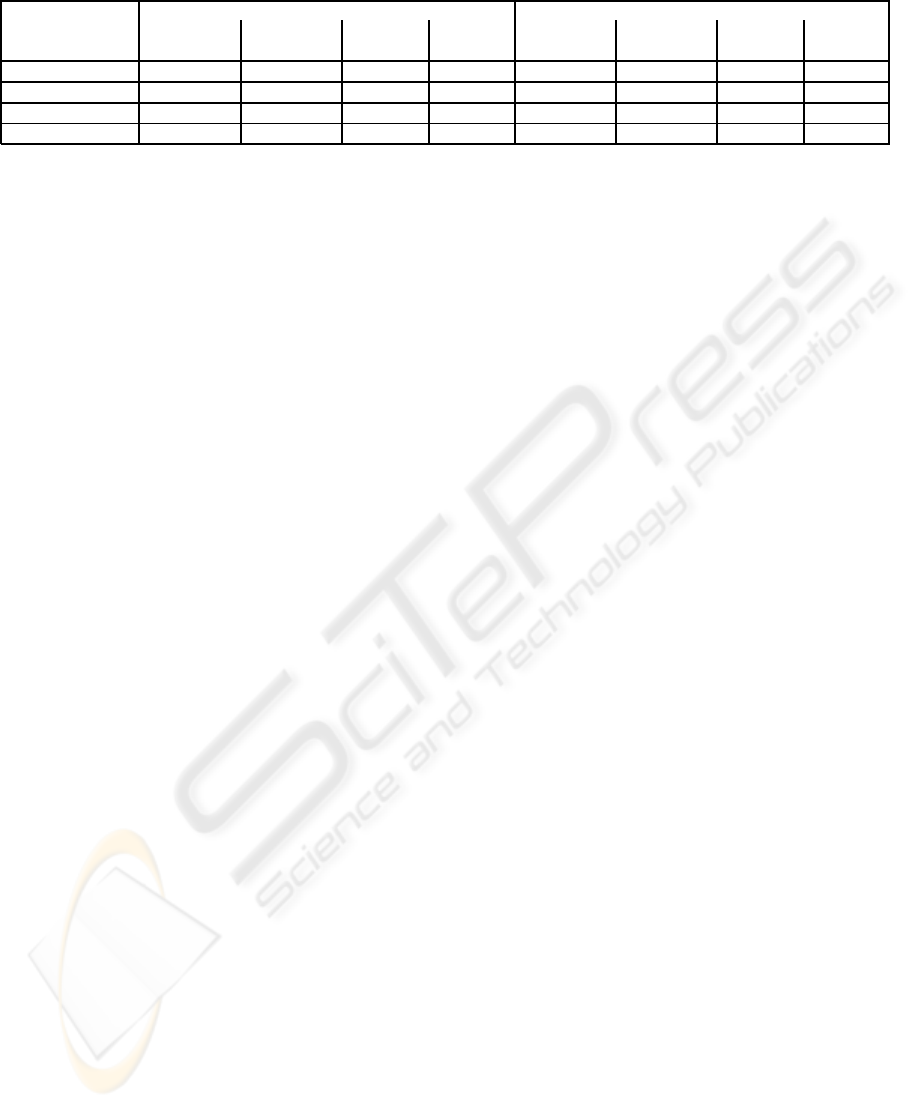

Comparison of the Methods. According to the Table

3, DO shows a quicker detection than DPCA when is

implemented a gradual fault in a sensor signal. In this

work, the gradual faults are added to a signal and only

the deviations about the normal operating point are

analyzed as residuals. In all fault cases, it is easy to

explain the fault propagation using both FDI methods,

i.e. the explanation facility metric is achieved.

Contribution plots indicate which variables are

hypothetically more associated to the fault since it is

possible that more fault cases are involved. On the

other hand, a set of DO can correctly isolate a fault if

all fault models and the model of the normal operating

condition are known with high reliability. For faults

in actuators, the normal operating conditions change

in more than two sensors and the diagnosis task can

0 50 100 150 200 250

−50

0

50

100

150

Time (seconds)

Water Flow Residue

Steam Flow Residue

Outlet Temperature Residue

Inlet Temperature Residue

Residue

Residual Analysis

Fault

(FT

1 :10s)

1

Fault

(TT

1 : 48s)

2

Fault

(FT

2 : 147s)

3

Fault

(TT

2 : 250s)

4

Figure 10: FDI result using DO under multiple faults.

FAULT DETECTION AND DIAGNOSIS IN A HEAT EXCHANGER

269

Table 3: Comparison of DPCA and DO approaches.

DPCA DO

Abrupt Gradual Actuator Multiple Abrupt Gradual Actuator Multiple

Metrics Fault(TT

2

) Fault(TT

2

) faults faults Fault(TT

2

) Fault(TT

2

) faults faults

Detection (s) 0 10−14 9−18 0 0 5 5−8 0

Isolation X X X - X X X X

Explanation X X X - X X X X

False alarm (%) 0 0 14.13 0 0 0 9.94 0

be complicated. In this work, DO shows a quicker

detection (i.e. almost the half of detection time) than

DPCA when faults in both actuators are implemented

at different times. For these faults, DO presents a

lower false alarm rate than DPCA (Table 3).

On the other hand, both FDI methods can de-

tect multiple faults which are implemented in all sen-

sors. However, DPCA can not isolate correctly when

several faults have been implemented. According to

computational requirements, the design of DO needs

greater computational resources. The training stage

of this method is more complicated than the DPCA

training; DO requires firstly a reliable ARX model

which must be translated to a state space model. Fur-

thermore, each fault case must be modeled in a partic-

ular state space model. Once the fault model is known

with high reliability, is designed a state observer; par-

ticularly in this work all models (fault cases and nor-

mal operating) are obtained in parallel. On the other

hand, the DPCA training is quickly executed once his-

torical data of the normal operating point are known.

6 CONCLUSIONS

A comparison between the Dynamic Principal Com-

ponent Analysis (DPCA) and a set of Diagnostic Ob-

servers (DO) under same experimental data from an

industrial Heat Exchanger (HE) is presented. DPCA

do very well on fast detection of abnormal situations,

it is easier to implement in industrial applications. A

process model was not required; however, a broad

acquisition of the historical measurements is needed.

Respect to false alarm rate, DPCA showed 42% more

of false alarms than DO for actuator faults.

DO presents a quicker detection than DPCA ([4−

10] seconds lower), DO requires an accurate state

space model of the process. Furthermore, each fault

case must be modeled. If the model is not reliable,

DO can not detect a fault correctly. Due to HE is

inherently a nonlinear system, it is more difficult to

implement a FDI method based on quantitative mod-

els. Finally, DPCA can not identify multiple faults

whereas DO can.

REFERENCES

Aitouche, A., Maquin, D., and Busson, F. (1998). Multiple

Sensor Fault Detection in Heat Exchanger Systems .

In Proc. of Int. Conf. on Ctrl. Appl., pages 741–745,

Trieste, Italy.

Ball´e, P., Fischer, M., F¨ussel, D., and Isermann, R. (1997).

Integrated Control, Diagnosis and Reconfiguration of

a Heat Exchanger . In American Control Conference,

pages 922–926, Albuquerque, New Mexico.

Caccavale, F. and Villani, L. (2004). An Adaptive Observer

for Fault Diagnosis Nonlinear Discrete-Time Systems.

In American Control Conference, pages 2463–2468,

Boston, Massachusetts.

Detroja, K., Gudi, R., and Patwardhan, S. (2005). Plant-

wide Detection and Diagnosis using Correspondece

Analysis. Control Engineering Practice.

Hotelling, H. (1993). Analysis of a Complex of Statistical

Variables into Principal Components. J. Educ. Psy-

chol., 24.

Isermann, R. (2006). Fault-Diagnosis Systems. Springer,

Germany, 1

st

edition.

Jackson, J. and Mudholkar, G. (1979). Control Procedures

for Residuals Associated with Principal Component

Analysis. Technometrics, 21:341–349.

Krishnan, R. and Pappa, N. (2005). Real Time Fault Diag-

nosis for a Heat Exchanger A Model Based Approach.

In IEEE Indicon Conference, pages 78–82, Chennai,

India.

Ku, W., Storer, R., and Georgakis, C. (1995). Disturbance

Detection and Isolation by Dinamic Principal Compo-

nents Analysis. Chemometrics and Intelligent. Lab.

Syst., 30:179–196.

Miller, P., Swanson, R., and Heckler, C. (1998). Contri-

bution Plots: A Missing Link in Multivariate Quality

Control. Appl. Math. and Comp. Sci., 4(8):775–792.

Mina, J. and Verde, C. (2007). Fault Detection for MIMO

Systems Integrating Multivariate Statistical Analysis

and Identification Methods . In American Control

Conference, pages 3234–3239, New York City, USA.

Morales-Menendez, R., Freitas, N. D., and Poole, D.

(2003). State Estimation and Control of Industrial

Processes using Particles Filters. In American Control

Conference, pages 579–584, Denver, Colorado, USA.

Simmani, S. and Patton, R. (2008). Fault Diagnosis of an In-

dustrial Gas Turbine prototype Using a System Iden-

tification Approach. Ctrl. Eng. Prac., (16):769–786.

Verde, C. (2001). Multi-leak Detection and Isolation in

Fluid Pipelines . Control Eng. Practice, 9:673–682.

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

270