MULTI SCALE MOVING CONTROL METHOD

FOR AUTONOMOUS OMNI-DIRECTIONAL MOBILE ROBOT

Masaki Takahashi and Takafumi Suzuki

Department of System Design Engineering, Keio University, 3-14-1, Hiyoshi, Kohoku-ku, Yokohama 223-8522, Japan

Keywords: Collision avoidance, Service robots, Hierarchical control, Omni-directional mobile robot.

Abstract: This paper proposes a hierarchical moving control method for autonomous omni-directional mobile robot to

achieve both safe and effective movement in a dynamic environment with moving objects such as humans.

In the method, the movement of the robot can be realized based on prediction of the movement of obstacles

by taking account of time scale differences. In this paper, the design method of the proposed method based

on the virtual potential approach is proposed. In the method, modules that generate the potential field are

structured hierarchically based on the prediction time to each problem. To verify the effectiveness of the

proposed method, the numerical simulations and the experiments using a real robot are carried out. From the

results, it is confirmed that the robot with the proposed method can realize safe and efficient movement in

dynamic environment.

1 INTRODUCTION

Recently, various essential technologies of an

autonomous mobile robot such as a self localization

scheme, an environmental map formation and path

planning, learning algorithm and communication are

developed in the area of robot. In addition, a variety

of service robots which offers service with the actual

environment with other moving objects, including

people are proposed and developed(B. Graf, 2004)-

(R. Bischoff). A variety of tasks are required for

such a service robot, but here we will focus on

problems related to moving, which is the most

fundamental and important of tasks. In the

environment include humans, safe and efficient

movement should be required. As for the movement

of the autonomous mobile robot, the problem which

has the various time scales, such as arrival to

destination, the collision avoidance for the obstacle

and the emergency collision avoidance for the

sudden obstacle, occurs simultaneously. Therefore,

the robot should keep coping with the problem

according to circumstance.

This paper proposes a hierarchical moving

control method for autonomous omni-directional

mobile robot to achieve safe and effective movement

in a dynamic environment with moving objects such

as humans. The hierarchical control method

considers a variety of prediction time to each action,

such as destination path planning, obstacle

avoidance within the recognizable range, and

emergency avoidance to avoid spontaneous events.

In the method, several modules for each action are

composed in parallel. The vertical axis is prediction

time scale in the control system. In the lowest

module, the robot can move to goal safely and

efficiently by planning from the environment

information which is obtained in advance. On the

other hand, in the higher module, the robot moves

more safely by using the estimated information of

obstacles based on shorter prediction time to avoid

them. By integrating the output of each module, it is

possible to realize the safe and efficient movement

according to the situation.

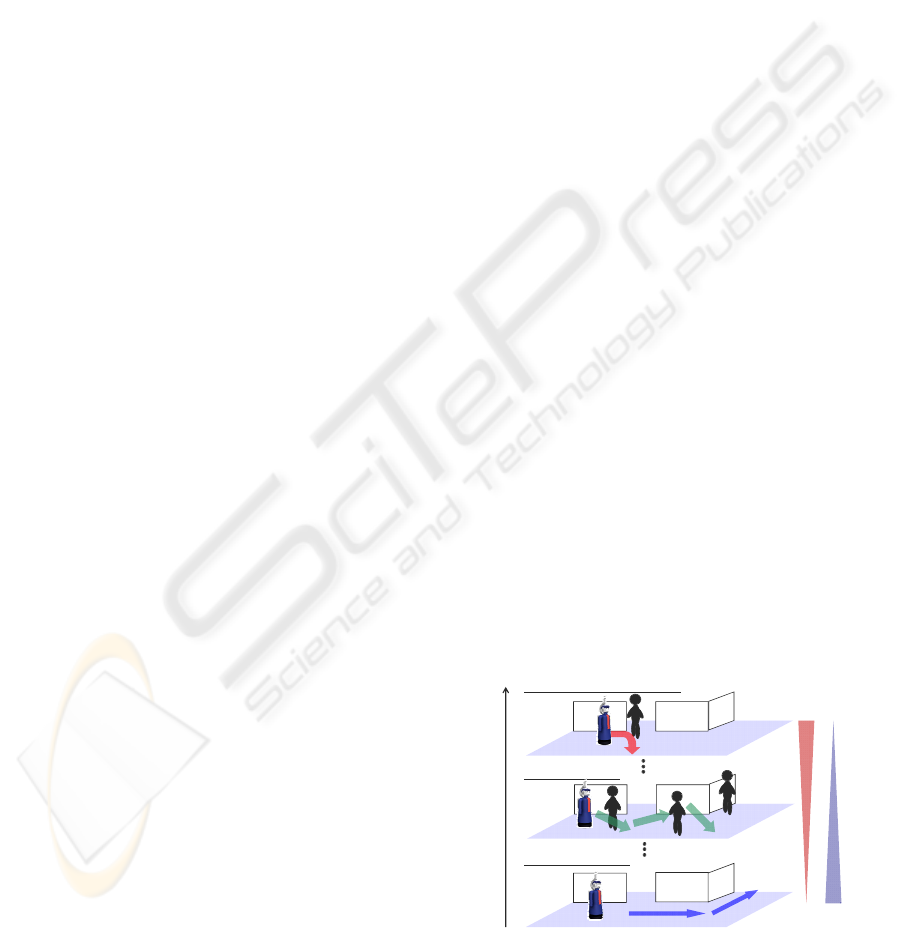

Obstacle Avoidance

Emergency Avoidance Behavior

Time Scale

Efficiency

Safety

Access to Destination

Figure 1: Problem Establishment for Action of Service

Robot.

449

Takahashi M. and Suzuki T. (2009).

MULTI SCALE MOVING CONTROL METHOD FOR AUTONOMOUS OMNI-DIRECTIONAL MOBILE ROBOT.

In Proceedings of the 6th International Conference on Informatics in Control, Automation and Robotics - Robotics and Automation, pages 449-452

DOI: 10.5220/0002217004490452

Copyright

c

SciTePress

In this paper, as one example of design method

of the proposed control method, the design method

which is based on the virtual potential method is

presented (Khatib, 1986) (Y. Koren, 1991). Firstly,

the module which generates the potential field based

on each prediction time is formed hierarchically.

Secondly, the virtual force which is derived from the

respective potential fields is synthesized. Thirdly,

the velocity command is decided on the basis of the

resultant force. To verify the effectiveness of the

proposed method, the numerical simulations which

suppose the environment where the obstacle exists

were carried out. Moreover, the experiments using

the real apparatus of the autonomous omni-

directional robot were carried out.

0

y

x

Robot

Obstacle

j

0

y

x

Robot

Obstacle

j

i

T

ρ

jj

oio

T+xv

i

T+xv

j

o

v

j

o

x

x

v

v

x

,

j

ro

x

,

j

ro

v

j

o

−v

j

o

x

j

o

v

Figure 2: World coordinate system and predicted shortest

distance.

2 HIERARCHICAL ACTION

CONTROL METHOD

2.1 Nomenclature

Symbol

Quantity

T

i

prediction time

d

ρ

distance between the robot and the destination

i

T

ρ

predicted shortest distance between the robot and the

obstacle

0

ρ

minimum of repulsive potential

x position vector of robot

d

x

position vector of the destination

j

o

x position vector of object

j

,

j

ro

x

position vector of the obstacle O

j

relative to the robot

v velocity vector of robot

j

o

v velocity vector of object

j

,

j

ro

v

velocity vector of the obstacle O

j

relative to the robot

i

T

j

U virtual potential about object

j

on each Time scale

i

T

j

F virtual force vector from

i

T

j

U

i index of each Time scale

j index of object

x x-axis

y y-axis

0

1

2

3

4

5

6

7

8

9

10

0

2

4

6

8

10

0

10

20

30

40

50

60

70

80

90

100

0

1

2

3

4

5

6

7

8

9

10

0

1

2

3

4

5

6

7

8

9

10

0

50

100

150

0

1

2

3

4

5

6

7

8

9

10

0

1

2

3

4

5

6

7

8

9

10

0

10

20

30

40

50

60

70

T

3

Module

VRF

VRF

VRF

Velocity

Reference

Low-pass Filter

Cutoff:1/ T

3

Low-pass Filter

Cutoff:1/ T

2

Low-pass Filter

Cutoff:1/ T

1

+

VRF: Virtual Resultant Force

T

2

Module

T

1

Module

3

[N]

T

F

2

[N]

T

F

1

[N]

T

F

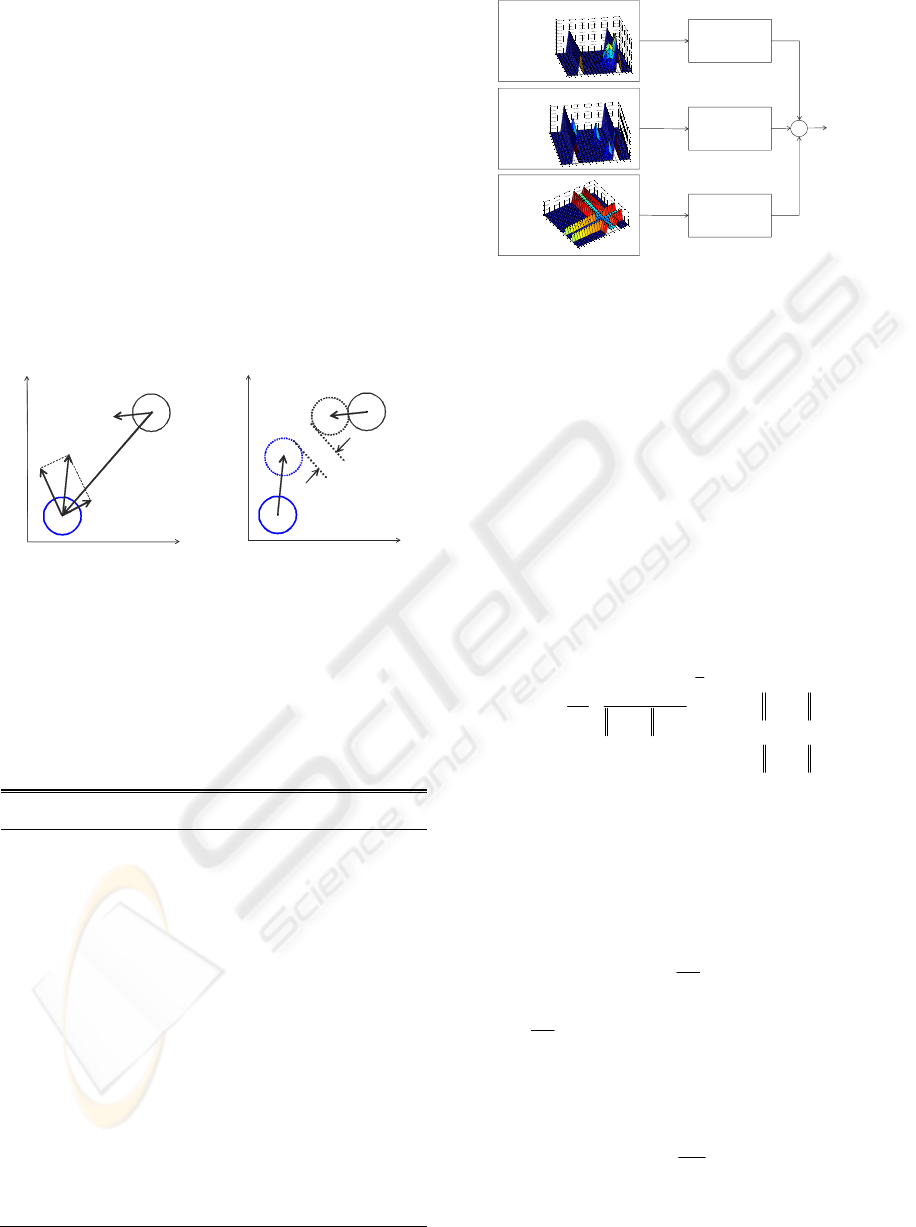

Figure 3: Output of each module and integration.

2.2 Design Approach

The module is a potential function with the

prediction time as a parameter, and generates a

potential field for each problem and virtual force on

the robot is calculated. In this study, the proposed

potential function was designed based on the

repulsive potential reported by Khatib (Khatib,

1986).

d

o

UU U=+

x

(1)

d

ad

Uk

ρ

=

x

(2)

i

T

oj

UU=

∑

(3)

1

,0

,0

,0

11

,

0,

i

ij

i

i

j

ij

T

iTiro

T

T

j

iro

Tiro

TT

U

T

T

η

ρρ

ρ

ρ

ρ

ρ

⎧

⎛⎞

⎪

⎜⎟

⎪

−≤+

⎪

⎜⎟

=

⎜⎟⎨

+

⎝⎠

⎪

⎪

>+

⎪

⎩

v

v

v

(4)

where

d

x is the destination position and

d

U

x

is an

attractive potential field. In the proposed method, a

repulsive potential function in consideration with

prediction time T

i

is used.

A force for the position x of the robot is derived

from the following equation.

()

U

∂

=−

∂

Fx

x

(5)

where

U

∂

∂

x

denotes the partial derivation vector of

the total virtual potential U. From Eqs. (2) and (5),

the attractive force allowing the position x of the

robot to reach the goal position x

d

is as follows:

d

d

a

k

ρ

∂

=−

∂

x

F

x

(6)

From Eqs. (4) and (5), the repulsive force to the

obstacle O

j

are as follows:

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

450

1

1

,0

2

,0

,0

11 1

,

0,

i

i

ij

i

i

i

j

ij

T

T

Tiro

T

jT

T

iro

Tiro

T

T

T

ρ

η

ρρ

ρ

ρ

ρ

ρ

ρ

−

⎧

⎛⎞

⎪

∂

⎜⎟

⎪

−≤+

⎪

⎜⎟

=∂

⎜⎟

⎨

+

⎝⎠

⎪

⎪

>+

⎪

⎩

v

Fx

v

v

(7)

The command vector F of the robot is derived from

the following equation.

d

o

=+

x

FF F

(8)

When combining the virtual force derived from a

potential field which is generated at each module,

we consider the robot as a point mass. The velocity

command with the same magnitude and direction is

determined by combining the forces to the robot. In

addition, the potential approach has a vibration

problem caused by the magnitude of velocity and

roughness of the control period. Thus, in the method,

a low pass filter on each element of the virtual force

output in each module is used to suppress such

vibration as shown in Fig.3. It was confirmed that

safe and effective motion is possible even in a

situation where movement to the destination,

avoiding moving obstacles, and emergency

avoidance all coexist. In the simulations, each low

pass filter uses the reciprocal of each prediction time

as a cut-off frequency.

3 EXPERIMENTAL RESULTS

3.1 Experimental Environment

To verify the effectiveness of the proposed method

in the actual situation, the experiments using the real

robot were carried out. The robot size is L 0.55

×

W

0.75

× H 1.25 m and the weight of the robot is about

60 kg. In order to recognize environment, the stereo

camera and the stemma camera, the laser range

finder and the ultrasonic sensor are loaded, but, in

this research the robot recognizes environment

making use of only the laser range finder. The

velocity limit of the robot is 0.5m/s and the

acceleration limit is 1.0m/s

2

.

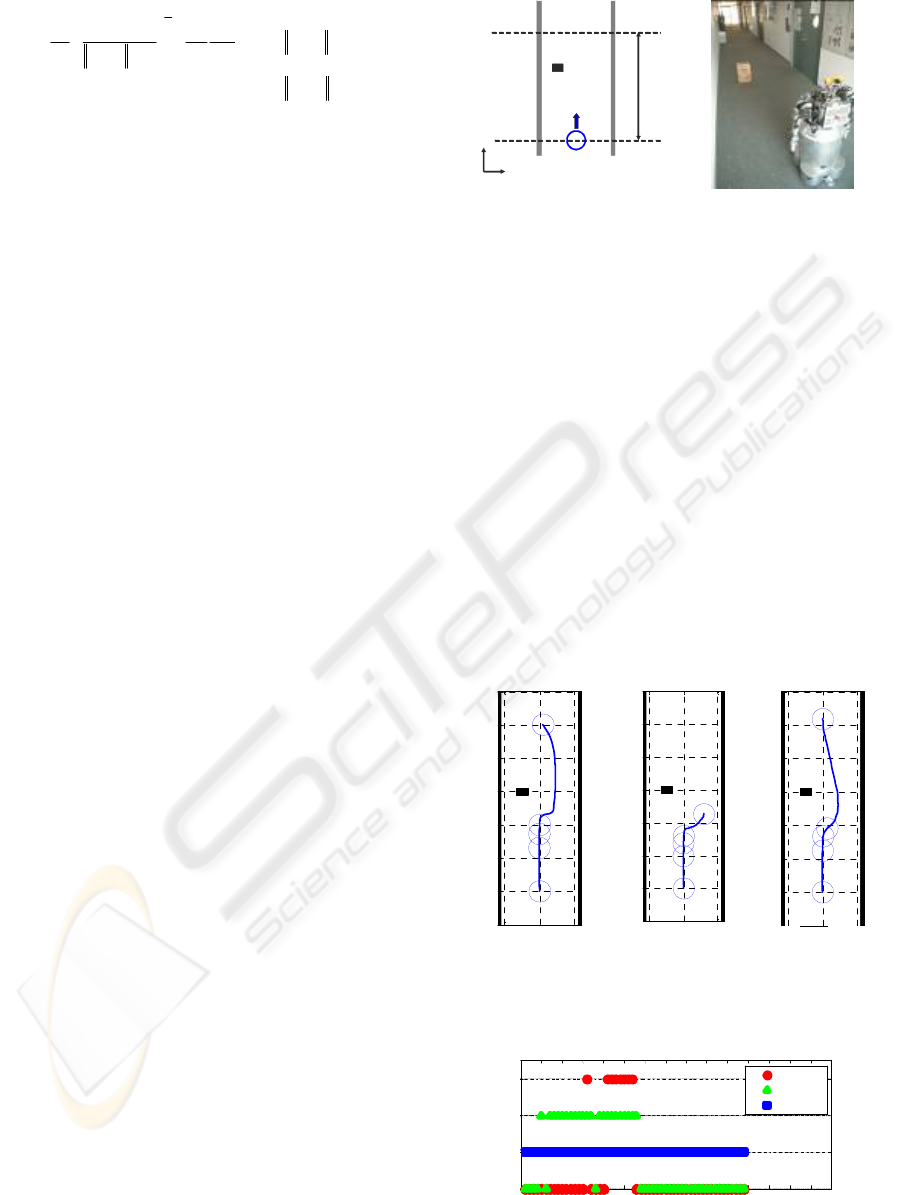

Figure 4 shows the experimental environment to

verify the effectiveness of the proposed method to a

static single obstacle. The initial position of the

robot is (0 m, 0 m). The obstacle size is L 0.20 W

0.33 H 0.50 and its initial position is (-0.5 m, 3.0 m).

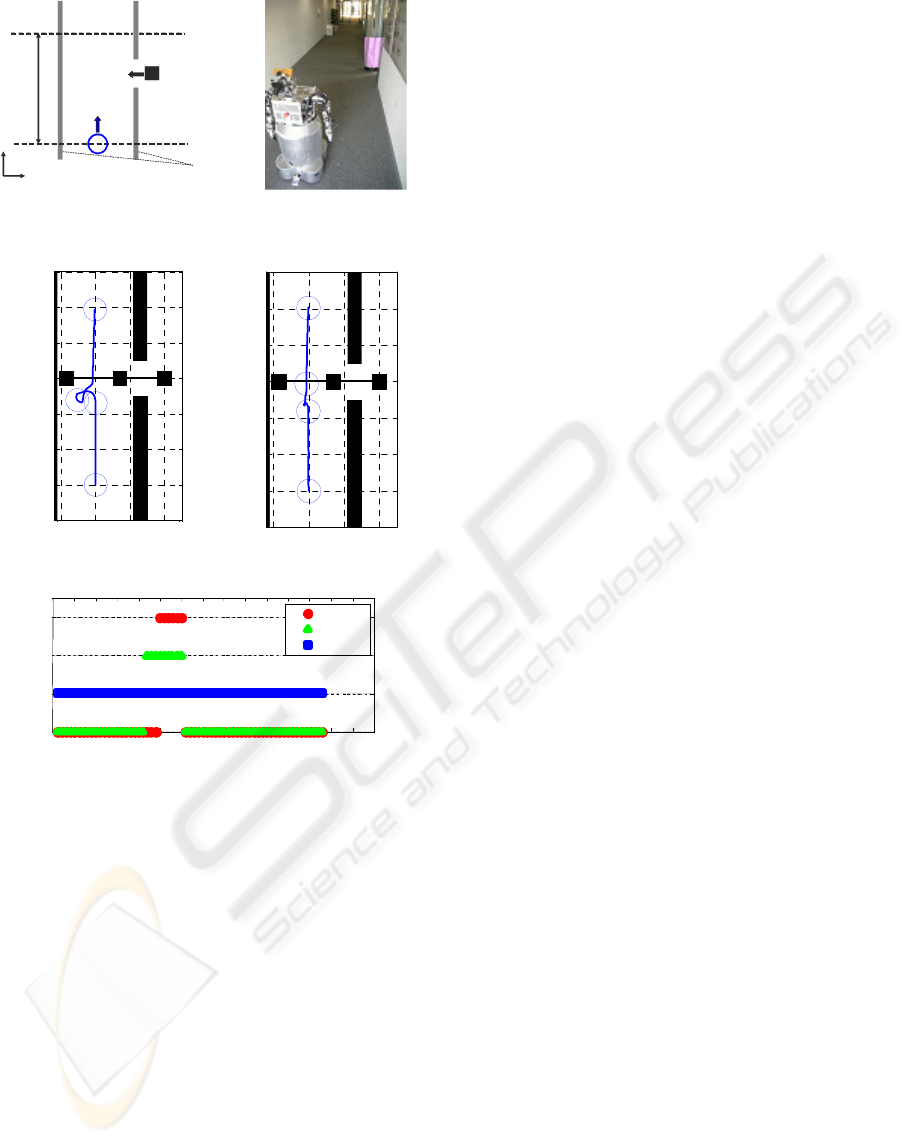

Figure 7 shows the experimental environment. In

this case, the moving obstacle bursts through the

blind corner at the speed of 0.5 m/s when the robot

comes close to the corner.

5.0m

()

0m, 0m

Start

Goal

x

y

()

-0.5m, 3.0m

Obstacle

Robot

r

v

Figure 4: Experimental Environment.

3.2 Experimental Results

Figure 5 (a), (b) and (c) show the trajectory of the

robot by using the Khatib (

0

0.8

ρ

= , 0.064

η

= ), the

Khatib (

0

1.5

ρ

= , 0.064

η

=

) and the proposed method

respectively.

From the result in Fig.5(a), it was confirmed that the

robot comes close to the obstacle because the

repulsive potential fields for the obstacle is small.

Fig.5 (b) shows that the robot does not approach to

the obstacle because the influence of the obstacle is

large. In addition it receives the influence of

repulsive force from the wall and thereby this can

lead to the stable positioning of the robot before

reaching its goal. On the other hand, it was

confirmed in Fig.5(c) that the robot with the

proposed method can reach its goal earlier than other

methods without colliding with the obstacle.

-1000 0 1000

-1000

0

1000

2000

3000

4000

5000

6000

x[mm]

y[mm]

Robot : t=4.0

Robot : t=0

Robot : t=3.2

Obstacle

Robot : t=18.0

Robot : t=4.6

x[m]

1.0

1.0

-1.0

-1.0

0

0

2.0

y[m]

3.0

4.0

5.0

6.0

-1000 0 1000

-1000

0

1000

2000

3000

4000

5000

6000

x[mm]

y[mm]

Robot : t=4.0

Robot : t=0

Robot : t=3.2

Obstacle

Robot : t=30.0

Robot : t=4.6

x[m]

1.0

1.0

-1.0

-1.0

0

0

2.0

y[m]

3.0

4.0

5.0

6.0

-1000 0 1000

-1000

0

1000

2000

3000

4000

5000

6000

x[mm]

y[mm]

Robot : t=4.0

Robot : t=0

Robot : t=3.2

Obstacle

Robot : t=15.0

Robot : t=4.6

x[m]

1.0

1.0

-1.0

-1.0

0

0

2.0

y[m]

3.0

4.0

5.0

6.0

(a)

0

0.8, 0.064

ρη

==

(b)

0

1.5, 0.064

ρη

==

(c) The proposed

method.

Figure 5: Experimental Result.

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0 12.0 13.0 14.015.0

0

1

2

3

time[sec]

Activation of Module

short

medium

long

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0 12.0 13.0 14.015.0

0

1

2

3

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0 12.0 13.0 14.015.0

0

1

2

3

time[sec]

Activation of Module

short

medium

long

Figure 6: Time History of the Activation of Module.

MULTI SCALE MOVING CONTROL METHOD FOR AUTONOMOUS OMNI-DIRECTIONAL MOBILE ROBOT

451

5.0 m

()

0m,0m

x

y

()

2.0 m, 3.0 m

Obstacle

Robot

Wall

r

v

o

v

Figure 7: Experimental Environment.

-1000 0 1000 2000

-1000

0

1000

2000

3000

4000

5000

6000

x[mm]

y[mm]

Robot : t=8.1

Robot : t=0

Robot : t=5.0

Obstacle : t=2.4

Obstacle : t=5.0

Obstacle : t=8.1

Robot : t=15.7

2.0

1.0

x[m]

1.0

-1.0

-1.0

0

0

2.0

y[m]

3.0

4.0

5.0

6.0

-1000 0 1000 2000

-1000

0

1000

2000

3000

4000

5000

6000

x[mm]

y[mm]

Robot : t=8.1

Robot : t=0

Robot : t=5.0

Obstacle : t=2.4

Obstacle : t=5.0

Obstacle : t=8.1

Robot : t=13.4

2.0

1.0

x[m]

1.0

-1.0

-1.0

0

0

2.0

y[m]

3.0

4.0

5.0

6.0

(a) Khatib method (b) Proposed method

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0 12.0 13.0 14.0 15.0

0

1

2

3

time[sec]

Activation of Module

short

medium

long

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0 12.0 13.0 14.0 15.0

0

1

2

3

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0 12.0 13.0 14.0 15.0

0

1

2

3

time[sec]

Activation of Module

short

medium

long

(c) Time History of the Activation of Module in the proposed method

Figure 8: Experimental Result.

Figure 8(a) and (b) show the trajectories of the

robot and the moving obstacle by using the Khatib

and the proposed method respectively. Figure 8(c)

shows the time history of the activation of module in

the proposed method. The robot can reach the goal

without colliding with the obstacle. However, the

robot moves in the direction of movement of the

obstacle because the predicted information of the

obstacle is not used. Thereby, the arrival time to the

goal is longer than our method.

From the results in Fig.8 (b), it was confirmed

that the robot recognizes the moving obstacle and

then stops on the moment and starts the movement

to the goal after the obstacle passes over. As shown

in Fig.8(c), the robot can move without colliding

against the moving obstacle by acting on the

emergency avoidance module simultaneously with

the collision avoidance module around 5.0sec which

it approaches to the robot.

4 CONCLUSIONS

This study proposed the hierarchical action control

method for an autonomous omni-directional mobile

robot to realize the safe and effective movement. In

the method, the module with different prediction

time processes in parallel, and the command velocity

to the robot is decided by integrating them. As for

each module, the selection condition is different

according to relative position and velocity about the

robot and the obstacle.

From the results of the numerical simulations

and the experiments, it was confirmed that the robot

can reach the goal efficiently without colliding with

both the static and the moving obstacles by using the

estimated information of them.

REFERENCES

Graf, B., Hans, M. and Schraft, R. D.: “Mobile Robot

Assis-tant,” IEEE Robotics and Automation, vol.11,

no.2, pp.67-77, 2004.

DeSouza, G. N. and Kak, A. C.: “Vision for Mobile Robot

Navigation: A Survey,” IEEE Trans. on Pattern

Analysis and Machine Intelligence, vol.24, no.2,

pp.237-267, 2002.

Thrun, S. et al: “MINERVA: A Second-Generation Mu-

seum Tour-Guide Robot,” Proc. IEEE Int. Conf. on

Robotics and Automation, pp.1999-2005, 1999.

Bischoff, R. and Graefe, V.: “HERMES - A Versatile

Personal Robotic Assistant,” Proc. IEEE vol.92,

no.11, pp.1759-1779, 2004.

Khatib, O.: “Real-time Obstacle Avoidance for Manipu-

lators and Mobile Robots,” Int. J. of Robotics

Research, vol.5, no.1, pp.90-98, 1986.

Koren, Y. and Borenstein, J.: “Potential Field Methods

and Their Inherent Limitations for Mobile Robot

Navigation,” Proc. IEEE Int. Conf. on Robotics and

Automation, pp.1398-1404, 1991.

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

452