TUNING OF INDUSTRIAL CONTROLLERS

OVER PUBLIC IP NETWORKS

Renato F. Fernandes Jr, Dennis Brandão

University of São Paulo, Av.Trabalhador Sãocarlense 400, São Carlos, SP, Brazil

Nunzio M. Torrisi

Universidade Federal do ABC, Rua Santa Adélia 166, Santo André, SP, Brazil

Keywords: PID control, Identification, Industrial systems, Remote control, Industraial networks.

Abstract: Tuning of industrial systems is executed in the initial phase of the system and mainly during the

maintenance phase, providing characteristics of the performance of the industrial process during production

life cycle. Remote tuning supports several practical applications, such as specialized companies outsourcing

services or companies distributed in different areas centralizing optimization. This paper proposes a

software tool for remote tuning of open or closed PID control loops in an industrial environment that fulfils

the requirements described above, in a single platform. The software tool could be used in control loops

tuning in industrial systems, as well as in an academic environment simulating control applications and

industrial networks.

1 INTRODUCTION

Increasing competitiveness in the industrial sector

has required continuous improvement in product

quality processes, optimizing the production and

reducing operational costs. Nowadays, researches

like (Avov, 2004) show the potential of the Internet

in the industrial environment. However, considering

the use of the Internet for control and supervision of

industrial processes, it should be noticed that the

nature of production and automation systems

demands some requirements to be secured, such as

managing multiple accesses, ensuring the

communication and the control system, setting

maximum periods for process data updates and

quality of service maintenance (Abdelzaher, 2002).

Remote access architectures may be

implemented at different levels in the control

hierarchy: at process level, at supervisory level and

at system optimization level (Yang, 2003). In terms

of process, the proposal is to include remote control

within the process control loop, according to

(Overstreet, 1999) (Yang, 2007). For this purpose,

the conventional discrete control structure should be

altered to conform to the Internet’s variable (Luo,

2000), (Yang, 2007).

The concern at the supervisory level is safety and

quality of service, discussed in (Kunes, 2001). Yang

et al. (Yang, 2003) proposes a remote control at

supervision level for services that are independent of

the Internet delay, which would be restricted to

acyclic services such as tuning parameters for PID

block and set points.

In the context of SCADA (Supervisory Control

and Data Acquisition) systems, the OPC (OLE for

process control) technology (OPC Foundation,

2006) combined with Web technologies, as

WebServices, is used to draw complex architecture

for manufacturing in order to create communication

system directly between shop-floor and

decentralized supervision systems (Zheng and

Nakagawa, 2001).

Commercial companies offer today solutions for

remote monitoring and tuning of industrial systems.

However, these solutions have some limitations,

because they may be based on non-standard

platforms for the industrial environment and may

use common WebServices (Calvo, 2006) (Batur,

2000) (Qin, 2007).

Torrisi (Torrisi, 2007) proposes a standard OPC

communication mechanism based on the Internet, a

platform-independent alternative to WebServices.

That standard, called CyberOPC, uses "open"

278

F. Fernandes Jr R., Brandão D. and M. Torrisi N. (2009).

TUNING OF INDUSTRIAL CONTROLLERS OVER PUBLIC IP NETWORKS.

In Proceedings of the 6th International Conference on Informatics in Control, Automation and Robotics - Intelligent Control Systems and Optimization,

pages 278-284

DOI: 10.5220/0002218002780284

Copyright

c

SciTePress

security technologies for light software components,

therefore providing better performance and

increasing guarantees for data security, when

compared to other technologies based on

WebServices.

This paper proposes an architecture to execute

remote tuning of industrial control systems using the

Internet, fulfilling acceptable security and

performance requirements. In order to validate the

architecture, a software application using CyberOPC

and called Cybertune will be presented. The

validation consists of a model-based identification

and tuning using first-order-plus-dead-time systems.

This paper is organized as follows: Section 2

shows the requirements for remote tuning and

problems related to supervision and remote control

of industrial systems. Section 3 presents the generic

architecture of the remote tuning system. Section 4

describes tests and results from remote tuning, and

finally section 5 presents the conclusions and

indicates future researches.

2 REMOTE TUNING

REQUIREMENTS

In control loop tuning, the system identification

phase demands over half of the effort (Yu, 2006),

(Hjalmarsson, 2005). In order to obtain the model in

time domain, the most common way to identify low

order systems is identifying the transient response to

a process alteration. The transient response is found

when stimulating the system using a step-format

signal, an impulse or a pseudo-random binary

sequence (PRBS) as a system input. Identification is

executed by estimating parameters through data

collection and expression using ARX (Auto-

Regressive Exogenous) or ARMAX (Auto-

Regressive Moving Exogenous) model (Aguirre,

2004) (Ljung, 1999).

Controllers are tuned in three phases, according

to model-based techniques: identifying the plant

model, tuning based on the identified model, and

validating tuning using simulations based on the

identified model with the new controller.

An important step in the model-based

identification consists of defining the sampling rate,

which must be constant and generally in the order of

ten times smaller than the time constant of the

system (Aguirre, 2004).

In general, the OPC technology has an update

rate defined in seconds for processes with fieldbus

technology. This rate reduces our scope to slower

systems with time constants and dead time 5 to 10

times of the time of the OPC acquisition, although

many industrial systems may fit this scenario, such

as temperature control and chemical processes.

2.1 Communication Problems related

to Remote Control and Monitoring

The Internet and WebServices available nowadays

create some obstacles when used in industrial

control systems (Abdelzaher, 2002), (Yang, 2003),

(Torrisi, 2007):

• Communication delay of different types,

throughout the data source up to the destination

nodes.

• Non-determinism of the network due to various

routes available on the Internet, where the

decision of the best route to be used should be

taken for each data packet received.

• Network data should be secured, meeting the

following security properties: confidentiality,

authentication and integrity of messages.

• Considering the remote control in public

networks, OPC solutions based on

WebServices are even slower than those based

on DCOM(Distributed Component Object

Model) (Advosol Inc., 2004).

3 GENERIC ARCHITECTURE

FOR REMOTE TUNING

The architecture proposed for the remote tuner is

based on the interconnection of modules in three

different contexts: the industrial plant, the server and

the client. It is based on the client-server cooperation

model, which consists of different interconnected

modules providing process and configuration

variables from the industrial plant to the remote

client. The proposed architecture is implemented in

a generic “open” design and can be used with any

commercial software component. The figure below

shows the components of the architecture.

Figure 1: Remote Tuner Architecture.

TUNING OF INDUSTRIAL CONTROLLERS OVER PUBLIC IP NETWORKS

279

Inside the "server" module, indicated in the

architecture proposed in Figure 1, the

communication driver is the communication

interface between the server and field devices for

data acquisition. Being a widely used standard in the

industrial environment, OPC was selected for this

project to communicate to the fieldbus network.

Moreover, in the server module, the HTTP

(Hypertext Transfer Protocol) Server is responsible

for processing remote requests from several clients

connected to server module. The communication

between the remote HTTP server and the clients can

use proprietary protocols, WebService and other

protocols over HTTP.

The "client" module represents the remote

monitoring and tuning unit. The client must be a

standard OPC client allowing the communication to

a variety of field device networks. The Cybertune

prototype for this study used an OPC client

architecture for local communication and a

CyberOPC client for remote communication.

In order to avoid the non-determinism of the

Internet, the strategy used in this work was attaching

a timestamp to each sample. This way, the time

measured will always be used, thereby obtaining the

actual rate for each performed identification. For the

remote communication, using CyberOPC ensures

that there will be a constant data acquisition on the

control side, with packet sequencing, determining

the information obtained by the remote client.

CyberOPC is based on open standard

technologies. It minimizes software and interfaces

layers for a better and faster network use because it

is a technology with a simple philosophy dedicated

to industrial applications with "soft real time"

requirements in IP networks with assured

bandwidth. One of the features from this protocol is

the use of an internal cache memory, which provides

better performance in processing messages.

Server and client roles in the proposed

architecture using CyberOPC communication

protocol are detailed below.

3.1 The CyberOPC Communication

System

The most commonly used OPC specification is the

OPC Data Access (DA) 2.x and 3.x. It does not

intend to compensate communication latencies that

can occur in wide area networks neither provide

communication for clients or servers intermittently

connected to the network. Another restriction comes

from the fact that OPC DA data cannot be

transferred over the Internet, because all TCP/IP

ports except Port 80, which allows only textual data,

are usually blocked at corporate firewalls. However,

OPC is based on a Microsoft standard for

component communication – DCOM (Distributed

Component Object Model) – that is not textual.

The OPC XML-DA and the incoming OPC-UA

specification (OPC Foundation, 2008) define a

WebServices based approach for reading from and

writing data to plant floor automation systems. In

this approach, all OPC data are formatted in XML

blocks and transmitted using simple object access

protocol (HTTP-SOAP). The choice to adopt

WebServices solves the problems related to binary

data blocked at firewalls and promotes software

integration manufacturing with WebServices

technologies, despite the low quality of service level

to address typical timing requirements of real time

process control networks.

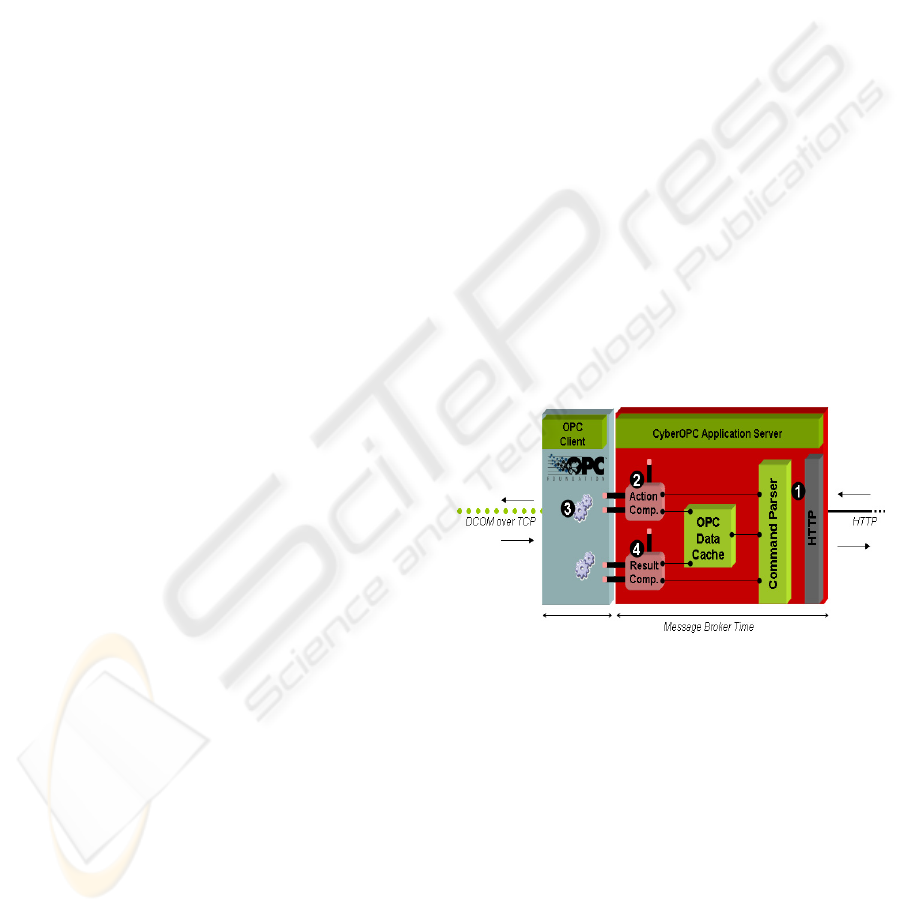

Step 1 in Figure 2 represents the processing of

CyberOPC commands without SOAP preprocessor.

Introducing the OPC cache strongly reduces calls to

the OPC Client. Tests have reported the reduction of

70% of the Message Broker Time when compared to

the time consumed by a Gateway WebServices

based. Steps 2, 3 and 4 represent the interaction

between the OPC library and the CyberOPC

Application Server

Figure 2: Message Broker Time for CyberOPC Gateway.

OPC Packet Data and requests are encoded as text using

JSON or XML syntax

For HTTP communications, there are two

categories of security mechanisms: transport level

security and message level security. The transport

level security mechanism uses Server Secure Socket

(SSL), using digital X.509 certificates (ITU

Recommendation, 1997). The CyberOPC

communication system replaces the OPC Polling

mechanism over SSL.

3.2 The Cybertune Structure

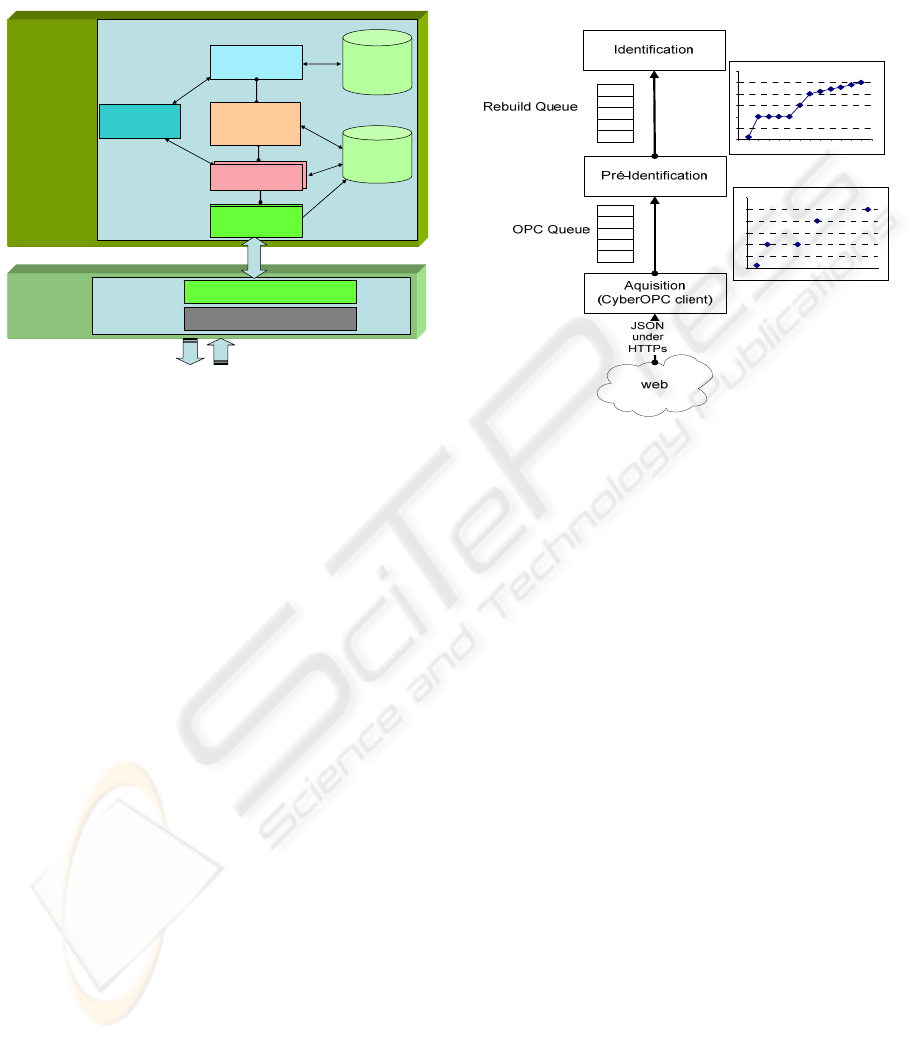

The Cybertune prototype consists of four main

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

280

operational modules: data acquisition, system

identification, model transformation and tuning

modules. A schematic of the structure is shown in

figure 3.

Cybertune

Data Aquisition

(OPC Client)

Identification

Tuning

Knowledge

base

Process

Data

Base

CyberOPC

OPC Server

HTTPS

JSON

Sobre HTTPS

Validation

Model

Transformation

Data Aquisition

(OPC Client)

Identification

Figure 3: Cybertune structure.

The data acquisition module consists of an OPC

or CyberOPC client in accordance with the

specifications of the OPC standard (OPC

Foundation, 2008) or the specifications in (Torrisi,

2007). Thus, the component interface has the same

data access philosophy, consisting of OPC library

records, adding groups and items to the database,

and acyclic communication per event, where the

client is notified when a new data event is issued by

the server.

For the identification module, responsible for

determining the system transfer function, the ARX

model was used, which provides good results for

first and second order linear systems, the most

common systems in industrial environments (Yu,

2006). As this project aims to validate the

architecture for online identification and tuning, the

Cybertune needs to receive process data and

automatically perform the identification.

Assuming that there are communication delays

and transmission failures while executing online

remote identification, this work proposes the

following methodology. First, every sample

collected by CyberOPC has a timestamp with the

time when the data was acquired by the gateway. In

addition, since the ARX model requires continuous

sampling and CyberOPC sends data (per event on

data change) in an optimized way, it is necessary to

rebuild the process signal at a constant sampling

rate.

To solve this case, a "pre-identification” module

was included, being responsible for receiving

queued data from the acquisition module and

sending samples to the identification data queue at a

constant sampling rate. Interpolation between two

sample points used the first order equation. An

example of this architecture is shown in figure 4.

0

5

10

15

20

25

30

0 1 2 3 4 5 6 7 8 9 10 11 12 13

0

5

10

15

20

25

30

0 1 2 3 4 5 6 7 8 9 10 11 12 13

Figure 4: Pre-Identification module.

After the identification and validation of the

ARX model is necessary to transform the ARX

model in open loop model to be subsequently

applied to the model based methods for tuning. The

algorithm used for model transformation module for

open and close loop was described in (Fernandes

and Brandão, 2008).

Finally, the tuning module applies the tuning

methods to the model obtained before. The

Cybertune uses Ziegler Nichols (ZN) and internal

model control (IMC) common model-based tuning

methods (Ang, 2005).

4 TESTS AND RESULTS

Identification tests were performed to validate the

proposed architecture simulating first-order-plus-

dead-time systems using local and remote

identification in a corporate network.

Tests were conducted using the FieldBus Plant

Simulator (FBSIMU), which simulates industrial

plant and fieldbus control logic. .The studies of

(Pinotti and Brandão, 2005) showed that FBSIMU

has good approach to simulate real system.

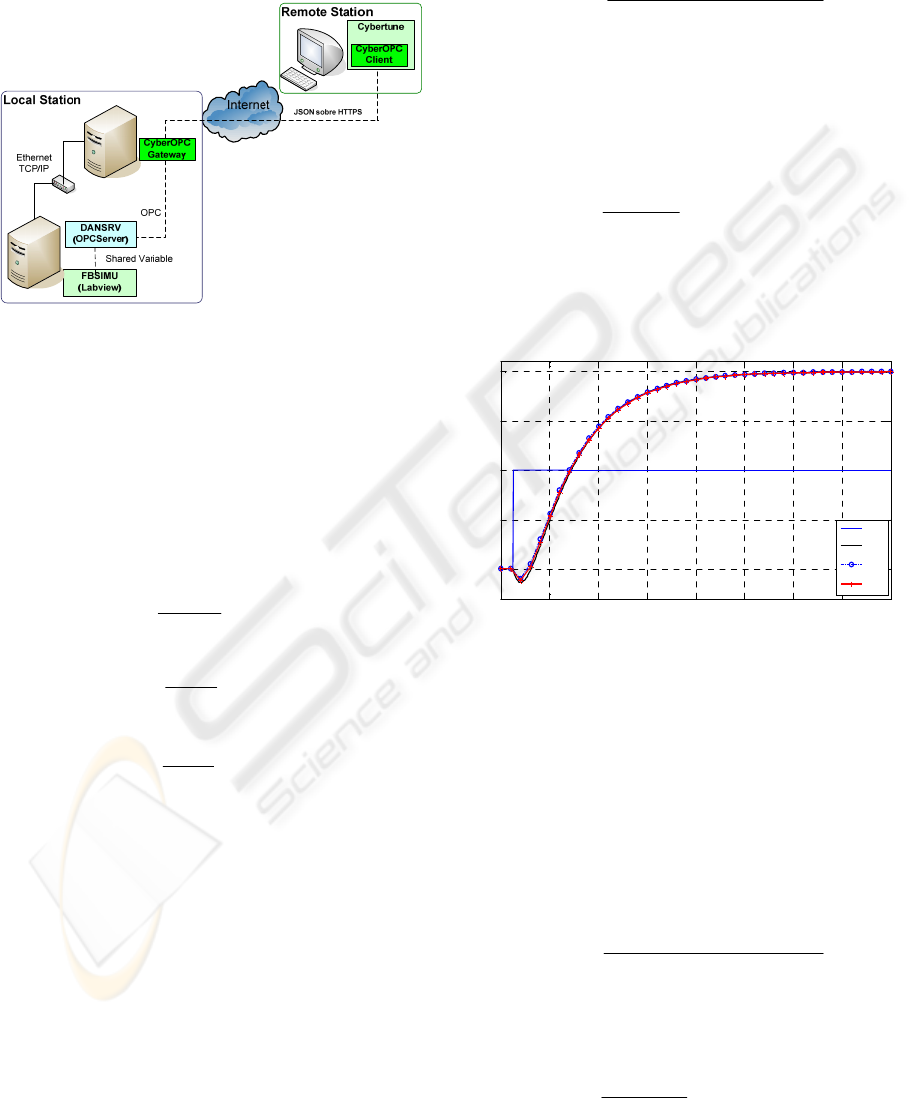

Figure 5 presents the tests scenarios of this work.

Local tests used communication with Cybertune and

FBSIMU in the same station. Remote tests used a

2Mbits internet connection.

TUNING OF INDUSTRIAL CONTROLLERS OVER PUBLIC IP NETWORKS

281

Server station consists of a CyberOPC gateway

module communicating via OPC to FBSIMU.

Remote client station consists of Cybertune

communicating via CyberOPC protocol with the

FBSIMU.

Figure 5: System architecture for local and remote

communication between Cybertune and FBSIMU.

Simulation tests were performed using three

systems with different characteristics: two tests used

slower systems (such as an oven or industrial

chemical process), and the other test used a fast

system (such as a flow control loop). The transfer

function of the systems were showed below, where

in this paper is called system 1 the equation (1),

system 2 the equation (2) and so on.

s

e

s

p

G

50

1100

2

−

+

=

(1)

s

e

s

p

G

35

115

25

−

+

=

(2)

s

e

s

p

G

20

1150

3

−

+

=

(3)

To validate the tests, the ITAE performance

index and the correlation index (FIT) were used in

relation to the actual signal and the identified signal.

For a correlation index higher the identification is

considered as good (Ljung, 1999).

3.1 Tests Results

For the first test, consider the transfer function (1) of

the system 1.

Initially regarding the local identification test,

identification is estimated according to

approximation using a fourth order ARX model and

sampling rate (To = 1.0 sec). The model shown in

(4) was obtained with FIT=96.75%:

4448.00129.0

z4280.0z0030.1z

0023.00105.0

0060.00170.0

)(

234

23

+−

−−

++

+

−

=

z

z

zz

zFTMA

(4)

Then, the ARX model is transformed into the

open loop model according to the equations

proposed in (Fernandes e Brandão, 2008), which

results in the following model approximation:

)30.46(

13.102

00.2

s

e

s

p

G

−

+

=

(5)

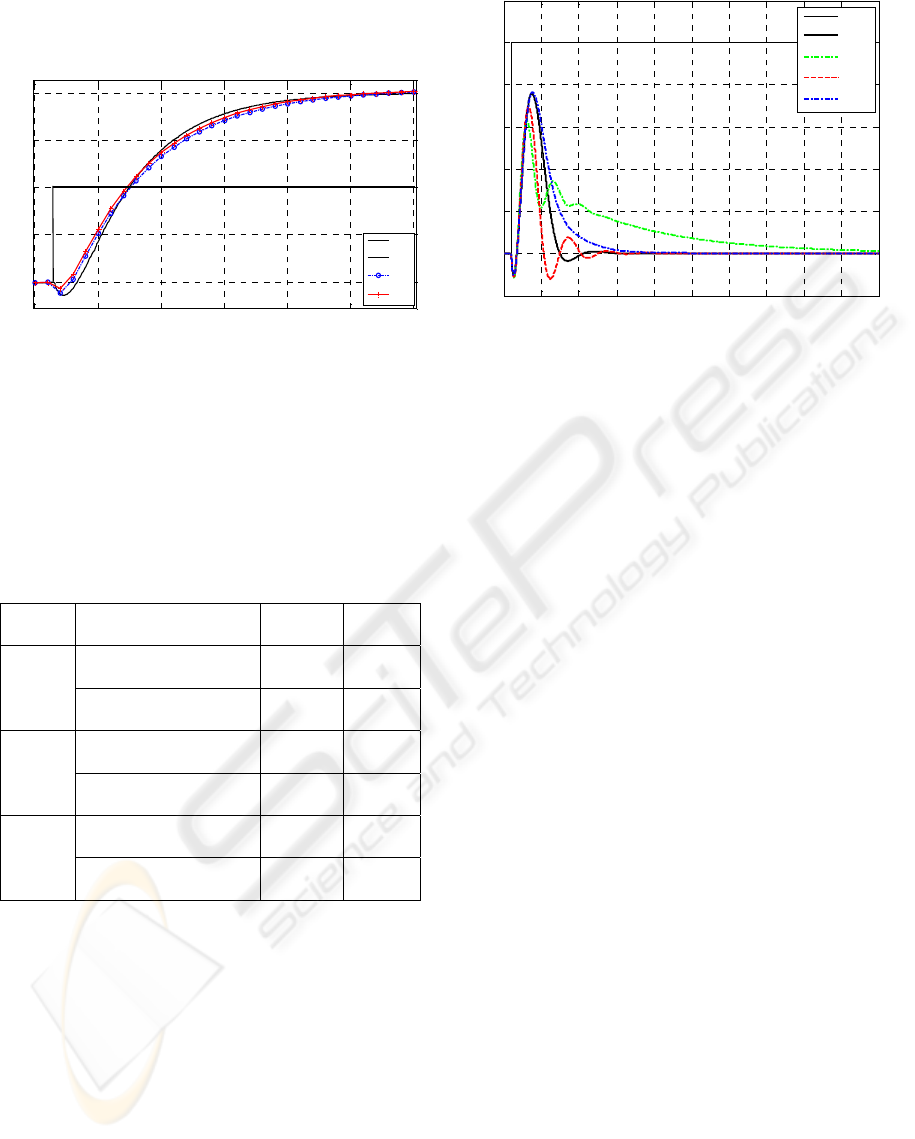

The graph shown in Figure 6 compares the real

system and the system identified locally. The final

solution has FIT equals to 98.21%.

0 100 200 300 400 500 600 700 80

0

0

0.5

1

1.5

2

Time [s]

Output

U

Y

real

Y

arx

Y

est

Figure 6: Cybertune identification of system 1 in a local

station. It shows the original signal (Yreal), the fourth

order ARX signal (Yarx) and the identified open loop

system (Yest).

The same system defined in (1) was used in the

remote identification test. As described in the

previous test, considering an approximation ARX

with a fourth order and sampling rate (To = 2.0 sec),

the model is estimated according to the following

equation (FIT=93.78%):

1931.007639.0

2

z1628.0

3

z4310.1

4

z

0080.00083.0

2

0120.0

3

0028.0

)(

++

+−

+

+−−

=

z

z

zz

zFTMA

(6)

After transforming the ARX model into the open

loop model, the model approximation is obtained:

)7.38(

17.118

00.2

s

e

s

p

G

−

+

=

(7)

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

282

The graph shown in Figure 7 compares the real

system and the system identified remotely. The final

solution has FIT equals to 93.65%.

0 100 200 300 400 500 600

6

6.5

7

7.5

8

Time [s]

Output

U

Y

real

Y

arx

Y

est

Figure 7: Cybertune identification of a system 1 in a

remote station. It shows the original signal (Yreal), the

fourth order ARX signal (Yarx) and the identified open

loop system (Yest).

Table 1 summarizes the results from the three tested

systems. The experimental procedure for systems 2

and 3 are omitted because they are the same as

described for system 1.

Table 1: Local and Remote Tests Results.

System

Description of the test

with Cybertune

ITAE FIT[%]

1

Local identification

(T

o

= 1.0 sec)

4.57E+2 98.21

Remote identification

(T

o

= 2.0 sec)

6.34E+3 93.65

2

Local identification

(T

o

= 1 sec)

5.93E+2 98.46

Remote identification

(T

o

= 5 sec)

8.13E+3 91.60

3

Local identification

(T

o

= 1 sec)

3.54E+2 99.77

Remote identification

(T

o

= 5 sec)

1.86E+3 92.80

In the tuning phase is used the open loop model

obtained from the identification phase. The figure

below shows the tuning with common methods

ISTE, ITAE and IMC and ZN.

5 CONCLUSIONS

This paper proposed an architecture to execute

remote tuning of industrial control systems using the

Internet, fulfilling acceptable security and

performance requirements. In order to validate the

architecture, a software application using CyberOPC

and called Cybertune were presented. The validation

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000

-0.2

0

0.2

0.4

0.6

0.8

1

1.2

U

Y

atual

Y

ISTE

Y

ITA E

Y

IMC

Figure 8: Example of tuning the model obtained in (7) in a

remote station. It shows the original tuning with ZN

(Y

atual

) and some common methods based in model.

consisted of a model-based identification and tuning

of three selected first order plus dead time systems

once this is a typical class of industrial systems, but

the architecture can be extended to other

configurations.

The tests and results session of this paper

focused on a given first order system with dead time

for PID controllers, tests for other two systems were

conducted and the results were summarized.

The tests demonstrated that the remote model

identification is very close to the local identification

and the original system, which validates the

architecture for identification and subsequent tuning

implemented with model-based methods.

For remote identification, it is necessary to pre-

filter the signal in order to increase the efficiency of

ARX identification.

In future researches, we intend to validate the

algorithm in real plant floor systems, through

fieldbus system applications.

ACKNOWLEDGEMENTS

The authors gratefully acknowledge the Brazilian

agency FAPESP for financial support received and

the academic support and research structure of the

Engineering School of São Carlos - University of

São Paulo.

REFERENCES

Abdelzaher, T. F..; Shin, K.G.S.; Bhatti, N., 2002.

Performance Guarantees for Web Server End-Systems:

TUNING OF INDUSTRIAL CONTROLLERS OVER PUBLIC IP NETWORKS

283

A Control-Theoretical Approach, In: IEEE

Transactions on Paralllel and distributed systems, vol

13, no 1, January 2002.

Aguirre, L. A., 2004. Introdução a Identificação de

Sistemas, Técnicas Lineares e Não Lineares aplicadas a

sistemas reais. 2ª edição, 2004, Editora UFMG.

Ang, K. H.; Chong, G.; Li, Y. (2005). PID Control System

Analysis, Design, and Technology. In: IEEE

Transaction on Control Systems Technology, Vol 13,

No 4, July 2005.

Avoy, T. M.; Jounela, S.L.J.; Patton, R.; Perrier, M.;

Weber, H.; Georgakis, C., 2004. Milestone report for

area 7 industrial applications. In: Control Engineering

Practice 12 (2004) 113-119.

Advosol Inc., XMLDA.NET White Paper, 2004

Available:http://www.advosol.com/driver.aspx?Topic=

WhitePaperXMLDANET.

Batur, C.; Ma, Q.; Larson, K., Kettenbauer, N., 2000.

Remote tuning of a PID position controller via internet.

In: American Control Conference, Chicago, 2000.

Brandão, D., Cunha, M. J., Pinotti, J. M., 2004 . Fieldbus

Control System Project Support Tool based on

Experimental Analysis and Modeling of

Communication Bus. In: IEEE International

Conference on Industrial Technology, 2004,

Hammamet, 2004.

Calvo, I.; Marcos, M.; Orive, D.; Sarachaga, I., 2006. A

methodology based on distributed object-oriented

technologies for providing remote access to industrial

plants. In: Control Engineering Practice, 14 (2006),

pp. 975-990

Fernandes, R. F., Brandão, D., 2008. Método de

identificação online de sistemas industriais com

controladores PI em malha fechada, In: Conferência

Internacional de Aplicações Industriais, Poços de

Caldas. Anais do VIII INDUSCON, 2008.

Hjalmarsson, H., 2005. From experiment design to closed

loop control. Automatica, 41 (2005) pp. 393-438.

ITU Recommendation, 1997. X.509 version 3.

Information Technology - Open Systems

Interconnection - The Directory Authentication

Framework, August 1997.

Ljung, L., 1999. System Identification – Theory for the

User. Second Edition, 1999, Englewood, Prentice

Hall.

Luo, R.C.; Chen, T.M., 2000. Development of a

multibehavior-based mobile robot for remote

supervisory control through the Internet. In:

IEEE/ASME Transactions on mechatronics, vol. 5, no.

4, December 2000.

Kunes, M., Sauter, T., 2001. Fieldbus-Internet

connectivity: The SNMP approach. In: IEEE

Transactions on Industrial Electronics, 48(6), 1248–

1256.

Kurose, J. F., Ross, K. W., 2006. Redes de computadores

e a Internet. 3ª Edição, 2006, Editora Addison Wesley.

Qin, W., Wang, Q., 2007. An LPV approximation for

admission control of an internet web server:

Identification and control. In: Control Engineering

Practice, Feb 2007.

OPC Foundation, 2006. OPC Standard. In:

<www.opcfoundation.org

>. Access em: 26 jul. 2007.

Overstreet, J. W., Tzes, A., 1999. Internet-based

client/server virtual instrument designs for real-time

remote-access control engineering laboratory. In

Proceedings of the American control conference, Vol.

2, pp. 1472–1476.

Pinotti Jr., M., Brandão, D., 2005. A flexible fieldbus

simulation platform for distributed control systems

laboratory courses. The International Journal Of

Engineering Education, Dublin, v. 21, n. 6, p. 1050-

1058, 2005.

Torrisi, N. M. ;Oliveira, J. F. G. 2007. Remote Control of

CNC Machines using the cyberopc communication

system over public networks. International Journal of

Advanced Manufacturing Technology, v. 2007, p. 001,

2007

Torrisi, N. M., 2007. Sistemas de comunicação para redes

IP dedicado a dados industriais codificados em JSON.

Patente submetida ao Instituto Nacional da Propriedade

Industrial (INPI), sn 018070047508, 2007.

Yang, S.H.; Chen, X.; Alty, J.L., 2003. Design issues and

implementation of internet-based process control

systems. In: Control Engineering Practice (11) 2003,

709-720.

Yang, S. H., Dai, C., Knott, R.P., 2007. Remote

Maintenance of Control System performance over the

Internet, In: Control Engineering Practice, Volume 15,

Issue 5, May 2007, Pages 533-544

Yu, C. C., 2006. Autotuning of PID Controllers: A Relay

Feedback Approach. 2nd Edition, Springer, 2006.

Zheng, L., Nakagawa, H., 2002. OPC (OLE for process

control) specification and its developments, SICE

2002 – Proceedings of the 41st SICE Annual

Conference, pp. 917-920 vol. 2, 2002.

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

284