THE FINS PROTOCOL FOR COMPLEX

INDUSTRIAL APPLICATTIONS

A Case Study

Júlio Costa, Nuno Carvalho

Industrial Electronics Department/ALGORITMI, University of Minho, Guimarães, Portugal

Filomena Soares

Industrial Electronics Department/ALGORITMI, University of Minho, Guimarães, Portugal

José Machado

Mechanical Engineering Department/CT2M, University of Minho, Guimarães, Portugal

Keywords: Complex Control Systems, Industrial networks, Industrial protocols, PLCs networks.

Abstract: This paper presents a comparative approach on the use of different industrial networks configurations and

industrial communication protocols. Some aspects, that may influence the right choice of the most indicated

protocol for each industrial network configuration, are discussed. It is presented a case study and two

configurations networks implementing two industrial communication protocols. The respective advantages

and disadvantages are presented. All the detailed aspects including the data exchange are presented too. The

obtained results are extrapolated for other similar industrial applications.

1 INTRODUCTION

This works appears on the context of developing and

implementing new solutions for industrial networks

implementation. This line of research is being

developed by a team from the School of Engineering

of University of Minho and involves some

departments of the School.

The first results, here presented, are the first one

obtained from an initial study that it is intended to be

more complex and exhaustive.

Industrial communications have significantly

evolved since their appearance in the 1970s. Faster

and more reliable communication protocols have

been proposed and deployed in industrial

applications (IEC 61784-2).

The necessity that the companies have to

improve their competitiveness has lead to many

developments on this field, related with more

complex industrial networks applications and with

more complex communication protocols elaboration.

This increasing of competitiveness is a constant

objective for all the companies in general and for the

Portuguese companies, in particular.

In order to facilitate the management and control

of manufacturing processes it is, currently, very

important the flexibility of the implemented

management and control systems for the

manufacturing processes. For that accomplishment,

it is necessary a fast access at the information,

means that allow a fast decisions according the

manufacturing process behavior and, more

important, the possibility of improvement of the

manufacturing systems efficiency.

With the development of the communication of

the industrial networks, with the evolution of the

industrial communication protocols and the

increasing of the exigency level - characteristic of

the manufacturing process control - the knowledge

and the know-how associated at these realities is

becoming crucial on the development and

improvement of competitiveness of the industrial

companies.

348

Costa J., Carvalho N., Soares F. and Machado J.

THE FINS PROTOCOL FOR COMPLEX INDUSTRIAL APPLICATTIONS - A Case Study.

DOI: 10.5220/0002249603480354

In Proceedings of the 6th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2009), page

ISBN: 978-989-674-000-9

Copyright

c

2009 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

In this paper it is intended to compare and

conclude about industrial network configurations

and to compare industrial communication protocols

too. Some propositions for the best communication

protocol to be applied on some industrial network

configurations are also presented.

In order to achieve the main goals proposed on

this paper, the paper is organized as follows: Section

1 used to present the challenge of the work. In

section 2 it is presented a background about

industrial networks and industrial communication

protocols. Further, section 3, it is presented a case

study that permits the application of two industrial

network configurations and, also, two industrial

communication protocols application. Section 4 is

devoted to the presentation of the developed work

followed by the Section 5, where are presented and

discussed the obtained results. Finally, section 6,

there are presented the main conclusions of this

study and some guidelines for the future work.

2 BACKGROUND

In this section it is presented a brief overview of

industrial networks and some of the most used

communication industrial protocols.

2.1 Industrial Networks

The industrial networks can be implemented

considering several types of controllers.

Among these controllers, the Programmable

Logic Controllers (PLCs) are the most used due to

their robustness when submitted to industrial

environments which are characterized by adverse

conditions (like magnetic fields, vibrations, dust,

noise, among others).

With the current increase of industrial networks,

the availability of user friendly environments and

software tools that allow a better use of the industrial

networks capabilities is also improved.

The access to different network nodes must be

fast and must allow supervising all the processes

even if they are physically independent.

An industrial network may have different

components; therefore, it implies that the connection

type between these components may be different,

leading to the need of using sub-networks. Thus, to

define some order and criteria on these links, it can

be considered a set of hierarchical levels related to a

common industrial network. These hierarchical

levels can be defined by different ways and using

different criteria. Nevertheless, the pyramid CIM

(Computer Integrated Manufacturing) (ISA-

dS95.01-1999) is a good approach for illustrating

these levels (Figure 1).

Figure 1: CIM Pyramid (ISA-dS95.01-1999).

The CIM Pyramid is divided in levels

concerning the type of application to be controlled.

The considered levels are Management, Control,

Process, and, finally, the Inputs and Outputs

variables.

The Management level is concentrated on all the

information concerning to the network. Usually, it is

used a Personal Computer (PC) in which it can be

seen all the performance of the plant using a

Supervisory Control and Data Acquisition (SCADA)

system (Pires and Oliveira, 2006).

At the Control level it is established the

connection between PCs and PLCs.

The Process level is characterized by the

controllers and PLCs for the industrial process

control.

Finally, the Inputs and Outputs level includes the

sensors and actuators devices. This is the lowest

level of the CIM Pyramid. It is also the closer level

to the plant, where the network is applied.

In the Management level, as in the Control level,

the type of network used is a Local Area Network

(LAN) (IEEE 802.1AB-2005) as for example the

Ethernet (Felser, 2005).

At the Process level other types of networks are

used. One of the most implemented is the

PROFIBUS network (PROFIBUS International, Liu

et al., 2007). Also, at this level, the Actuator/Sensor

Interface (AS-I) network may be used (Lee, 2001).

The Ethernet appears with the main goals of

reducing costs, increasing dependability, sharing the

information and the physical resources in the same

transmission environment by using a coaxial cable.

THE FINS PROTOCOL FOR COMPLEX INDUSTRIAL APPLICATTIONS - A Case Study

349

The Ethernet technology has, as physical

devices, the coaxial cables with small and large

diameter, or the plaited pair of cables.

With the Ethernet network some topologies are

possible: star, tree or ring type configurations. For

the communication between the several devices

there exist some transmission environments: the

Simplex, where the transmission is done in a

unilateral direction; the half duplex, where the

transmission is done from and to each device; and

the full duplex, where each device simultaneously

transmits and receives information.

The Profibus network has different

functionalities for its communication protocols: the

profibus Fieldbus Message Specification (FMS), the

Distributed Peripherals (DP) and the Process

Automation (PA), where the physical transmission is

done by RS485. The profibus FMS is a protocol

used on the PCs and PLCs communication, but

Ethernet network is substantially increasing on this

domain application. The DP profibus is used for the

communication between small PLCs and for the

communication between PLCs and the controllers.

With the transmission environment RS485, it can be

used a complexity until 32 devices, including the

first initial node of the connection. Usually, this

node is a small PLC. The PA profibus network is

implemented to link sensors and actuators,

connected to a master PLC that centralizes all the

relevant data to the control system.

The AS-I network is used for the lowest level of

automation systems. There are about 80 international

developer companies that use this type of network.

This is a low cost network and easy to expand.

Like Profibus, it is allowed the use of a maximum of

32 devices. The maximum allowed length is about

100 meters.

2.2 Industrial Communication

Protocols

With the increasing of the competitiveness and the

set of different PLC products existing in the market,

it is usual, in an industrial plant, to coexist different

types of PLCs. The communication between these

systems is necessary in order to accomplish all the

benefits proposed by the industrial networks.

For the communication between these physical

devices, different solutions in the set of industrial

communication protocols are used. The advantages

of universal protocols (open protocols) seem natural,

because they allow the exchanging of data and

information between different types of systems.

In this group of protocols, one of the most used

is the serial communication protocol. But there are

others, like the Synchronous Serial Interface (SSI)

and the Bi-directional Synchronous Serial Interface

(BiSS). As open protocol, the Profibus (previously

described) is also very used.

There are, also, other protocols that are restrict

and proprietary of the controllers’ manufacturers.

For instance, the Hostlink and the Factory Interface

Network Service (FINS) protocols are two examples

of a large set of these closed protocols (Kizza,

2005).

The main advantage of using closed protocols is

improving the simplicity of network implementation

and configuration. The manufacturers of these

protocols have well adapted software tools and a

very structured set of configurations that

considerably help the designers.

The main advantage of open protocols is that

they can be used and shared by different devices

from different manufacturers. Using these protocols

it is possible to exchange data and information

between several commercial devices. The

characteristics of these protocols are similar, no

matter the device manufacturer, so different

companies use them as a way to promote their own

products and also to increase the competiveness

between the device manufacturers.

In fact, if it is necessary to expand the industrial

network, adding new devices, these protocols have

real advantages when compared to the closed

protocols. In addition, they are at low cost. The main

reason to decrease the cost of these protocols is that

the devices manufacturers intend to increase the

competitiveness (Kizza, 2005).

3 CASE STUDY

The automated line production which was used in

this study is a didactic Modular Production System

(MPS) of the Mechanical Engineering Department

Automation Laboratory of University of Minho, in

Portugal. Although being didactic, this equipment is

a well achieved simulation of a real system. Its

command module is being used in real line

production systems. All the control tasks are assured

by a Programmable Logic Controllers (PLCs)

Network specially designed for the purpose (figure

2).

This system is composed by five modules,

named as follows:

Module 1 – Distribution

Module 2 – Test

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

350

Module 3 – Processing

Module 4 – Transport

Module 5 – Separation

Figure 2: Modular Production System.

These modules have an independent control,

each one being controlled by a single PLC, all the

PLCs being controlled by a PC.

The identification of the component type is made

in the module 2. The control programming assure

that on the module 5, the components are assorted

by size, colour or material, as well as rejected

components, each one being directed to an

appropriated conveyor.

In order to obtain some results comparing the

communication protocols it was decided to

configure the control structure in two different kinds

of networks really implemented in industrial

systems.

In a first step, the PLCs corresponding to each

module were connected in a network, in a parallel

configuration, as shown in figure 3. All the

networked PLCs are at same level of control

(network N1).

Figure 3: Scheme of the implemented network (step 1 of

the study).

In a second step, the MPS was separated into

five independent modules, where each one

represents a sub-network, as illustrated in figure 4,

network N2.

Figure 4: Scheme of the implemented network (step 2 of

the study, with sub-networks).

The used protocols for this study were the

Hostlink and FINS protocols from OMRON

Company (www.omron.com).

On the first step approach it was used the

Hostlink protocol and on the second step approach it

was used the FINS protocol.

4 DEVELOPED WORK

Networks N1 and N2 were implemented

(www.omron.com).

In the case of network N1, Hostlink protocol is

often employed. Each PLC has a dedicate

identification number (ID). The configuration frame

includes: the PLC ID number, the definition of the

action to be performed, e.g. to read a process

variable value (counting pieces in a process line

production) or to send a command value to the

working system (switching on an actuator).

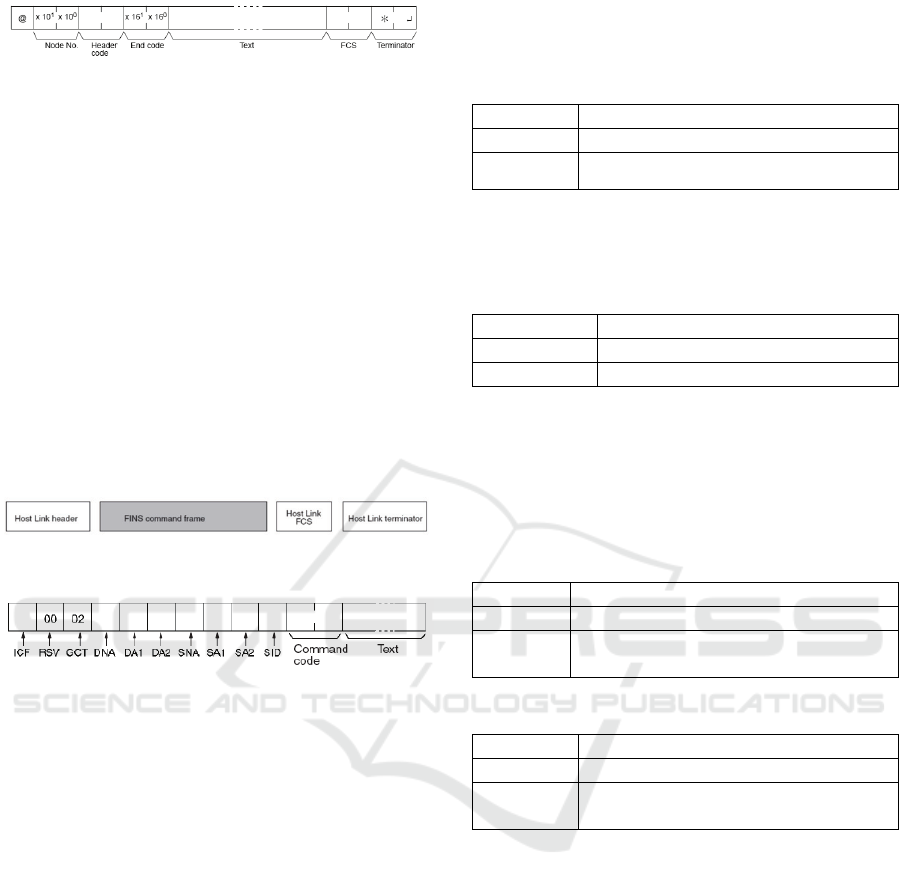

The command frame includes the following

fields (Figure 5): constant parameters definition, the

first one indicates the frame starting point and the

terminator parameter designates the ending point;

the node number is the PLC ID number for

communication; the header code and the text are the

definition of the action and the data to be exchanged

in the communication process, respectively.

Figure 5: Hostlink command frame.

The response frame to the previous command is

shown in Figure 6. The start and ending points are

identical to the command frame. The difference is in

the end code parameter definition which corresponds

to an indicator of success or error in the transmission

line established.

THE FINS PROTOCOL FOR COMPLEX INDUSTRIAL APPLICATTIONS - A Case Study

351

Figure 6: Hostlink response frame.

This protocol is adequate for using in a small

network with parallel PLCs configuration which can

be a constraint when working with complex control

systems. To overcome this limitation and when sub-

industrial networks are implemented (Network N2),

FINS protocol is an adequate solution.

Figure 7 shows the structure of the command

frame sent to the network to communicate to the

PLC. The frame is similar to the Hostlink protocol

but it includes the specific FINS command, the

action to be performed, the target sub-network and

the corresponding PLC, in order to establish the

communication. This frame is detailed in figure 8.

In the frame it must be defined the destination

PLC and to where (which network and PLC) the

response message should be returned.

Figure 7: FINS protocol frame.

Figure 8: Parameter specification in FINS command.

Between the FINS characteristic parameters, the

parameters DNA, DA, SNA and SA1 are particular

important, as they define the PLC communication

command target and the destination of the response

message. DNA is the destination network address,

DA1 is the destination node address and in order to

define to where the response message should be

sent, the SNA, source network address ans SA1,

source node address, must be configured.

5 RESULTS DISCUSSION

Hostlink and FINS protocols were tested and

compared in two types of industrial networks: a

simple network N1, represented in Figure 3 and a

more complex one, N2, shown in Figure 4.

First, network N1 was tested. Two values were

read from the PLC memory position Core Input

Output (CIO) starting from position number 10.

Table 1 shows the configuration of the command

frame for writing, sent by the personal computer

(PC) to the PLC, by using both protocols, Hostlink

and FINS.

Table 1: Command frame for writing.

Protocol Frame

Hostlink

@00WR000A0001000237*

FINS

@00FAF000000000102B0000A0000020001

000200*

Table 2 shows the response frame sent by the

PLC to the PC, also employing both protocols.

Table 2: PLC response frame to writing command.

Protocol Frame

Hostlink

@00WR0045*

FINS

@00FA00400000000102000040*

The test was repeated but for reading command

of two values in PLC memory CIO which are in

position 9. Tables 3 and 4 show the command for

reading sent by the PLC and the corresponding

response frame sent by the PLC.

Table 3: Command frame for reading.

Protocol Frame

Hostlink

@00RR000900034A*

FINS

@00FAF000000000101B000090000

0278*

Table 4: Answer table from PLC.

Protocol Frame

Hostlink

@00RR0000000001000243*

FINS

@00FA00400000000101000000010

00240*

Analyzing Tables 3 and 4 it is verified that the

frame lengths are different. This is due to the fact

that the configuration parameters are diverse. In this

case, network N1, Hostlink protocol is easier to

configure, the frames are shorter, being more

adequate for the application system.

A second configuration was tested, network N2,

where the MPS process is controlled by the PLC

connected to a specific sub-network.

As Hostlink protocol cannot be used in industrial

systems where sub-networks are configured, only

the FINS protocol was implemented.

Table 5 presents the command for writing sent

from the PC to the PLC positioned in a sub-network

and the corresponding PLC response command. The

command consists of writing two values starting in

position 10 of CIO memory.

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

352

Table 5: FINS writing command/response frames.

FINS protocol Frame

Command code

@00FAF8000020101000000000001

02B0000A000002000100020A*

Response

command

@00FA00C0000200000001020000

010100000025002232*

Table 6 tests the command for reading two

positions in PLC (placed in the sub-network) CIO

memory starting from position number 10.

Table 6: FINS reading command/response frames.

FINS protocol Frame

Command code

@00FAF800002010100000000000

101B0000A0000020A*

Response

command

@00FA00C0000200000001010000

010100000025002231*

As it can be seen in Tables 3 to 6, the frames

lengths are different in all tested cases, being the

FINS frame larger than the Hostlink. FINS protocol

needs more parameters to configure the

communication. For a correct and successful data

transmission, all the FINS parameters must be

defined even if they have null value.

In the Hostlink code, the writing and reading

command frames make use of two specific

characters, namely, RR and WR, respectively.

In FINS protocol the code is implemented using

two hexadecimal values, four characters. For

example, the code 0101 is for reading and 0102 is

for writing. Both can be used to read and write in

any PLC memory position. On the contrary,

Hostlink protocol needs other commands to write in

a different memory position. Both frames signal

when the communication is successful.

Apart from having different frame lengths,

Hostlink and FINS have also different data

transmission capacity. FINS has a maximum

capacity of 1115 characters while Hostlink has a

lower capacity, 131 characters.

In summary, with FINS protocol we can access

the whole network, including the PLCs that are in a

sub-network. By using such a network it is possible

to monitor and manage the whole line production

from a working place.

For a correct use of both protocols, it is

necessary to know the network type. If two PLCs are

connected by a profibus link, the PLC slave cannot

be accessed if both master and slave PLCs are in the

same network as the PC. In profibus network, the

slave device periodically sends to the master the

memory positions, configure by the network

manager.

6 CONCLUSIONS AND FUTURE

WORK

This paper presents part of the on-going work

regarding industrial networks design for complex

systems.

An automated line production, a didactic

Modular Production System (MPS), was used as the

case-study. In spite of being didactic, this equipment

is a well achieved simulation of a real world

controlled system. All the control tasks are assured

by a Programmable Logic Controllers Network

specially designed for the purpose.

The communications protocols Hostlink and

FINS used as information coordination methods

between the PLCs and the production equipment

control system were described and tested.

Although being a proprietary communication

protocol, FINS becomes particular important due to

its simplicity, economy of time and development

costs.

In the near future, we are going to implement,

test and discuss other types of industrial protocols

using the demonstration system. An extensively

comparative study for evaluating the protocols’

performance will be carried on.

REFERENCES

IEC 61784-2: Industrial communication networks –

Profiles - Part 2: Additional fieldbus profiles for

realtime networks based on ISO/IEC 8802-3, available

at www.iec.ch

ISA-dS95.01-1999, Draft Standard, Enterprise - Control

System Integration, Part 1: Models and Terminology,

November, available at

1999www.mel.nist.gov/sc5wg1/isa95part1-d14.pdf)

Pires, P. S. M. and Oliveira, L. A. H. G., 2006, Security

aspects of SCADA and corporate network

interconnection: An overview, Proceedings of the

International Conference on Dependability of

Computer Systems (DEPCOS-RELCOMEX’06), pages

127–134, May.

IEEE 802.1AB-2005 - IEEE Standard for Local and

metropolitan area networks Station and Media Access

Control Connectivity Discovery; available at

www.ieee.org

Felser, M., 2005, Real-time Ethernet - industry

prospective, Proceedings of the IEEE, Volume 93,

Issue 6, June Page(s): 1118 – 1129

THE FINS PROTOCOL FOR COMPLEX INDUSTRIAL APPLICATTIONS - A Case Study

353

PROFIBUS International: PROFINET: Technology and

Application, System Description, Document number:

4.132, Issue April 2006, available at

www.profibus.com

Liu, J., Fang, Y., Zhang, D., 2007, PROFIBUS-DP and

HART Protocol Conversion and the Gateway

Development, Second IEEE Conference on Industrial

Electronics and Applications

Lee, K., 2001, Sensor Networking and Interface

Standardization, IEEE Instrumentation and

Measurement Technology Conference, Budapest,

Hungary, May 21-23.

Kizza, J.M., 2005, Security Threats to Computer

Networks, Computer Communications and Networks

Part II, Springer.

Spratt, Michael P.; Albrecht, Alan; Curcio, Joe; Dove,

Dan; Goody, Steve, 1994, An Overview of IEEE

802.12 Demand Priority, HP Labs Technical Reports,

available at

http://www.hpl.hp.com/techreports/94/HPL-94-17.html

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

354