LMI

APPROACH FOR AIR-MANAGEMENT IN DIESEL ENGINES

USING PDC FUZZY CONTROLLERS

S. Garc

´

ıa-Nieto, J. Salcedo, J. M. Herrero and C. Ramos

Instituto Universitario de Autom

´

atica e Inform

´

atica Industrial

Universidad Polit

´

ecnica de Valencia, Camino de Vera s/n, 46022 Valencia, Spain

Keywords:

Fuzzy Systems, LMIs, Nonlinear Control, Diesel Engines.

Abstract:

Air management control in a turbocharged diesel engine presents itself as a challenge due to its nonlinear

behavior, then classic control techniques are unable to provide the required performance. Hence, it is proposed

to design fuzzy controllers based on PDC structure (Parallel Distributed Compensation) using a previously

obtained Takagi-Sugeno fuzzy model for the engine. Controller parameters are obtained from a minimization

problem subject to LMIs (Linear Matrix Inequalities).

1 INTRODUCTION

A turbocharged diesel engine is a very complex sys-

tem which must fulfil user requirements (high power,

low fuel consumption, flexible driving, etc.), as well

as meeting increasingly strict emission standards.

These new requirements, together with new environ-

mental constraints (Guzzella and Amstutz, 1998), are

forcing continuous improvements in the performance

of air management. In order to tackle this tradeoff,

a better development of the entire system is needed,

especially the air management process. Current tur-

bocharged diesel engines are very complex and non-

linear processes where a large set of variables are

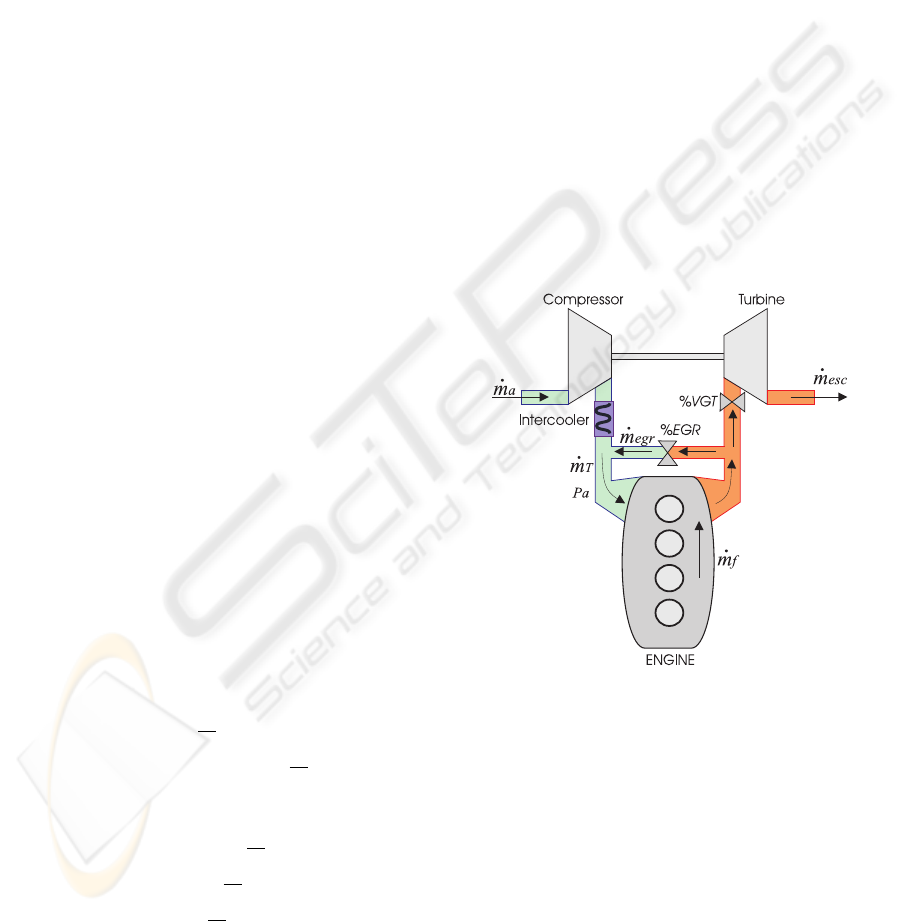

involved in the behavior of the whole system. Fig-

ure 1 shows a schematic view of a turbodiesel en-

gine, where the most important physical magnitudes

involved in the dynamic response of the system are:

- ˙m

a

: Air mass flow

³

Kg

h

´

- ˙m

T

:

Total collector mass flow

³

Kg

h

´

-V

GT : Variable geometry turbine (%)

-EGR: Exhaust gas recirculation. Valve (%)

- ˙m

esc

: Exhaust mass flow

³

Kg

h

´

- ˙m

e

gr

: EGR mass flow

³

Kg

h

´

- ˙m

f

:

Fuel mass flow

³

Kg

h

´

-p

a

:

Intake mainfold pressure (bar)

There are other two variables that affect the

behavior of the system in a similar way to the

manipulable variables EGR and V GT . One is the

Figure

1: Turbocharged diesel engine.

speed of the engine (N) (Nieuwstadt et al., 2000; Kim

and Park, 2007), which depends on several variables

such as engine torque, load torque, vehicle inertial

moment, etc.

The other variable, obviously, is the flow of fuel

injected ( ˙m

f

) (Guzzella and Amstutz, 1998) and this

determines the AFR.

This work proposes to use Takagi-Sugeno

(T-S) fuzzy models as mathematical approximation

of the turbocharged engines behavior (Takagi and

Sugeno, 1985; Khiar et al., 2007; Lee et al., 2007).

Next, a fuzzy controller PDC Parallel Distributed

41

García-Nieto S., Salcedo J., Herrero J. and Ramos C. (2009).

LMI APPROACH FOR AIR-MANAGEMENT IN DIESEL ENGINES USING PDC FUZZY CONTROLLERS.

In Proceedings of the International Joint Conference on Computational Intelligence, pages 41-46

DOI: 10.5220/0002274200410046

Copyright

c

SciTePress

Compensator (PDC) structure is proposed (Sugeno

and Kang, 1986; Tanaka and Wang, 2001) based on

a fuzzy TS model obtained previously. The control

design can be recast as a minimization problem

subject to a set of Linear Matrix Inequalities (LMIs)

(Boyd et al., 1987). Therefore, the result of the design

stage is a fuzzy controller that guarantees closed loop

stability as a global approach.

The remainder of this article is organized as fol-

lows: Section 2 provides a mathematical description

of T-S fuzzy models and PDC controllers. In Sec-

tion 3, the T-S fuzzy model used is defined. Section 4

shows the PDC control strategy proposed. In section

5, the simulation results obtained by using the pro-

posed control strategy are commented. Finally sec-

tion 6 offers the main conclusions.

2 MATHEMATICAL BASE

2.1 T-S Fuzzy Model

The structure of T-S fuzzy models is based on r num-

ber of rules composed of two terms: the premise and

the consequent of the rule. The premise term de-

scribes the degree of fulfillment of each rule for each

time step. The consequent term expresses the local

dynamics of each fuzzy implication with a linear state

space model.

RULE i :

IF z

1

(k) Is M

i1

& ·· · & z

p

(k) Is M

ip

Then

X(k + 1) =

ˆ

A

i

X(k) +

ˆ

B

i

U(k),

Y (k) =

ˆ

C

i

X(k), i = 1, 2, ..., r

(1)

Where M

i j

defines the fuzzy membership func-

tions of the variables z

p

(k) which conform the

premise term of the fuzzy rules, r is the number of

rules in the model and, matrices

ˆ

A

i

,

ˆ

B

i

and

ˆ

C

i

define

the state space model for the consequents. Then, the

output of the T-S fuzzy model is:

X(k + 1) =

∑

r

i=1

h

i

(z(k))(

ˆ

A

i

X(k) +

ˆ

B

i

U(k))

(2)

Y (k) =

∑

r

i=1

h

i

(z(k))(

ˆ

C

i

X(k))

(3)

Where,

z(k) = [z

1

(k) ··· z

p

(k)],

w

i

(z(k)) = Π

p

j=1

M

i j

(z

j

(k)),

h

i

(z(k)) =

w

i

(z(k))

∑

r

i=1

w

i

(z(k))

(4)

2.2 Structure of the PDC Controller

During the last decade, a class of numerical optimiza-

tion problems called linear matrix inequality (LMI)

problems has received significant attention (Boyd

et al., 1987). These optimization problems can be

solved in polynominal time and hence are tractable.

For systems and control, the importance of LMI opti-

mization stems from the fact that a wide variety of

system and control problems can be recast as LMI

problems. One example is presented in (Tanaka and

Wang, 2001), where the design problem of PDC con-

trollers expressed in terms of LMIs is handled.

The structure of a PDC fuzzy controller is based

on r rules composed of two terms: the premise and the

consequent of the rule, and the number of rules and

the premise structure is the same as the fuzzy model

used for the controller design. The consequent of the

PDC is composed of a state feedback law. There-

fore, the fuzzy controller design determines these lo-

cal feedback gains K

i

. With the PDC, we have a sim-

ple and natural procedure for handling nonlinear con-

trol systems (Tanaka and Wang, 2001).

RULE i :

If z

1

(k) Is M

i1

& ·· · & z

p

(k) Is M

ip

Then

U(k) = −

ˆ

K

i

X(k), i = 1, 2, ..., r

(5)

Where M

i j

defines the fuzzy membership func-

tions of the variables z

p

(k) which conform the

premise term of the PDC rule, r is the number of rules

in the model and,

ˆ

K

i

are the matrices which feedback

the state vector at each rule. Then, the global control

action of the PDC controller can be defined as:

U(k) = −

∑

r

i=1

h

i

(z(k))(

ˆ

K

i

X(k))

(6)

3 T-S FUZZY MODEL FOR THE

AIR MANAGEMENT SYSTEM

The fuzzy model used in this article was first

introduced in (Garc

´

ıa-Nieto and Mart

´

ınez, 2007),

where the identification methodology used is based

on (Babuska and Verbruggen, 1996) and (Babuska,

1998). The main idea in (Garc

´

ıa-Nieto and Mart

´

ınez,

2007) is to apply fuzzy clustering over the space of the

variables (Gustafson and Kessel, 1979; Zhao et al.,

1994; Mart

´

ınez and Herrera, 2003; Yu and Li, 2008).

The goal is to identify subspaces with similar char-

acteristics where linear submodels will be character-

ized. Those submodels are part of a global nonlin-

ear model which combines all the linear models us-

ing fuzzy rules. The identification method produces

IJCCI 2009 - International Joint Conference on Computational Intelligence

42

a matrix membership that expresses the degree of ful-

fillment of each fuzzy rule. Later, the membership

function for each antecedent variable is directly ob-

tained from the projection of that membership matrix.

The model introduced in (Garc

´

ıa-Nieto and

Mart

´

ınez, 2007) has been modified normalising the

process variables within −1 and 1, where the goal

of this modification is a better identification accu-

racy. The fuzzy model of the system only has 3 rules

that define the engine behavior throughout its working

range:

RULE i :

If ˙m

a

(k) Is D

i

& ˙m

a

(k − 1) Is E

i

& p

a

(k) Is F

i

&

p

a

(k − 1) Is J

i

& RPM(k) Is L

i

& ˙m

f

(k) Is M

i

& EGR(k − 1) Is N

i

& V GT (k − 1) Is Z

i

Then

X(k + 1) =

ˆ

A

i

X(k) +

ˆ

B

i

U(k) + Ψ

1

W (k),

Y (k) =

ˆ

C

i

X(k)

(7)

Where

X(k) =

˙m

a

(k − 1)

˙m

a

(k)

p

a

(k − 1)

p

a

(k)

EGR(k − 1)

V GT (k − 1)

,

U(k) =

·

∆EGR(k)

∆V GT (k)

¸

, W (k) =

RPM(k)

˙m

f

(k)

1

,

Y (k) =

·

˙m

a

(k)

p

a

(k)

¸

, z(k) = X(k),

(8)

w

i

= D

i

( ˙m

a

(k)) · E

i

( ˙m

a

(k − 1)) · F

i

(p

a

(k))·

J

i

(p

a

(k − 1)) · L

i

(RPM(k)) · M

i

( ˙m

f

(k))·

N

i

(EGR(k)) · Z

i

(V GT (k))

(9)

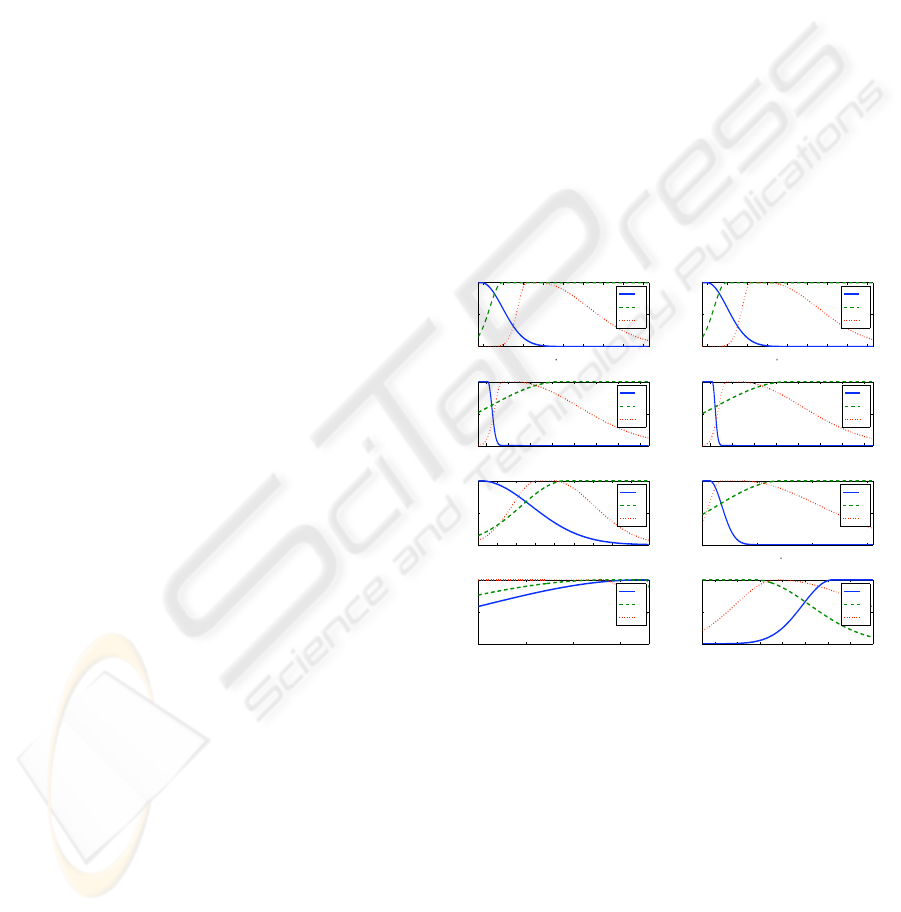

In the appendix, the membership functions for

the antecedents variables (see Figure 6) and the state

space model matrices are described.

4 PDC FUZZY CONTROLLER

DESIGN

Firstly,

ˆ

A

i

matrices in equation (7) are extended with

two integrators. The purpose of this modification is

to get rid of steady state error for ˙m

a

and p

a

in the

tracking problem.

Secondly, state space feedback matrices are de-

signed requesting three conditions: stability, mini-

mization of the closed loop decay rate and fulfill con-

straints for control variables and process outputs. Sta-

bility and a specific decay rate are guaranteed by ap-

plying theorem 10 introduced in (Tanaka and Wang,

2001) and the decay rate definition stated in that ref-

erence, which certifies that Lyapunov function de-

creases exponentially:

∆V (k) ≤ (α

2

− 1)V (k), α < 1,

⇒ V (k + 1) ≤ α

2

V (k),

(10)

Then, considering that the decay rate (α

2

) is to

be minimized and taking advantage of theorem 10 in

(Tanaka and Wang, 2001), it is drawn that it is neces-

sary to solve the following GEVP which comes from

the product of β and F:

Minimize

F,M

1

,...,M

r

,Y

0

β

Sub ject to :

F > 0,

·

βF F

ˆ

A

T

i

− M

T

i

ˆ

B

T

i

ˆ

A

i

F −

ˆ

B

i

M

i

F

¸

> 0,

(11)

·

βF Aux

T

Aux F

¸

≤ 0,

Aux =

ˆ

A

i

F +

ˆ

A

j

F −

ˆ

B

i

M

j

−

ˆ

B

j

M

i

2

,

ˆ

V

i j

< 0, i > j sub ject to h

i

∩ h

j

6= φ

(12)

Where

β = α

2

, M

i

=

ˆ

K

i

F,

ˆ

K

i

= M

i

F

−1

, i = 1, 2, ..., r

(13)

Variables h

i

and h

j

stand for the multivariate

membership function of the rule (see equation (7)).

Finally, the LMIs which introduce the constraints

for control actions and outputs are to be added in the

minimization problem. The theoretical base to insert

constraints for this variables is in theorems 11, 12 and

13, from (Tanaka and Wang, 2001). The join of those

results derives theorem 4.1.

Theorem 4.1 Assume that kX(0)k < θ, where X(0)

is unknown but the upper bound is known. The con-

straints kU(k)k

2

≤ µ and kY (k)k

2

≤ γ are enforced at

all times k ≥ 0 if the LMIs

θ

2

I ≥ F, (14)

·

F M

T

i

M

i

µ

2

I

¸

≥ 0, (15)

·

F F

ˆ

C

T

i

ˆ

C

i

F γ

2

I

¸

≥ 0, M

i

=

ˆ

K

i

F (16)

LMI APPROACH FOR AIR-MANAGEMENT IN DIESEL ENGINES USING PDC FUZZY CONTROLLERS

43

Concluding, the proposed design is based on solv-

ing the conditions (11-12) and (14). However, con-

ditions (11) and (12) are not LMIs but GEVP due to

the product of β and F, hence an iterative method to

get a solution is needed (Boyd et al., 1987). In this

work, those conditions have been solved by using bi-

section algorithm over β. In particular, this methodol-

ogy has been applied to the model of the air manage-

ment process (7), obtaining β as 0.9984. For each

value of β conditions (11) and (12) become LMIs,

which altogether with LMIs (14) have been solved us-

ing the toolboxes Yalmip and LMItoolbox for Matlab

(L

¨

ofberg, 2004). The corresponding feedback matri-

ces are:

ˆ

K

1

=

0.0677 −0.2053

−0.2539 0.2601

−0.0877 1.5966

0.5705 −0.6142

1.0089 −0.0147

−0.0411 1.1141

0.0717 −0.0049

−0.0594 −0.0867

T

(17)

ˆ

K

2

=

0.4283 −0.2427

−0.8365 0.2576

0.2110 −1.0279

−0.1050 2.3448

1.0076 −0.0107

−0.0034 1.0882

0.0764 −0.0040

−0.0277 −0.0816

T

(18)

ˆ

K

3

=

1.2042 −0.2927

−1.8973 0.3474

0.2409 −0.2448

−0.7746 1.4879

1.0210 −0.0070

−0.0062 1.0418

0.0637 −0.0059

0.0177 −0.0779

T

(19)

The controller presents a structure equivalent to the

model, equation (20) shows the controller designed.

RULE i :

If ˙m

a

(k) Is D

i

& ˙m

a

(k − 1) Is E

i

& p

a

(k) Is F

i

&

p

a

(k − 1) Is J

i

& RPM(k) Is L

i

& ˙m

f

(k) Is M

i

& EGR(k − 1) Is N

i

& V GT (k − 1) Is Z

i

Then

U(k) = −

ˆ

K

∗

i

X

∗

(k)

(20)

5 RESULTS VALIDATION

Once the controller has been designed, its perfor-

mance can be checked. However, this is not an easy

task, because it is not possible to modify the air man-

agement control strategy included in the electronic

control unit (ECU) of the vehicle. These units are re-

stricted by the manufacturer and cannot be modified,

1

and so the control strategy with the physical engine

and its ECU cannot be tested. Moreover, the complete

engine behavior is not modeled, and so any tracking

reference for variables such as N or m

f

cannot be de-

termined. For this reason, the goal of the simulation

is to decrease the mean value of the air pressure, and

track the air mass flow obtained in real tests. If the

air pressure is lower with similar levels of air mass

flow, then the NOx emissions will decrease since the

behavior of the engine in terms of torque should be

similar.

To validate the controller, it is necessary to iso-

late the air management process and create realistic

test conditions, which will provide coherent and com-

parable data to the experimental data from the real

engine and its ECU. It is known that the ECU imple-

ments the control strategy by defining a reference for

˙m

a

(related with ˙m

f

through AFR control) and sub-

ject to p

a

being within an appropriate working range

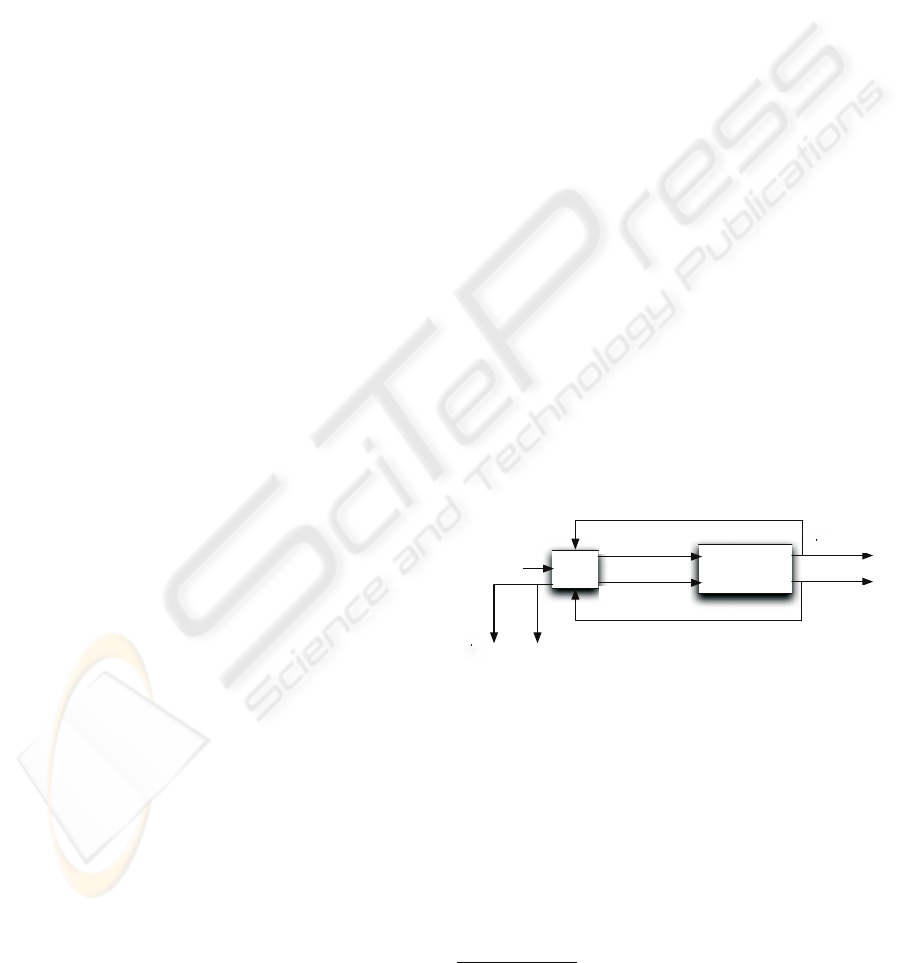

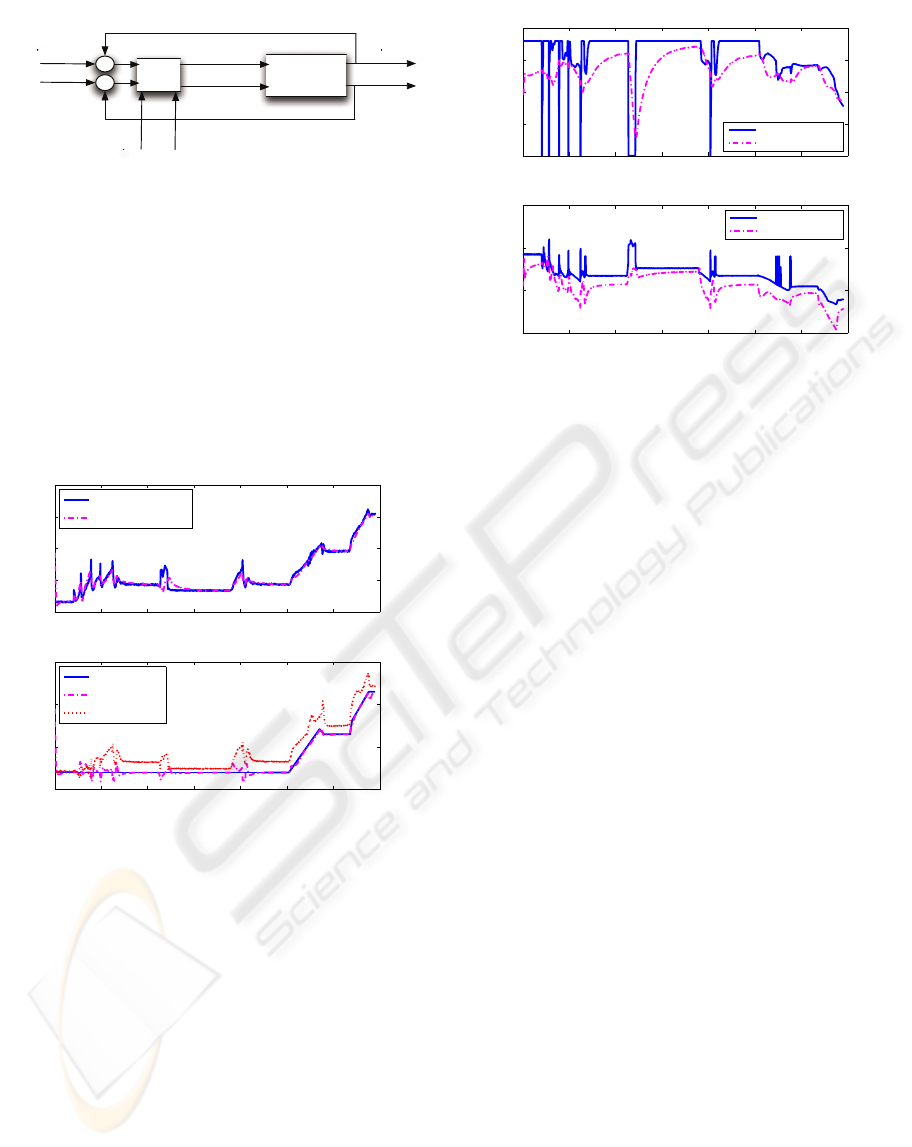

(see Figure 2). The diagram adopted for the simula-

tion is shown in Figure 3, where the air management

process has been isolated from the global process, and

˙m

a

from the real test is used as the reference to track.

The reference for p

a

is below that obtained in the ex-

perimental test. Under these conditions, it is possible

to compare the designed subcontroller with the sub-

controller implemented in the ECU.

Figure 2: Air management control implemented in commer-

cial ECUs.

Figure 4 shows how ˙m

a

time evolution manages to

track the desired reference. Therefore, the mechani-

cal behavior will be similar to the one obtained when

the ECU manages the process. Additionally, it can be

seen how p

a

is able to track a given pressure profile.

In both cases, the time response of the controlled vari-

ables ( ˙m

a

p

a

), given a change in the references, or in

the event of a perturbation, is determined by the decay

rate defined during the design procedure. If the decay

1

The ECU implements other controls and additional

functions for air management, which are essential for ve-

hicle performance.

IJCCI 2009 - International Joint Conference on Computational Intelligence

44

!"##$%&'()*

+,-

-'./0'*

1%234%

1%536

78%

98

:

:

;

;

4)<%=%78%>42?@A

4)<B%98

!"#$%&'"()*&)+*,&%"+&'"()*-.!$%'!*

7<%>42?@A

4+&%>42?@A

Figure 3: Air management control proposed.

rate had not been used in the design of the controller,

the control system would have produced a consider-

ably slower response.

Figure 4 shows that the air pressure when the ECU

takes control is higher than the level obtained with the

proposed fuzzy controller, although generating more

NO

x

. It can also be seen that for low demands of ˙m

a

,

the fuzzy controller keeps p

a

near the atmospheric

pressure, while the ECU provides greater values.

0 50 100 150 200 250 300 350

−1

−0.5

0

0.5

1

Time (s)

Air Mass (m

a

)

0 50 100 150 200 250 300 350

−1

−0.5

0

0.5

Time (s)

Air Pressure (P

a

)

Ref. p

a

p

a

p

a

(Real ECU)

Ref. m

a

(Real ECU)

m

a

Figure 4: Response of ˙m

a

and p

a

.

Figure 5 shows how the control actions EGR

and V GT , proposed by the designed T-S fuzzy con-

troller, present less transitions between the limits of

the valves. This fact could be critical for the actuator

life cycle, since a persistent switch between bounds

would damage the mechanical parts of the valves.

6 CONCLUSIONS

This article presents the process to design an air man-

agement control system for a turbocharged diesel en-

gine. It has been exposed the design of a stabilizer

fuzzy controller that provides the fastest response

possible considering the constraints for the control ac-

tions and outputs. The controller is the result com-

0 50 100 150 200 250 300 350

−1

−0.5

0

0.5

1

Time (s)

EGR

0 50 100 150 200 250 300 350

−0.5

0

0.5

1

Time (s)

VGT

VGT (Real ECU)

VGT

EGR (Real ECU)

EGR

Figure 5: Control actions EGR and V GT .

ing out from a GEVP problem where additional terms

have been added in order to ensure control actions

within bounds.

Secondly, the design proposed in this article con-

trols p

a

in such a way that the emission of NO

x

is

reduced.

Finally, the implementation of this controller on

open ECUs, where the user can define the controller

structure and its parameters, is left as future work.

The goal of such an implementation is to test the T-

S fuzzy controller with a real vehicle to confirm the

simulation results obtained. Moreover, the robustness

of the controller will be studied in future works, since

possible implementations in real engines must be re-

liable and durable.

ACKNOWLEDGEMENTS

Partially funded by GVPRE/2008/326 and DPI2008-

02133/DPI.

REFERENCES

Babuska, R. (1998). Fuzzy modeling for control.

Babuska, R. and Verbruggen, H. (1996). An overview

of fuzzy modeling for control. Control Engineering

Practice, 4(11):1593–1606.

Boyd, A. S., Ghaoui, L. E., Feron, E., and Balakrishnan,

V. (1987). Linear matrix inequalities in system and

control theory. Book, page 203.

Garc

´

ıa-Nieto, J. V. S. S. and Mart

´

ınez, M. (2007). Identifi-

caci

´

on y control fuzzy en motores diesel turboalimen-

tados. XXVIII Jornadas de Autom

´

atica.

LMI APPROACH FOR AIR-MANAGEMENT IN DIESEL ENGINES USING PDC FUZZY CONTROLLERS

45

Gustafson, D. and Kessel, W. (1979). Fuzzy clustering with

a fuzzy covariance matrix. Proc. IEEE CDC, 2:761–

766.

Guzzella, L. and Amstutz, A. (1998). Control of diesel en-

gines. IEEE Control Systems.

Khiar, D., Lauber, J., Floquet, T., Colin, G., Guerra, T., and

Chamaillard, Y. (2007). Robust takagi-sugeno fuzzy

control of a spark ignition engine. Control Engineer-

ing Practice, 15:1446–1456.

D. Kim, and J. Park. (2007). Application of adaptive control

to the fluctuation of engine speed at idle. Information

Sciences, DOI: 10.1016/j.ins.2006.12.021.

Lee, S., Howlett, R., Crua, C., and Walters., S. (2007).

Fuzzy logic and neuro-fuzzy modelling of diesel spray

penetration: A comparative study. Journal of Intelli-

gent and Fuzzy Systems, 18:43–56.

L

¨

ofberg, J. (2004). Yalmip : A toolbox for modeling and

optimization in MATLAB. In In Proceedings of the

CACSD Conference, Taipei, Taiwan.

Mart

´

ınez, J. M. and Herrera, F. (2003). Estrategia para la

construcci

´

on de modelos difusos utilizando clustering

y transformaci

´

on ortogonal. X Convenci

´

on Interna-

cional Inform

´

atica.

Sugeno, M. and Kang, G. T. (1986). Fuzzy modeling and

control of multilayer incinerator. Fuzzy Sets Systems,

18(3):329–345.

Takagi, T. and Sugeno, M. (1985). Fuzzy identification of

systems and its applications to modelling and control.

IEEE Trans. On Systems, Man, and Cybern, 15:116–

132.

Tanaka, K. and Wang, H. O. (2001). Fuzzy Control Systems

Design and Analysis: A Linear Matrix Inequality Ap-

proach. John Wiley & Sons, Inc.

M.J. van Nieuwstadt, I.V Kolmanovsky, P.E Moraal, A. Ste-

fanopoulou, and M. Jankovic. (2000). EGR-VGT con-

trol schemes: experimental comparison for a high-

speed diesel engine. IEEE Control Systems Magazine,

20(3):63 – 79.

Wen Yu and Xiaoou Li. (2008) On-line fuzzy modeling via

clustering and support vector machines. Information

Sciences, 178(22):4264 – 4279.

Zhao, J., Wertz, V., and Gorez, R. (1994). A fuzzy cluster-

ing method for the identification of fuzzy models for

dynamical systems.

APPENDIX

• Consequent for Rule 1:

ˆ

A

1

=

0 1 0 0 0 0

−0.1647 0.8911 −0.0049 −0.0371 −0.0279 0.1219

0 0 0 1 0 0

−0.0522 0.1016 0.7063 0.0855 −0.0027 0.0305

0 0 0 0 1 0

0 0 0 0 0 1

(21)

ˆ

B

1

=

0 0

0 0

0 0

0 0

1 0

0 1

,

ˆ

C

1

=

·

0 1 0 0 0 0

0 0 0 1 0 0

¸

(22)

• Consequent for Rule 2:

ˆ

A

2

=

0 1 0 0 0 0

−0.5445 1.4793 −0.2511 0.2831 −0.0082 −0.0088

0 0 0 1 0 0

−0.0201 0.0272 −0.6058 1.5700 −0.0024 0.0415

0 0 0 0 1 0

0 0 0 0 0 1

(23)

ˆ

B

2

=

0 0

0 0

0 0

0 0

1 0

0 1

,

ˆ

C

2

=

·

0 1 0 0 0 0

0 0 0 1 0 0

¸

(24)

• Consequent for Rule 3:

ˆ

A

3

=

0 1 0 0 0 0

−0.6235 1.5663 −0.0448 0.0691 −0.0100 −0.0128

0 0 0 1 0 0

−0.0760 0.1241 −0.1426 1.0824 −0.0009 0.0160

0 0 0 0 1 0

0 0 0 0 0 1

ˆ

B

3

=

0 0

0 0

0 0

0 0

1 0

0 1

,

ˆ

C

3

=

·

0 1 0 0 0 0

0 0 0 1 0 0

¸

(25)

• Membership functions of the variables z

p

(k):

!!"# !!"$ !!"% !!"& ! !"& !"% !"$ !"#

!

!"'

(

)

*

+,-

µ

.

.

!!"# !!"$ !!"% !!"& ! !"& !"% !"$ !"#

!

!"'

(

)

*

+,!(-

µ

.

.

!!"# !!"$ !!"% !!"& ! !"& !"% !"$

!

!"'

(

/

*

+,-

µ

.

.

!!"# !!"$ !!"% !!"& ! !"& !"% !"$

!

!"'

(

/

*

+,!(-

µ

.

.

!!"# !!"$ !!"% !!"& ! !"& !"% !"$

!

!"'

(

012+,-

µ

.

.

!( !!"' ! !"'

!

!"'

(

)

3

+,-

µ

.

.

!( !!"' ! !"'

!

!"'

(

450+,-

µ

.

.

!!"( ! !"( !"& !"6 !"% !"' !"$

!

!"'

(

758+,-

µ

.

.

9

(

9

&

9

6

4

(

4

&

4

6

:

(

:

&

:

6

;

(

;

&

;

6

<

(

<

&

<

6

2

(

2

&

2

6

=

(

=

&

=

6

>

(

>

&

>

6

Figure 6: Membership functions of the TS Model.

IJCCI 2009 - International Joint Conference on Computational Intelligence

46