INTELLIGENT SUPPORT

TO ANALYSIS-BASED DESIGN IMPROVEMENT PROCESS

PROPOSE: An Intelligent Consultative Advisory System

Marina Novak and Bojan Dolšak

Faculty of Mechanical Engineering, University of Maribor, Smetanova ul. 17, SI-2000 Maribor, Slovenia

Keywords: Computer-aided Design, Structural Analysis, Design Optimization, Intelligent Decision Support.

Abstract: The paper presents the use of intelligent consultative decision support computer system in engineering

design. The system presented is able to provide an expert advice to designer engineers how to improve a

certain design solution considering the results of the preceding engineering structural analysis. The system

guides design engineers through the post-processing phase of the structural analysis and suggests them the

appropriate redesign actions in case the structure is under- or over-dimensioned. The application of the

system in practice is presented by two examples.

1 INTRODUCTION

Engineering design is a set of decision-making

processes and activities used to determine the form

of an object. Considering the technical, economic,

safety, social and certain other constraints, the

designers use their creative abilities to synthesize

alternative design solutions.

Engineering analysis can prove or reject a design

candidate by predicting and simulating its

performance or behaviour. Structural analysis is thus

an integrate part of the design process for many

components. Finite Element Analysis (FEA) is the

most extensively used numerical analysis in

mechanical engineering practice and is incorporated

into many computer aided design systems

(Zienkiewicz, Taylor and Shu, 2005). A candidate

design that fails to satisfy the constraints should be

modified, new values regarding form should be

chosen, and the changed/redesigned candidate

reanalyzed. Engineering analyses play a very

important role in the design improvement process.

The skilled usage of Computer Aided Design

(CAD) tools increases the designers’ effectiveness

and their capabilities when solving complex design

problems (McMahon and Browne, 1999). CAD

systems cover different design activities, such as

modelling, kinematics, simulations, structural

analysis or just drawing technical documentation. In

spite of all this, these kinds of systems do not offer

sufficient support to the designer during the more

creative parts of the design process involving

complex reasoning as, for example, when a possible

candidate design needs to be evaluated and

modified.

In analysis-based design improvement process

the results of engineering analysis need to be studied

and decisions made regarding the design’s suitability

with respect to its engineering specifications. In

general, design changes are indispensable and

designers need help to deal with this problem

properly.

The prototype of an intelligent rule-based

consultative system is being developed by the

authors to provide such advice when considering a

description of the design structure’s critical area.

The system can deal with the results of prior strain-

stress or thermal analysis. It presents a short list of

proposed design changes that should be taken into

account when improving the design.

According to the experience gained so far by

applying the system in engineering practice as well

as in design education, redesign recommendations

presented as a list of the proposed design changes

can support decision making process significantly.

135

Novak M. and Dol

ˇ

sak B. (2009).

INTELLIGENT SUPPORT TO ANALYSIS-BASED DESIGN IMPROVEMENT PROCESS - PROPOSE: An Intelligent Consultative Advisory System.

In Proceedings of the International Conference on Knowledge Engineering and Ontology Development, pages 135-140

Copyright

c

SciTePress

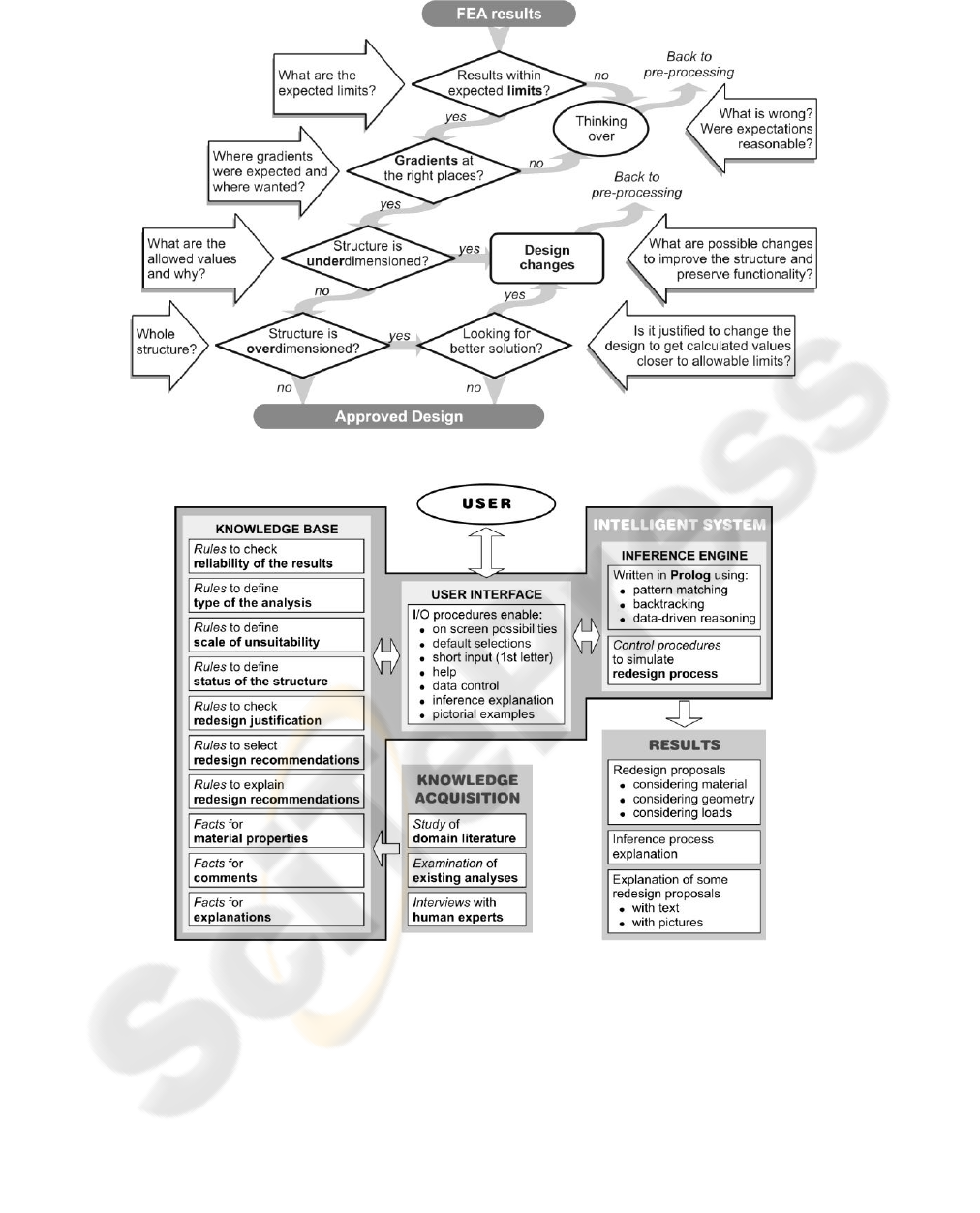

Figure 1: Some crucial decisions in FEA-based design improvement process.

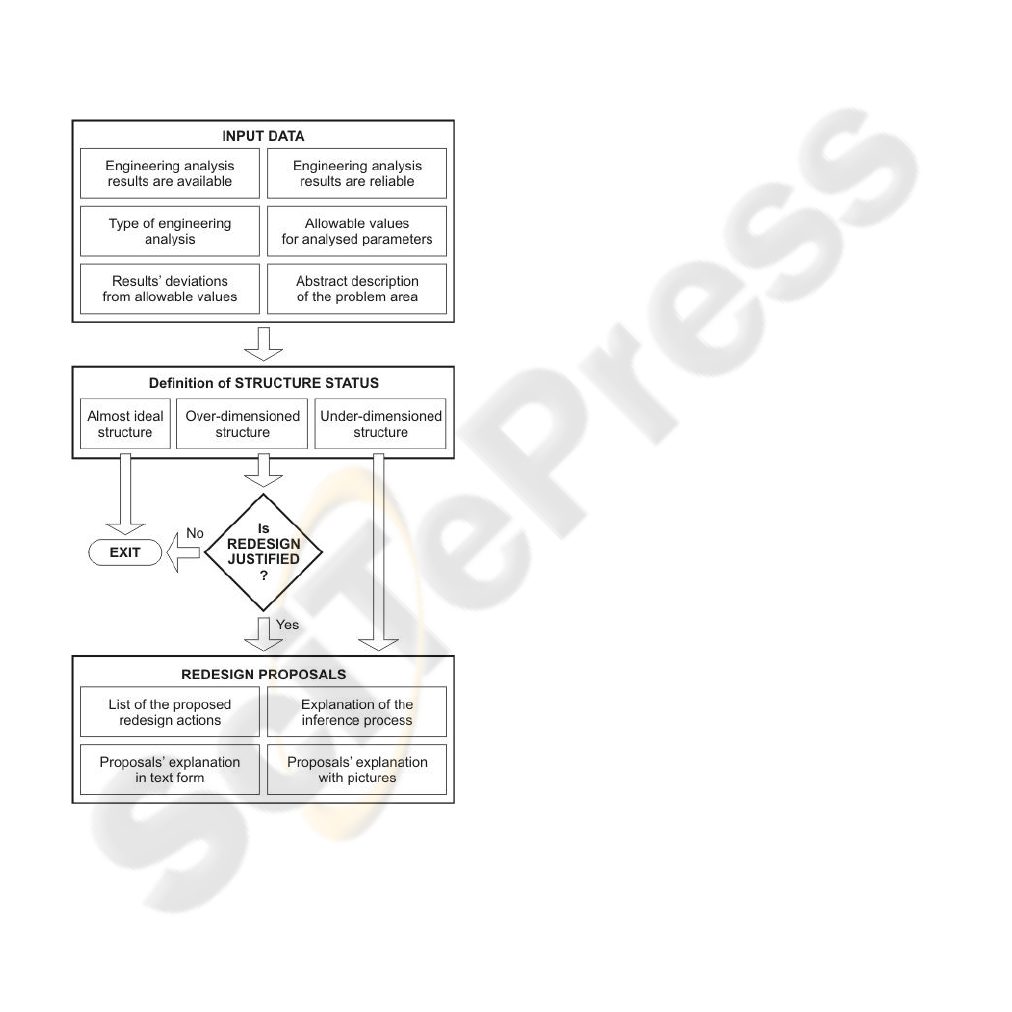

Figure 2: Basic architecture of the PROPOSE system.

2 ANALYSIS-BASED DESIGN

IMPROVEMENT

Design is iterative process. How many iteration

steps are needed directly depends on the quality of

the initial design and later design changes. Basic

parameters for design improvement process are

often the results of some engineering analyses. Post-

processing phase of the engineering analysis

represents a synthesis of the whole analysis and is

therefore of special importance. It concludes with

the final report of the analysis, where the results are

quantified and evaluated with respect to the next

design steps that have to follow the analysis in order

to find approved design solution. At this point, FEA

software offers an adequate computer graphics

KEOD 2009 - International Conference on Knowledge Engineering and Ontology Development

136

support in terms of reasonably clear pictures

showing a distribution of unknown parameters

inside the body of the structure. However, the user

still has to answer many questions and solve many

dilemmas in order to conclude the analysis and to

choose the appropriate redesign steps. Figure 1

shows basic algorithm that the design engineer have

to perform in analysis-based design improvement

process.

It is obvious the algorithm presented requires a

lot of knowledge and experience, not only in the

area of analysis itself, but also in design, giving the

word design its broadest meaning. Designer has to

be able to judge, whether the results of the analysis

are correct and reliable, and also to decide what kind

of design changes are needed, if any.

Many young inexperienced engineers need

intelligent advice to perform the analysis’ results

interpretation and consequent design improvement

process adequately. Unfortunately, this kind of help

still cannot be expected from the present FEA

software, as the traditional systems are rather

concentrated on numerical aspects of the analysis

and are not successful in integrating the numerical

parts with human expertise. Intelligent decision

support is required (Turban, Aronson and Liang,

2004).

3 PROPOSE – INTELLIGENT

DECISION SUPPORT SYSTEM

A prototype of the intelligent system named

PROPOSE, is being developed to support analysis-

based design improvement process (Novak and

Dolšak, 2008). PROPOSE provides a list of redesign

recommendations that should be considered to

improve the design candidate considering the results

of a prior analysis. As a rule, there are several

redesign steps possible for design improvement. The

selection of one or more redesign steps that should

be performed in a certain case depends on the

requirements, possibilities and also on wishes.

The most important part of the system is the

knowledge base. The theoretical and practical

knowledge about design and redesign actions are

presented within the system in form of production

rules.

As it can be seen in Figure 2, the knowledge

base of the system is consisted of many different

types of rules and facts that are necessary for the

system to be functional. For example, several rules

are needed just to define the status of the structure

(not stiff enough, under-dimensioned, over-

dimensioned or satisfactory). However, from the

technical point of view, the most important rules in

the knowledge base are those defining redesign

recommendations.

The system is encoded in Prolog that was chosen

because of its built-in features such as rule-based

programming, pattern matching and backtracking

(Bratko, 2000). Our work was concentrated on

declarative presentation of the knowledge, using

data–driven reasoning, which is built in Prolog.

However, some control procedures were also added

to the inference engine of the system to adjust the

performance to the real-life design process.

For the user interface, our goal was to simulate

the communication between the student and design

expert. As presented in Figure 2, the user interface

has many features including help, which enables the

efficient and user-friendly communication. It is

however evident that PROPOSE is a prototype,

which is still the subject of research and, as such,

cannot be compared with commercial software.

A detailed description of the system architecture

including all development phases can be found in

(Novak and Dolšak, 2008). Here we will concentrate

on some application characteristics of the system.

4 APPLICATION

OF THE PROPOSE SYSTEM

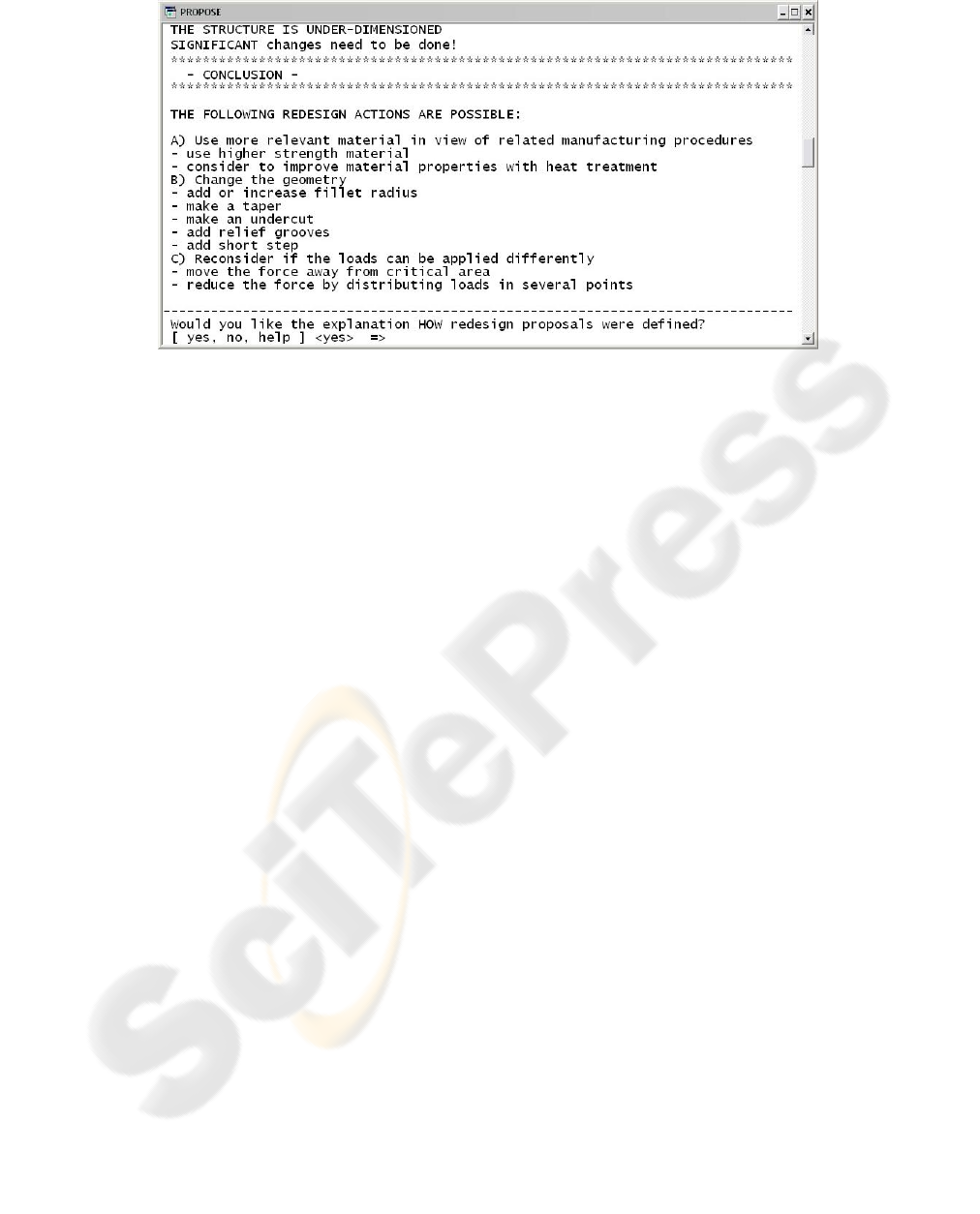

In order to use the system, the user simply needs to

run the executable file "PROPOSE.exe". The

execution starts with the system introduction

presented on the screen including some basic

information how to use the system. From that point,

the system leads the user from the specification of

the problem to the final conclusions and

recommendations for design improvement. The

actual data flow that is followed in the application

process is presented in Figure 3.

First, the user needs to present the qualitative

manner of the information about the results of the

engineering analysis: the results reliability, the type

of the engineering analysis (strain-stress or thermal

analysis), the results deviations from allowable

limits, the type of the structure and the abstract

description of the problem area. In case the problem

area can be described in different ways, it is

advisable to do so, as the system will be able to

propose more improvements that are possible.

Help is available through the whole data input

process. For every problem area, the system searches

INTELLIGENT SUPPORT TO ANALYSIS-BASED DESIGN IMPROVEMENT PROCESS - PROPOSE: An Intelligent

Consultative Advisory System

137

for the redesign recommendations in the knowledge

base. The results in form of the redesign

recommendations are written on the screen. The user

can also get insight into the inference process.

If required by the user, the system presents all

the steps that led to the final conclusion together

with the list of recommended design changes.

In addition to the explanation of the inference

process, the user can also get more information

about certain redesign proposals. This kind of

information is provided not only for the geometry

changes, but also to support the selection of more

relevant material. Redesign proposals are explained

with text or with pictorial examples. Some proposals

are explained in either ways.

Figure 3: Data flow of the PROPOSE system.

5 PRACTICAL EXAMPLES

In continuation, two design studies are briefly

presented to demonstrate the use of PROPOSE

system in practice. Complex, expensive and time

consuming analysis-based design improvement is

justified and makes sense when the product needs to

satisfy certain structural and other specific criteria.

Mass production where even small savings per

single product can lead to significant savings for the

whole production quantity is the other important

optimization criteria. Our first example is an ice axe

that has to fulfil very strict structural criteria, as the

life of the user depends on its strength. At the same

time the ice axe also needs to be as light as possible.

Our second example is an open-end spanner. It

belongs to the group of products that are produced in

big series, while structural criteria are also

prescribed in detail.

5.1 Ice Axe Design Optimization

Ice axe is special mountaineering equipment.

Considering the strength, two types of ice tools

exist. In the project presented here, the basic type

with lower strength for use in general circumstances

as on glacier for snow hiking, for ski mountaineering

etc., was a subject of consideration. The material of

the ice axe should be as light as possible, while at

the same time it has to ensure the strength and

toughness at low temperatures. There are several

static, dynamic and fatigue test methods and

requirements prescribed for the ice axe in special

standards (EN-13089 and UIAA-152).

The optimization of the ice axe design was

performed in step-by-step manner. First of all, a

simple initial design was made in geometric

modeller. This model and each consecutive design

candidate was then analyzed according to the tests

and requirements prescribed by the standard. After

every analysis, the PROPOSE system was applied to

get some recommendations for further design

improvements (Kurnik and Zerdin, 2007). Figure 4

presents an example of the recommendations

provided by the PROPOSE system.

In process of improving the ice axe design all

three possible types of design changes (A, B and C)

were made. The first FEA results for the axe “made”

entirely from aluminium alloy clearly shown, that

the pick of the axe is not strong enough. As a

consequence, it was decided to design the axe as a

combination of the steel pick and aluminium shaft

(change type A). The position of the juncture

between both parts of the axe was chosen carefully

to move the force from the critical cross-section area

(change type C). However, most of the changes

addressed the geometric appearance of the axe

(changes type B). In earlier design optimization

phases, geometry was changed in order to improve

KEOD 2009 - International Conference on Knowledge Engineering and Ontology Development

138

Figure 7: The execution of the proposed design change.

The functionality of the spanner remains

unchanged, while material use and consequently the

weight are reduced. Thus, analysis-based design

optimization supported by intelligent advisory tool

has proved to be successful again.

6 CONCLUSIONS

Structural analysis-based design optimization is a

part of development process for many products.

When numerical part of the engineering analysis is

finished, designer has to be able to judge, whether

the results of the analysis are correct and reliable,

and decide what kind of design changes are needed,

if any. Most of design engineers need “intelligent”

advice to perform results interpretation adequately

(Pinfold and Chapman, 2004). Unfortunately, this

kind of help cannot be expected from the present

software. For this reason, many research activities

are oriented in making analysis-based design

optimization process more intelligent and less

experience-dependent (Chapman and Pinfold, 2001).

In this paper an intelligent aid for analysis

results’ interpretation is presented in form of the

intelligent consultative advisory system, which

provides a list of redesign recommendations that

should be considered to optimize a certain critical

area within the structure, considering the results of a

prior stress/strain or thermal analysis.

The user has to define design problem and

present the results of the engineering analysis. In

addition, critical areas within the structure need to be

qualitatively described to the system. These input

data are then compared with the rules in the

knowledge base and the most appropriate redesign

changes are determined and recommended to the

user. The abstract description of the problem area

should be as common as possible to cover the

majority of the problem areas, instead of addressing

only very specific products.

In cases when the problem area can be described

to the system in different ways, it is advisable to run

the system several times, every time with different

description. Thus, the system will be able to propose

more design actions, at the expense of only a few

more minutes at the console.

Some experts individually evaluated the system

from two points of view. Firstly, they tested and

evaluated the user interface of the system by

inspecting how well the system helps and guides the

user, or even enables him or her to acquire some

new knowledge. Secondly, they analysed the

performance of the system on some real-life

examples. They evaluated the suitability, clearness

and sufficiency of the recommended design changes.

They all shared general opinion that the PROPOSE

system is an effective tool, which provides useful

guidance for further design steps. All comments,

critiques and suggestions presented by the experts

were taken into consideration and resulted into

numerous corrections and adjustments of the system.

REFERENCES

Bratko I., 2000. Prolog: Programming for Artificial

Intelligence, Addison-Wesley. 3rd edition.

Chapman C., Pinfold M., 2001. The application of a

knowledge based engineering approach to the rapid

design and analysis of an automotive structure. In

Advances in Engineering Software, 32, 903-912.

EN-13089 and UIAA-152. Ice Tools (Axes and Hammers).

Kurnik R., Zerdin D., 2007. Analysis-based design

optimization using intelligent advisory system

PROPOSE. Seminar work for the subject: Intelligent

CAD systems, Faculty of Mechanical Engineering,

University of Maribor.

McMahon C., Browne J., 1999. CADCAM: Principles,

Practice and Manufacturing Management, Prentice

Hall. 2nd edition.

Novak M., Dolšak B., 2008. Intelligent FEA-based Design

Improvement. In Engineering Applications of

Artificial Intelligence, 21, 1239-1254.

Pinfold M., Chapman C., 2004. Using knowledge based

engineering to automate the post-processing of FEA

results. In International Journal Computer

Applications in Technology, 21, 99-106.

Podpecan A., 2009. Applying PROPOSE system for open-

end spanner design optimization. Seminar work for the

subject: Intelligent CAD systems, Faculty of

Mechanical Engineering, University of Maribor.

Turban E., Aronson J.E., Liang T.P., 2004. Decision

Support Systems and Intelligent Systems, Prentice

Hall. 7th edition.

Zienkiewicz O.C., Taylor R.L., Shu J.Z., 2005. The Finite

Element Method: Its Basis and Fundamentals,

Butterworth-Heinemann. 6th edition.

KEOD 2009 - International Conference on Knowledge Engineering and Ontology Development

140