AN APPROACH TO SUPPORT INTERDISCIPLINARY VARIANT

DIVERSITY OPTIMIZATION

Planning Variant Diversity – Beyond Complexity Reduction

Reiner Anderl, Sebastian Maltzahn and Daniel Spieß

Fachgebiet Datenverarbeitung in der Konstruktion (Computer Integrated Design), Technische Universität Darmstadt

Petersenstraße 30, 64287 Darmstadt, Germany

Keywords: Variant diversity, Variant decision, Planning diversity, Decision support.

Abstract: The increasing number of variants in manufacturing companies’ product ranges leads to rising costs due to

process and product complexity. The expected profit of higher diversity is often overrated while its costs are

underestimated because of missing methods and insufficient process transparency. This paper introduces a

methodical approach to identify the optimal diversity considering available capacities and the effects on

profit and costs for each variant to support variant decisions within the product and process planning.

Therefore a mathematical model of the described diversity planning problem is developed. This complex

decision problem is solved using a particle swarm algorithm, which is able to compute the optimal solution

within reasonable time. The found solutions can be discussed and evaluated by an interdisciplinary planning

team considering even qualitative aspects, leading to an increased transparency in the decision process.

1 INTRODUCTION

Manufacturing companies have to take great

challenges in a globalized competitive environment.

To face these challenges most European companies

follow the strategy of differentiation to improve their

competitive situation. This differentiation strategy

leads to greater variant diversity in the companies’

product ranges. Higher diversity causes higher

complexity in involved business and manufacturing

processes due to the increasing number of different

items which are to be handled. Furthermore national

norms, standards and laws, as well as differentiated

customer requirements enforce globally operating

companies to develop country-specific product

variants.

On the one hand companies benefit from variant

diversity because of increasing sales. On the other

hand increasing diversity means more complexity in

all business and manufacturing processes.

Complexity in turn leads to increasing costs because

the capacity of each involved department has to be

expanded. These costs rise exponentially with

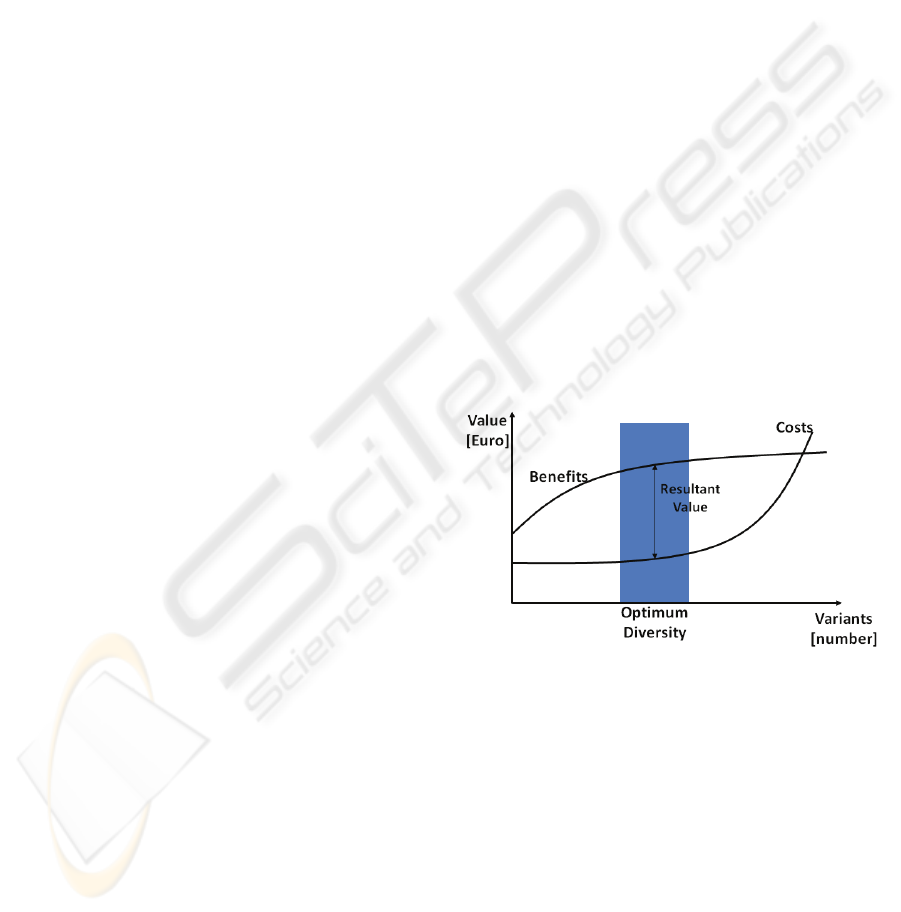

increasing variant diversity. In contrast, benefits

have a concave development (Alders, 2006).

Figure 1: Optimum diversity regarding benefits and costs.

Figure 1 shows that the optimal diversity lies in

between the two extrema of very high and very low

variant diversity. In fact the optimum diversity is

characterized by the maximum difference between

benefits and costs. Finding this maximum resultant

value is a typical decision problem. In the following

we characterize this problem in the context of an

interdisciplinary product planning process. Our

approach is to support this decision process with the

methods of Operations Research. For this purpose

we describe the problem mathematically and will

show that solving this mathematical problem with

408

Anderl R., Maltzahn S. and Spieß D. (2009).

AN APPROACH TO SUPPORT INTERDISCIPLINARY VARIANT DIVERSITY OPTIMIZATION - Planning Variant Diversity – Beyond Complexity

Reduction.

In Proceedings of the International Conference on Knowledge Engineering and Ontology Development, pages 408-411

DOI: 10.5220/0002295404080411

Copyright

c

SciTePress

the help of a particle swarm algorithm promotes the

optimal decision under given constraints.

2 PROBLEM DESCRIPTION

Variant decisions are the result of a multilevel

problem solving process (Heina, 1999). First of all

the sales department performs a market analysis to

identify customer needs. Taking into account the

sales volume of previous products and forecasts for

the new product, the sales department proposes

different “variant scenarios” (Alders, 2006). Though

these scenarios imply a combination of different

product variants they often have the same diversity.

These scenarios are then analysed and evaluated by

an interdisciplinary team in terms of profits and

costs. This process may take up to one week for only

one part or assembly. It is assumed that most of the

time is wasted with recurring discussions about

capacities and costs (Alders, 2006).

The variant decision process is often dominated by

the sales department because of their knowledge

about markets and customer demands. The sales

department benefits from higher product diversity

through increasing volumes but does not bear the

costs of the increasing process complexity, like for

example the departments of production and logistics.

This is the reason why benefits of additional variants

are often overrated while their impact on process

complexity and costs is underestimated

(Rathnow, 1993).

Moreover, as human capacity is limited, only a

few alternative scenarios can be analysed. It is

unlikely that the optimal solution is one of these.As

a result, this process tends to expand production

capacities and human resources instead of

questioning the demand for a variant.

In the following we introduce an approach to

solve these problems with the help of a decision

support system.

3 SUPPORTING

INTERDISCIPLINARY

VARIANT DECISIONS

Our approach is based on the variant decision

process described in section 2. To avoid recurring

discussions about capacities and costs we propose to

support this decision process by a decision support

system (DSS). This system analyses and evaluates

the whole solution space of the variant decision

problem simultaneously, instead of discussing three

or four “scenarios” sequentially. The required data,

profits and costs are still forecasted by the experts of

each department (cf. section 2). Based on this data

we introduce the Interdisciplinary Variant

Optimization Model IVOM. This mathematical

description of the variant decision problem allows

computing the optimal diversity considering all

effects on business profits and given capacity

constraints.

Decision problems are represented

mathematically by optimization models. They

consist of an objective function

which has to

be minimized or maximized and one or more

constraints which define the possible solution

space of that particular problem either by equations

or inequations.

(1)

,

,

;

(2)

Based on this general optimization model we

define the Interdisciplinary Variant Optimization

Model IVOM as a specialized knapsack problem.

3.1 The Interdisciplinary Variant

Optimization Model (IVOM)

IVOM represents the variant decision problem

described in section 2. The objective of the variant

decision problem is the identification of the

optimum diversity given by the maximum difference

of profits and costs. According to formula (1) the

objective function of IVOM is

(3)

Where x is a binary variable to decide whether

variant j=1,...,n is selected or not. The resultant

value of a variant is given by the difference of its

profit n and its costs c (cf. Figure 1):

; (4)

The indices i and j specify that variant j causes

costs in the departments i=1,...,m.

At first, we want to define the optimum diversity

for the given capacities. In a second step one could

discuss the expansion of specific capacities

AN APPROACH TO SUPPORT INTERDISCIPLINARY VARIANT DIVERSITY OPTIMIZATION - Planning Variant

Diversity - Beyond Complexity Reduction

409

considering this method’s results. The given

capacities of the involved departments are

represented by constraints in the form of

inequations. In general, a constraint for a capacity

l=1,...,u is defined as shown in formula (5).

(5)

K is the limit of capacity l. The variant j exploits

units of capacity l. We call the capacity driver

of variant j. This inequation assures that the chosen

variants (x=1) do not exceed the capacity limit.

Inequations can be defined by the experts of each

department for all kinds of limited capacity

(e.g. storage capacity, machine time). To enhance

transparency, the data and the capacity constraints

should be published. The constraint that affects all

involved business processes is human ressource.

Hence, we introduce the manpower-constraint

exemplarily.

Increasing diversity strains human resources.

That is why the given manpower resources are a

very important constraint.

The mathematical definition of the manpower-

constraint is defined as follows:

_

_

(6)

For human resources both, time and transaction

drivers can be taken into account:

and

.

Normally a work step is characterized by the time

that is needed to accomplish it. Sometimes,

especially for administrative tasks, this cannot be

detected separately. A time lump-sum per

transaction is needed. Potential units for the capacity

drivers as well as the capacity limit K are man-day,

man-month or man-year.

In the same manner we defined transaction and

stock constraints for the purchasing and logistics

department. A special stock constraint for the

production area considers the limited space for

different variants in an assembly area to avoid

special picking areas:

·

(7)

For assembling, variant j is provided in a

standard box that occupies the space d. In

conjunction with the number of boxes (z) that have

to be provided for variant j and the total space

available K, this constraint assures that the

production area does not need cost-intensive picking

areas.

And finally we defined a production constraint to

take machine hours and set-up time into account.

Many more are imaginable for different problems.

3.2 Solving IVOM

At this stage the variant decision problem is split and

formulated in the objective function and the

constraining inequations. In the next step the

described model of the variant decision problem has

to be solved by an applicable algorithm.

Algorithms were developed for different types of

problems. First of all we have to characterize IVOM

as a specific problem type. Secondly we select one

of the possible algorithms for this type of problem

that promises the best and efficient solution.

The variant decision problem as it is represented

by IVOM is a special knapsack problem. It has more

than one constraint; strictly it might have multiple

constraints for every department and all kinds of

capacities. This type of problem is called a

multidimensional knapsack problem

(Kellerer, 2004).

Concerning its computing time, a study by

Kennedy and Spears (Kennedy, 1998) came to the

conclusion that particle swarm algorithms are most

suitable for complex multidimensional binary

problems. Hence, to find the optimum solution of

IVOM we used a particle swarm algorithm.

3.3 Qualitative Aspects of the Variant

Decision

After IVOM is properly defined for a given variant

decision problem the swarm algorithm is able to

identify its optimal solution. The found quantitative

optimal solution might be in conflict with qualitative

constraints, e.g. the brand image.

The proceeding of the particle swarm algorithm

allows saving several very good solutions, delivering

optimal valid solutions within the defined constrains.

In every step of the algorithm the best position of

each particle is saved. This arises the opportunity to

add a qualitative analysis made by the

interdisciplinary team after the algorithm identified a

set of the best solutions, giving optimal decision

support.

3.4 Decision Support through IVOM

The result of the IVOM approach is a list, consisting

of all valid, optimum solutions found by the particle

KEOD 2009 - International Conference on Knowledge Engineering and Ontology Development

410

swarm algorithm. Every solution is described by its

values for the parameters and the objective function,

which were calculated by the swarm particle at its

position in the solution space. For each solution the

consequences for the company, explicit the benefits,

the costs and needed resources in general can be

calculated. The list can be used to discuss all options

by the decision team, to consider undefined

constraints like e.g. corporate strategy.

4 CONCLUSIONS

Current strategies of complexity reduction and

complexity control are time consuming, recurring

and often do not take all major constraints into

account. Especially in interdisciplinary teams the

team members trade for their own account with their

own perception of possible solutions (e.g. the sales

department). Finding the optimal diversity is a key

factor for success for manufacturing companies in

today’s globalized competitive market. We achieve

this by substituting sales department’s perception by

an impartial algorithm, based on interdisciplinary

expert knowledge. The optimal solution for a

company as a whole can be identified. Preventing

complexity by planning variant diversity in early

development phases of a product has the potential to

design future product lifecycles much more efficient.

It allows concentrating on the optimal variants,

rather then spending much time and assets in the

development and sale of barely demanded variants.

In this paper we presented the mathematical

concept, we called “Interdisciplinary Variant

Optimization Model” (IVOM), to define given

constraints in diversity problem discussions, as well

as the definition of an objective function which

allows computing the optimal diversity considering

all effects on business profits and costs. The

proposed particle swarm algorithm is capable not

only to find the best solution, but even computes and

stores local optima and delivers multiple very good

solutions. These can be discussed in interdisciplinary

decision teams, concerning even qualitative aspects.

IVOM has a major impact on decision making

processes to find optimal diversity and thus reducing

complexity within the whole product lifecycle. It

deliveres qualitative solutions within the solution

space in reasonable time and highly supports

decision discussions, allowing to elaborate the

consequences of the expansion of capacities or the

cancellation of a product variant.

REFERENCES

Alders, K., 2006. Komplexitäts- und

Variantenmanagement der AUDI AG. In: Lindemann,

U.; Reichwald, R.; Zäh M.F.(Ed.): Individualisierte

Produkte - Komplexität beherrschen in Entwicklung

und Produktion. Springer Berlin et al.

Rathnow, P., 1993. Integriertes Variantenmanagement:

Bestimmung, Realisierung und Sicherung der

optimalen Produktvielfalt. Vandenhoek und Ruprecht

Göttingen.

Heina, J., 1999. Variantenmanagement - Kosten-Nutzen-

Bewertung zur Optimierung der Variantenvielfalt.

Gabler Wiesbaden.

Kellerer, H., Pferschy, U., Pisinger, D., 2004. Knapsack

Problems. Springer Berlin et al.

Kennedy, J., Spears, W. M., 1998. Matching algorithms to

problems - an experimental test of the particle swarm

and some genetic algorithms on the multimodal

problem generator. In: Proceedings of the IEEE

international conference on evolutionary computation.

AN APPROACH TO SUPPORT INTERDISCIPLINARY VARIANT DIVERSITY OPTIMIZATION - Planning Variant

Diversity - Beyond Complexity Reduction

411