ONTOLOGY DEVELOPMENT FOR MODEL-DRIVEN DESIGN

IN KNOWLEDGE BASED ENGINEERING

Stefan van der Elst and Michel van Tooren

Design of Aircraft and Rotorcraft, Delft University of Technology, Kluyverweg 1, 2629 HS Delft, The Netherlands

Keywords: Knowledge Based Engineering, Knowledge base, Ontology development, Routine design, Design

automation, Assignment problem, Wire harness design.

Abstract: Knowledge is a vital component of engineering design. Computer systems enriched with logic and

engineering knowledge can support engineering design by automating routine configuration design

processes. This automation is well structured in the framework concept of a Design and Engineering

Engine, applying Knowledge Based Engineering techniques. The lack of recognized development

methodologies implies significant investments for the development and maintenance of Design and

Engineering Engines. To alleviate the required effort an ontology for engineering knowledge is being

developed. To that end, a classification of configuration design processes is proposed as well as a

classification of knowledge elements. The resulting knowledge repository can be considered a Domain

Specific modelling Language. To validate the proposed ontology, a case study is presented, addressing an

assignment problem in the field of wire harness design. Using the Domain Specific modelling Language, the

source code for the product model can be generated automatically using a model-driven approach.

1 INTRODUCTION

Modern-day market dynamics and the current

economic climate require an increasing industrial

focus on lifetime cost reduction, shorter time-to-

market and greater product differentiation. In order

to achieve the associated improvement in product

development and remain competitive in a globalized

market, the engineering industry needs more cutting

edge productivity enhancements.

While the continuous improvement of the

production process by the application of lean

principles is making good progress, the increase of

the effectiveness and efficiency of the engineering

processes by adopting lean principles is still in its

infancy. The next step in the efficiency increase is to

reuse corporate engineering knowledge to a larger

extent (Drucker, 2001) (Quinn, 1992) .

Knowledge is a vital component of engineering

design and significant reductions in costs and

product development time can be realized if

engineering knowledge would be reused to a larger

extent and more often. Where previously the

geometric model took a central position in product

development, today design knowledge should have

the focus: human intellect should be managed and

engineered as a key business asset (Drucker, 2001).

Computer systems enriched with logic and

engineering knowledge can support engineering by

automating repetitive and time-consuming routine

design processes. This reuse of knowledge decreases

the intellectual resources required during product

development processes and relieves engineers from

repetitive and tedious design activities, making more

time available to exploit their creativity and

engineering skills. Knowledge Based Engineering

(KBE) is known as the cross product of engineering

and Knowledge Based Systems (KBS) and enables

this automation of routine engineering design

processes (La Rocca, 2002). By defining parametric

generative models of systems, KBE enables

designers to explore the design space more

efficiently by automatically generating and

analyzing new design configurations and instances.

Although huge time and cost benefits can be

gained, KBE techniques are not yet widely adopted

by industry. Efficient utilisation of knowledge in

software implies significant investments for the

development and support of KBE applications due to

a lack of acknowledged methodologies. In addition,

developed applications are frequently considered

261

van der Elst S. and van Tooren M. (2009).

ONTOLOGY DEVELOPMENT FOR MODEL-DRIVEN DESIGN IN KNOWLEDGE BASED ENGINEERING.

In Proceedings of the International Conference on Knowledge Engineering and Ontology Development, pages 261-268

DOI: 10.5220/0002305102610268

Copyright

c

SciTePress

‘black boxes’, since the applied methods are poorly

documented and the source code is inexpressive.

This has a negative effect on the maintainability and

the extendibility of such applications.

In this paper an ontology, a structure of the

existing knowledge categories and their relations, is

proposed to support the implementation of a second

generation KBE systems in industry. The ontology

for engineering knowledge is geared towards routine

design processes. It entails a categorisation of

knowledge elements into product versus process

knowledge and domain-specific versus problem-

specific knowledge. The proposed ontology aims to

achieve better use of intellectual human resources as

tangible asset: it enables the reuse of domain

knowledge across multiple design problems as well

as sharing problem related knowledge across

multiple application fields. Repositories of

knowledge based on the proposed ontology provide

a platform to rapidly develop design models for

KBE applications, reusing the knowledge already

captured and formalised.

2 ENGINEERING DESIGN

Engineering design can be considered a deliberate

search problem in a solution space for artefacts that

satisfy functional needs within a set of constraints.

The solution space or design space can be

considered a range of available components and a

set of relations between those components in order

to form artefacts. Although the solution space can

encompass an infinite number of solutions, in

general only a small number of artefacts form

feasible and satisfying, not to mention optimal,

solutions. Such a solution to the design problem

entails a collection of components and their

relations, that together provide a complete

specification of the system that delivers the

requested functions and satisfies the constraints

(Chandrasekaran, 1990).

2.1 Design Problem Categorisation

Design problem solving can be divided into routine

and non-routine design activities, based on the

identification and availability of the knowledge

involved in the design process. Brown and

Chandrasekaran identified three classes of design,

related to the level of ‘routineness’ (Brown, 1989):

For the first class, Class 1 Design, neither all

possible decompositions of the artefact nor the

approach to solve the design problem is

known in advance.

For Class 2 Design, the possible

configurations and components are known,

however the problem solving strategy is not.

For the third class, Class 3 Design, all possible

configurations, components and design

variables are known. Furthermore, the

problem solving approach is acknowledged,

resulting in the availability of so-called design

plans.

The three abovementioned classes of design

correspond to the general acknowledged categories

of design into routine design, innovative design and

creative design as introduced by Gero (Gero, 1993).

Here, routine design concern designs that fit within

the space of previous solutions. Therefore in routine

design the components and their variables, the

constraints for those variables and the type of

requirements are known in advance. Innovative

designs are based on known design options, however

the applicable range of values for the variables is

extended. Creative design involves the definition of

new components, variables or relations between

components. Here, neither all components nor the

problem solving strategy is known in advance.

Innovative and creative design together make up the

non-routine design problems. Typically, a

development process for a new product will

encompass routine, innovative and creative design

activities. The remainder of this paper will focus on

routine design problems.

2.2 Routine Design Problems

Judged by the type of components and the assembly

of the artefact, different dimensions of routine

design problems can be distinguished (Wielinga,

1997). Figure 1 summarizes the most common types

of routine design problems. It should not be

considered an attempt to provide a comprehensive

overview of all routine design problems.

Starting with the most basic form of routine

design, verification problems aim to confirm the

validity of a synthesized artefact, where both the

assembly as well as the components are predefined.

Assignment problems deal with matching sets of

resources (components in product design) with a

fixed collection of subjects, defined as the assembly

outline or skeleton. Example problems are the

assignment of airplanes to terminal gates or the

assigned queuing of travellers at airport security

gates. Lay-out design or scheduling problems also

involve fixed sets of components, but the outline nor

composition of the artefact is known in advance. An

example is the arrangement of machines for a

factory layout. Parametric design assumes a

KEOD 2009 - International Conference on Knowledge Engineering and Ontology Development

262

predefined assembly and is concerned with the

assignment of values to component parameters in

order to meet the requirements. An example is the

sizing of an structural beam according to a static

load case. Skeletal design is concerned with a

continuous solution space and involves the matching

of parametric components to a given assembly.

Finally, configuration design involves the assembly

of an undetermined set of parametric components to

meet a set of requirements. An example problem is

the design of an aircraft wing, where the

composition as well as the values for the parameters

belonging to the different components shall be

determined (e.g. material, number of ribs and

thickness of the spar web).

Configuration design is closest to non-routine

design problems and differs from innovative design

by the constrained values ranges for the design

parameters for which the problem solving strategy

holds.

The provided types of design problems are listed

in order of increasing complexity. Both the amount

of applicable components and the collection of

settable parameters add to the degrees of freedom of

the assembly enlarging the valid solution space.

Since the approach, the components and the

requirements are known for routine design problems

they are particularly well suited for design

automation using KBE techniques (Chandrasekaran,

1990).

3 KNOWLEDGE BASED

ENGINEERING

According to La Rocca (Milton, 2008) KBE

concerns the development of software systems to

support engineers, usually design engineers, to

increase their productivity. KBE systems are

considered a subset of Knowledge Based Systems or

Expert Systems dedicated to engineering design and

therefore empowered with Computer Aided Design

(CAD) capabilities. The KBE cornerstones are

considered to be rule-based design, object-oriented

programming, and parametric CAD (La Rocca,

2005). KBE systems are able to capture and reuse

engineering product and process knowledge to

automatically solve engineering design problems

involving the manipulation of geometry, product

configuration and analyses and computations.

The main objective of KBE is reducing time and

cost in product development by means of the

following:

Automation of recurring and routine

engineering design activities. This mainly

involves the automation of the preceding

routine design problems for which all related

knowledge can be captured and formalised.

Due to the nature of product development, it

best suits detailed design.

Support and integration of multidisciplinary

design and optimisation problems. It

facilitates innovative and creative design since

it concerns the definition of new components,

design parameters and configurations in order

to create novel solutions and investigate

multiple ‘what-if’ scenarios. It mainly applies

to the conceptual and preliminary phases of

the design process.

The automation of engineering design problems

is well structured using the framework concept of a

Design and Engineering Engine.

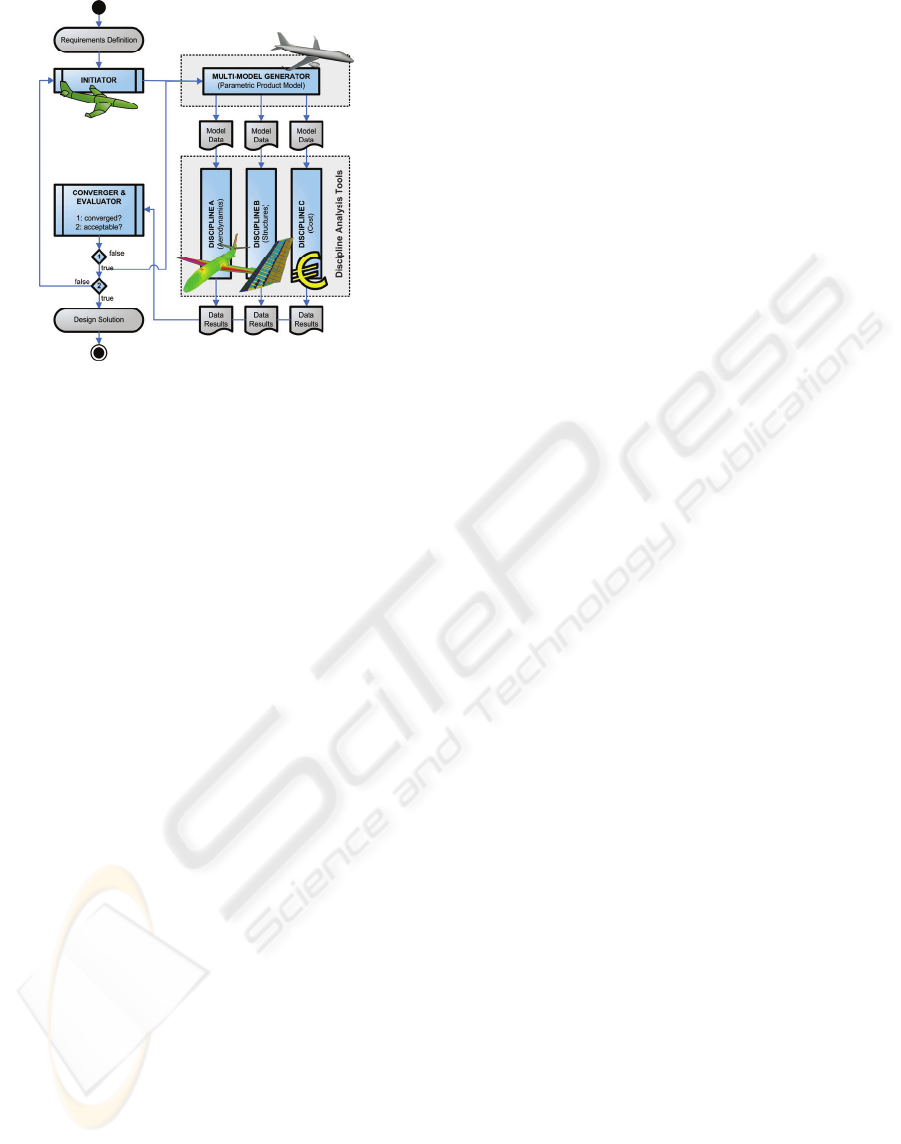

3.1 Design and Engineering Engine

A Design and Engineering Engine (DEE) is defined

as an advanced design environment that supports

and accelerates the design process of

multidisciplinary product families through the

automation of routine and recurring design activities

(La Rocca, 2002). Figure 2 shows a schematic

drawing of the DEE concept for the aerospace

sector.

The main components of the DEE are the

Initiator, the Multi-Model Generator, the Analysis

tools and the Converger & Evaluator.

Figure 1: The dimensions of components and assembly drive the different types of routine design.

ONTOLOGY DEVELOPMENT FOR MODEL-DRIVEN DESIGN IN KNOWLEDGE BASED ENGINEERING

263

Figure 2: The Design and Engineering Engine concept.

The Initiator is responsible for providing feasible

initial values for the design parameters in order to

instantiate the generative product model.

The Multi-Model Generator (MMG) is

responsible for instantiation of the generative

product model and extracts different views on the

model to facilitate the discipline specialist tools. The

MMG is where the KBE cornerstones object-

oriented programming, parametric CAD and rule-

based design are encapsulated. It forms the heart of

the DEE.

The Analysis (discipline specialist) tools are

responsible for evaluating one or several aspects of

the design in their domain or discipline (e.g.

structural response, cost or manufacturability).

The Converger & Evaluator is responsible for

checking convergence of the design solution,

compliance of the system’s properties with the

requirements and generation of a new design vector.

The framework concept of the DEE provides

engineers with a guided control mechanism to search

the solution space. The elements of the DEE are

addressed iteratively in order to define a feasible

design solution satisfying the requirements

definition. To that purpose, the framework also

offers communication capabilities through the

coupling of software agents using a Multi-Agent

Task Environment (Berends, 2008).

3.2 Multi-Model Generator

Design engineers like to think of a system or artefact

as a collection of components providing conceptual

solutions to fulfil functional requirements. To

support engineers in their perspective of design the

MMG provides a catalogue of parametric building

blocks, called High Level Primitives (HLPs) (La

Rocca, 2005). They represent classes of components

containing product related knowledge that drives the

instantiation of individual components by assigning

values to the parameters. The HLPs can be

individually sized and assembled to compose a large

number of different product configurations.

Therefore an assembly of HLPs can be considered a

generative product model, capable of generating

parametric geometric representations for families of

products with a similar composition. Next to the

HLPs Capability modules (CMs) form the other

main element in the MMG. CMs are ‘report writers’

applied to generate specific aspect views of a

system, e.g. an aerodynamic mesh or a Finite

Element model of an aircraft wing. The CMs

facilitate the analysis tools representing the various

engineering disciplines.

Consequently, the concept of the MMG supports

a modular approach to engineering design problems

and offers the designers a more effective approach to

visualize their ideas, compared to the approach

offered by conventional CAD systems. The HLPs

are considered principal elements storing

engineering knowledge. Instead of geometric

primitives incorporated by CAD systems, the MMG

is oriented to knowledge primitives.

4 DESIGN KNOWLEDGE

Knowledge is defined as the state of knowing about

a particular fact or situation and how to act

accordingly (Hornby, 2000). Most engineering

knowledge is not an explicitly and consistently

defined collective, but instead is concealed in the

processes, products, language and human specialists

themselves which define the local engineering

practices. This expertise should be transformed into

a well-defined body of knowledge suitable for

encoding into High Level Primitives and utilisation

in KBE systems.

When developing intelligent systems, the

developers or knowledge engineers should have a

good understanding of the various types of relevant

knowledge and representation techniques that suit

the application. Knowledge can be organised in

many different ways, not one of them being a

supreme theory that addresses the management of all

human intellect. Before engineering knowledge can

be utilised in KBE systems, it is therefore important

to get a thorough and formal description of the

knowledge involved.

4.1 Knowledge Base

In order to support the reuse of engineering

knowledge by KBE techniques, knowledge is

KEOD 2009 - International Conference on Knowledge Engineering and Ontology Development

264

initially captured and stored in a knowledge base, a

repository containing a formal description of

knowledge representing the expertise of a particular

domain (Milton, 2008). A knowledge base has

multiple main functions. In order to alleviate the

effort involved in developing KBE applications the

knowledge should be intelligible to both engineers

and software agents. It should therefore incorporate

two different perspectives on the design process:

Provide a comprehensive overview of the

routine design process (IST);

Provide insight in and understanding of the

KBE application and applied methods (SOL).

The anatomy of a knowledge base is identical to

the structures that underlie human expertise or

psychological registration. Psychologists have found

that this is based on four main elements;

components, attributes, values and relations (Milton,

2008). According to the Methodology and tools

Oriented to KBE Applications (MOKA) a

knowledge base should contain two primary types of

diagrams to visualise these knowledge components

(Stokes, 2001); process models and product models.

The process model is a process flow chart or activity

diagram. The process model focuses on the activities

performed by actors and is oriented to the ‘input-

behaviour-output’ perspective. It mainly contains

procedural knowledge. The product model is

considered a composition tree. It is a product-centric

and object-oriented model providing a hierarchical

decomposition of the system into subassemblies and

components. It is oriented to the ‘object-relation-

object’ perspective and mainly contains conceptual

knowledge.

Using both types of diagrams, two distinct

segments of the knowledge base can be built. This

partition complies with the contrasting perspectives

(IST and SOL). The segments are referred to as the

informal model and the formal model.

The informal model is used to capture and

validate the knowledge in close corporation with the

domain experts. The engineering knowledge is

represented using natural language, terminology

from the domain under consideration and pre-

defined forms. The informal model acts as an

analysis instrument, developed to obtain

understanding of the domain. The objective of the

informal part of the knowledge base is to verify the

correctness and completeness of the knowledge

involved in the routine design process. The concepts

in the domain of interest are organized without any

consideration of their role in the KBE application.

The formal model provides a more formal view of

the problem geared towards the involved knowledge

engineers, developers and software agents. The

formal model acts as blueprint for the design of the

KBE application and uses the elements of the

informal model to define reusable building blocks

representing predeveloped modules of knowledge.

The elements of the formal model form a

specification for the software classes that

encapsulate the engineering knowledge in the DEE.

These elements are indeed the HLPs, specified and

assembled to represent the generative product model

of the MMG. Frame representations are used to

define the characteristic attributes and specify their

values or parameters. Besides, CMs are defined in

accordance with the process flow description of the

informal model. The formal model will also define

the type of routine design problem and the

appropriate Problem Solving Method (PSM),

algorithm and optimisation criteria. The source code

for the DEE can be designed based on the formal

model and the model will provide insight in the

composition of and reasoning behind the software

(Larman, 2005) (Evans, 2000).

The different perspectives for the informal and

formal model of the knowledge base require

different structures. Whereas there are several

ontologies to capture engineering knowledge in

general, ontologies specifically built to develop KBE

applications using a model-driven approach are yet

to be determined. Such an ontology is proposed in

the next section. The structures of the informal and

the formal model are sketched in Figure 3.

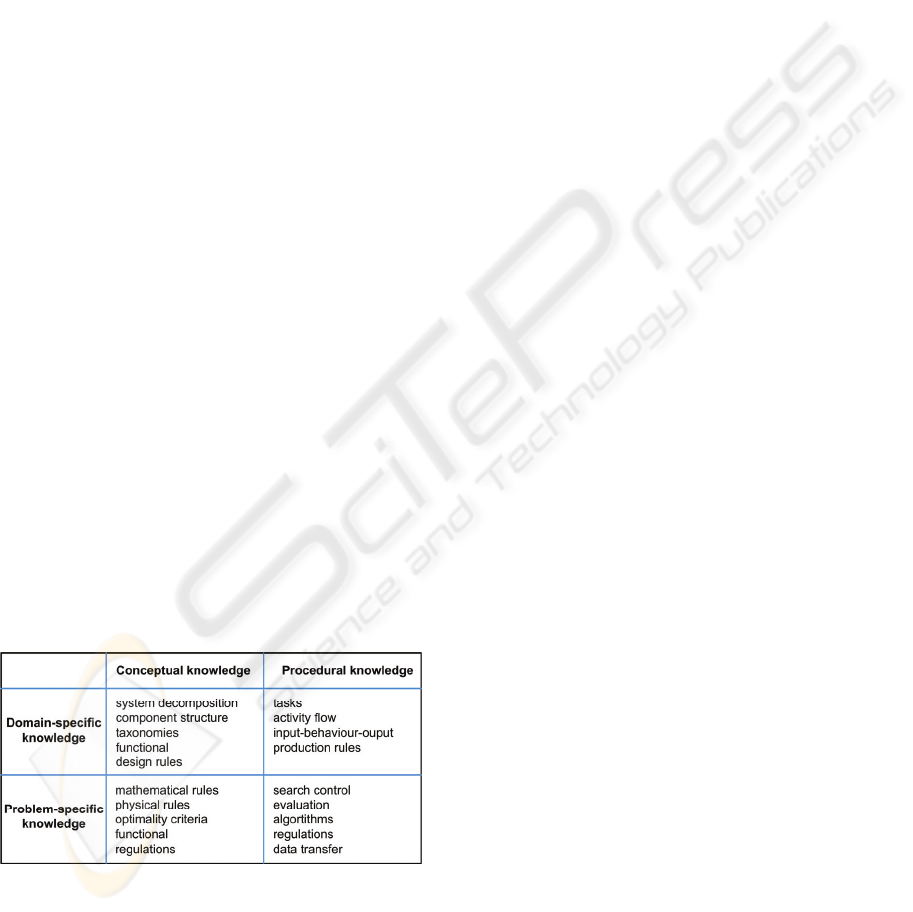

4.2 Ontology Proposition for KBE

In order to organise a body of knowledge for

utilisation in KBE applications, an ontology, an

armature of the existing knowledge categories and

their relations within a domain, is proposed. It is

based on two orthogonal categories of knowledge.

The first category defines procedural knowledge

versus conceptual knowledge (Stokes, 2001).

Figure 3: Schematic overview of knowledge base with

two-fold structure.

ONTOLOGY DEVELOPMENT FOR MODEL-DRIVEN DESIGN IN KNOWLEDGE BASED ENGINEERING

265

Procedural knowledge concerns processes, tasks and

activities. It describes the conditions, under which

specific tasks are performed, the order in which

tasks are performed and the resources required to

perform tasks. Conceptual knowledge or declarative

knowledge concerns the description of concepts or

components, their relation to one another and their

properties, e.g. the attributes and parameters.

The second category of knowledge distinguishes

problem-solving or problem-specific knowledge

from domain-specific knowledge. Problem-solving

knowledge specifies how to use the factual

knowledge about a domain to construct a solution to

the problem (Chandrasekaran, 1997). Considering

routine design problems, the problem solving

knowledge might concern for example suitable

Problem Solving Methods (PSMs), algorithms and

control regimes for a particular type of routine

design problem. Domain knowledge is defined as

factual knowledge representative for a specific

domain of interest (components, relations,

properties, rules etc.). Figure 4 presents an

assortment of different types of knowledge involved

in KBE. Note that there does not exist a clear

division between domain-specific and domain-

independent or problem-specific knowledge. For

example, the elements object, physical object, wing,

delta-wing and composite delta-wing are all

abstractions of the same object in order of increasing

domain-specificity (Chandrasekaran, 1997).

The resulting ontology entails two taxonomic

branches. The first branch allows for the structuring

of domain knowledge; the second branch arranges

problem-solving knowledge. This way, the

knowledge repository enables captured domain

knowledge to be shared and reused across multiple

different design problems, whereas the knowledge

for a particular type of design problem can be shared

and reused across multiple domains.

Figure 4: Classification of knowledge involved in KBE.

5 DOMAIN-SPECIFIC

MODELLING

According to the previous section, a knowledge base

embedding the proposed ontology contains two

disjointed sets of knowledge elements that together

can facilitate the modelling of DEEs. Developers

can select the predeveloped modular HLPs and CMs

and combine them with problem-solving methods to

construct models for new KBE applications.

Furthermore the reuse and extension of the

knowledge elements for future KBE applications or

DEEs is facilitated: the knowledge base can be

applied as an environment to intuitively model and

construct new components (HLPs), configurations or

algorithms for specific design problems. The

predeveloped knowledge elements from the

knowledge base are considered the building blocks

for formal models, like words are used in natural

languages to compose sentences. The knowledge

base, including the proposed ontology is therefore

considered a Domain Specific modelling Language

(DSL).

A DSL enables the abstract representation of

conceptual classes of the problem domain and is

considered a visual dictionary of noteworthy

abstractions, domain vocabulary and knowledge

content of the domain under consideration (Kelly,

2008) (Larman, 2005). While traditional modelling

languages like the Unified Modelling Language

(UML) aim to be as generic as possible to serve a

broad range of domains, a DSL is carefully defined

to allow modelling of systems within a particular

problem domain.

5.1 Model-Driven Design

Since a DSL focuses on a narrow field of application

the elements of the formal model require limited

effort to be mapped one-on-one to equivalent

software classes that will embed the engineering

knowledge in source code. If the ontology of the

knowledge base incorporates the correct syntax for

the programming language of the KBE platform, the

definitions of the knowledge elements also become

intelligible to virtual machines. It has been

demonstrated that dynamic source code generation

can be achieved from the formal model via code

generators (Kelly, 2008) (Van der Elst, 2008a). The

DSL provides a visual representation of elements for

ease of construction. Furthermore it can be reasoned

that the DSL facilitates the model-driven design of

KBE applications thereby increasing the level of

abstraction of the models that define DEEs. Hence

KEOD 2009 - International Conference on Knowledge Engineering and Ontology Development

266

less expertise and effort is required to develop

correct and novel KBE applications.

The concepts of DSL and model-driven design

have been applied to develop a KBE application for

the aircraft wiring harness industry.

6 CASE STUDY: AIRCRAFT

WIRE HARNESS DESIGN

Aircraft electric wiring harnesses can be comprised

of hundreds of cables and ten thousands of wires,

providing electrical connectivity between all the

mission and vehicle systems ensuring sufficient

redundancy and reliability. Aircraft wiring design

has a repetitive, time-consuming and rule-based

nature making it a well-suited domain to implement

KBE techniques. The development of the KBE

application is performed in close corporation with a

main, international partner on the aircraft electric

wiring market, regarding both design and

manufacturing.

For the wiring harness design process, one of the

key opportunities for the application of KBE is the

assignment of signals at disconnects. At the

disconnects, also known as production breaks,

electrical connectors connect the different wiring

harnesses (Figure 5). Each wiring harness connector

can include up to 150 slots, called pins, to

accommodate signals. The pins can vary in size, as

do the wires transferring the individual signals.

This process of pin assignment is considered

routine and time-consuming due to the vast quantity

of signals to be assigned and rework caused by

changing input, e.g. governed by design iterations

for the aircraft structural design. Furthermore

separation of signals across multiple wiring harness

segments is enforced by numerous opposing design

rules and regulations, e.g. redundancy of flight

controls and electro-magnetic compatibility.

The allocation of electrical signals (subjects) to a

collection of conducting pins at disconnects

(resources) is considered a problem of the type

assignment: the outline of the system, the total set of

signals is given whereas the problem solving process

involves the definition of the collection of pins

(distribution, size, position etc.) that can best

accommodate these signals.

Figure 5: Connectors applied at an aircraft wire harness.

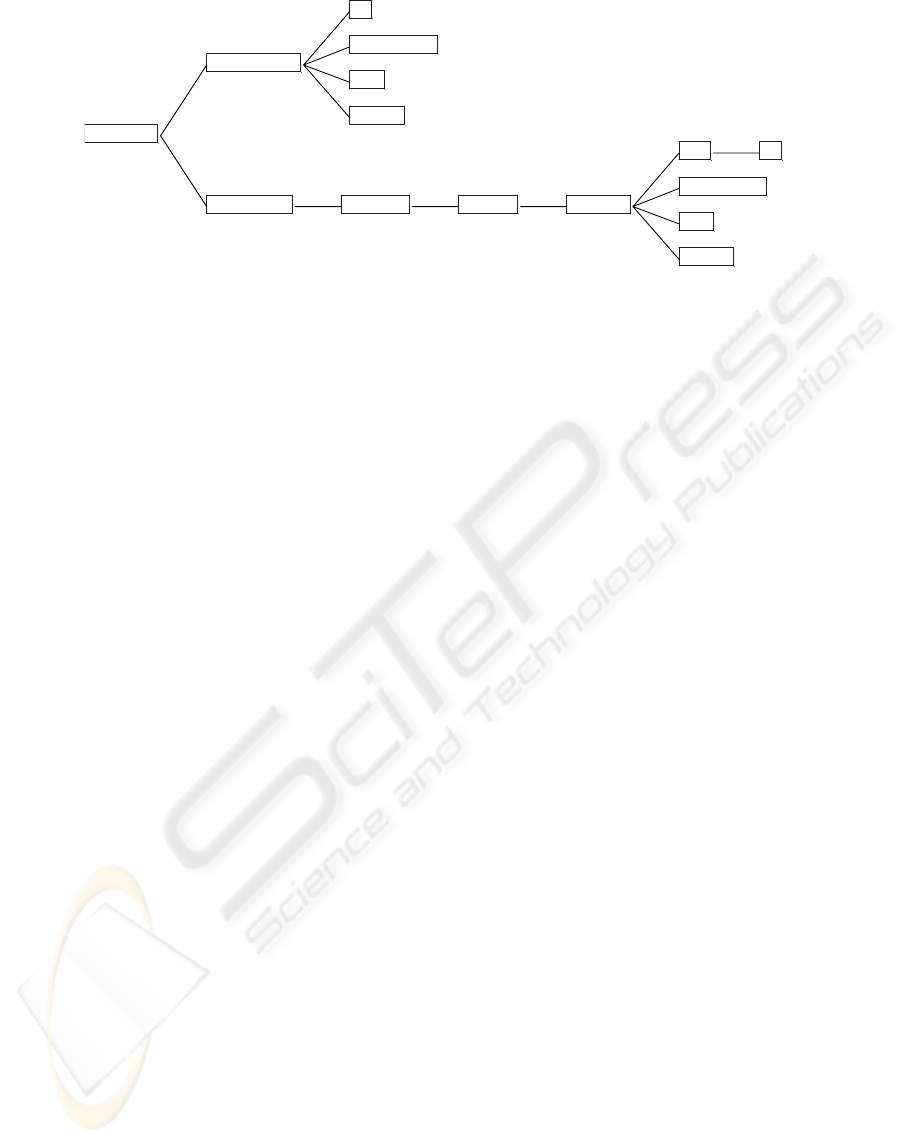

6.1 Wire Harness Knowledge Base

An ontology for the wire harness domain is

developed in order to support the design of the KBE

application. The knowledge base and the associated

ontology are developed using the Knowledge

Management (KM) software suite PCPACK 5, using

the Extensible Mark-up Language XML to store the

knowledge. The ontology used to structure the

knowledge base is derived from the MOKA

(meta)ontology which is by itself oriented to the

engineering domain in general.

Besides relationships and attributes, there are

four types of elements constituting the ontology:

objects (components), constraints, activities and

rules. Concerning the pin assignment process, four

main conceptual classes of objects are identified:

signal, production-break, connector and pin. Note

that signal is not a physical object. Next to the

conceptual classes, the ontology also contains the

definition of relevant classes of software objects.

These software classes contain the definition of the

High Level Primitives according to the KBE system.

The KBE system utilized for the development of the

MMG is Genworks’ GDL. Both the conceptual

classes and the software classes can be considered

super-classes of the HLPs, as displayed by the

taxonomy in Figure 6.

The concept of inheritance enables the

integration of relevant attributes for respectively the

wire harness domain and the software development

domain into the class definition of the HLPs. Each

object type has a specific frame structure called

annotation template, used to define the characteristic

properties (attributes) of the class. By specifying the

values of the properties, specific instances of classes

are instantiated.

Instances of the four object classes comprise the

structural composition of the wire harness

production-break and are related by the - has part -

relationship. The geometric representation of the

connector is based on the child ‘back-shell’.

Although the back-shell is a component of a

connector and therefore a conceptual class in the

problem domain, it is not considered a primitive in

the software domain. A back-shell is an instance of

the software class ‘circle’ (geometrical primitive).

By defining new classes, for example rectangular

connectors, additional design options can be defined

and new configurations can be generated. In the

example of rectangular connectors, the class

‘rectangular connector’ would be added to the

knowledge base, while the associated back-shell

becomes an instance of the class ‘box’, another

geometric primitive defined by the GDL software

ONTOLOGY DEVELOPMENT FOR MODEL-DRIVEN DESIGN IN KNOWLEDGE BASED ENGINEERING

267

classes. The pin primitive can be reused to provide

the rectangular connector with a set of contacts.

The application of the functional object-oriented

programming language enables the structure of the

software code to resemble the composition of the

product model in an intuitive and intelligible

manner. The conceptual classes from the problem

domain and the software classes from the software

domain have become each others domain equivalent,

describing identical domain knowledge on different

levels of abstraction. The Knowledge Base acts as

DSL and alleviates the effort required to implement

knowledge into the software code embodying the

HLPs. Hence it decreases the time required for the

development of the application. Furthermore,

engineers are not only capable of operating the

design application; they will also gain better

understanding of the Problem Solving Method the

application uses in order to generate solutions. The

latter has proven of critical importance for the

successful implementation of KBE techniques (Van

der Elst, 2008b).

Using the resulting KBE application, the lead-

time for the pin assignment process is reduced by

approximately 80%.

REFERENCES

Berends, J., Van Tooren, M. and Schut, E., 2008. Design

and Implementation of a New Generation Multi-Agent

Task Environment Framework. 4th AIAA

Multidisciplinary Design Optimization Specialist

Conference, AIAA-2008-2142.

Brown, B., Chandrasekaran, B., 1989. Design Problem

Solving: Knowledge Structures and Control Strategies.

Research notes in Artificial Intelligence. Pitman.

Chandrasekaran, B., 1990. Design Problem Solving: A

Task Analysis. AI Magazine Vol. 11 No. 4. AAAI.

Chandrasekaran, B., Josephson, 1997. The Ontology of

Tasks and Methods. AAAI Technical report SS-97-06.

AAAI.

Drucker, P., 2001. Management challenges for the 21st

century, Butterworth-Heinemann.

Evans, E., 2000. Domain-Driven Design. Addison Wesley.

Gero, J., Maher, M., 1993. Modelling creativity and

knowledge-based creative design. Lawrence Erlbaum

associates.

Hornby, A., 2000. Oxford Advanced Learner’s Dictionary,

Oxford, Oxford University Press, 6th edition.

Kelly, S., Tolvanen, J., 2008. Domain-specific Modeling.

John Wiley & Sons, Inc.

La Rocca, G., Van Tooren, M., 2005. Enabling Distributed

Multidisciplinary Design of Complex Products: A

Knowledge Based Engineering Approach. Journal of

Design Research, Vol.5, No. 3, pp 333-352.

La Rocca, G., Krakers, L., Van Tooren, M., 2002.

Development of an ICAD generative model for

blended wing body aircraft design. 9th AIAA/ISSMO

Symposium on Multidisciplinary Analysis and

Optimization, AIAA-2—2-5447.

Larman, C., 2005. Applying UML and Patterns. Prentice

Hall, 3rd edition.

Milton, N., 2008. Knowledge technologies. Polimetrica.

Quinn, J., 1992. Intelligent enterprise. Free Press.

Stokes, M., 2001. Managing Engineering Knowledge,

MOKA: ‘Methodology and Tools Oriented to

Knowledge Based Engineering Applications’.

Professional Engineering Publishing Ltd.

Van der Elst, S., Van Tooren, M., 2008. Domain Specific

Modelling Languages to Support Model-Driven

Engineering of Aircraft Systems. 26

th

International

Congress of the Aeronautical Sciences.

Van der Elst, S., Van Tooren, M, and Vermeulen, B.,

2008. Application of a Knowledge Based Design

Methodology to Support Fuselage Panel Design.

RAeS/CEAS Aircraft Structural Design Conference.

Van Tooren, M., Van der Elst, S. and Vermeulen, B.,

2009. Structured Design Automation. CIRP Integrated

Product-Service System.

Wielinga, B., Schreiber, G., 1997, Configuration-Design

Problem Solving. AI in Design.

ob

j

ect classes

conce

p

tual classes

p

in

p

roduction-brea

k

si

g

nal

connector

software classes GDL Ob

j

ects

g

eom-base base-ob

j

ect

circle

p

in

p

roduction-brea

k

connector

si

g

nal

Figure 6: Partial knowledge base taxonomy encompassing conceptual classes and software classes.

KEOD 2009 - International Conference on Knowledge Engineering and Ontology Development

268