PREDICTION OF SURFACE ROUGHNESS IN TURNING USING

ORTHOGONAL MATRIX EXPERIMENT AND NEURAL

NETWORKS

John Kechagias, Vassilis Iakovakis

Department of Mechanical Engineering, Technological Educational Institute of Larissa, Larissa, Greece

George Petropoulos

Department of Mechanical & Industrial Engineering, University of Thessaly, Volos, Greece

Stergios Maropoulos, Stefanos Karagiannis

Department of Mechanical Engineering, Technological Educational Institute of West Macedonia, Kozani, Greece

Keywords: ANN, Modelling, Turning, Surface roughness.

Abstract: A neural network modeling approach is presented for the prediction of surface texture parameters during

turning of a copper alloy (GC-CuSn12). Test specimens in the form of near-to-net-shape bars and a titanium

nitride coated cemented carbide (T30) cutting tool were used. The independent variables considered were

the cutting speed, feed rate, cutting depth and tool nose radius. The corresponding surface texture

parameters that have been studied are the R

a

, R

q

, and R

t

. A feed forward back propagation neural network

was developed using experimental data which were conducted on a CNC lathe according to the principles of

Taguchi design of experiments method. It was found that NN approach can be applied in an easy way on

designed experiments and predictions can be achieved, fast and quite accurate. The developed NN is

constrained by the experimental region in which the designed experiment is conducted. Thus, it is very

important to select parameters’ levels as well as the limits of the experimental region and the structure of the

orthogonal experiment. This methodology could be easily applied to different materials and initial

conditions for optimization of other manufacturing processes.

1 INTRODUCTION

Copper-based alloys are used in the mass production

of electrical components and water pipe fittings.

They are usually machined using high speed CNC

machines, which are mostly very high speed lathes

fed with brass wire of a relatively small diameter, so

that the maximum speed is limited to 140-

220m/min, although the tooling is capable of a good

performance at much higher speeds.

When copper alloys are machined, very high

forces act on the tool, particularly at low cutting

speeds. This is due to the large contact area on the

rake face resulting in a small shear plane angle and

thick chips (Trent and Wright, 2000).

This is the main reason why copper is considered

to be one of the most difficult materials to machine.

Generally, when the cutting speed is increased the

cutting forces are decreased and the surface finish is

improved.

A study of the effects of different process

parameters: tool radius (r), feed rate (f), cutting

speed (V), and cutting depth (a) in turning of a

copper alloy (GC-CuSn12), on the surface texture

parameters Ra, Rq, Rt, is attempted in the current

work, using the Taguchi methodology and neural

networks modelling.

Thus, an L

9

(3

4

) orthogonal matrix experiment

was conducted (Phadke, 1989). A matrix experiment

consists of a set of experiments where the settings of

several process parameters to be studied are changed

145

Kechagias J., Iakovakis V., Petropoulos G., Maropoulos S. and Karagiannis S. (2010).

PREDICTION OF SURFACE ROUGHNESS IN TURNING USING ORTHOGONAL MATRIX EXPERIMENT AND NEURAL NETWORKS.

In Proceedings of the 2nd International Conference on Agents and Artificial Intelligence - Artificial Intelligence, pages 145-150

DOI: 10.5220/0002588301450150

Copyright

c

SciTePress

from one experiment to another in a combinatory

way.

Experimental results are used in order to train a

feed forward back propagation neural network

(FFBP-NN) in order to predict surface texture

parameters in turning of near-to-net shape parts of

copper alloy. Using FFBP-NN in combination with

orthogonal matrix experiment, an easy way

modeling could be achieved, and applied on

experimental region in order to predict surface

texture parameters.

2 EXPERIMENTAL SETUP

The material used for cutting is specified as GC-

CuSn12. It is a copper alloy containing 84 to 85%

Cu, 11 to 14% Zn, under 1% Pb, less than 2% Ni,

and finally under 0.2% Sb.

The machine used for the experiments was a

Cortini F100 CNC machine lathe (3.7kW) equipped

with a GE Fanuc Series O-T control unit. The test

specimens were in the form of bars, 32mm in

diameter and 80mm in length for near-to-net-shape

machining. Tailstock was not used (Figure 1).

The cutting tools were titanium nitride screw-on

positive inserts, CCMT 09T30, with a 0.4 and

0.8mm tool nose radii, accordingly (Figure 2).

Figure 1: Cortini F100 CNC machine lathe.

Figure 2: Machined specimens and inserts.

The surface texture parameters; average surface

roughness (R

a

, μm), root mean square roughness (R

q

,

μm), and maximum height of peaks (R

p

, μm) were

measured using the Taylor Hobson, Talysurf 10

tester (Figure 3).

Figure 3: Surface roughness measurements.

Average roughness (R

a

) can be obtained by

taking the average of 1150 different positional

deviations over a 4 mm length with a cut-off at

0.8mm. The equation of average surface roughness

is given as

∑

=

=

1150

11

1150

1

ia

zR

(1)

where z

i

is the value of surface roughness in

irregular measurement points.

Root mean square roughness R

q

can be obtained

by the form:

()

∑

=

=

1150

11

2

1150

1

iq

zR

(2)

Α four parameter design was performed as

shown in Table 1. Note that Level 1 and level 3 for

the parameter r assign the same value. This is not an

obstacle for the methodology followed.

Table 1: Parameter design.

levels

Νο Process Parameters 1 2 3

1 Tool Radius (r, mm) 0.4 0.8 0.4

2 Feed Rate -(f, mm/rev) 0.05 0.15 0.25

3 Cutting Speed (V, m/min) 100 150 200

4 Cutting Depth (a, mm) 0.2 0.6 1

The standard (L9(34)) orthogonal matrix

experiment was used (Table 2).

Columns 1, 2, 3, and 4 are assigned to tool radius

(r), feed rate (f), cutting speed (V) and depth of cut

(a), respectively.

ICAART 2010 - 2nd International Conference on Agents and Artificial Intelligence

146

Table 2: Orthogonal array L

9

(3

4

).

Column

No

Exp

1 2 3 4

1 1 1 1 1

2 1 2 2 2

3 1 3 3 3

4 2 1 2 3

5 2 2 3 1

6 2 3 1 2

7 3 1 3 2

8 3 2 1 3

9 3 3 2 1

3 EXPERIMENTAL RESULTS

The Taguchi design method is a simple and robust

technique for optimizing the process parameters. In

this method, main parameters, which are assumed to

have an influence on process results, are located at

different rows in a designed orthogonal array. With

such an arrangement randomized experiments can be

conducted. In general, signal to noise (S/N) ratio (n,

dB) represents quality characteristics for the

observed data in the Taguchi design of experiments.

In the case of surface roughness amplitude

(Kechagias, 2007; Petropoulos et al, 2008; Tsao,

2009), lower values are desirable. These S/N ratios

in the Taguchi method are called as the smaller-the-

better characteristics and are defined as follows:

⎥

⎦

⎤

⎢

⎣

⎡

−=

∑

=

n

i

i

y

n

1

2

10

1

log10

η

(3)

where y

i

is the observed data at the i

th

trial and n is

the number of trials. From the S/N ratio, the

effective parameters having an influence on process

results can be obtained and the optimal sets of

process parameters can be determined.

Based on Robust design, the standard orthogonal

array (L

9

(3

4

)) has been selected in order to perform

the matrix experiment (Table 3). Three levels for

each factor were selected (Table 1). Following the

(L

9

(3

4

)) orthogonal array nine experiments were

performed with each experiment producing a test

part which was tested for average surface

roughness

(R

a

, μm), root mean square roughness (R

q

, μm), and

maximum height of peaks (R

p

, μm).

Table 3: Matrix experiment.

Ex.

No.

r f V a R

a

R

q

R

t

1 0.4 0.05 100 0.2 0.24 0.33 1.4

2 0.4 0.15 150 0.6 1.51 1.95 11.4

3 0.4 0.25 200 1 0.54 0.75 4.4

4 0.8 0.05 150 1 0.44 0.61 3.4

5 0.8 0.15 200 0.2 0.27 0.38 2.4

6 0.8 0.25 100 0.6 0.69 0.92 5.4

7 0.4 0.05 200 0.6 0.34 0.4 1.4

8 0.4 0.15 100 1 0.84 1.03 4.1

9 0.4 0.25 150 0.2 0.32 0.43 1.8

Mean (m) 0.57 0.75 3.96

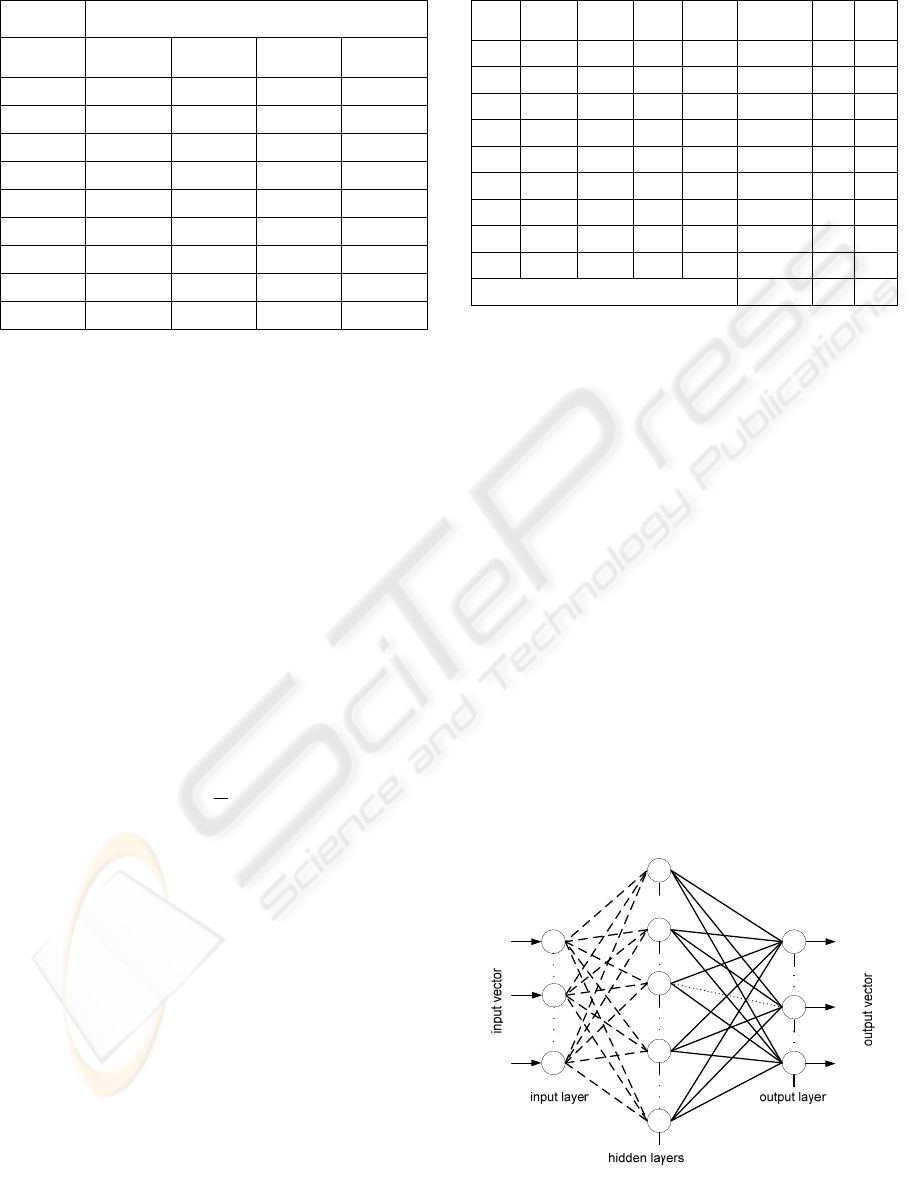

4 NEURAL NETWORK SET-UP

In general, NNs are parallel distributed information

processing systems that demonstrate the ability to

learn, recall, and generalize from training patterns or

data. Models of NN are specified by three basic

entities: models of synaptic interconnections and

structures, models of the neurons, and the training

rules for updating the connecting weights (Lin and

Lee, 1996; Jiao et al, 2004; Ozel and Karpat, 2005;

Kechagias and Iakovakis 2008).

A NN consists of a set of highly interconnected

neurons such that each neuron output is connected

through weights, to other neurons or to itself. Hence,

the structure that organizes these neurons and the

connection geometry among them should be

specified for a NN.

A neural network consists of at least three layers,

where input vectors (p

i

) applied at the input layer

and output vectors (a

i

) are obtained at the output

layer (Figure 4).

1+k

i

f

1

1

+k

f

k

f

1

k

j

f

kk

ji

w

,1

,

+

1+k

i

b

1

1

+k

b

k

b

1

k

j

b

k

b

2

1

1

+k

a

1+k

i

a

1+k

m

f

1+k

m

a

i

p

1

p

q

p

Figure 4: A multilayer feed-forward NN.

PREDICTION OF SURFACE ROUGHNESS IN TURNING USING ORTHOGONAL MATRIX EXPERIMENT AND

NEURAL NETWORKS

147

Figure 5: FFBP-NN details.

Each layer consists of a number of neurons

which are also called processing elements (PE). PEs

can be viewed as consisting of two parts: input and

output. Input of a PE is an integrated function which

combines information coming from the net.

Considering a feed forward NN (Figure 4), the net

input to PE i in layer k+1 is:

∑

+++

+=

j

k

i

k

j

kk

ji

k

i

bawn

1,1

,

1

(4)

where w

i,j

and b

i

are the corresponding weights and

biases.

The output of PE i will be

a

i

k+1

=f

k+1

(n

i

k+1

) (5)

where f is the transfer function of neurons in (k+1)

th

layer.

Training of the network uses training rules to

adjust the weights associated with PE inputs.

Unsupervised training uses input data alone while

supervised training works by showing the network a

series of matching input and output examples

{(p

1

,t

1

), (p

2

,t

2

), …(p

q

,t

q

)}.

MATLAB version 6.5 program was used to

create, train, and test the FFBP-NN (Feed Forward

Back Propagation Neural Network) through network

data manager. Generally, MATLAB NN toolbox

refers to the input layer as the input vector. A layer

that produces the network output is called output

layer. All the other layers are called hidden layers.

A number of trials was executed to select the

appropriate topology of the FFBP-NN, which is

shown in Figure 5.

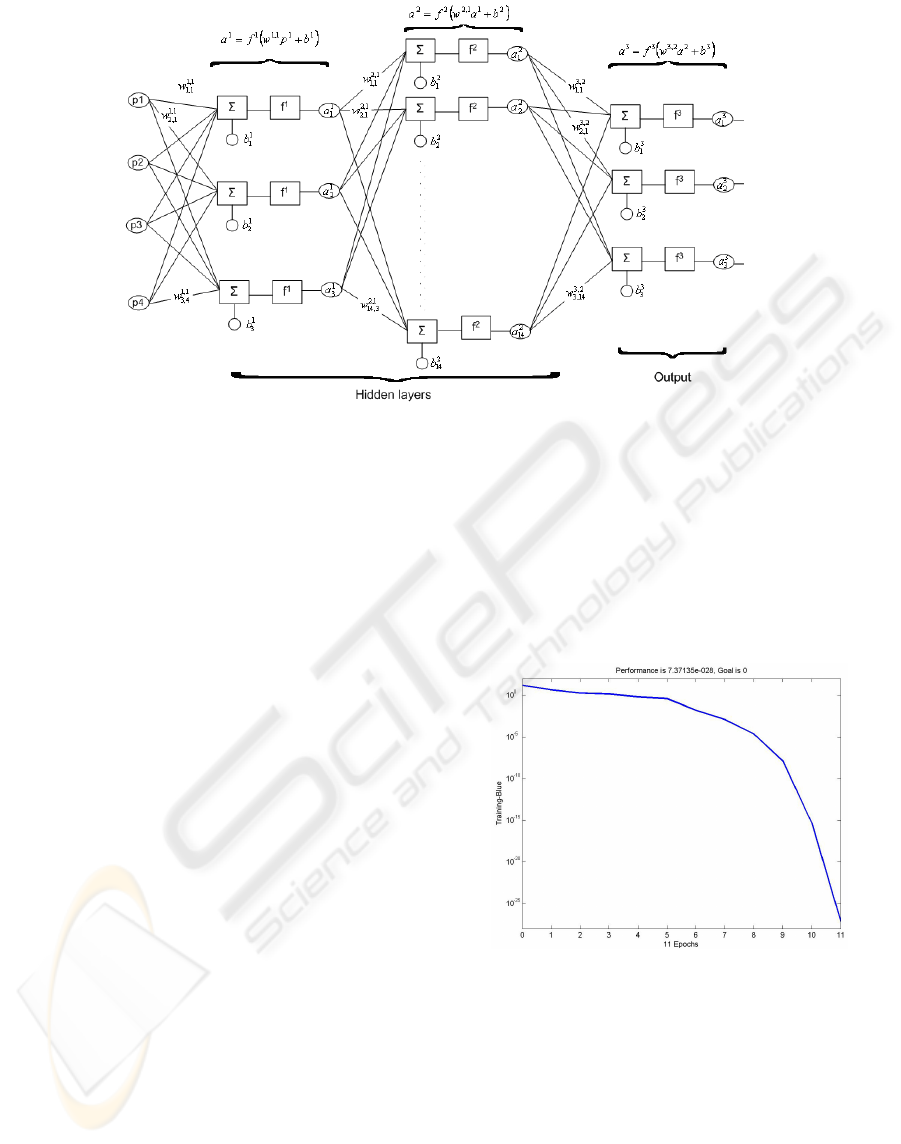

Tool radius (r), feed rate (f), cutting speed (V),

and the depth of cut (a) were used as the input vector

into the NN. Roughness parameters (Ra, Rq, Rt)

were used as the output layer. Two hidden layers

were selected, after a number of trials, having 3 and

14 neurons respectively. This network had the best

performance among them that have one or two

hidden layers (Figure 6).

Figure 6: FFBP-NN training process.

Hyperbolic tangent sigmoid transfer function

(tansig) was used as transfer function for the hidden

layers (Eq. 6, Fig. 7). The transfer function for the

output layer was the linear function (Eq. 7, Fig. 7).

a

1

=f

1

(w

1,1

p

1

+b

1

)=tansig(w

1,1

p

1

+b

1

)=

tansig(n)=[2/(1+e

-2n

)]-1

(6)

a

2

=f

2

(w

2,1

a

1

+b

2

)=purelin(w

2,1

a

1

+b

2

)=

purelin(n)=n

(7)

ICAART 2010 - 2nd International Conference on Agents and Artificial Intelligence

148

Figure 7: Hyperbolic tangent sigmoid and linear transfer

function.

Training functions repeatedly apply a set of input

vectors to a network, updating the network each

time, until some stopping criteria are met. Stopping

criteria can consist of a maximum number of epochs,

a minimum error gradient, an error goal, etc.

The Levenberg–Marquardt (TRAIN-LM)

algorithm selected for training the FFBP-NN, which

is a variation of the classic back-propagation

algorithm that, unlike other variations that use

heuristics, relies on numerical optimization

techniques to minimize and accelerate the required

calculations, resulting in much faster training.

LEARNGDM is used as ‘adaption learning

function’ which is the gradient descent with

momentum weight and bias learning function.

Biases (b

j

) simply being added to the product

(w

j,i

+b

j

).

The performance of FFBP-NN was measured

with the mean squared error (MSE) of the testing

subset which calculated by the form:

∑∑

==

=−−=

Q

q

q

T

q

M

qq

Q

q

TM

qq

eeatatMSE

11

2

1

)()(

2

1

(8)

where a

q

M

is the output of the network

corresponding to q

th

input p

q

, and e

q

=(t

q

-a

q

M

) is the

error term.

It must be noted that the outcome of the training

greatly depends on the initialization of the weights,

which are randomly selected. Training process can

be seen in Figure 6.

5 EVALUATION

Using the extracted FFBP-NN the surface texture

parameters can be predicted quickly and easy. In

order to evaluate the NN model an evaluation

experiment was conducted and the result shows that

the NN model gives values close to the actual ones

(Table 4).

Below the surface response of the performance

of the R

a

, R

q

, and R

t

can be seen for all the

combination of V and f keeping constant the tool

nose radius (r=0.4mm) and the cut of depth

(a=1mm).

Table 4: Evaluation experiment (r=0.8mm, f=0.05mm/rev,

V=200m/min, a=0.2mm).

R

a

(μm) R

q

(μm) R

t

(μm)

Actual 0.17 0.21 1.3

Predicted 0.23 0.34 1.94

The surface responses show that generally when

increasing the cutting speed the surface texture

parameters decreasing. Also, when increasing the

feed rate the response is getting worse when it takes

a value of about 0.15mm/rev (see Figure 8).

Also, using the NN model, all the ` of the

parameter levels were predicted and the process was

optimized according to average surface roughness

(R

a

). It was found that the best combination (that

gives R

a

=0.2μm) is: r=0.4mm, f=0.05mm/rev,

V=150m/min, and a=0.06mm.

6 CONCLUSIONS

The surface texture parameters (R

a

, R

q

, and R

t

) of

copper alloy near-to-net-shape parts during turning

was measured according to a matrix experiment. The

results were used to train a feed forward back

propagation neural network with a topology of

4X3X14X3 neurons. The proposed NN can be used

to predict the surface texture parameters as well as to

optimize the process according to each one of the

surface texture parameters.

As a future work Authors plan to improve the

performance of FFBP-NN incorporating more

experiments as well as investigate the performance

of alternatives training algorithms. In addition a

comparison among other approaches such as

regression and additive modeling will be performed.

Using the extracted NN the surface response of

R

a

, R

q

, and R

t

can be drawn and the effects of

process parameters be estimated inside the

experimental region in which the designed

experiment is conducted. This methodology could be

easily applied to different materials and initial

conditions for optimization of other material

removal processes.

REFERENCES

Jiao, Y., Lei, S., Pei, Z.J., Lee, E.S., 2004. Fuzzy adaptive

networks in machining process modeling: surface

roughness prediction for turning operations. Int. J.

Mach. Tools Manuf. Vol. 44, p. 1643-1651.

PREDICTION OF SURFACE ROUGHNESS IN TURNING USING ORTHOGONAL MATRIX EXPERIMENT AND

NEURAL NETWORKS

149

Figure 8: Surface response for R

a

, R

q

, and R

t

using NN model (r=0.4mm, a=1mm).

Kechagias, J., 2007. An experimental investigation of the

surface roughness of parts produced by LOM process.

Rapid Prototyping J. Vol. 13 No 1, p. 17-22.

Kechagias, J., Iakovakis, V., 2009. A neural network

solution for LOM process performance. Int. J. Adv.

Manuf. Technol. Vol. 43 No. 11, p. 1214-1222.

Lin, C.T., Lee, G.C.S., 1996. Neural fuzzy systems- A

neuro-fuzzy synergism to intelligent systems. Prentice

Hall PTR, p. 205-211.

Petropoulos, G., Mata, F., Davim, J. P., 2008. Statistical

study of surface roughness in turning of peek

composites. Materials & Design, Vol. 29, No. 1, p.

218-223.

Ozel, T., Karpat, Y., 2005. Predictive modeling of surface

roughness and tool wear in hard turning using

regression and neural networks. Int. J. Mach. Tools

Manuf. Vol. 45, p. 467-479.

Phadke, M.S., 1989. Quality Engineering using Robust

Design. Prentice-Hall, Englewood Cliffs, NJ.

Trent, E.M., Wright, P.K. 2000. Metal Cutting.

Butterworth- Heinemann, Boston.

Tsao, C. C., 2009. Grey–Taguchi method to optimize the

milling parameters of aluminum alloy, The

International Journal of Advanced Manufacturing

Technology. Vol. 40, p. 41–48

R

a

f

V

R

q

f

R

t

f

V

V

ICAART 2010 - 2nd International Conference on Agents and Artificial Intelligence

150