ORGANIZING AND PLANNING THE ASIC DESIGN PROCESS BY

MEANS OF A MULTI-AGENT SYSTEM

Jana Blaschke

1

, Christian Sebeke

1

1

Robert Bosch GmbH, T

¨

ubinger Straße 123, 72762 Reutlingen, Germany

Wolfgang Rosenstiel

Department of Computer Science, University of T

¨

ubingen, Sand 13, B 207, 72076 T

¨

ubingen, Germany

Keywords:

Multi agent simulation, Global scheduling, Local scheduling, Task planning, ASIC design.

Abstract:

Because of constantly improving technologies, the complexity of Integrated Circuits (ICs) is continuously

increasing. Consequently IC design becomes continously more challenging and complex. A huge number of

different possible design flows exists, delimited by different constraints. The design flow dynamically changes

as recursions between design tasks occur. An approach that allows a fast and efficient ASIC design and that

can deal with this huge complexity and dynamics is needed. Therefore we propose a methodology based on a

multi-agent simulation combined with global and local scheduling techniques to construct a time-dependent,

detailed model of the ASIC design process, which permits an extensive analysis and efficient organization.

1 INTRODUCTION

Smaller channel width in microelectronics together

with design automation enables a realization of very

complex ICs for electronic devices, comprising a vast

number of functionalities (Moore, 1998). As several

recursion steps occur between the frontend and back-

end design, the whole design process is extremely dy-

namic and difficult to predict. Another degree of com-

plexity is introduced by different methods to realize

the design steps. Altogether the design process of

ASICs is a highly complex, dynamic and non-linear

procedure, depending on human decisions.

If Moore’s Law persists, the required design ef-

fort for ICs exceeds realistic imaginations. Limit-

ing factors restricting the ASIC design are e.g. CPU

power, human capability to work faster or tool run-

times. An approach that allows an analysis and effi-

cient planning of ASIC design projects is needed to

realize more complex projects. As Multi-agent sys-

tems (MAS) inherit properties that are very suitable

for modelling and simulating highly complex prob-

lems involving human decisions in domains within a

dynamically changing environment, we developed a

methodology based on MA simulation combined with

scheduling mechanisms. The simulation is organized

in two distinct phases: a long term planning based on

a Genetic Algorithm (GA) optimization for a high-

level plan, and a short term planning to react dynami-

cally to events. By this means we are able to develop

optimized but realistic project courses of ASIC design

projects for an efficient project organization. Addi-

tionally it allows a what-if analysis and comparison

of different design flows with different design tools.

2 PREVIOUS WORK

MAS are widely used for simulation of human net-

works, organizing themselves to reach a defined goal

(Schurr et al., 2005).

Scheduling of ASIC design projects is an issue for a

long time (Easley et al., 1989). But due to a quickly

changing design environment, design automation and

new technologies ASIC design project planning re-

quirements are changing constantly, old approaches

become obsolete. Recent research in Design Project

Scheduling focuses on selected design steps, as for

example the high level synthesis of net lists (Lin and

Kim, 2006), instead of scheduling the whole project.

Models of aother research groups are based on de-

rived metrics (Leppelt et al., 2006). But this neither

allows what-if analysis of projects nor a reasonable

planning for investments and resources.

459

Blaschke J., Sebeke C. and Rosenstiel W. (2010).

ORGANIZING AND PLANNING THE ASIC DESIGN PROCESS BY MEANS OF A MULTI-AGENT SYSTEM.

In Proceedings of the 2nd International Conference on Agents and Artificial Intelligence - Artificial Intelligence, pages 459-463

DOI: 10.5220/0002698704590463

Copyright

c

SciTePress

3 APPROACH

Our approach has to enable the analysis and optimal

organization of the ASIC design process and has to

provide an efficient planning of ASIC project courses

considering a lot of prerequisites. First, a simulation

of finished projects for evaluation purposes and com-

parison to other projects needs to be enabled. Second,

new and ongoing projects need to be planned in con-

sideration of budget, resources, deadlines, alternative

design styles and the task organization.

As we have to deal with a highly complex prob-

lem and a dynamic environment, MAS are an ade-

quate way of simulating a group of humans executing

design tasks. So a MAS simulation is chosen as the

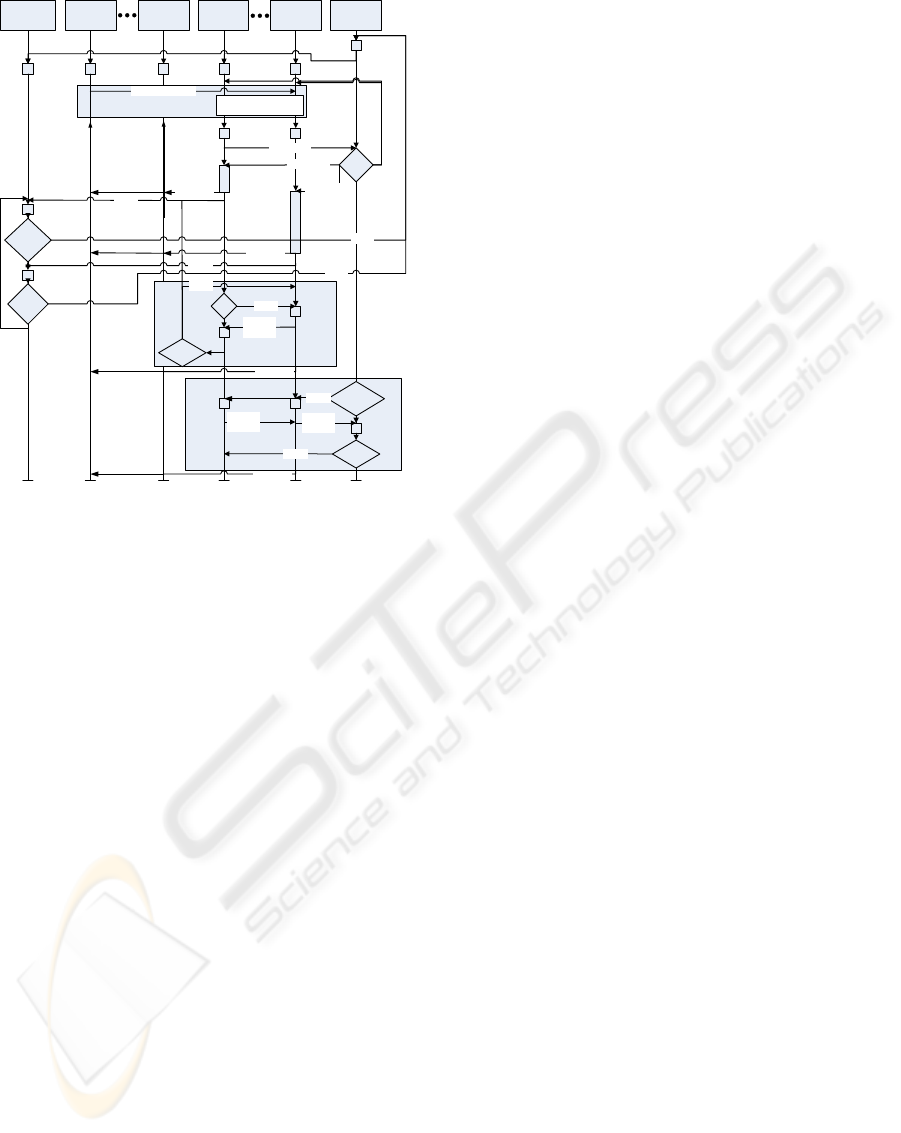

core of the system model. The ASIC-MAS architec-

ture is shown in fig. 1. For task execution we need

two types of ressources agents, a designer agent and

the design tool agent. These agents belong, according

to their expertise and functions, to different design ar-

eas. A high-level plan for task execution and design

organization is provided by a planning agent, also re-

sponsible for the resource allocation of the tasks. Dy-

namics are introduced to our system by an interfer-

ence module modelling recursive processes and un-

foreseen events, perturbing the smooth schedule exe-

cution and modelling dynamics inherent in processes

lead by humans. A monitoring agent is tracking the

simulation, calculating the deviation of the high-level

schedule and the actual simulation. The schedule and

the MAS organization are adapted during the simu-

lation if their deviation exceeds a given limit. Local

scheduling methods can re-organize small parts of the

simulation in a sensible way. The tracked agent activ-

ity gives a realistic estimate of the duration of design

process and a suggestion how to organize it.

4 MULTI-LEVEL

ORGANIZATION OF THE

ASIC-MAS

We developed a two-stage planning strategy to obtain

an efficiently organized MA simulation.

4.1 Long-term Planning

We implemented a long term scheduling that takes

place at the beginning of the simulation to gain a

high level plan for an efficient simulation organiza-

tion. This algorithm assigns resources to tasks and

produces a (near) optimal task execution order. The

objective of the optimization is the minimization of

D

D

D

T

T

T

D D

T

T

T

T

T

T

D

D

D

D

D

D

D

D

T

T

T

T

GA

Planner

Monitor

Agent

Digital Circuit Design

Analogue Circuit Design

Analogue Layout

Digital Layout

replanning

Interference

Modul

Figure 1: ASIC-MAS architecture.

the overall execution time of an ASIC design project:

min T

design

, while tasks need to be assigned to design-

ers with different experience modes out of different

design regions and tools considering task dependen-

cies and resource constraints. We use a scheduling op-

timization heuristic based on genetic algorithms (GA)

(Blaschke et al., 2009). Designers planned holidays

are incorporated in the optimized schedule.

The high level scheduling is managed by one ded-

icated planning agent. He passes the necessary task

and resource information to the GA scheduling algo-

rithm and receives the optimization result of the GA.

He assigns the tasks to requesting designers.

4.2 Short-term Planning

The high level plan is an optimized schedule under

optimal designing conditions: every designer acts ex-

actly as planned. But reality is different: designers

become ill, take one or two days off, task execution

takes longer or shorter than assumed and many recur-

sions occur between tasks, resulting in new recursive

tasks. The design process is dominated by these dy-

namic events, which cannot be modelled and consid-

ered by the static high level plan produced by the GA.

To model these events we developed an interfer-

ence module. It introduces the dynamics inherent in

the ASIC design process. Therefore, during process-

ing the agent simulation deviates more and more from

the optimized GA schedule. The reaction to this di-

vergence is the local planning of the designer agents.

Different mechanisms are used for different events,

which are shown in fig. 2. We will describe the mech-

anisms in detail in the following subsections.

The monitoring agent tracks the simulation. He

compares it to the high level plan at frequent intervals.

The deviation at simulation time s

j

is:

dev =

n

∑

i=1

f (δ(t

i

, s

j

)) · (1 +a(t

i

) − p(t

j

))

+δ(ra(s

j

)),

where n is the number of tasks, f (δ(t

i

, s

j

)) calculates

the delay of the task t

i

in the simulation compared to

the schedule, a(t

i

) weights the number of dependent

ICAART 2010 - 2nd International Conference on Agents and Artificial Intelligence

460

search tool

inform

else:

inform when

tasks

available

search tool

Monitoring

Agent

Tool

Agent

Designer

Agent

Planning

Agent

high level

plan

start start start

Designer

Agent

Tool

Agent

start start

tool license

found

tool license

found

if

task

provide task

provide task

execute

task

execute

task

search tool

search tool

inform

inform

compare:

schedule –

simulation

compare:

schedule –

simulation

if

exceed

limit

if

exceed

limit

replan

replan

if

ill

inform

local

planning

local

planning

inform

decisions

task

recursion

local

planning

local

planning

inform

decisions

decision?

decision?

inform

tools offer services

designers: compete for

tool licences

task request

after each period

inform

local

planning

inform

decisions

Figure 2: Short term scheduling negotiation architecture.

tasks to t

i

, p(t

j

) is the buffer time of the task in the

optimized high level schedule and δ(ra(s

j

)) is the re-

source workload of the simulation at time s

i

. If this

value exceeds a given limit, a global re-scheduling is

initiated. All tasks that are being executed at that mo-

ment are still finished. All other tasks are scheduled

anew with the GA.

Illness and short holidays are dynamic events in-

duced by the interference module and thus not plan-

able by the GA. As a global re-schedule would be

oversized and far to timeconsuming, a local planning

mechanism is chosen for an adequate reaction. If one

of these events occurs while a designer is accomplish-

ing a task, the task execution is interrupted and the

overall execution time prolonged. As many tasks do

have dependent tasks and the schedule is also opti-

mized with respect to the resource workload, this pro-

longation delays tasks scheduled later, which leads to

a bad resource workload and project elongation. The

consequences of task delays can often be reduced by a

local re-planning of the designer agents and a transfer

of partial tasks from one agent to another. The deci-

sion and planning process be seen in flow chart 2. The

goal is the minimization of a project delay.

Recursions often occur between frontend and

backend tasks if the backend discovers that some

specifications can not be fulfilled. These recursions

cannot be planned. Hence we defined a Markov Chain

that evokes recursions. This implicates new tasks with

interdependencies to other tasks which have to be in-

serted into the simulation. As a new GA scheduling

is not always necessary, a local planning between the

designer agents takes place. They try to insert the new

tasks into the simulation in an efficient manner. The

local planning process is shown in fig. 2.

5 MAIN RESULTS

In this section we present the results of our ASIC-

MAS and give a statement about its applicability.

5.1 Verification of the Model

We generated several problems to verify the GA opti-

mization as well as the MA simulation in conjunction

with the interference module.

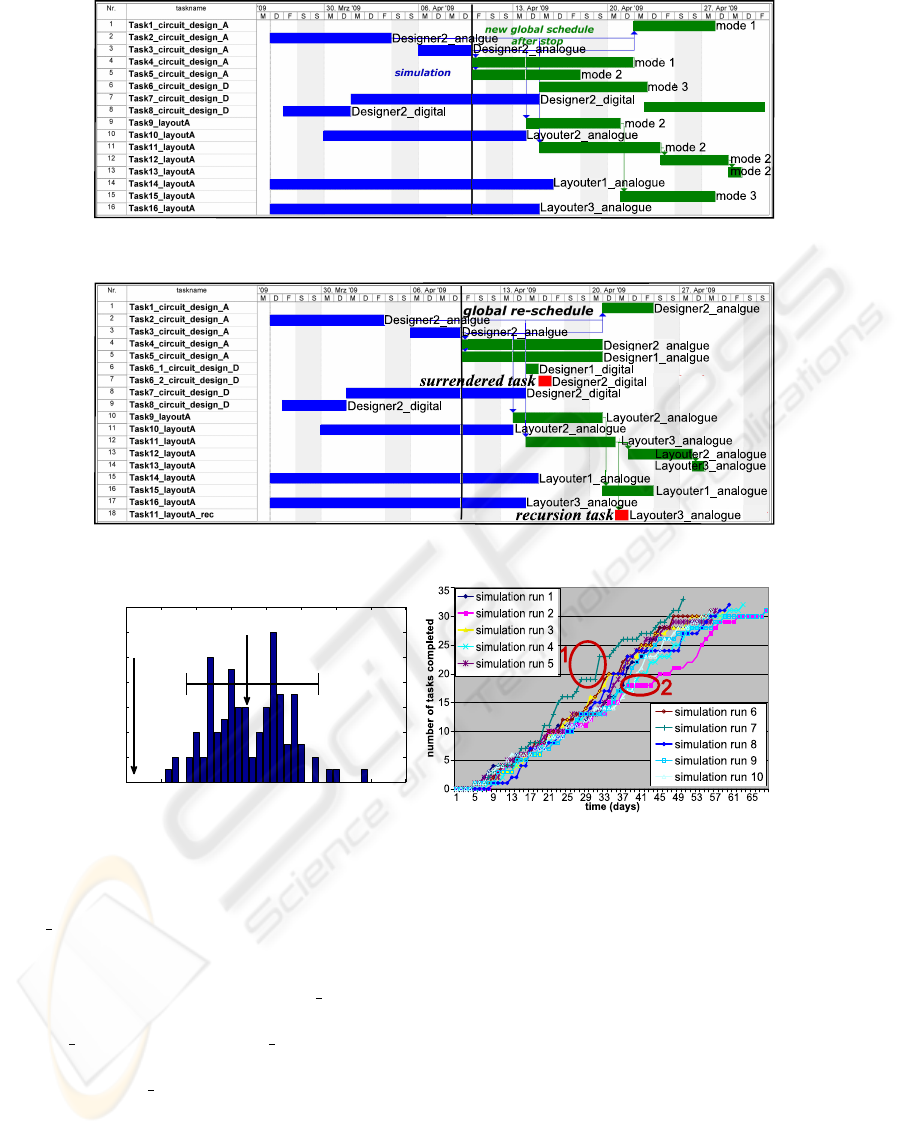

In this section we describe and analyse the perfor-

mance of our MAS by applying it to a representative

but clearly arranged problem. At first we demonstrate

the correct performance of the simulation. We chose

a simulation run where a re-scheduling occurs, a task

is handed over from one agent to another and a task

recursion happens. Then we analyse the simulation

part of the MAS before a re-schedule is initiated (fig.

3) and the second GA schedule that is produced after

the re-schedule (also fig. 3). At the end we analyse

the whole simulation run (depicted in fig. 4).

A project execution schedule is produced at every

begin of a simulation run by the GA. The makespan of

the schedule is 20 days. This is the minimal makespan

possible under consideration of all constraints.

After the schedule optimization we applied the

high level schedule to the MAS with the interference

module switched on. Fig. 3 shows the MA simulation

until the re-schedule stop occurred, and the new GA-

optimized global schedule for the remaining tasks.

The simulation deviates from the schedule due to dif-

ferent reasons. Some tasks need a longer execution

time than planned, delaying the schedule and other

dependent tasks. Abscent designers prolong task exe-

cutions. After 11 days the simulation-schedule devi-

ation is too large, a re-schedule is initiated. All tasks

that have already been started are finished despite the

re-schedule. The new global schedule supplements

perfectly the simulation considering all constraints.

The Gantt chart of the tracked agent activity of

the whole simulation is shown in fig. 4. Task4 needs

one day less to be accomplished than planned. There-

fore Task1, which is dependent on resources previ-

ously occupied by Task4, can be started and ended

earlier. The execution of Task5 takes one day longer

than planned. The first digital designer becomes ill

while executing Task6. He offers the remaining task

ORGANIZING AND PLANNING THE ASIC DESIGN PROCESS BY MEANS OF A MULTI-AGENT SYSTEM

461

Figure 3: Two stages of the whole simulation, separated by a horizontal bar.

Figure 4: Tracked agent activity of the whole simulation.

Figure 5: (a) Statistic of several simulation runs, (b) completion degree of simulation runs.

to the other agents of his design region. As De-

signer2 digital does not work on a task at that point

he takes Task6. Task11 is processed in two days

less than planned. A recursion is induced after it

is completed. A recursive task, Task11 rec, is cre-

ated and proposed to all analogue layouters. Only

Layouter2 analogue and Layouter3 analogue are free

and can compete for that new task. According to the

schedule Layouter2 analogue has to execute a task

earlier than Layouter3, Layouter2 wins the task. The

simulation of the second part is finished one day ear-

lier than the second global schedule proposed.

The optimized global schedule has an overall exe-

cution time of 20 days. The overall execution time

of the MA simulation lasts 23 days. In considera-

tion of all interrupting events a deviation of three days

from the optimal execution time is little. As well the

global re-scheduling as the two local scheduling tech-

niques re-organize the simulation so efficiently that

these perturbations do effect the overall project sim-

ulation time little. The re-scheduling techniques re-

spond efficiently to and head of the prolonging effects

of interruptions and improved the resource utilization.

5.2 Analysis of Projects

The ASIC-MAS can be used for an extensive analy-

sis of projects. Multiple design-simulation runs give

statistics of estimated runtimes. A sample of a statis-

tic shows fig. 5(a) for a project with 30 activities. It

ICAART 2010 - 2nd International Conference on Agents and Artificial Intelligence

462

shows the results of 100 simulation runs. The opti-

mal GA-schedule runtime (45) days is indicated by

an arrow, as well as the mean simulation runtime of

61 days, a project runtime of 60 days ± 9 days can

be expected. The mean degree of project completion

for every day of the simulation depicts fig. 5(b) for 10

simulation runs. The analysation of several runs gives

an overview of advantageous start configurations (cir-

cle 1) and critical activities that often lead to bottle-

necks (circle 2). Here, simulations starting with activ-

ity 8, 5 and 15 tend to result in shorter runtimes than

simulations starting with activity 2 or 13. Bottlenecks

are entailed sometimes by activities 1, 3, 6, 26 and

30. With this information the project leader can react

adequatly.

6 CONCLUSIONS AND FUTURE

WORK

The generated schedule and the MA simulation can

be used for analysis, optimization and planning of fin-

ished, ongoing or future projects. The schedule opti-

mization provides suggestions for an efficient orga-

nization of projects and permits a subsequent analy-

sis for identification of weak spots within the project

course. The setting of different project parameters,

e.g. different resource availabilities, allows what-if-

analysis. The simulation allows to observe the project

execution. An interfere module disturbes the smooth

simulation of the optimized schedule, allowing as-

real-as-possible simulations to gain reliable and real-

istic predictions on project courses and makespans.

Local scheduling and global re-scheduling methods

head off prolonging effects by organizing and allocat-

ing parts in an efficient and sensible way.

In future experiments we are going to evaluate the

performance of the System to investigate how good

our whole model reflects reality.

REFERENCES

Blaschke, J., Sebeke, C., and Rosenstiel, W. (2009). Using

genetic algorithms for planning of ASIC chip-design

project flows. In Proceedings of the IEEE Congress on

Evolutionary Computation (CEC 2009), page P135.

Easley, S., Freeman, E., and Steele, D. (1989). Asic design

project scheduling. ASIC Seminar and Exhibit, 1989.

Proceedings., Second Annual IEEE, pages P11–2/1–4.

Leppelt, P., Hassine, A., and Barke, E. (2006). An approach

to make semiconductor design projects comparable.

In 7th Asia Pacific Industrial Engineering and Man-

agement Systems Conference (APIEMS 2006), pages

CD–ROM. Asian Institute of Technology.

Lin, C.-H. and Kim, J.-C. (2006). A novel scheduling

methodology for asic design. System-on-Chip for

Real-Time Applications, The 6th International Work-

shop on, pages 131–134.

Moore, G. E. (1998). Cramming more components onto in-

tegrated circuits. Proceedings of the IEEE, 86(1):82–

85.

Schurr, N., Marecki, J., and Tambe, M. (2005). The future

of disaster response: Humans working with multia-

gent teams using defacto. In In AAAI Spring Sympo-

sium on AI Technologies for Homeland Security.

ORGANIZING AND PLANNING THE ASIC DESIGN PROCESS BY MEANS OF A MULTI-AGENT SYSTEM

463