DETECTION OF DNA AT THE MICROCHIP

Study of DNA Detection Microchip by Oxidation Peak of DNA

Gi-sung Joo, You-Cheol Jang, Islam Atm Kamrul

Department of Nano Science and Engineering, Myongji University, Gyeonggi, Korea

Yong-Sang Kim

Department of Electric Engineering, Myongji University, Gyeonggi, Korea

Keywords: Capillary electrophoresis, Amperometry, Polyacrylamide, Microfluidics.

Abstract: We have demonstrated the separation and detection of DNA on the microchip based on amperometric with

capillary electrophoresis. To enhance analytic perfermance such as throughput and analysis time,

electrophoretic separation of DNA in capillaries or on microchips has been investigated using various

microchip structures. Compared with commonly used laser induced fluorescence method, this method is

more compatible with microchip and offer improved portability and miniaturization. Through Cyclic

voltammetric experimental, we could optimized detection voltage for detection of DNA. At the optimal

detection voltage, DNA fragments were successfully separated and detected with high sensitivity and stable

baseline.

1 INTRODUCTION

DNA analysis is important step in area of

biochemistry as well as molecular biology. In most

cases DNA is detected by fluorescent or optical

spectroscopy after agarose gel electrophoresis.

However, this procedure is tedious, time consuming

and require expensive equipments. Therefore

miniaturization of DNA analysis is necessary.

Capillary electrophoresis (CE) microchip, intro-

duced by Manz et al. in the early 1990s, alternative

for separation of biological compounds. To enhance

throughput and to shorten analysis time, electro-

phoretic separation of DNA in capillaries or on

microchips has been suggested using different

microchip structures. Optical microarrays are

arguably the most widely used type of biosensors in

DNA analysis where detection of specific DNA

sequences are based on labeling sample DNAs with

fluorophores. While fluorescence-based detection

technologies have shown tremendous utility, they

suffer from the drawbacks of labor-intensive sample

preparation, high cost, and complex and bulky

fluorescence detection instrumentation. However,

amperometric method is measured to change current

according to oxidation of analytes. Guanine and

adenine electro-oxidation is useful for the

amperometric method. Using this technique,

fragments of negatively charged DNA can be

resolved inside a capillary by application of potential.

The resolved DNA can be detected ampero-

metrically using oxidation peak of adenine base.

In the present work, we have attempted to develop

an amperometric. The microchips are usually

fabricated from silicon and glass. However,

polymeric materials are also used due to their

properties such as low cost, high flexibility, and

simply fabrication procedures. Several polymers

such as poly(dimethylsiloxane) (PDMS) and poly

(methyl methacrylate) (PMMA), polyester have

been reported for fabrication of microchip. Our

microchip was fabricated on glass substrate and

microchannels were laid in PDMS mold. The

capillary was filled with polyacrylamide gel and

separation was achieved by application of DC

potential. This technique was used in resolving DNA

fragments

117

Joo G., Jang Y., Atm Kamrul I. and Kim Y. (2010).

DETECTION OF DNA AT THE MICROCHIP - Study of DNA Detection Microchip by Oxidation Peak of DNA.

In Proceedings of the Third International Conference on Biomedical Electronics and Devices, pages 117-120

DOI: 10.5220/0002744001170120

Copyright

c

SciTePress

2 EXPERIMENTAL

2.1 Chemicals

The testing analyte was DNA ladders (100–1500 bp,

9 fragments) (Biosesang). We have used Sylgard

184 from Dow Corning Corp. (Midland, MI,USA)

and SU-8 50 photoresist and XP SU-8 developer

from Micro-Chem Co. Acrylamide: bisacrylamide

(29:1) solution was purchased from Bio Basic.

Ammonium persulphate (APS) and N,N,N’,N’-

tetramethylethylenediamine (TEMED) were bought

from Biosesang. Other reagents were purchased

from Biosesang. Deionized water (DIW) was used

throughout this research.

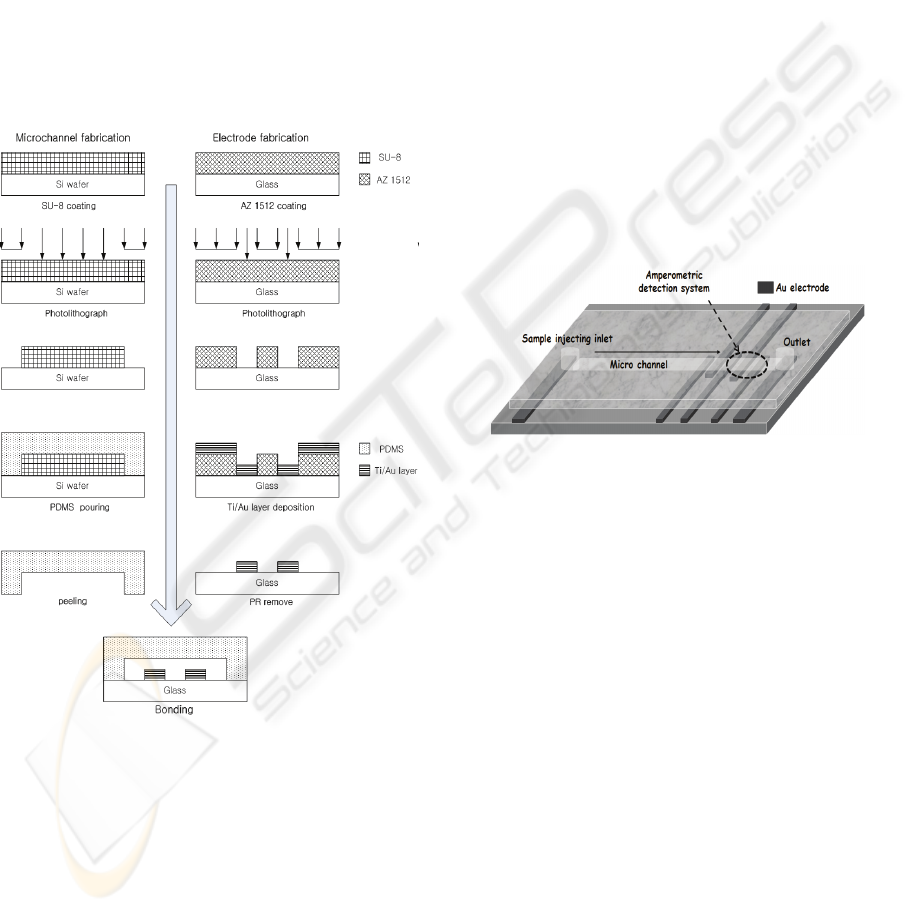

Figure 1: Fabrication process for Microchip.

2.2 Fabrication of the Microchip

Fig. 1 shows the simple procedure for the fabrication

of the CE–AD device. A silicon wafer was cleaned.

The wafer was then coated with SU-8 negative

photoresist using a spin coater. The molding masters

were made by photolithographic process. The height

of the positive patterns on the molding masters,

which were equal to the channel depth created on the

PDMS layer, was 200 μm when measured with a

surface profiler. The PDMS layer was fabricated by

pouring a degassed mixture of Sylgard 184 silicone

elastomer and curing agent (10:1) onto a molding

master, followed by curing for at least 1 h at 72 ℃.

The cured PDMS was peeled off from the mold, and

reservoirs were made at the end of each channel

using a 3 mm circular punch. The channels had a

width of 250 μm. The separation channel was 2 cm

long. The Au-electrodes for use in CE–AD were

deposited on a glass substrate by thermal eva-

poration system. For this purpose, 1.8 μm thick

photoresist (AZ-1512) was spin-coated on the bare

glass and patterned for Au-electrodes. After

evaporation, 320 nm thick Au layer was deposited

on an adhesion layer of 50 nm thick Ti. In order to

avoid the interference of high separation electric

field on amperometric detection, two decoupling-

ground electrodes were positioned in front of the

three-electrode amperometric detection system that

consisted of Au-electrodes of 250 μm width (Fig. 2).

Finally, the PDMS mold was bonded with glass

substrate after UV-ozone treatment for 40 min.

Figure 2: Schemetic of PDMS/Glass device.

2.3 Microchannel Treatment

Before use in CE–AD procedure, the microchannel

was cleaned by flushing with 1 M NaOH for 45 min

followed by D.I. water for 15 min at 5 μl/min flow

rate using a precision pump (KD Scientific, USA)

and then dried. Thereafter, 5% polyacrylamide

prepolymer solution consisting of a mixture of 875

μl Phosphate Buffered Saline (PBS), 125 μl 40%

(29:1) acrylamide/bisacrylamide solution, 1 μl TE-

MED and 4 μl 10% APS was introduced into the

microchannel. The microchip was ready for DNA

separation after 30 min of polymerization time.

2.4 CE-AD Procedure

For CE–AD, 5 μl testing sample was introduced in

the injection reservoir using a micropipette. After

the sample loading, an electric field was applied

between the sample reservoir and the sample waste

reservoir. Amperometric detection was performed

with three-electrode configuration (Fig. 2) placed in

the path of buffer flow. The potential between

BIODEVICES 2010 - International Conference on Biomedical Electronics and Devices

118

working and reference electrode was +1 V DC.

Redox reaction of adenosine from testing analyte on

the working electrode generated current peaks,

which was detected, recorded and stored directly on

a notebook computer using a CHI 800B potentiostat.

This instrument recorded 100 data points per second.

The testing analyte consisted of 9 fragments

(dsDNA).

3 RESULTS AND DISCUSSION

The CE–AD microchip developed in the present

research was used in separation and analysis of

DNA fragments. The chip was fabricated on

transparent glass substrate, which assisted in

Uvozone bonding with PDMS mold containing

microchannel as well as loading of samples into the

reservoir. The benefits of using PDMS as the

material for fabricating microchannel were its tran-

sparent color, ease in fabrication using negative

molding method, flexibility, mechanical strength and

stability. The amperometric detection system

consisted of in-channel working, counter and

reference electrodes. Two decoupler electrodes were

used to ground the separation current in order to

minimize electric noise. The choice of gold Micro-

electrodes was based on its inertness and ease in

patterning over glass substrate.

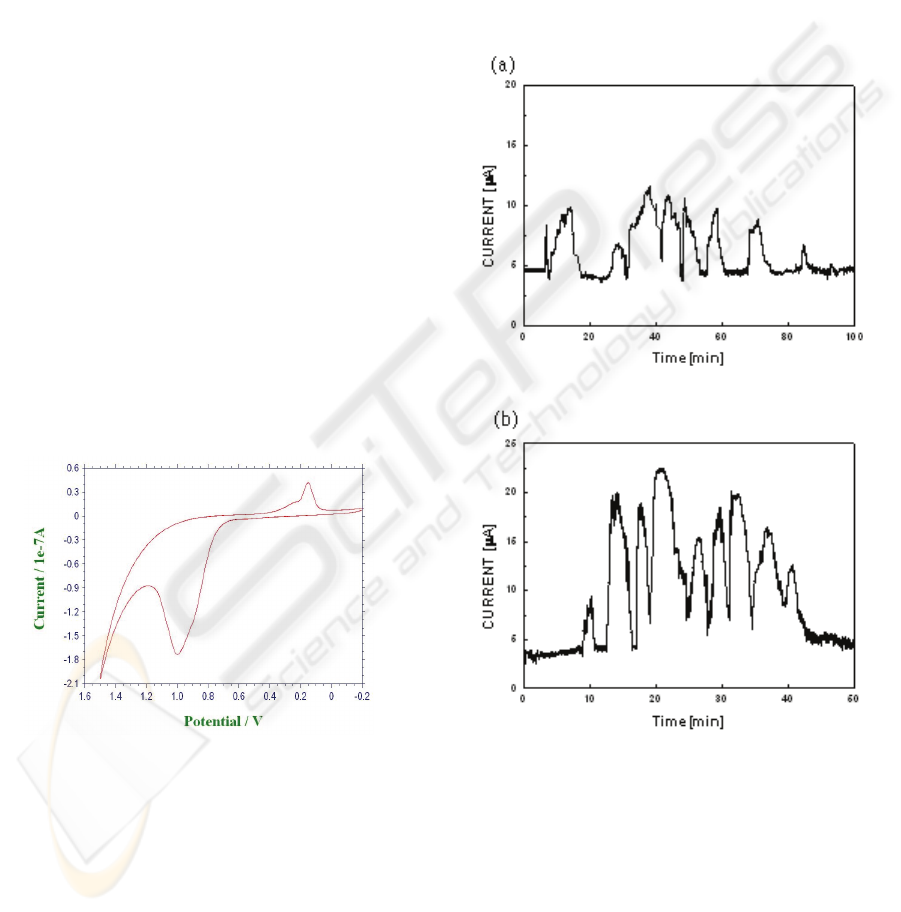

Figure 3: Cyclic voltammogram of DNA ladders in

microchip. The scan rate is 10mV/s

-1

.

The adenine and guanine base in the DNA chain is

to produce oxidation peak at +1 V DC (Fig.3).

Therefore, this potential was used for detection of

DNA fragments being separated inside the

microchannel filled with 5% polyacrylamide gel.

Although technically it was possible to resolve DNA

fragments in a narrow capillary without the use of

polyacrylamide, but that would require quite long

capillary length which may hinder the detection of

DNA due to its adsorption on long PDMS capillary

walls. Therefore, to minimize the detection time as

well as increase detection sensitivity, we used 2 cm

channel length filled with 5% polyacrylamide. The

DNA fragments were separated in the process due to

difference in molecular weight. Separation DC

potential is important factor as well as buffer

solution to enhance perfermance of device. We have

demonstrated effect of separation potential. all nine

fragments could be identified (Fig. 4 a,b) from the

Electropherogram for 85min at 100 V/cm and 40min

at 150 V/cm, repectively.

Figure 4: Electropherogram of DNA fragments using PBS

with 5% polyacrylamide for applied separation field

100V/cm (a) and 150V/cm (b).

The DNA fragments could be resolved during CE–

AD process and all nine fragments could be

identified from the Electropherogram (Fig.4). This

proved the feasibility to build a cost-effective and

power efficient microchip to analyze DNA

fragments. The specificity of proposed CE–AD

method shall depend on the presence of additional

electroactive species pro-ducing amperometric peak

DETECTION OF DNA AT THE MICROCHIP - Study of DNA Detection Microchip by Oxidation Peak of DNA

119

at + 1 V. The numbers of such species are limited in

most of the molecular biology techniques involving

DNA electrophoresis, including PCR, therefore

causing limited impact on the effectiveness of

proposed method.

4 CONCLUSIONS

In the present study, we devised a PDMS-based

microchip for capillary electrophoresis ampero-

metric detection of DNA fragments. At the cyclic

voltammetry experimental, oxidation peak of

adenine and guanine was indicated at + 1 V. The

capillary was filled with 5% polyacrylamide gel for

effective separation of DNA fragments under the

influence of separation potential. The amperometric

detection (AD) system involved in-channel gold

micro-electrodes and this technique was used in

resolving DNA fragments.

ACKNOWLEDGEMENTS

This work was supported by Grant No. ROA-2006-

000-10274-0 from the National Research Laboratory

Program of the Korea Science & Engineering

Foundation.

REFERENCES

F.M. Ausubel, R. Brent, R.E. Kingston, D.D. Moore, J.G.

Seidman, J.A. Smith, K. Struhl, Current Protocols in

Molecular Biology, John Wiley & Sons, 2003.

M.J. Schoning, M. Jacobs, A. Muck, D.-T. Knobbe, Sens.

Actuators, B 108 (2005) 688.

J.H. Kim, C.J. Kang, Y.-S. Kim, Microelectron. Eng. 71

(2004) 119.

J.H. Kim, C.J. Kang, Y.-S. Kim, Microelectron. Eng.

73/74 (2004) 864.

BIODEVICES 2010 - International Conference on Biomedical Electronics and Devices

120