LOW NOISE MEASUREMENT OF PHOTOCURRENT FOR

CONTINUOUS GLUCOSE MONITORING

Low Noise Measurement System Enables Continuous Monitoring of Glucose in

Subcutaneous Interstitial Fluid

Daniel W. Cooley

1

and David R. Andersen

1,2

1

Department of Electrical and Computer Engineering, The University of Iowa, 132 IATL, Iowa City, IA, U.S.A.

2

Department of Physics, The University of Iowa, 132 IATL, Iowa City, IA, U.S.A.

Keywords: Continuous glucose monitoring, IR photodiode, Transimpedance amplifier.

Abstract: We have developed a data acquisition unit (DAU) for continuous, low noise measurement of glucose

concentration in subcutaneous interstitial fluid (ISF). The system is comprised of a glucose sensor

(Olesberg, 2006), op-amps for signal conditioning, and delta-sigma (∆-Σ) ADCs. The glucose sensor has

two IR LEDs which emit light with wavelength of 2.2 to 2.4 μm where there are peaks in the glucose

absorption spectrum. The IR light propagates through a glass fluid chamber containing interstitial fluid and

a linearly variable bandpass filter before impinging on a 32 channel photodiode array. The center frequency

of the filter varies along one dimension of the filter, so that each photodiode is sensitive to equally spaced

portions of the glucose absorption spectrum. Transimpedance amplifiers (TIAs) convert the photocurrents

into voltages which are sampled by ADCs. We developed a noise model which predicts the noise

characteristics of the system. We use low noise metal film resistors to verify the DAU noise characteristics.

Non-ideal characteristics such as limited photocurrent and low photodiode shunt resistance increase

difficulty of obtaining low noise measurements. We demonstrate that the DAU provides low noise (41.7 dB

SNR) photocurrent measurements and is suitable for use in a continuous glucose monitoring system.

1 INTRODUCTION

We have designed and demonstrated a data

acquisition unit for low noise measurement of

glucose in subcutaneous ISF. In the future the

glucose sensor and DAU will be miniaturized for

use in an implantable, continuous glucose monitor.

The motivation for this research is clear as 23.8

million people in the U.S.A. had diabetes as of 2007

(CDC, 2007). Self monitoring of blood glucose

(SMBG) is one important method used to control

diabetes (Saudek, 2006)(Chia, 2004). Efforts

towards continuous monitoring of blood glucose are

under way to prevent high and low blood sugar

conditions and to use as part of an artificial pancreas

offering a type of "cure" for diabetes (Chia, 2004).

We measure the glucose concentration in ISF instead

of whole blood because it provides several

advantages. Measuring ISF glucose by an implanted

device is less painful and less invasive than repeated

use of finger-sticks to measure blood glucose

concentration (Rebrin, 2000). An implantable

glucose monitor would also require limited user

intervention and not require the cost of materials

required for SMBG with finger-sticks (Olesberg,

2006).

The glucose sensor measures the absorption

spectrum of glucose by passing IR light through a

fluid chamber containing ISF to a spectrometer. Two

LEDs provide IR light with wavelength in the range

2.2 to 2.4 um, near features of the glucose

absorption spectrum. The light propagates through a

linearly variable bandpass filter before impinging on

a 32 element photodiode array. Measuring the

current from each photodiode provides data for

determining the spectrum of the analyte. Our IR

photodiodes have low photocurrent due to the

limited amount of light that reaches the filter and is

transmitted to each photodiode. This limits the

maximum SNR the system can achieve. The shunt

resistance, R

T

, of the photodiodes is relatively low

which also limits the system SNR. The DAU must

provide low noise glucose measurements at a

195

W. Cooley D. and R. Andersen D. (2010).

LOW NOISE MEASUREMENT OF PHOTOCURRENT FOR CONTINUOUS GLUCOSE MONITORING - Low Noise Measurement System Enables

Continuous Monitoring of Glucose in Subcutaneous Interstitial Fluid.

In Proceedings of the Third International Conference on Biomedical Electronics and Devices, pages 195-200

DOI: 10.5220/0002747901950200

Copyright

c

SciTePress

frequency of 1 Hz on a continuous basis. We use

low noise metal film resistors to simulate the

glucose sensor while evaluating noise characteristics

of the DAU.

2 THEORY

2.1 Glucose Sensor

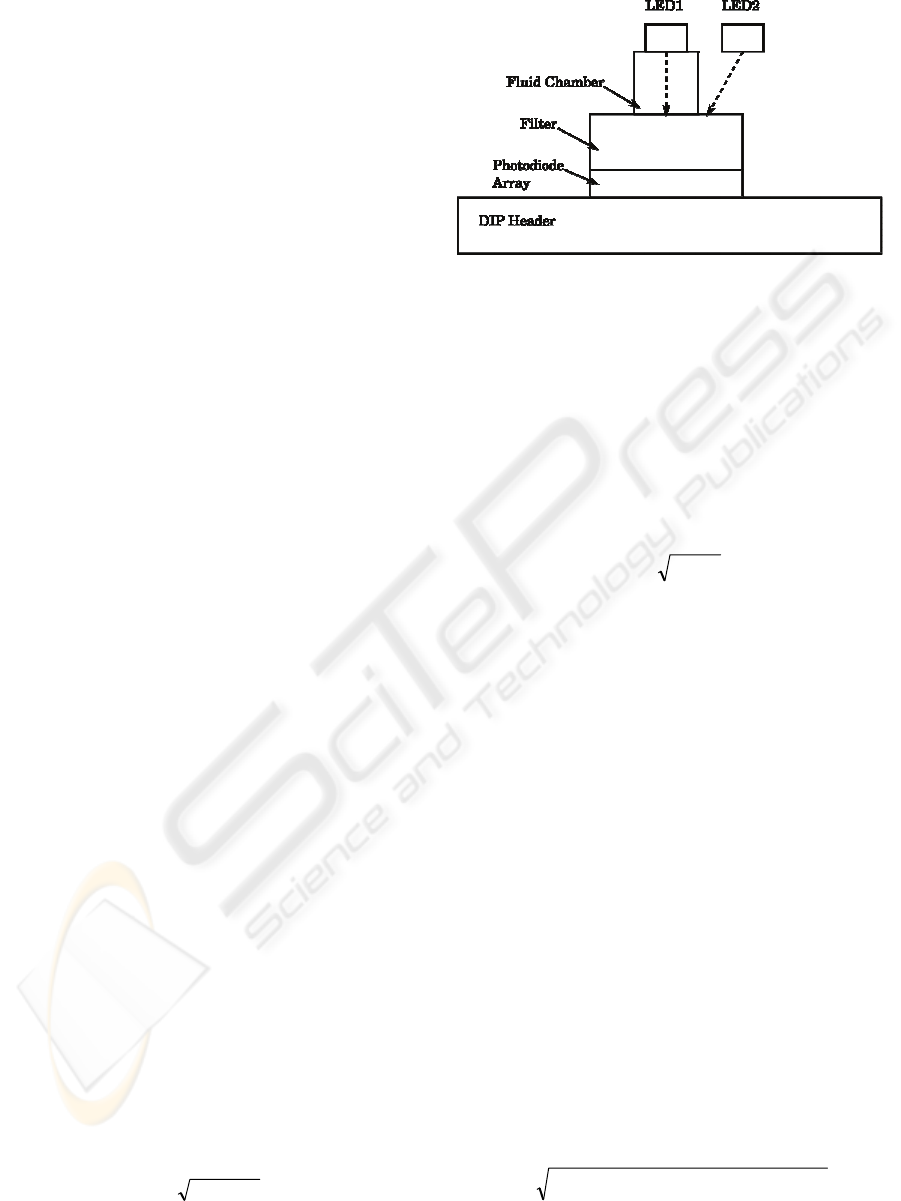

Figure 1 shows a schematic of the glucose sensor.

The sensor has two IR LEDs. LED1 emits light

directly into the fluid chamber containing ISF and

through the linearly variable filter to the 32 channel

photodiode array. Light from LED2 goes around the

fluid chamber before reaching the filter and

photodiodes. The fluid chamber is a thin-walled

capillary with square cross section and 0.8 mm inner

dimensions. The center frequency of the linearly

variable bandpass filter changes along the length of

the filter within the 2.2 to 2.4 μm wavelength range.

Thus each photodiode collects light from a different

portion of the glucose absorption spectrum when

LED1 is on. As IR light from LED1 propagates

through the ISF sample, glucose absorbs a portion of

the light near peaks in the glucose absorption

spectrum.

When the glucose sensor is used with the DAU,

we measure photocurrents with one LED on at a

time and also without any LEDs on in order to

normalize and compensate the sensor data for

temperature changes. To verify the DAU noise

characteristics in preparation for use with glucose

sensors we use low noise metal film resistors with

resistance equal to the photodiode shunt resistance in

place of the photodiodes.

Next we develop a mathematical model for the

noise present in the DAU to evaluate the system

noise performance.

2.2 Noise Model

2.2.1 Transimpedance Amplifier

Two types of noise that affect the system operation

are thermal noise and shot noise (Motchenbacher,

1993). The random motion of charge carriers in a

conductor causes thermal noise, also known as

Johnson noise. The thermal noise voltage of a

resistor R is in series with the resistor and is

f4kTRE

T

Δ=

,

(1)

Figure1: The glucose sensor. LED1 emits light through

fluid chamber to the filter and diode array. LED2 light

goes around the fluid chamber.

where k is Boltzmann's constant, T is temperature in

Kelvin, and ∆f is the measurement bandwidth. The

series combination of the resistor and its thermal

noise voltage may be converted into a current source

of value E

T

/R in parallel with the resistor. Shot noise

occurs in transistors and diodes and is due to

quantized current flowing across a potential barrier.

The shot noise current for I amps of current is

f2qII

S

Δ=

,

(2)

where q is the electronic charge.

We chose the transimpedance amplifier, Figure

2, to convert photodiode current into a voltage for

measurement by an ADC. Another method would be

to use a current input ADC, but we chose the TIA in

order to maximize the system SNR. To develop the

noise model we start with a schematic for the TIA

including op amp noise terms (Steffes, 2005) as

shown in Figure 3. Here E

NI

is the op amp input

noise voltage, I

BI

is the op amp input current noise,

R

T

is the test resistor simulating the photodiode

shunt resistance, I

RT

is the noise current equivalent

to the thermal noise from R

T

, R

F

is the feedback

resistor, and E

RT

is the feedback resistor thermal

noise. We omitted the photodiode series resistance

from the noise model because of its relatively small

magnitude.

We find an expression for the noise at the TIA

output by incoherently adding the noise terms (E

NI

,

I

BI

, I

RT

, and E

RF

) multiplied by the gain between the

noise term and the TIA output. With G

N

= 1 + R

F

/R

T

and combining some terms, the noise voltage at the

TIA output is Eq. 2 from (Steffes, 2005) with R

S

=

0:

()()

NF

2

FBI

2

NNIO

G4kTRRIGEE ++= .

(3)

BIODEVICES 2010 - International Conference on Biomedical Electronics and Devices

196

Figure 2: Transimpedance amplifier.

Figure 3: TIA with noise terms.

Including a term for the ADC noise voltage, V

ADC

,

and the voltage reference noise, V

REF

, in Eq. 3 we

find a noise model for the TIA:

()()

2

REF

2

ADCNF

2

FBI

2

NNIO

V/NVG4kTRRIGEE Δ+Δ+++=

, (4)

where typically N = 250 ADC samples are averaged

per data point. We calculate the SNR of the noise

model using the expression

(

)

OFPC10

E/RIlog10SNR = ,

(5)

where I

PC

is the photocurrent. One multiplies the

logarithm in Eq. 5 by 10 instead of 20 when

calculating the SNR because the photocurrent is

proportional to the luminosity of light arriving at the

photodiode and luminosity is luminous power per

unit area.

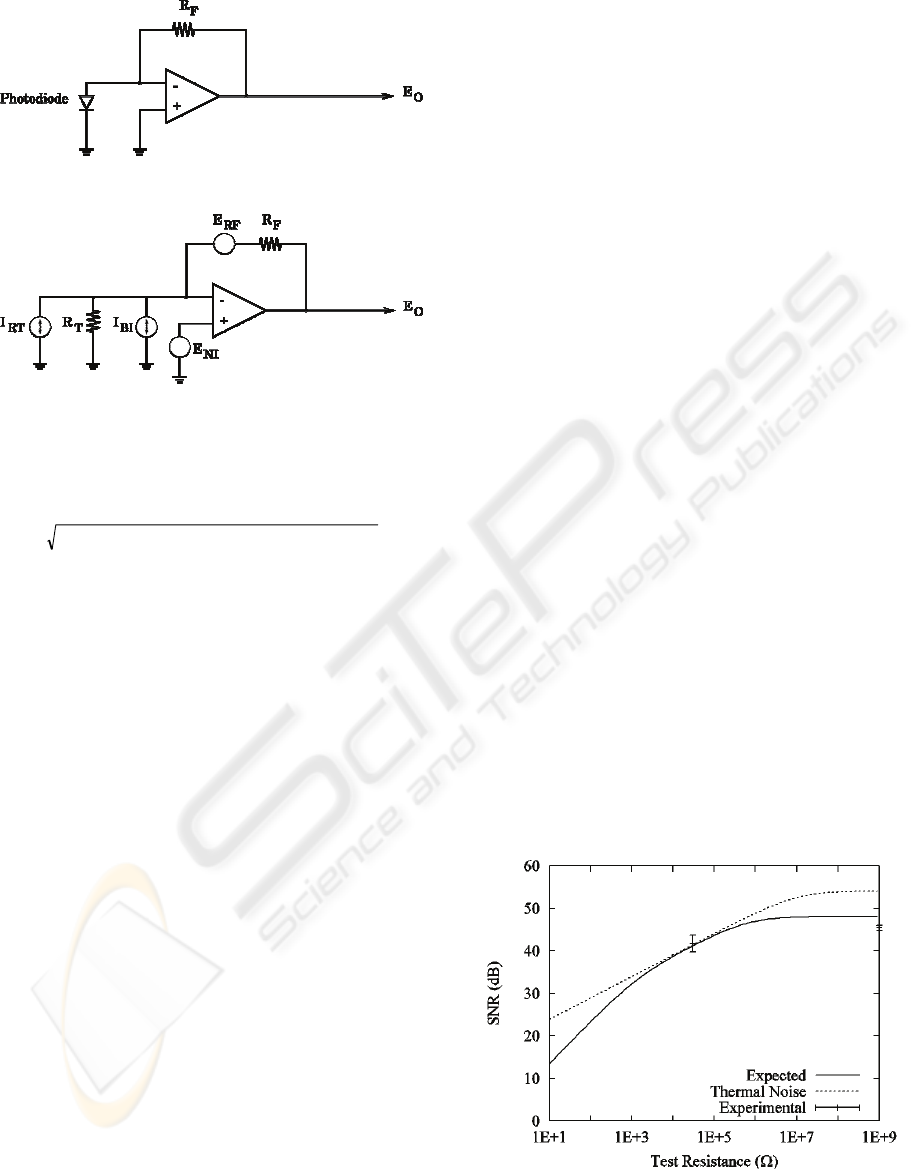

A plot of the noise model, Figure 4, has three

straight segments and a different term from Eq. 4 is

dominant in each segment. The left segment has a

slope proportional to 1/R

T

and is due to the E

NI

term

in Eq. 4. As E

NI

increases the left segment of the

curve will shift down. The middle segment has a

slope inversely proportional to the square root of R

T

and is due to the third term, the thermal noise. An

increase in thermal noise will reduce the SNR. The

middle section of the curve also shows that

increasing R

T

increases the SNR. The final, flat

section arises from the combination of noise from

thermal noise of the feedback resistor, input current

noise, V

ADC

, and V

REF

. Calculating these noise

voltages with our final component values shows that

the voltage reference noise provides the SNR limit

within the right segment of Figure 4.

2.2.2 Photodiode

The IR photodiode I-V characteristic differs from

typical Si photodiode characteristic curves in several

ways. The IR photodiodes have lower reverse

breakdown voltage, higher reverse saturation

current, lower shunt resistance, and, when operating

as part of the glucose sensor, lower photocurrent

than Si photodiodes. For example the IR

photodiodes have reverse breakdown of 1 to 2 volts

and reverse saturation current of approximately 1A.

The S1133 has a maximum reverse voltage of 10V

and dark current of 15 pA at 10V reverse voltage

(Hamamatsu, 2001).

From our experimental results I

PC

is measured to

be 10 nA. We chose a value of 10 M for R

F

in

order to yield a signal voltage of 0.1 V that is within

the input range of the ADC. The relatively small

photocurrent due to the limited amount of light

reaching the filter and limited amount of light

transmitted through the filter reduce the achievable

SNR when compared to Si photodiodes in typical

applications. For example, the S1133 Si photodiode

can provide 100 A of output current with high

enough illumination (Hamamatsu, 2001), which is

10,000 times more photocurrent than we can obtain

from our glucose sensor.

The IR photodiodes have shunt resistance, R

T

, of

approximately 30 k. This also increases the

difficulty in increasing SNR since the thermal noise

is proportional to the amplifier gain, 1 + R

F

/R

T

. The

typical S1133 shunt resistance is 100 G

(Hamamatsu, 2001), much greater than the IR

photodiode shunt resistance. The low shunt

resistance is due to the increased bandgap

wavelength of the IR photodiodes (2.5 m) versus

that of typical silicon diodes (1.1 m).

Figure 4: Plot of the output from our noise model with

N=250. Thermal noise and experimental data also shown

for comparison.

LOW NOISE MEASUREMENT OF PHOTOCURRENT FOR CONTINUOUS GLUCOSE MONITORING - Low Noise

Measurement System Enables Continuous Monitoring of Glucose in Subcutaneous Interstitial Fluid

197

We cannot reverse bias the IR photodiodes due

to their high reverse saturation current. Increasing

reverse bias increases the dark current and shot noise

on the dark current would dominate other noise

sources and reduce the SNR. Also, since the dark

current increases with more reverse bias as the

photocurrent remains constant, a smaller portion of

the current flowing into the TIA is due to the

photocurrent, reducing the SNR.

2.3 Circuit Design

Figure 5 shows the final circuit design used for each

channel. We added the shot noise on the offset

current, op amp input current noise, and op amp

voltage noise for a number of op amps to select an

op amp for the TIA. Here the offset current is the

sum of the op amp input offset current and the

current in R

T

due to the op amp offset voltage. We

included shot noise on the offset current since the

source of the photodiode current is a diode junction.

We chose the MAX4478 (Maxim, 2005) because it

minimized the sum of these noise voltages.

The chief factors affecting choice of the ADC

are the resolution, number of delta-sigma (∆-Σ)

blocks in the device, ability to daisy-chain serial data

ports of devices, and conversion time. We chose a

24-bit ∆-Σ ADC with 8 channels, 8 ∆-Σ blocks, and

maximum sampling rate of 52.7 kHz when using

high resolution (Texas Instruments, 2008). Four

ADCs are necessary to sample all 32 channels

simultaneously. We need a minimum of 20 bit ADC

resolution to keep the quantization error well below

the system noise. Since there is one ∆-Σ block for

each photodiode channel, multiplexing ADCs is

unnecessary, allowing time efficiency and

simplifying the software required to archive data.

The serial ports of the ADC we chose can be

daisy-chained which also simplifies the system

because only one serial port is required. We need to

record four types of samples to calculate the glucose

concentration: with LED 1 on/LED2 off, both LEDs

off, LED1 off/LED2 on, and both LEDs off. Since

we sample all channels simultaneously and typically

record N = 250 samples per second, recording four

types of data samples requires a sampling rate of 1

Figure 5: Schematic of one DAU channel.

kHz, well below the ADS1278 maximum sample

rate. We selected a low noise voltage reference with

noise voltage of 1.5 μV and a low temperature

coefficient of 0.6 PPM/deg. C. (Cirrus Logic, 2009)

3 EXPERIMENT AND RESULTS

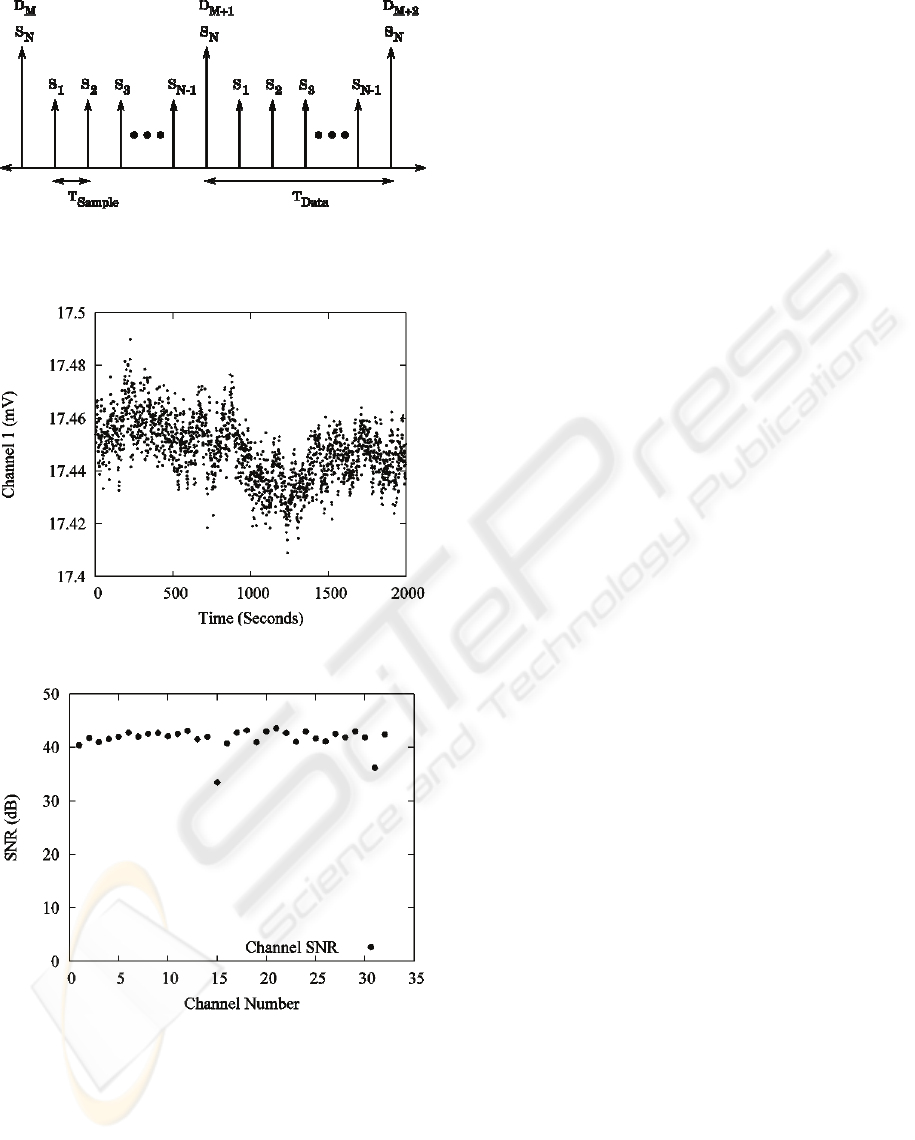

Figure 6 shows the method we use to record

experimental data. The time per data point, T

Data

, is 1

second and N = 250 so that T

Sample

= 1/250 second.

The DAU samples the voltage on all channels at

points labeled S

n

. At points labeled D

m

the average

value of the samples for all channels are calculated

and archived. When we use the glucose sensor the

four types of data mentioned above must be

recorded in each sample period to calculate the

glucose concentration. While verifying the SNR of

the DAU system in this paper we utilize low noise

resistors and only one of the four types of data is

required since there are no LEDs present without the

glucose sensor.

To test the SNR we record a large (1k data

points) set of experimental data and calculate the

SNR. Figure 7 shows a plot of channel voltage vs.

time for a representative channel. Figure 7 shows

2000 data points from channel 1 taken at a rate of 1

Hz – the last 1000 data points were used to calculate

the SNR. The plot shows approximately 20 µV of

drift with +/- 10 µV of noise in the last 1000 data

points. The standard deviation of this portion of data

is 9.12 μV and the SNR for channel 1 is calculated

to be 40.4 dB. Fig. 8 shows the SNR for all 32

channels. The mean SNR is 41.7 dB and the

standard deviation of the SNR is 2.0 dB. Channels

15 and 31 do have 5 to 7 dB more noise than the

other channels. This is likely due to slight

differences in noise characteristics of the op amps.

Fig. 4 also shows the thermal noise present in the

BIODEVICES 2010 - International Conference on Biomedical Electronics and Devices

198

Figure 6: Method for recording experimental data.

Channels are sampled at S

n

and data points are calculated

and recorded at D

m

.

Figure 7: Voltage on channel 1 versus time.

Figure 8: SNR of all 32 channels.

TIA to indicate the maximum SNR possible if the op

amps, ADCs, and voltage reference were ideal

components. The experimental results are within one

standard deviation of both the expected noise and

thermal noise for R

T

= 30 kΩ but the experimental

data point with an open circuit, 45.4 dB, is slightly

below the expected noise of 48 dB. This difference

has been traced to excess ripple on the voltage

reference supply voltage.

4 DISCUSSION

Although thermal noise limits the DAU SNR when

using low noise metal film test resistors, additional

noise sources will be present when using actual

glucose sensors with the DAU. The photocurrent

and dark current would both provide shot noise since

they originate from a diode junction. In order to

eliminate shot noise from dark current the

photodiodes cannot be reverse biased. The shot

noise from 10 nA of photocurrent is 57 fA. The

voltage created by this current passing through R

F

is

0.57 µV. The mean SNR of 41.7 dB corresponds to

6.76 µV of noise voltage. Adding these two noise

voltages still results in 41.7 dB SNR so the shot

noise on the photocurrent will not significantly

degrade the SNR.

A fan cooled the DAU to reduce the effects of

thermal drift during our experiments. This is

reasonable here since when the DAU and glucose

sensor are designed into an implantable device the

system will be in an environment with constant

temperature.

5 CONCLUSIONS

The experimental measurements of SNR agree very

well with the SNR calculated with the noise model

for the TIA. The experimental SNR of 41.7 dB for

R

T

= 30 kΩ is also very close to the thermal noise

limit, i.e., it is the maximum SNR possible with this

TIA design and R

T

of 30 kΩ. This indicates the

DAU is acceptable for use with prototype glucose

sensors and for future miniaturization of the DAU

system and glucose sensor into a continuous glucose

monitoring system.

A noise model was developed for the DAU and

experimental data verified that the system works as

expected by theory. In the future we will use the

DAU to test glucose sensors by measuring

absorption spectra of water and glucose. We also

plan studies using ISF with the glucose sensors

before miniaturization of the sensor and DAU

electronics.

LOW NOISE MEASUREMENT OF PHOTOCURRENT FOR CONTINUOUS GLUCOSE MONITORING - Low Noise

Measurement System Enables Continuous Monitoring of Glucose in Subcutaneous Interstitial Fluid

199

ACKNOWLEDGEMENTS

The authors would like to acknowledge support from

NIH Grant No. DK064569.

REFERENCES

Olesburg, J. T., Cao, C., Yager, J. R., Prineas, J. P.,

Coretsopoulos, C., Arnold, M. A., L. J. Olafsen, L. J.,

Santilli, M., 2006. Proc. of SPIE 694, 609403.

Centers for Disease Control and Prevention, 2007.

"National Diabetes Fact Sheet, 2007,” Department of

Health and Human Services - Centers for Disease

Control and Prevention.

Saudek, C. D., Derr, R. L., Kalyani, R. R., 2006. JAMA

295 No. 14 p. 1688.

Chia, C. W., Saudek, C. D., 2004. Endocrinol. Metab.

Clin. N. Am. 33 p. 175.

Rebrin, K., Steil, G. M., 2000. Diabetes Tech. and

Therapeutics 2 No. 3 p. 461.

Motchenbacher, C. D., Connelly, J. A., 1993. Low-Noise

Electronic System Design, John Wiley and Sons. New

York.

Steffes, M., 2005. Application Report SBOA066A, "Noise

Analysis for High-Speed Op Amps,” (www.ti.com).

Hamamatsu, 2001. Datasheet, “Si Photodiode

S1087/S1133 series,” Hamamatsu Photonics K. K.

Maxim, 2005. MAX4478 datasheet. “MAX4478 SOT23,

Low-Noise, Low-Distortion, Wide-Band, Rail-to-Rail

Op Amps,” Maxim Integrated Products, Inc.

Texas Instruments, 2008. ADS1278 datasheet. “ADS1278

Quad/Octal, Simultaneous Sampling, 24-Bit Analog-

to-Digital Converters,” Texas Instruments, Inc.

Cirrus Logic, 2009. VRE3025 datasheet. “VRE3025

Precision Voltage Reference,” Cirrus Logic, Inc.

BIODEVICES 2010 - International Conference on Biomedical Electronics and Devices

200