AL

2

O

3

NANOLAYER AS EVANESCENT WAVEGUIDE

FOR BIOMEDICAL SENSOR APPLICATION

A. Purniawan, P. J. French

Electronic Instrumentation Laboratory (EI), TU Delft, Mekelweg 4, room 13.260, 2628 CD Delft, The Netherlands

Y. Huang

,

G. Pandraud, P. M. Sarro

Delft Institute of Microsystems and Nanoelectronics (DIMES), TU Delft

Feldmannweg 17, 2628 CT Delft, PO Box 5053, 2600 GB Delft, The Netherlands

Keywords: Evanescent waveguide, Drain fluid, Anastomosis leakage, ALD, Thin film stress.

Abstract: The aim of our research is to develop a sensitive sensor for biomedical applications. A nanolayer Al

2

O

3

is

used as evanescent waveguide. The material was deposited on a silicon wafer by using atomic layer

deposition (ALD). In the present paper, we will report the preliminary results of our project such as

deposition, characterization of nanolayer, and evanescent waveguide sensor design. Lambert beer’s law and

some waveguide concepts are combined in the design to obtain the optimum parameters of the evanescent

waveguide sensor. Furthermore, characterizations to investigate optical properties and internal stress of the

thin film were done. Based on the results of lattice parameter analysis, we can conclude that thin film

thickness have effect not only on sensitivity of the sensor but also on the mismatch stress between substrate

and thin film. Design results show that a thickness of waveguide of 50 nm and an optical path length of the

sensor of 1 mm can be used as waveguide dimension with a transmission of 75%. 50 nm thin film thickness

shows low mismatch stress and that was shown by high radius curvature 32.34 m.

1 INTRODUCTION

Anastomosis is an operation to make continue the

organ as like colon, bowel, pancreas etc.

Anastomosis leakage is still a problem in medical

especially post-operate. The patient’s mortality rate

due to anastomosis leakage is still high, because

often the leakage is identified too late. The

indication of anastomosis leakage is the presence of

a high concentration of bacteria in the drain fluid.

There are many types of bacteria like Bacteriodes

sp., Lactobacillus acidophilus, Klebsiella sp., and

Eschericia coli (E. Coli) in drain fluid. These

bacteria are essential for food digesting. However,

due to malfunction in the colon, bacteria could enter

the abdominal cavity causing severe infections

(Chaeron, 2007 and Pakula et al., 2005).

The conventional identification needs at least

seven days to obtain accurate results. Currently,

there are three existing experiment methods to

perform a microbiological analysis on drain fluid,

being bacteria culture, Raman spectroscopy, and

polymerase chain reaction (PCR) to make million

DNA copies of the bacteria. The disadvantages of

the methods are the time to analyze and high cost.

In our research, an evanescent waveguide

sensor is developed to detect bacteria in drain fluid

as an indication of anastomosis leakage. The

properties of material and structure are very

important to obtain a sensor with high sensitivity.

Aluminum oxide (Al

2

O

3

) has a high refractive index.

Therefore the material has high potential as thin film

material waveguide. Atomic layer deposition (ALD)

was used to deposit Al

2

O

3

due to its advantages to

produce high conformality, uniformity, and

smoothness. In order to obtain optimal parameters,

Lambert beer’s law and waveguide evanescent

sensors were combined to calculate the optimal

waveguide dimensions. In this paper, we present

evanescent waveguide sensor design and

experimental results of the optical and structural

characterization.

1.1 Lambert Beer’s Law

Lambert beer’s law is often used to analyze the

44

Purniawan A., French P., Huang Y., Pandraud G. and Sarro P. (2010).

AL2O3 NANOLAYER AS EVANESCENT WAVEGUIDE FOR BIOMEDICAL SENSOR APPLICATION.

In Proceedings of the Third International Conference on Biomedical Electronics and Devices, pages 44-48

DOI: 10.5220/0002751400440048

Copyright

c

SciTePress

absorbance (A) of media while light is transmitted in

the media. The transmission of light is called

transmissivity (T), the ratio between output and

input of light. The transmissivity is expressed as:

o

I

T

I

=

(1)

And the formula of absorbance as:

A

cl

σ

= (2)

The relationship between transmission and

absorbance is as follows:

10 10

1

log 2 log %

A

T

T

==−

(3)

Where σ is the molar absorption coefficient (M

-1

cm

-

1

), c is media concentration and l is path length of

light in waveguide (cm).

1.2 Evanescent Waveguide Design

Planar waveguide is more used in optical integrated

system. The source of light couples with edge of

waveguide and the receiver in the other side. The

light through the waveguide with difference

refractive index between core and cladding such as

n

1

is refractive index of core (Al

2

O

3

) and n

2

is

refractive index of cladding. Furthermore, the light

wave through the optic material with angle (

θ

1

) is

called incident angle and the reflective angle (

θ

2

) is

the angle of the direction of the reflection light

wave. In order to obtain maximum reflection, the

expected light way in the cladding is at lease parallel

with the both materials interface and other word that

the reflective angle (

θ

2

) is 90

o

. The critical incidence

angle is defined as the minimum incident angle to

obtain a reflective angle of 90

o

.

By using Snell’s law,

the critical incidence angle can be calculated.

Critical incidence angle implies

θ

2

= 90

o

and that

sin

θ

2

= 1. Hence, the critical incident angle can be

expressed as:

1

2

1

1

sin

n

n

θ

−

⎛⎞

=

⎜⎟

⎝⎠

(4)

In the evanescent sensor wave guide, penetration

depth is the maximum depth from which the sensor

can obtain information. The penetration depth is

very important to estimate the performance of sensor

to detect objects in the sensor surroundings. The

range over which excitation is possible is limited by

the exponential decay of the evanescent wave energy

in the z-direction, perpendicular to the interface. In

this case energy is proportional with light intensity.

The following equation defines this intensity as a

function of distance from the interface:

()

exp

z

d

zo

II

−

=

(5)

I

z

is the energy at a perpendicular distance z from the

interface, and I

0

is the energy at the interface. The

penetration depth state when d = z and the

penetration depth intensity is 100% x e

-1

(36.7% I

o

).

The range over which excitation is possible is

limited by the exponential decay of the evanescent

wave energy in the z-direction. The penetration

depth d, is dependent upon the wavelength of the

incident illumination, λ

i

, the angle of incidence, and

the refractive indices of the media at the interface,

according to the Equation (6) and the general

formula of light propagation in waveguide expressed

in Equation (7).

()

1

22 2

2

112

sin

4

i

dxn n

λ

θ

π

−

=−

(6)

2

1

12

2

12

2

22

22

22

2

22

22

2

arctan

arctan 0

eff eff

eff

eff

eff eff

eff

p

p

nnn

t

nn

nn n

nnn

m

nn n

π

λ

π

⎡

⎤

⎛⎞

−

⎢

⎥

+−

⎜⎟

⎜⎟

−

⎢

⎥

⎝⎠

⎣

⎦

⎡⎤

⎛⎞

−

⎢⎥

−−=

⎜⎟

⎜⎟

−

⎢⎥

⎝⎠

⎣⎦

(7)

Where n

eff

is refractive index effective and m is

constant of waveguide mode.

1

.sin

eff

nn

k

β

θ

==

(8)

Where

β

is the propagation constants along z is

expressed by

β

= k.n

1

sin

θ

. Furthermore the Eq. (7)

is derived to obtain the normalized parameters that

to be used to calculate geometry of the sensor that

the more detail was be explained by Veldhuis et al,

2000. Cutoff condition is the optimum condition

when the effective refractive index is equal to the

cladding’s refractive index. Then, the sensitivity of

sensor can be calculated using equation

22

2

2

2

2

1

eff eff

eff tot

nnn

P

S

nnP

⎧⎫

−

⎪⎪

=+

⎨⎬

⎪⎪

⎩⎭

(9)

Where S is sensitivity, P

c

/P

tot

is ratio energy

(intensity), n

2

is cladding’s refractive index.

2 EXPERIMENTAL

A silicon wafer was used as substrate material

whereas the Al

2

O

3

as thin film material. In order to

obtain homogeneity, conformality and low internal

stress, ALD was employed to deposit the thin film.

Tetra methyl aluminum (Al(CH

3

)

4

) and H

2

O are as

precursors and N

2

is used as gas carrier. The cycle

AL2O3 NANOLAYER AS EVANESCENT WAVEGUIDE FOR BIOMEDICAL SENSOR APPLICATION

45

processes used ratio 1:2:1:3 s. It means that the pulse

time is one second for 1

st

precursor (Al(CH

3

)

4

), two

seconds for purge (N

2

), then one second for 2

nd

precursor (H

2

O) and finally three seconds for purge

(N

2

). The total time for one cycle is seven seconds.

Process temperature is 300

o

C. Subsequently the thin

film was characterized using Atomic Force

Microscope (AFM) to investigate topography and

surface roughness of thin film, thickness

measurement and stress measurement to measure the

internal stress of thin film.

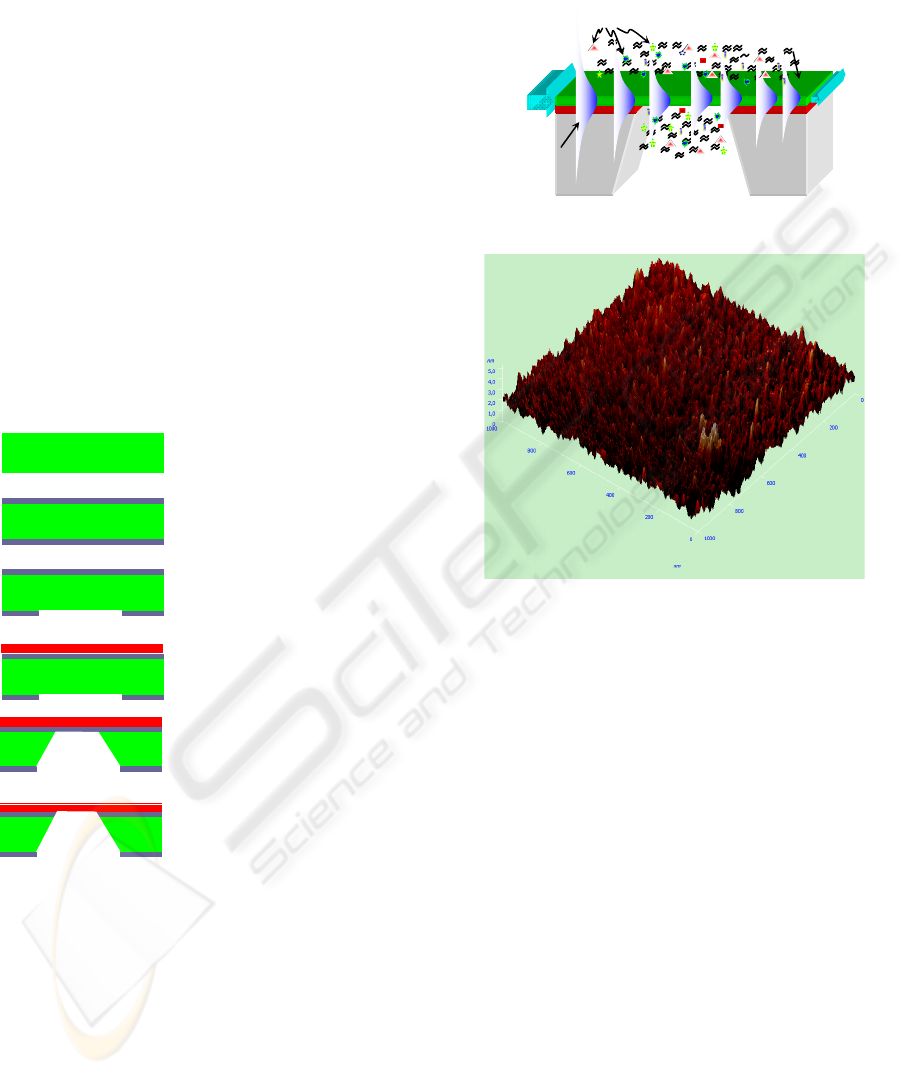

In the fabrication process, to pattern the

structure, three masks for contact aligner lithography

were designed consists of two masks for front side to

make ribs and bridges structures and one mask to

open SiO

2

in backside. Firstly, the process

fabrication makes windows in the backside. Then

after patterning the front side and finally etching the

backside. The structure is made the free standing.

The flowchart of the detail process is shown in Fig.

1(a) – (f).

Figure 1: Fabrication process flowchart for waveguide free

standing structure

.

The freestanding waveguide structure and

evanescent field region is shown in Figure 2.

3 RESULTS AND DISCUSSIONS

Based on experiment results, the thickness of Al

2

O

3

is 46.6 nm during 500 cycles, (0.9Å/cycle), the

refractive index is 1.65 and the internal stress of

Al

2

O

3

thin film is 246 MPa. By using AFM, the

surface topography and surface roughness of Al

2

O

3

can be seen in Figure 3.

Figure 2: Evanescent waveguide.

Figure 3: AFM Topography of Al

2

O

3

-ALD with root mean

square 0.5 nm.

In previous research of our group, drain fluid

transmission analysis was conducted by using

visible light and infrared light wavelength. The

results show that the visible light spectrum did not

show any distinction wavelength at which the

transmission was implicitly bacteria contamination

dependent. Moreover, low contamination was not

measurable with the visible light set-up. The other

wavelength, infrared spectrum was used in the

experiment. Infrared wavelength spectrums 2µm and

4.3µm have high sensitivity to make difference

transmission results when the light through drain

fluid (Pakula et al, 2005). It means that both

wavelengths can be used as light source in drain

fluid analysis. In the present research 2 µm

wavelength is used as light input of the sensor. In

addition, drain fluid with variable bacteria

concentrations analysis to obtain the transmission

percentage was conducted in previous experiment by

our group (Chaeron, 2007).

From medical point of view, 20% concentration

of bacteria in drain fluid is the critical range. The

results from the experiment were taken for further

Drain fluid, n

2

Light

source

Si

Si

Bacteria

Output

Evanescent

field region

Drain fluid, n

2

Al

2

O

3

, n

1

(a) Starting material (N-type

100 Silicon wafer)

(b) 2 micron SiO

2

using wet

thermal oxidation for 8

hours 12 minutes

(c) Open SiO

2

windows in the

backside plasma etching

Drytec Triode for 6

minutes.

(d) 100nm Al

2

O

3

deposition

using ALD then patterning

rib and bridge on the front

side using RIE Alcatel

plasma etching

(f) SiO

2

backside etching

using RIE Alcatel.

(e) Backside etching using

TMAH with protecting

holder on the front side

(etching process stop on

SiO

2

)

BIODEVICES 2010 - International Conference on Biomedical Electronics and Devices

46

analysis, especially near critical concentration (20%)

which is 25% bacteria concentration. By taking

value of transmission of drain fluid with E.Coli exist

in the drain fluid for 1 day after taken from patient

and path optical length 0.865 cm, the transmission

result is 8.3% then the transmission value is plotted

in Figure 1 to obtain the absorbance value is 1.08.

By using Equation (2) can be calculated the molar

absorption coefficient which is 0.4998. Furthermore,

the optical path length is fixed at 1 mm and using the

Equation (2) the absorbance is 0.125. By plotting the

absorbance result to Figure 1, the transmission value

is found to be 75%.

The important parameters have to be analyzed

to obtain the critical incident angle. It depends on

material properties especially refractive index of the

materials of both core and cladding material. The

incident angle must be more than critical angle to

obtain total reflection. Based on measurement Al

2

O

3

,

deposited by ALD, refractive index ‘n

1

’

is 1.646.

Cladding’s refractive index ‘n

2

’ is 1.33. The angle

can be calculated from Snell’s law modified as

Equation (4) and the result of critical incident angle

is 53.9

o

. In this experiment, the waveguide will be

coupled with source of light with incident angle 90

o

,

λ

i

= 2000 nm and using Equation (6), the penetration

depth of the waveguide sensor can be calculated of

164 nm. Due to the symmetrical waveguide, a

maximum sensitivity S

max

= 2.S (Velduis et al, 200).

Hence, using Equation (9) can be found the

maximum sensitivity of sensor as shown in Table 1.

Table 1: Sensitivity of waveguide of varying waveguide

thickness.

Thickness, nm

(t)

Effective index

(n

e

ff

)

Sensitivity

(S

max

)

50 1.331 0.997

100 1.333 0.989

150 1.338 0.975

200 1.344 0.965

The film has as incompatible elastic mismatch

strain with respect to the substrate; this strain might

be due to thermal expansion effects, epitaxial

mismatch, phase transformation, chemical reaction,

moisture absorption or other physical effects.

Whatever the origin of the strain, the goal here is to

estimate the curvature of the substrate, within the

range of elastic response, induced by the stress

associated with the incompatible strain.

Stoney’s formula is original analysis of the

stress in a thin film deposited on a rectangular

substrate was based on a uniaxial state of the stress.

Consequently, his expression for curvature did not

involve use of the substrate biaxial modulus M

s

.

Consequently, it can be applied in situations in

which mismatch derives from in elastic effect (Freud

and Suresh, 2003). The expression for curvature is

famous Stoney’s formula relating curvature to stress

in the film as:

2

6

mf

s

s

h

M

h

σ

κ

=

(10)

Where

κ

represents the curvature, or inverse of the

radius of curvature, of this plane,

σ

f

is mean stress,

h

f

is the thickness of the thin film, M

s

is substrate

biaxial modulus and h

s

is substrate thickness. The

mean mismatch strain of substrate and the

corresponding mismatch stress of thin film

expressed as:

23

23

Si Al O

m

Al O

aa

a

ε

−

=

(11)

mmf

M

σε

=

(12)

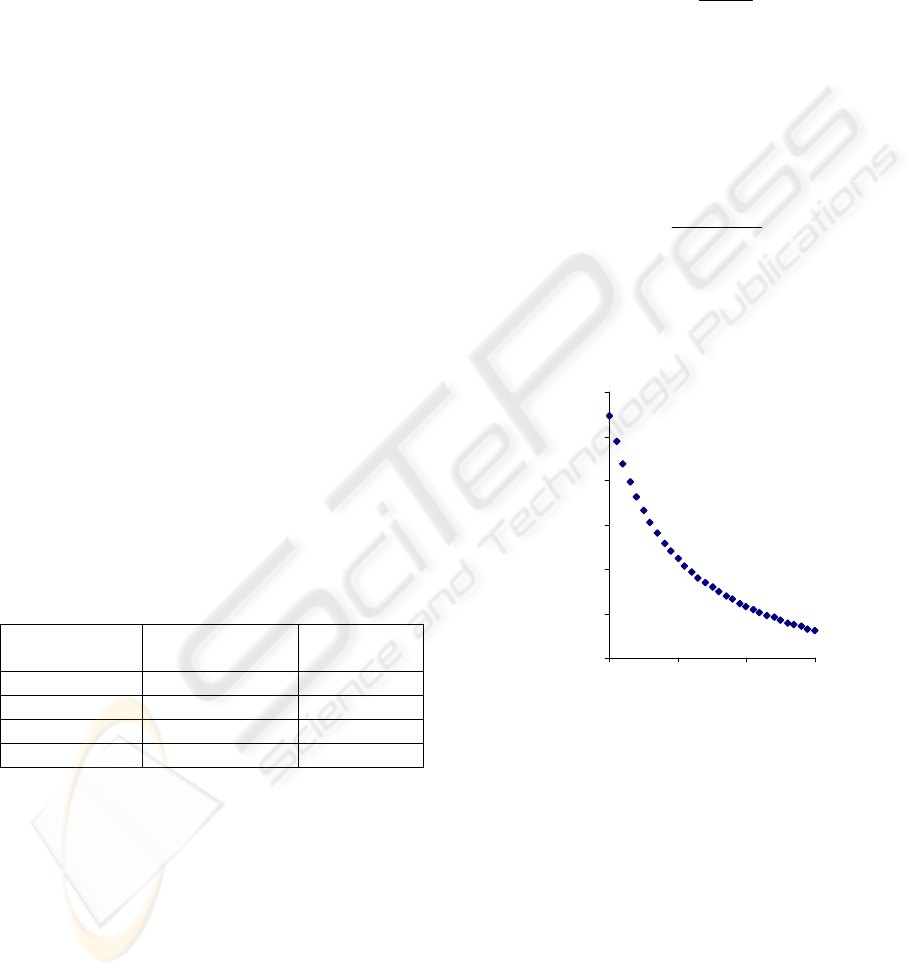

Figure 4 shows the curvature radius of various thin

film thickness. The curvature radii gradually

decrease with increasing thin film thickness.

5

10

15

20

25

30

35

50 100 150 200

Thickness

(nm)

Radius (m)

Figure 4: Curvature radius as function of thin film stress of

Al

2

O

3

in the surface substrate with various thin film

thickness.

By taking the thin film thickness h

f

= 50 nm of Al

2

O

3

is grown on Si-wafer substrate with thickness h

s

=

500 µm, lattice parameter of a

Al

= 0.405nm, a

O

=

0.683 nm and a

Si

= 0.5431nm. The lattice parameter

of Al

2

O

3

at room temperature is a

Al2O3

= 0.53a

Al

+

0.47a

O

= 0.536 nm. The biaxial modulus of Al

2

O

3

(M

f

) and Si (M

s

) are 380 GPa and 180.5 GPa,

respectively. By substitute Equation (11) and

Equation (12) into Equation (10) can be obtained

κ

=

0.031. Then the change of curvature radius is

ρ

=

κ

-1

= 32.34 m. The result of the curvature value is

AL2O3 NANOLAYER AS EVANESCENT WAVEGUIDE FOR BIOMEDICAL SENSOR APPLICATION

47

positive (+), it implies that the substrate is convex on

the face away from the bonded film.

4 CONCLUSIONS

The optimum condition of evanescent wave guide

sensor for anastomosis leakage detection can be

estimated by analytical and then should be verified

by experiments. In the preliminary results, we found

that AL

2

O

3

deposited on Si-wafer have high

potential as waveguide sensor. Based on the results,

it can be concluded that thin film thickness have

high effect not only on sensitivity of the sensor, but

also on the mismatch stress between substrate and

thin film. That was shown by high radius curvature

32.34 m with convex structure for thickness 50nm.

ACKNOWLEDGEMENTS

The authors would like to acknowledge the Dutch

Technical Foundation, STW and the support

provided by Electronic Instrumentation Laboratory

(EI) and The Delft Institute of Microsystems and

Nanoelectronics (DIMES), TU Delft, The

Netherlands. The authors also wish to thank IC

process group of DIMES for technical assistance.

REFERENCES

Chaeron, S. R. A. (2007) "An optical measurement system

for the analysis of bacteria in drain fluid," MSc Thesis,

TUDelft, The Netherlands.

Pakula, M. P, D. Tanase, K. Kraal, G. d. Graaf, J. F.

Lange, and P. J. French, (2005), "Optical

Measurements on drain fluid for the detection of

anastomotic leakage," Proceedings of the 3rd Annual

International IEEE EMBS Special Topic Conference

on Microtechnologies in Medicine and Biology,

Kahuku, Oahu, Hawaii pp. 72 - 75.

Veldhuis, G. J., O. Parriaux, H. J. W. M. Hoekstra, and P.

V. Lambeck, (2000), "Sensitivity Enhancement in

Evanescent Optical Waveguide Sensors," J. Lightwave

Technol., vol. 18, pp. 677.

Freund L. B, and S. Suresh, (2003), The book, "Thin Film

Materials: Stress, Defect Formation and Surface

Evolution," Cambridge University Press.

BIODEVICES 2010 - International Conference on Biomedical Electronics and Devices

48