BIOREACTOR FOR MECHANICAL CELL STIMULATION

Concept and Design

J. G. Rocha, V. Correia

Industrial Electronics Dept., University of Minho, Campus de Azurem, 4800-076 Guimaraes, Portugal

J. L. Gomez Ribelles

Centro de Biomateriales, Universidad Politécnica de Valencia, 46022, Valencia, Spain.

Regenerative Medicine Unit, Centro de Investigación Príncipe Felipe, Autopista del Saler 16, 46013 Valencia, Spain

CIBER en Bioingeniería, Biomateriales y Nanomedicina, Valencia, Spain.

S. Lanceros-Mendez, A. Pitaes

Physics Dept., University of Minho, Campus de Gualtar, 4700-058 Braga, Portugal

Keywords: Bioreactor control, Cell cultivation, Three-dimensional scaffold.

Abstract: Mechanical stimulation plays an important role in improving cell growth in the skeletal system, for

example. In this article we describe a bioreactor in which cells in a three-dimensional scaffolds are

stimulated by cyclically applied mechanical loads. The objective of this study is to develop a custom-

designed bioreactor capable of applying controlled compressive loads to a cell-encapsulating scaffold. Its

working principle is based on an innovative design of a feedback controlled electromagnetic actuator, which

allows the application of compressive forces to the samples and at the same time, it allows the measurement

of the produced displacement.

1 INTRODUCTION

In vivo, skeletal cells such as osteoblasts and

chondrocytes are subjected to mechanical

stimulation imposed by muscle contraction and body

movement (lee, 2009). It has been demonstrated

mechanical stimuli play a role in improving cell

growth in the skeletal system (Nugent-Derfus,

2007), (Kisidaya, 2004), (Cooper, 2007), (Garvin,

2003). Many research groups have developed

bioreactors to stimulate cell-seeded, three-

dimensional scaffolds. The mechanical environment

influences tissue growth and development. The

proper mechanical force that can produce correct

bone tissue is a key issue in order to being able to

develop bone tissue in vitro. Static constant

mechanical loads have little or no effect in cell

growth and proliferation, but cyclically applied loads

do have profound effects (Meyer, 2001) (Guldberg,

2002).

Several models of bioreactors have been

developed for the stimulation of three-dimensional

scaffolds of bone and cartilage (Godstein, 2001),

(Botchwey, 2001), (Hillsley, 1994). All of these

bioreactors are satisfactory for the growth of tissues

but do not include the possibility of applying cyclic

loads that might be important in the case of skeletal

cells.

The main goal of this work is to develop and test

a bioreactor in which cells in three-dimensional

scaffolds are stimulated by cyclically applied

mechanical loads. The objective of this study was to

develop a custom-designed bioreactor capable of

applying controlled compressive loads to a cell-

encapsulating scaffold.

2 BIOREACTOR DESCRIPTION

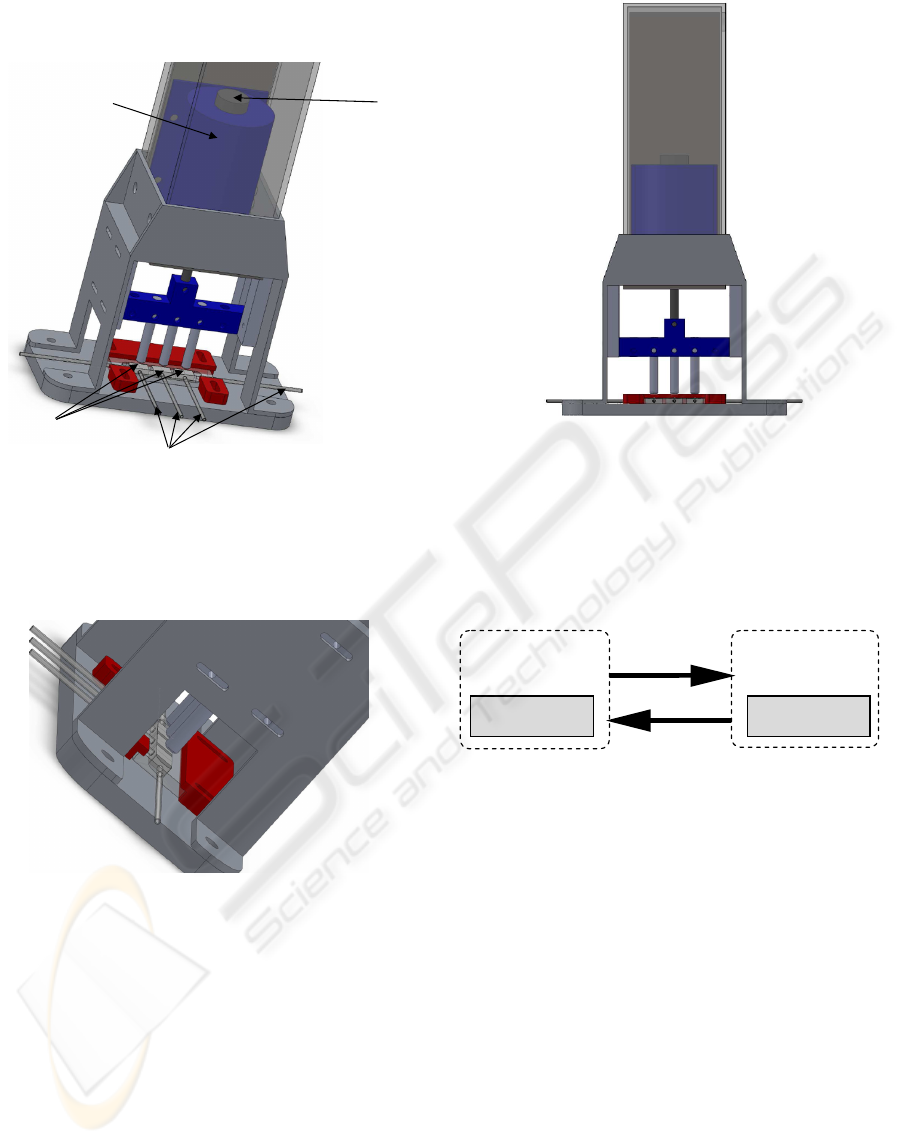

Figure 1 shows a drawing of the mechanical

actuation system of the bioreactor. It is composed by

an iron core, where four coils are placed. Two of the

coils will produce magnetic fields that displace the

147

Rocha J., Correia V., Gomez Ribelles J., Lanceros-Mendez S. and Pitaes A. (2010).

BIOREACTOR FOR MECHANICAL CELL STIMULATION - Concept and Design.

In Proceedings of the Third International Conference on Biomedical Electronics and Devices, pages 147-151

DOI: 10.5220/0002759401470151

Copyright

c

SciTePress

core, while the other two work as sensors to

feedback the core position to the controller.

Figure 1: Bioreactor design.

Figure 2 shows a detail of the bioreactor, where the

compression and circulation systems are seen in

detail.

Figure 2: Detail of the actuation system of the bioreactor.

Figure 3 shows the front-view of the bioreactor

actuating system.

3 CONTROL ELECTRONICS

The general system architecture is a master-slave

structure since there are two control units: a high-

level one (master) and a low-level one (slave).

The high-level control unit, central processing

unit or simply the master is responsible for

supporting the user interface, exchanging and

processing the necessary information between the

user and The low-level control unit and storing the

Figure 3: Bioreactor actuation system front view.

measurement data. It is based on a computer (PC).

The low-level control unit or slave main component

is a microcontroller. It is responsible for acquiring

the data from the sensor and controlling the stress

applied to the samples under test.

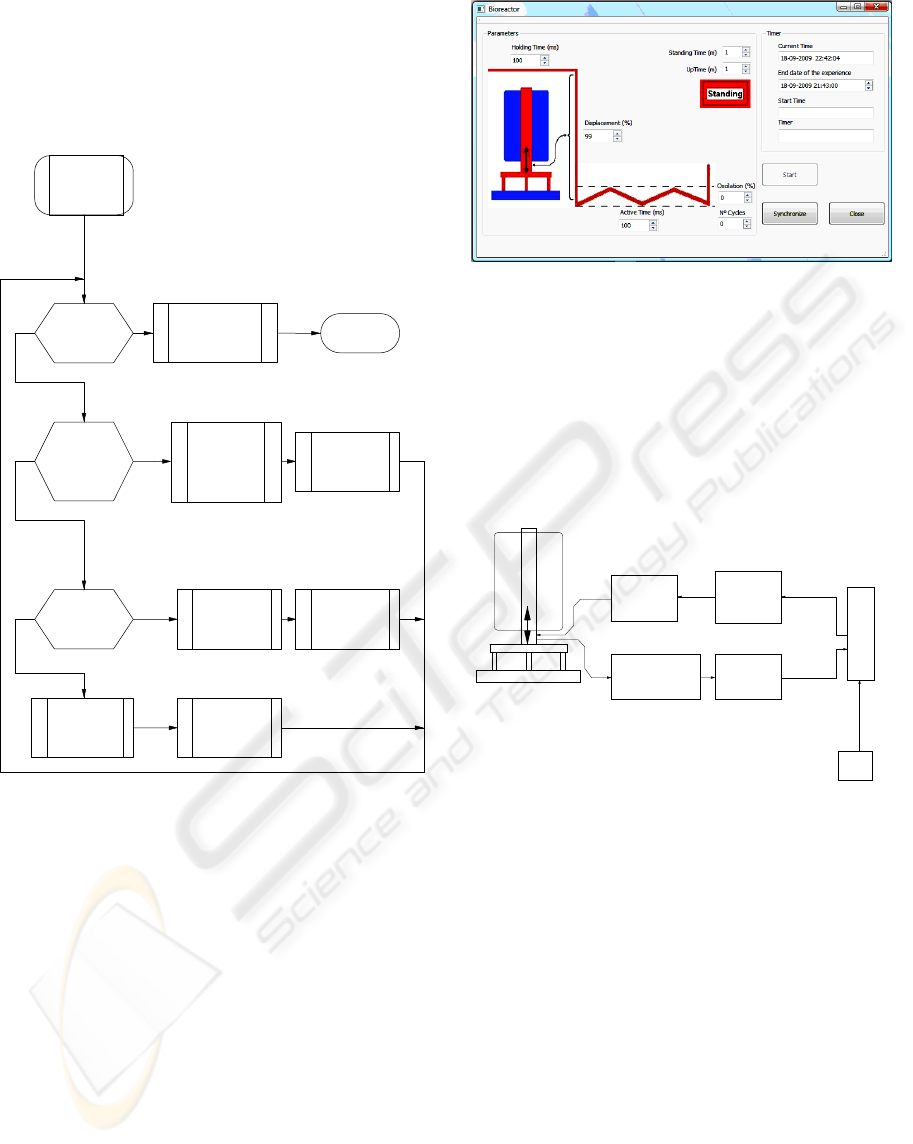

Figure 4 shows the system architecture.

Figure 4: System architecture. The PC operates as master

and the microcontroller operates as a slave. The

microcontroller functionalities are programmed by the PC,

which receives the measured data.

3.1 Master Block

In order to obtain the optimal operation point, that is,

when the cellular growth approximates the one that

happen in the human body, it is necessary a generic

system able to change the operation parameters

during the experiments. In this way, in the proposed

system, the user is able to control the following

parameters:

- Initial date and time;

- Final date and time;

- Shape of the stimulus (on/off, sine wave,

pulse, ramp);

- Holding time;

- Active time;

- Displacement;

Sends actuation

parameters

Sends performance

Information

PC

Maste

r

Slave

Microcontrolle

r

Windings

Core

Biological fluid

circulation system

Compression

system

BIODEVICES 2010 - International Conference on Biomedical Electronics and Devices

148

- Oscillation amplitude and frequency;

- Number of oscillation cycles;

- Standing Time (to generate a sequence);

- Up time

Figure 5 shows the flow chart of the master

algorithm.

Figure 5: Master control flow chart.

It consists in a main loop where three decisions must

be taken. The first one is related to the end of the

experiment. If it happens, the actuator must be

stopped, the user must be informed and the program

stops. The second one is related to the end of a hold

or active state. In this case, the new state parameters

must be loaded and sent to the slave block. The third

one is related with the oscillation of the actuator. If

the oscillation is not activated, its parameters must

be loaded and sent to the slave block. If the

oscillation is activated, the next deformation step

must be calculated and sent to the slave block.

Figure 6 shows a picture of the front panel of the

control application.

Figure 6: Front panel of the control application.

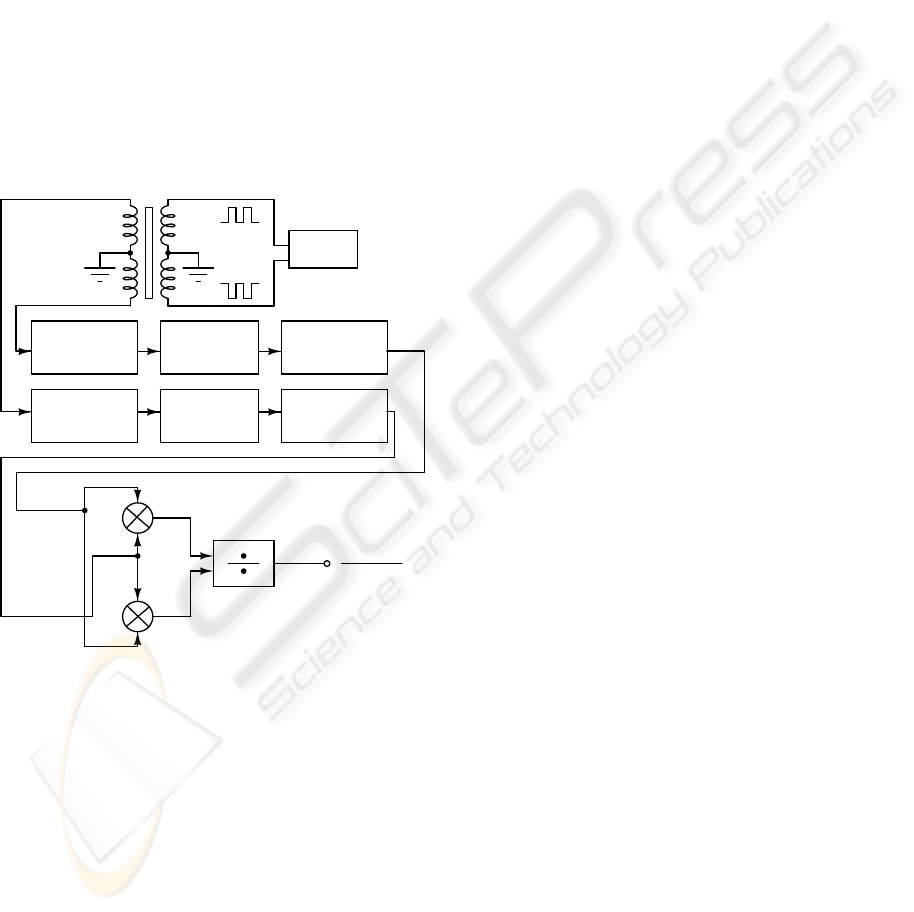

3.2 Slave Block

The Slave block is constituted by a microcontroller,

a power switching circuit based on a H-bridge, two

actuators (solenoids) and a measurement system

whose working principle is based on a LVDT

(Linear Variable Differential Transformer). Fig. 7

shows the block diagram of the whole system.

Figure 7: Control system of the mechanical movements of

the bioreactor.

The main goal of this system is to generate a set of

mechanical stimulus in a cellular cultivation region.

The microcontroller receives the desired stimulus

parameters from the computer and reads the actual

displacement of the actuator from the measurement

circuit. With that information, it calculates the duty-

cycle of the PWM and sends it to the power

switching circuit, in order to produce the correct

voltage to the actuator.

The displacement is the most important

parameter of the system, but the mechanical actuator

only allows the control of the mechanical stress

applied to the cultivation cell. In this way, the

control of the displacement is made in a feedback

loop, where a displacement sensing mechanism is

introduced.

Begin

End of

experiment?

y n

End of

hold/active

state?

y n

Is the

oscillation

activated?

Calculate

deformation

info

Stop actuator.

Informs the

user

Loading of

new state

parameters.

Jump to

new state

Loading of

oscillation

parameters

Send

deformation

info to

microcontrolle

r

Send state

info to

microcontroller

Send

oscillation

info to

microcontroller

Stop

y

n

Power

switching

circuit

Actuator

system

Measurement

system

Readout

circuit

PWM

position

info

Microcontroler

PC

USB

BIOREACTOR FOR MECHANICAL CELL STIMULATION - Concept and Design

149

The displacement actuator is then constituted by

four windings: two primary windings with a small

number of turns and two secondary windings with a

larger number of turns. The primary windings are

excited by the power switching circuit in order to

produce the displacement of the core. The secondary

windings use to advantage the switching frequency

of the PWM in order to measure the displacement,

as it will be described in the following paragraphs.

A block diagram of the displacement transducer

and respective signal conditioner is shown in Figure

8. The circuit consists of a PWM wave generator to

drive the primary windings, a conditioner circuit for

each secondary winding, a differential amplifier that

determines the difference between the voltages of

the secondary windings and a summing amplifier,

which determines the sum of the secondary winding

voltages.

Figure 8: block diagram of the displacement transducer

and signal conditioner.

The PWM wave that is applied to the primary

windings, where besides producing the displacement

of the core, it induces in the secondary windings a

voltage whose magnitude difference is proportional

to the core position. These two secondary voltages

are band-pass filtered for the fundamental frequency

of the PWM generator. So, the output from the band-

pass filters consists of a pair of sine waves whose

amplitude difference, (VA–VB), is proportional to

the core position.

In order to operate in a ratiometric principle and

thus eliminating the errors associated to non-

constant amplitude of the PWM signal, the circuit

computes (VA-VB)/(VA+VB).

The signals VA and VB are firstly rectified and

low-pass filtered. A signal with precise frequency is

not necessary because the inputs are rectified and

only the sine wave carrier magnitude is processed.

There is also no sensitivity to phase shifts between

the primary excitation and the secondary outputs

because synchronous detection is not employed.

Then, the signals are applied to the differential

amplifier and to the summing amplifier. The ratio

(VA-VB)/(VA+VB) is performed by the A/D

(analog to digital) converter. The (VA-VB) signal is

applied to its input and the (VA+VB) signal is used

as reference voltage for the A/D conversion. Finally,

The digital signal is read by the microcontroller.

4 CONCLUSIONS

In this article, it is described the design of a

bioreactor to apply controlled mechanical

stimulation to cell cultures. The bioreactor consists

on a mechanical loading actuator, experimental

chamber, and control system. The actuator is based

on an innovative design of a feedback controlled

electromagnetic actuator, which allows the

measurement of its own position. The control system

is based on a master-slave architecture, where the

master (computer) receives the user commands and

sends the actuation parameters to the slave

(microcontroller). This last one reads and feedback

controls the actuator position.

ACKNOWLEDGEMENTS

The authors thank the Portuguese Foundation for

Science and Technology (FCT) Grants

PTDC/CTM/73030/2006, PTDC/CTM/69362/2006

and NANO/NMed-SD/0156/2007. V. Correia thanks

the FCT for the PhD Grant (SFRH/BD/48708/2008).

J. L. G. Ribelles acknowledge the support of the

Spanish Ministry of Education through project No.

MAT2007-66759-C03-01 (including the FEDER

financial support. and founding in the Centro de

Investigación Principe Felipe in the field of

Regenerative Medicine through the collaboration

agreement from the Conselleria de Sanidad

(Generalitat Valenciana), and the Instituto de Salud.

+

+

-

+

VA-VB

VA+VB

VA

-VB

Full wave

Rectifier

Full wave

Rectifier

Low-pass

Filter

Low-pass

Filter

PWM

Band-pass

Filter

Band-pass

Filter

VA-VB

VA+VB

BIODEVICES 2010 - International Conference on Biomedical Electronics and Devices

150

REFERENCES

Lee, S.J., Jeong Hun Park, Yong-Joon Seol, In Hwan Lee,

Sang Soon Kang, Dong-Woo Cho, Development of a

bioreactor for the mechanical stimulation of agarose

hydrogels, Microelectronic Engineering 86 (2009)

1411-1415.

Nugent-Derfus G. E., Takara T., O’Neilly J. K., Cahill S.

B., Gortz S., Pong T., Inoue H., Aneloski N. M., Wang

W. W., Vega K. I., Klein T. J., Hsieh-Bonassera N. D.,

Bae W. C., Burke J. D., Bugbee W. D. and Sah R. L.,

Continuous passive motion applied to whole joints

stimulates chondrocyte biosynthesis of

PRG4,OsteoArthritis and Cartilage (2007) 15, 566-

574.

Kisidaya J. D., Jinb M., DiMiccod M. A., Kurze

B.,Grodzinsky A. J., Effects of dynamic compressive

loading on chondrocyte biosynthesis in self-

assembling peptide scaffolds, Journal of Biomechanics

37 (2004) 595-604.

Cooper Jr. J. A., Wan-Ju Li, LeeAnn O. Bailey, Steve D.

Hudson, Sheng Lin-Gibson, Kristi S. Anseth, Rocky

S. Tuan, Newell R. Washburn, Encapsulated

chondrocyte response in a pulsatile flow bioreactor,

Acta Biomaterialia 3 (2007) 13-21.

Garvin, J., Qi, J., Maloney, M., Banes, A.J., Novel System

for Engineering Bioartificial Tendons and Application

of Mechanical Load, Tissue Engineering Vol. 9 (5)

2003, 967-979.

Meyer U, Terodde M, Joos U, Wiesmann HP., Mechanical

stimulation of osteoblasts in cell culture, Mund Kiefer

Gesichtschir. 2001;5:166-72.

Guldberg RE., Consideration of mechanical factors, Ann

N Y Acad Sci 2002, 961, 312-314.

Godstein AS, Juarez TM, Helmke CD, Gustin MC, Mikos

AG. Effect of convection on osteoblastic cell growth

and function in biodegradable polymer foam scaffolds.

Biomaterials 2001, 22, 1279-1288.

Botchwey EA, Pollack SR, Levine EM, Laurencin CT.

Bone tissue engineering in a rotating bioreactor using

a microcarrier matrix system, J Biomed Mater Res

2001, 55, 242-253.

Hillsley MV, Frangos JA. Review: Bone tissue

engineering: the role of interstitial fluid flow,

Biotechnol Bioeng 1994, 43, 573-581.

BIOREACTOR FOR MECHANICAL CELL STIMULATION - Concept and Design

151