E-LEARNING TOOLS FOR EDUCATION AND TRAINING IN

DIAGNOSTICS AND MACHINE CONDITION MONITORING

Ondrej Kreibich and Radislav Smid

Faculty of Electrical Engineering, Department of Measurement

Czech Technical University in Prague, Technicka 2, Prague, Czech Republic

Keywords: e-Learning, Machine Condition Monitoring, Simulator.

Abstract: This paper presents an integration of e-learning into an existing course of diagnostics, machine condition

monitoring (MCM) and nondestructive testing (NDT), educated at our university. A diagnostics education

belongs to field of study where e-learning is used less commonly than in other fields for its necessity to

attending a laboratory. Laboratory education, forms an integral part of many university courses, mainly in

natural and technical university education, are necessary to improve students’ knowledge by experiments

with laboratory samples and devices. There could arise a problem for foreign and distance students, who

cannot physically attend these courses. Therefore the aim of this project is presentation of a possible

solution on the example of laboratory electro-mechanical device fully accessible via Internet.

1 INTRODUCTION

Nowadays, e-learning as a modern educational

method is used in many fields of study, mainly in

humanities, natural science and computer science.

On the other hand, there are a few fields e.g. in

Electrical or Mechanical Engineering, where

students should attend laboratory courses in order to

improve their knowledge by the experiments with

laboratory samples and devices.

Within the frame of recently solved project

concerning the development of vibrodiagnostic

device in our NDT laboratory, there has arisen an

idea to enable remote access to this vibrodiagnostic

device via the Internet and to extend the device with

IP camera. In addition to already existed online

support to this course in the Moodle system. Such

design helps to foreign and distance students almost

feel they are working with a real laboratory device.

Furthermore remote access to laboratory

equipment could not be used for education purposes

only; for instance could be suitable for presentation

of research projects.

2 PREVIOUS WORK

In the past, we developed for educational and

research purposes an electro-mechanical device, cal-

led vibrodiagnostic simulator. The simulator is based

on simple mechanical system, which is able to

demonstrate individual damages of transmission

system e.g. gear transmission, bearings and

unbalance (Vachtsevanos, 2006). These damages

can occur at common machines due to unsuitable

procedures in manufacture, unsuitable construction

and finally sudden changes in operating state.

Simulated damages are analyzed by means of

usual vibrodiagnostic methods. Results of analysis

of these phenomena can serve for project planning

of maintenance of devices in industry and thus

protect them against already mentioned damages

during expected lifetime of the devices. Next

important factors are minimalization of time for

maintenance and reparation, optimalization of

performance of the devices and provide safety of

operation.

Methods of simulation of possible damages can

be useful for searching and specification damages

without necessity for complete dismounting of all

machine.

The simulators are used in such cases where the

laboratory experiments on real devices are not

possible due to oversize of real machinery. Next

important reasons for application of simulators are

unavailability of real machinery testing samples,

limitations in manufacture and limitations

performance of real device.

357

Kreibich O. and Smid R. (2010).

E-LEARNING TOOLS FOR EDUCATION AND TRAINING IN DIAGNOSTICS AND MACHINE CONDITION MONITORING .

In Proceedings of the 2nd International Conference on Computer Supported Education, pages 357-361

Copyright

c

SciTePress

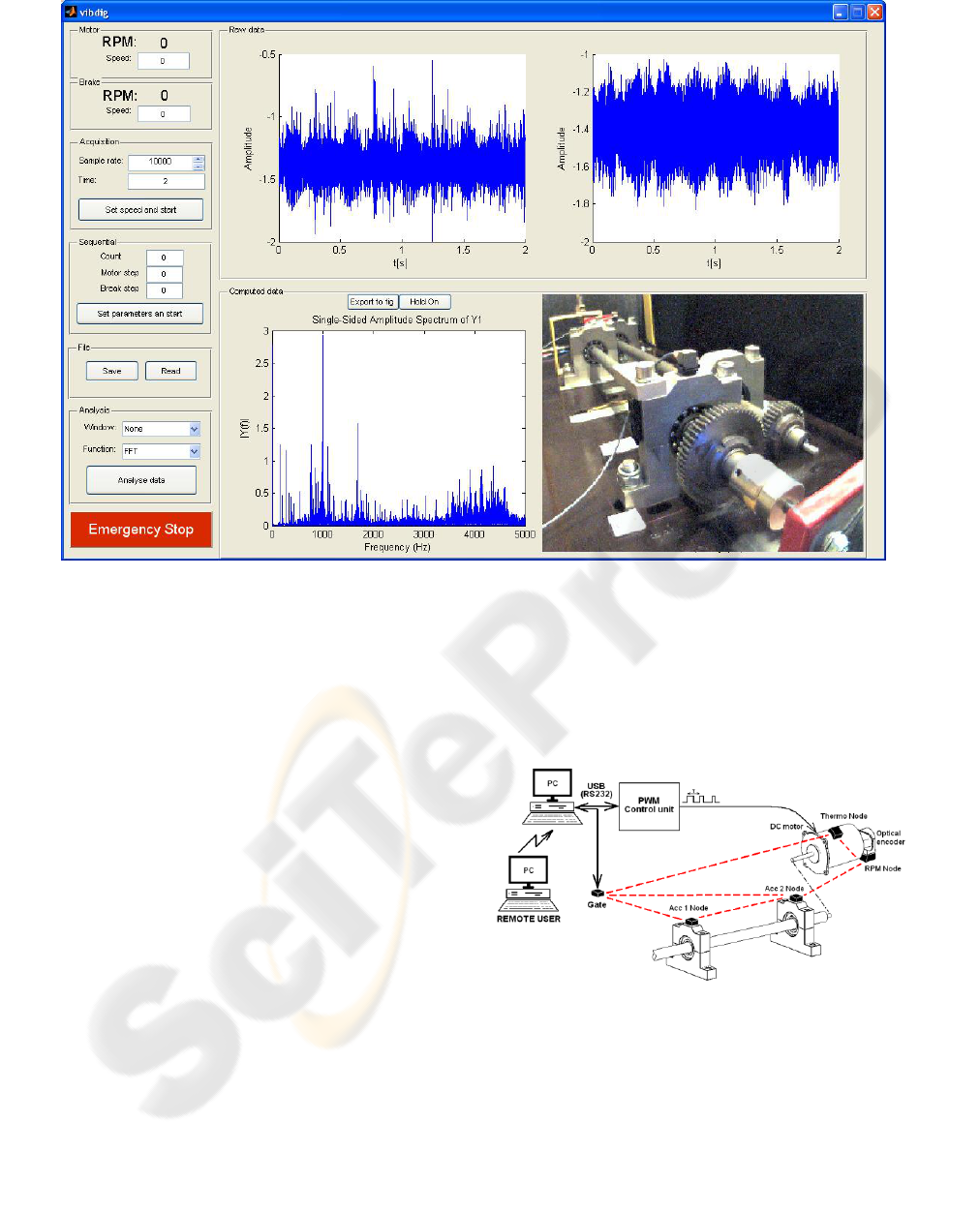

Figure 1: The fundamental design of training device.

2.1 Mechanical Design

Mechanical components of the training device were

chosen from available commercial products, such as

DC motors, ball bearings, jaw couplings.

Commercially unavailable parts were made

individually.

Technical documentation of all the components

was made for manufacturing procedures of the

device.

Figure 2: The training device prepared for an exercise in

our laboratory.

Simulator is suitable for:

demonstration of failures of gear transmission

demonstration of failures of ball bearings

demonstration of failures of unbalance

measurement of revolution speed of device

loading of device with electronically controlled

brake

orbit measurement of one of the shafts due to

two sensors IN-081 (Brüel & Kjær).

2.2 Acquisition of Vibration Signals

Electronic control of the simulator was divided into

two individual sections (Fig. 3):

Control unit - controls revolution speed of device

Data acquisition unit - serves for digitalization of

signals received from accelerometers

Figure 3: The block diagram of data acquisition unit and

electronic control unit.

2.2.1 Electronic Control Unit

The control unit transforms data coming from PC

onto signal which is important for control of the

engine. For this purpose is most used PWM method

– pulse width modulation. Such received signal

controls power switch. By means of the alternating

switching on/off is changed average value of current

flow over DC motor and thus its speed of rotation is

controlled.

Speed of the engine rotation is detected by sensor

of RPM (optical encoder). Microcontroller is able to

find time period between of individual pulses and

this information is sent to the PC. By means of

simple calculation is determined the rotation speed.

2.2.2 Data Acquisition Unit

Data acquisition unit is PMD-1208FS provided by

Measurement Computing was used in this device

owing to relatively low price and direct support of

data acquisition toolbox under the Matlab software.

3 GOAL

First of all, there should be suitable to mention a few

words about knowledge and skills which students

attending our NDT laboratory course should obtain.

Within the framework of education at faculty of

electrical engineering there are students with good

theoretical background, but have never tried to apply

electrotechnical knowledge to other field before. In

this case the NDT course offers a great opportunity

to interconnection among electrical and mechanical

engineering.

The content of this course consists in finding and

diagnose damages in prepared material samples (in

case of demonstration of ultrasound, eddy-current

CSEDU 2010 - 2nd International Conference on Computer Supported Education

358

and acoustic emission diagnostic methods) or on

laboratory devices (vibrodiagnostic method), the

same as mentioned simulator is.

Students gain experience in various NDT

methods, signal analysis, data acquisition and

principles of sensors operation. These experiments

bring to students significant improvement

engineering skills and imagination in addition to

theoretical education.

3.1 Integration of the Vibrodiagnostic

Simulator Device into e-Learning

Scheme

A meaningful extension of a classic laboratory

education by e-learning depends on providing the

similar perceptions to remote users like students

physically attending a laboratory have. Main these

perceptions are:

visual sensation, students could easily figure out

how does device work and what to do for

successful manage the laboratory task.

control and monitoring a device via PC

data acquisition from sensors

manipulation with a device.

If e-learning laboratory is useful, these

mentioned points will be respected. In case of

vibrodiagnostic simulator device, these points were

solved by the following way.

3.1.1 Visual Sensation

The visual sensation is assured by a video

transmission from IP camera which overlooking

motion and state of device to remote user. There is

used compact 1.3 megapixel network camera with

digital pan-tilt-zoom that enhances viewing and

monitoring. It uses 179 degrees wide angle lens to

view horizontal and 99 vertical degrees of the actual

vision. This cam lets move view around using a

smaller viewing window.

There is even possibility to define a preset path,

and the camera will cruise along the path you

defined. When there is something that catches user

attention, this cam allows zoom-in to see the details.

It also allows recording at the same time.

3.1.2 Control and Monitoring

The vibrodiagnostic simulator device was made as

fully electronically controlled from PC. There arise a

solution in the remote desktop which solve remote

access to device, thus any changes in design of

existent control unit were not required.

Figure 4: A snapshot from IP camera.

3.1.3 Control and Monitoring

The vibrodiagnostic simulator device was made as

fully electronically controlled from PC. There arise a

solution in the remote desktop which solve remote

access to device, thus any changes in design of

existent control unit were not required.

The remote desktop allows a user to log in to a

remote system and access the desktop, applications

and data on the system as well as control it remotely.

However, this is only available in certain Windows

editions, but for instance Windows XP and

Windows Vista have this system pre-installed. A

efficient firewall and regular system are

recommended to block unauthorized access.

3.1.4 Data Acquisition

Data acquisition is provided by unit, connected with

PC via USB interface, as described in 2.2.2. There is

one software environment for control and data

acquisition, equipped by GUI (graphical user

interface), programmed under Matlab software. A

remote user gets access to this application via

mentioned remote desktop.

3.1.5 Manipulation with the Device

Generally, according to principle e-learner has not a

free hand in manipulation with laboratory devices

and must rely on mechanical and software

possibilities which are allowed to them.

In the simulator case, manipulation is not

allowed even to attending students during laboratory

lesson for its complexity. Maintenance and changes

in the structure a supervisor does on its own.

Therefore the remote user has the same access to the

device as an attending student.

E-LEARNING TOOLS FOR EDUCATION AND TRAINING IN DIAGNOSTICS AND MACHINE CONDITION

MONITORING

359

Figure 5: The application screen.

4 FUTURE WORK

The above mentioned approach is applicable for e-

learning in this form; however there is still space for

an improvement and extension.

Firstly, with the remote desktop only one user

can work at the same time and other users have no

chance to login to the device. Therefore the next step

consists in programming web server application

which enables multiuser access. In this scheme a

user has access to the web application anytime and

entered parameters stay in a line. If the device is free

and prepared, it sends measured data back.

Furthermore similar concept is used to connect to a

device such as a PLC, which are used in machine

condition monitoring very often. Both, distance and

full-time students see how this technology works.

Secondly, a power-on function in the current

version of the device, mainly electronic control unit,

is not available, hence a staff must switch it on and

check the device for proper function.

Finally, in our NDT laboratory, there is another

current research project concerned Wireless Sensor

Network systems.

Within this project, the simulator will be

equipped with wireless sensor nodes which will

communicate over a gate connected with PC (Fig.

6). There will be nodes for measure:

Temperature

Vibration

RPM

Figure 6: Block diagram of applied WSN on the training

device.

This network structure makes possible teaching in

next WSN fields in addition to signal analysis of

vibrodiagnostic signals:

New applications of WSN

Network topology (ad-hoc, mesh)

Coexistence of various WSN

CSEDU 2010 - 2nd International Conference on Computer Supported Education

360

Disturbance in WSN

Implementation of signal pre-processing into

nodes

One of the aims of this project is to make the

WSN system available to remote users and use it for

e-learning in NDT course or create a new course

concern WSN only.

5 CONCLUSIONS

In this paper we propose an enhancement of

machine condition monitoring education by means

of vibrodiagnostic simulator. This instrument adds a

real experience with analysis of fault symptoms

typical for rotating machinery. The integration of

remote accessed simulator with traditional Moodle

e-learning system and IP camera gives the teacher a

complex tool for effective remote delivering of

specialized knowledge in the area of machine

condition monitoring.

ACKNOWLEDGEMENTS

This research was supported by the FRVŠ of the

Czech Republic, Grant No. 33/090480/13138 and by

the research program No. MSM6840770015

"Research of Methods and Systems for

Measurement of Physical Quantities and Measured

Data Processing " of the CTU in Prague sponsored

by the Ministry of Education, Youth and Sports of

the Czech Republic.

REFERENCES

Vachtsevanos, G., Lewis, F., Roemer, M., Hess,A. & Wu,

B., 2006, Intelligent Fault Diagnosis and Prognosis

for Engineering Systems, John Wiley & Sons, Inc..

Römer, K. Friedemann M., 2004, The Design Space of

Wireless Sensor Networks. IEEE Wireless

Communications 11 (6): 54–61. December 2004.

doi:10.1109/MWC.2004.1368897.

Hadim S., Nader M., 2006, Middleware Challenges and

Approaches for Wireless Sensor Networks. IEEE

Distributed Systems Online 7 (3): 1. 2006

doi:10.1109/MDSO.2006.19.

E-LEARNING TOOLS FOR EDUCATION AND TRAINING IN DIAGNOSTICS AND MACHINE CONDITION

MONITORING

361