IMPACT OF A LOSSY IMAGE COMPRESSION ON PARAMETER

ESTIMATION WITH PERIODIC ACTIVE THERMAL IMAGING

Agn

`

es Delahaies

1

, David Rousseau

1

, Laetitia Perez

2

Laurent Autrique

1

and Franc¸ois Chapeau-Blondeau

1

1

Laboratoire d’Ing

´

enierie des Syst

`

emes Automatis

´

es (LISA), Universit

´

e d’Angers

62 avenue Notre Dame du Lac, 49000 Angers, France

2

Laboratoire de Thermocin

´

etique de Nantes, Rue Christian Pauc, 44000 Nantes, France

Keywords:

Image compression, Thermal imaging, Parameter estimation, Material characterization.

Abstract:

Periodic thermal imaging is a method of active thermography based on a periodic thermal stimulation of an

inspected sample material and the analysis of its thermal response when a steady regime is reached. The

original data, a sequence of images sampling the thermal response on a large number of periods, are usually

stored in a raw format. For accurate exploitation of these measurements, the whole sequence of images requires

a significant amount of storage space. In this report, we address the question of the lossy compression of these

sequences of images when they are applied to perform physical parameter estimation. The study investigates

the impact of lossy image compression on the performance of the physical parameter estimation procedure, and

shows the possibility of preserving robust estimation with high compression rate. Perspectives and applications

are then discussed. Performing good enough estimate of physical parameters with compressed images would

permit the use of portable thermal cameras with limited resources in terms of data storage. This would enable

the use of periodic active thermal imaging to perform relatively low cost embedded characterization of thermal

properties of materials.

1 INTRODUCTION

Recent advances (technological improvement, or re-

duction of the production costs) in the domain of pho-

tonic devices, imaging sensors, involving data acqui-

sition, transmission and storage, constitute a stimulat-

ing source of research for information sciences. Re-

cently, there has been the emergence of new types

of nonconventional imaging (polarimetric imaging,

multi-or hyperspectral imaging, ...) which used to be

limited by their capacity of acquisition and storage of

information. Novel domains of application, formerly

restricted by the production costs, have also appeared

for existing imaging systems (MRI or thermal imag-

ing). This context brings forth new configurations and

challenges for the classical signal and image process-

ing operations (detection, estimation, segmentation,

compression, ...).

In this framework, we consider here a task of com-

pression applied to thermal imaging. Introduced in

the 1960’s, thermal imaging uses the Planck law (Lu-

gin, 2008; Breitenstein et al., 2003) which expresses

the luminance of a black body in thermal equilib-

rium at a given wavelength to measure temperatures.

Thermal images poses a practical problem in terms

of compression when long sequences of images are

required. This is specially the case with active ther-

mography methods where the thermal evolution of a

scene is recorded while some external time varying

energy is injected into the scene. There are two main

distinct techniques of active thermal imaging : pulsed

thermal imaging (Lugin, 2008) and periodic thermal

imaging (Breitenstein et al., 2003). The question of

compression has only recently (Lugin, 2008) received

some attention in the domain of active pulsed thermal

imaging. In this report we consider periodic thermal

imaging which, to the best of our knowledge, has not

been yet considered under the scope of compression.

We investigate the impact of a lossy compression on

the performance of a parameter estimation with peri-

odic thermal imaging.

17

Delahaies A., Rousseau D., Perez L., Autrique L. and Chapeau-Blondeau F. (2010).

IMPACT OF A LOSSY IMAGE COMPRESSION ON PARAMETER ESTIMATION WITH PERIODIC ACTIVE THERMAL IMAGING.

In Proceedings of the International Conference on Imaging Theory and Applications and International Conference on Information Visualization Theory

and Applications, pages 17-22

DOI: 10.5220/0002816500170022

Copyright

c

SciTePress

2 PRINCIPLE OF PERIODIC

ACTIVE THERMAL IMAGING

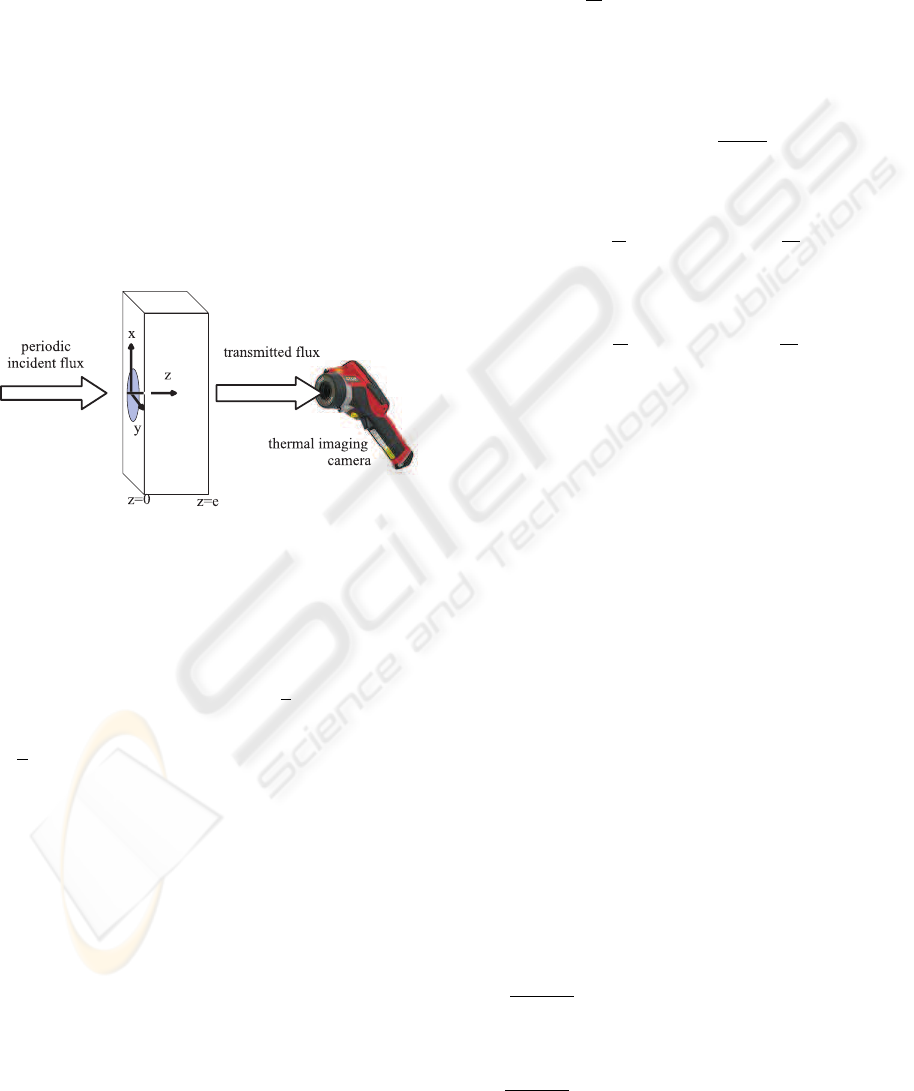

The principe of periodic active thermal imaging is de-

picted in Fig. 1. The setup of Fig. 1 describes the

inspection of a material sample Ω a solid of thick-

ness e. We note X = (x,y, z). The front surface

(Γ

0

: X

0

= (x,y, 0) ∈ Ω) of the sample Ω receives a si-

nusodal radiative flux with angular frequency ω. The

radiative flux Φ : Φ

0

cos(ωt) is spatially centered on

O = (0, 0, 0) and is uniform over a disk of radius R and

zero outside this disk. If the radiative flux is absorbed

by the material, the resulting heat diffuses inside the

material. When the diffused heat arrives on the op-

posite side (Γ

e

: X

e

= (x,y, e) ∈ Ω) a flux is radiated.

A thermal imaging camera is placed on the opposite

side to the incident radiative flux source and receives

a transmitted radiative flux.

Figure 1: Principe of periodic active thermal imaging for

the inspection of a material sample Ω of thickness e.

The camera then uses the Planck law to calculate

the surface temperature on Γ

e

from this transmitted

radiative flux. When the steady periodic regime is

reached, the temperature in the sample Ω and on the

opposite side Γ

e

is θ(X,t) = R e{θ(X,t)} (Breiten-

stein et al., 2003) with

θ(X,t) = θ

DC

(X)+ M(X)exp( jωt)exp( jϕ(X)) ,

(1)

where θ

DC

(X) is the average temperature at X, M(X)

is the modulus image of the thermal oscillations

which depicts the spatial attenuation of the incident

heat flux in the material sample, and ϕ(X) the phase

image which represents the delay between the inci-

dent and the transmitted heat flux due to the material

sample. Both images M(X) and ϕ(X ) thus carry in-

formation on the thermal properties of the material.

A specific interest of the phase ϕ(X) is that it does

not depend on the knowledge of the sample emissiv-

ity (Breitenstein et al., 2003). In the following we will

thus only use the phase ϕ(X) to analyze the thermal

behavior of the sample.

There are various experimental sources of noise

in the phase image ϕ(X) including spurious high fre-

quency components in the excitation and electronic

noise on the thermal cameras. Therefore, high ac-

curacy measurement of ϕ(X) requires heavy statis-

tics. A sequence of N thermal images θ(X ,n) with

n ∈ [0, N −1] is usually acquired to cover a large num-

ber of periods

2π

ω

with a high frequency rate (typically

of some 50 images per period). If we assume the noise

in θ(X,n) to be Gaussian, the maximum likelihood

estimator

ˆ

ϕ(X) of image ϕ(X) can be shown to be ap-

proximately for large N (Kay, 1993)

ˆ

ϕ(X) = arctan

µ

−

β

2

(X)

β

1

(X)

¶

, (2)

with

β

1

(X) =

2

N

N−1

∑

n=0

θ(X,n)cos

µ

ω

n

F

e

¶

, (3)

and

β

2

(X) =

2

N

N−1

∑

n=0

θ(X,n)sin

µ

ω

n

F

e

¶

. (4)

An example of phase

ˆ

ϕ(X) evaluated from the exper-

imental setup of Fig. 2 is visible in Fig. 3. As ex-

plained in Fig. 2, the amount of memory required to

produce Fig. 3 with a good accuracy is huge.

In the following, we are going to show how it is

possible to use the phase images ϕ(X ) of Fig. 3 to

perform estimation of a physical parameter in a ma-

terial. We will then compare the performance of this

estimate with a periodic active thermal imaging se-

quence applied on raw thermal images θ(X, n) and on

the same sequence after a lossy compression.

3 APPLICATION TO

PARAMETER ESTIMATION

Periodic active thermal imaging as described in sec-

tion 2 can be applied to perform physical parameter

estimation of a material. This requires the modeling

of the sample response of Fig. 2 which can be done in

the following way (Perez and Autrique, 2009). Tem-

perature θ(X ,t) in the material sample Ω, assumed

here homogeneous and isotropic, follows from heat

diffusion equation

α

∂θ(X,t)

∂t

− ∆θ(X,t) = 0 ,∀(X,t) ∈ Ω × T , (5)

and boundary conditions on Γ

0

λ

∂θ(X,t)

∂z

= hθ(X ,t) − Φ ,∀(X,t) ∈ Γ

0

× T , (6)

IMAGAPP 2010 - International Conference on Imaging Theory and Applications

18

3

2

1

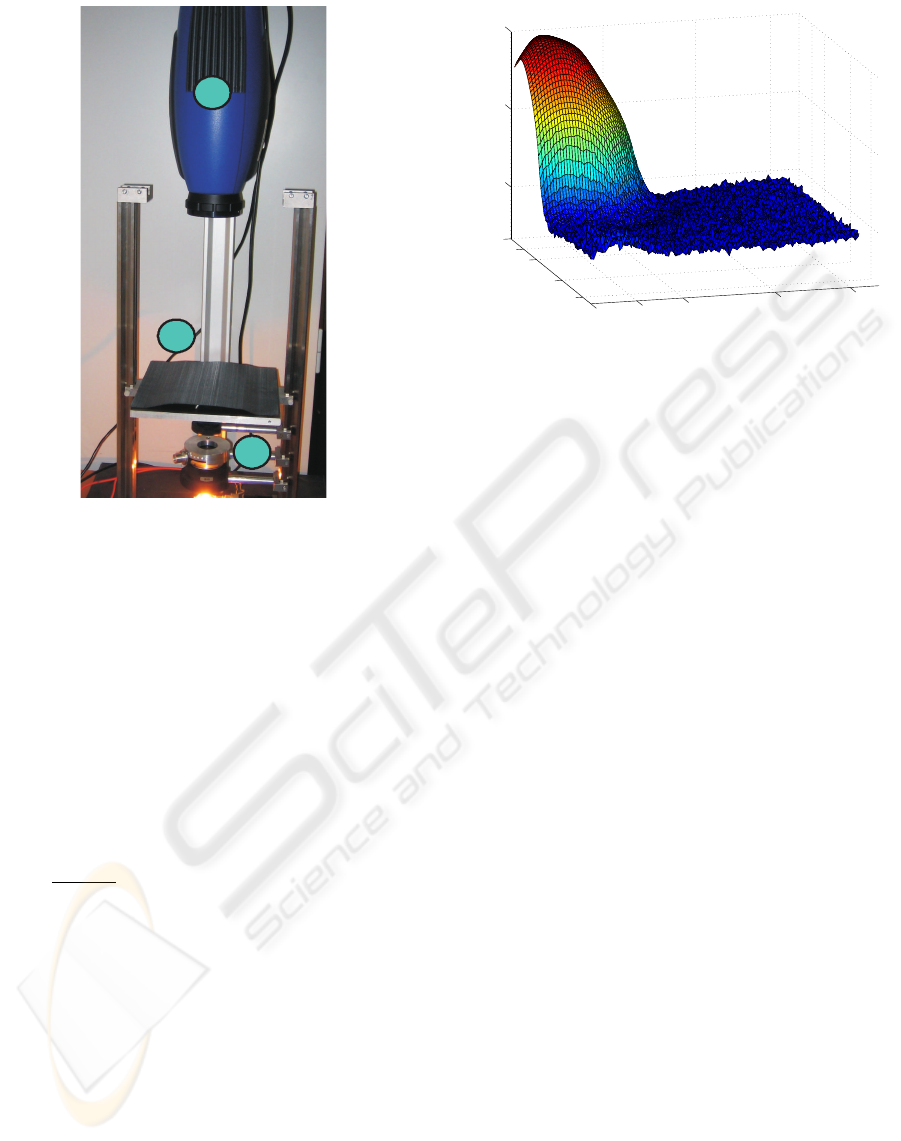

Figure 2: Experimental setup of periodic active thermal

imaging used to perform the analysis. The material sam-

ple (sticker 2) taken as reference is a plate of titanium of

thichness e = 1 mm. This sample is placed in the focal

plane of a K

¨

ohler lightning device (sticker 1) which pro-

duces a uniform flux on a circular disk of radius R = 2.5

mm. The incident radiative flux is produced by an halo-

gen lamp (36V-400W) placed under the sample and con-

trolled by a on/off switch of angular frequency ω = 5.66

rad.s

−1

. Thermal images θ(X,n) are acquired by a SC5000

FLIR thermal camera (sticker 3) at the sampling frequency

F

e

= 50 Hz with format 320 × 256 coded on 14 bits. The

phenomenon is recorded on 18 periods. This produce a file

of 999 images representing 1.67 Go to be stored.

on Γ

e

λ

∂θ(X,t)

∂z

= hθ(X ,t) , ∀(X ,t) ∈ Γ

e

× T , (7)

and initial temporal condition θ(X ,0) = 0 ∀(X) ∈ Ω.

Physical parameters of the modeling of Eqs. (5)-(7)

are the diffusivity α in [m

2

.s

−1

], the convective coeffi-

cient h in [W.m

−2

.K

−1

] and the conductivity λ = αρc

in [W.m

−1

.K

−1

] where ρ is the density in [kg.m

−3

]

and c the specific heat in [J.kg

−1

.K

−1

]. Resolution

of Eqs. (5)-(7) provides the temperature θ(X,t) in

the whole material Ω. It is then possible to confront

the temperature θ(X,t) on the surface of the side Γ

e

measured by the thermal imaging and deduced by the

model of Eqs. (5)-(7). One can use this experiment-

model confrontation to estimate the value of an un-

known parameter. In the general case, there exists no

exact analytical explicit expressions for ϕ(X). The

solution of Eqs. (5)-(7) can be numerically performed

0

5

10

20

30

0

5

10

20

30

−600

−300

0

phase in °

Figure 3: Phase ϕ(X ) evaluated with Eqs. (2)-(4) from raw

images acquired with experimental setup and material sam-

ple described in Fig. 2. The phase plotted as a function of

position (x,y) in mm has been unwrapped with the standard

Itoh’s algorithm (Ghiglia and Pritt, 1998).

by the method of (Perez and Autrique, 2009). We

show in Fig. 4 an example of confrontation of an

experimental phase ϕ(X) obtained with the setup of

Fig. 1 and the algorithm of Eqs. (2)-(4) with the nu-

merical resolution of Eqs. (5)-(7). In Fig. 4, the un-

known parameter is the conductivity λ. The estimated

value (given in Table 1 for the material of Fig. 2)

is chosen as the one which minimizes the average

quadratic error between the phase ϕ(X) in experi-

ments and in the numerical solution of Eqs. (5)-(7).

In Fig. 4, the parameter estimation has been per-

formed on raw data. We will now compare with the

estimation when the algorithm of Eqs. (2)-(4) is per-

formed on compressed images.

4 INFLUENCE OF A LOSSY

COMPRESSION

To illustrate our methodology in assessing the impact

of a lossy compression of images on physical param-

eters estimation, we choose one lossy compression

technique usually implemented by default in ther-

mal cameras. A reasonable choice (Bovik, 2000) is

the standard JPEG compression. Temperature images

θ(X,n) are coded on 14 bits with the camera pre-

sented in Fig. 2. The standard JPEG compression

codes images on 8 bits. Therefore, requantization (al-

ready bringing a 2

14

/2

8

compression factor) and nor-

malization are necessary before the JPEG compres-

sion step is applied. For each image θ(X,n) of the

acquired sequence, the maximum θ

max

and minimum

θ

min

temperature over the whole sequence are stored

separately and an intermediate 8-bit gray level image

IMPACT OF A LOSSY IMAGE COMPRESSION ON PARAMETER ESTIMATION WITH PERIODIC ACTIVE

THERMAL IMAGING

19

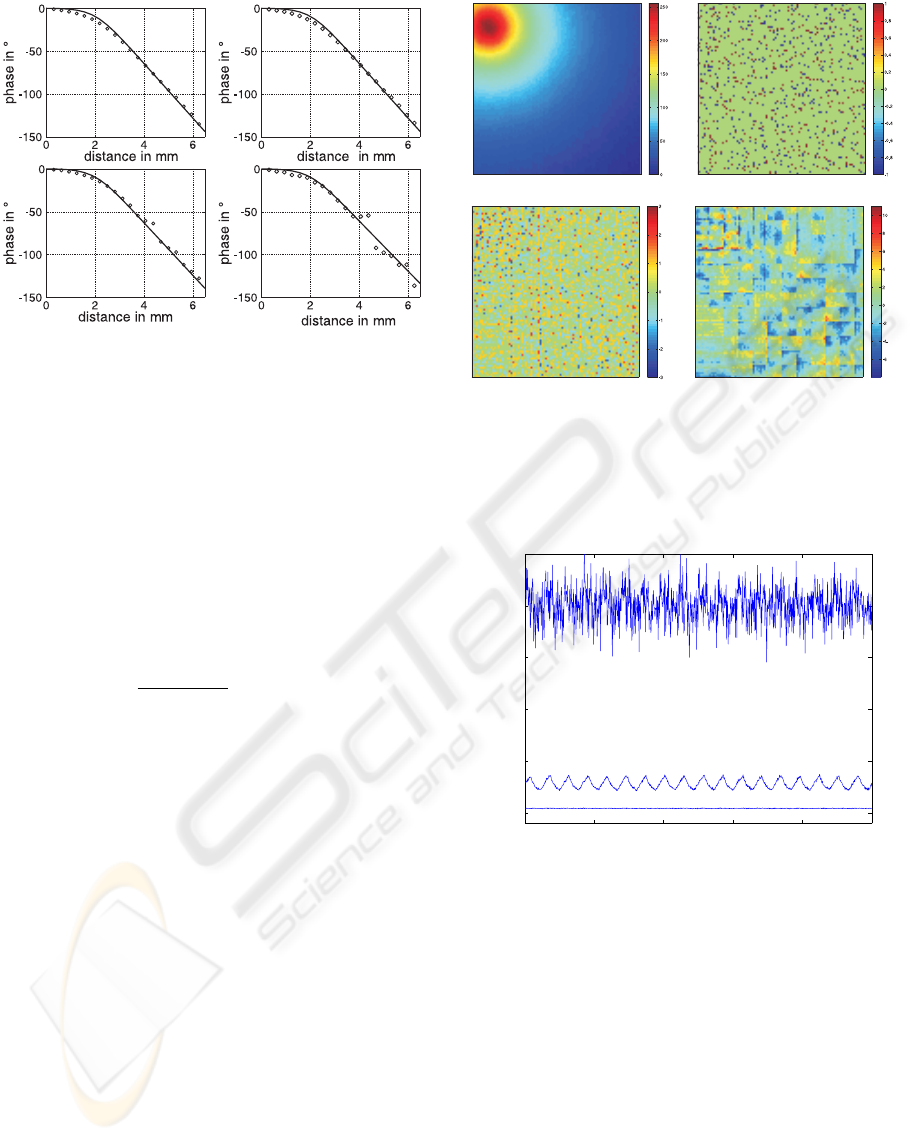

C D

A B

Figure 4: Phase as a function of distance. Solid line

is the numerical solution of Eqs. (5)-(7) with α = 9.3 ×

10

−6

m

2

.s

−1

, h = 20 W.m

−2

.K

−1

, ρ = 4507 kg.m

−3

, c =

520 J.kg

−1

.K

−1

. Circles stand for the experimental points

obtained from the setup of Fig. 2. By comparison with

Fig. 3, the analysis is performed on a line starting at the

maximum heating point in the modulus image M(X,t) taken

as phase reference. (A) is for a phase calculated with raw

images directly acquired by the thermal camera. (B)(C)(D)

is for a phase calculated with images after a JPEG compres-

sion with compression parameter CMP of section 4 respec-

tively equal to 100, 90 and 25. The conductivity estimated

from each panel (A)-(D) are visible in Table 1.

I(X ,n) is created with

I(X ,n) =

255

θ

max

− θ

min

(θ(X,n)− θ

min

) . (8)

A standard JPEG compression is then applied to

I(X ,n) to create the compressed sequence of images

I

CMP

(X,n). We used the JPEG compression available

in the programming language Matlab (version 7) with

a compression parameter CMP in the range [1-100]

for varying the quality/size ratio. The value 100 for

CMP corresponds to high quality at low compression

and 1 to low quality at high compression. A visual ap-

preciation of the typical impact of the distorsion due

to this JPEG compression is visible in Fig. 5. For an

uncompressed raw image I(X,n) in Fig. 5A consid-

ered at a given instant n, Fig. 5 displays, for various

values of the compression parameter CMP, the error

image ε(X,n) defined as

ε(X,n) = I(X,n)− I

CMP

(X,n) . (9)

A possible way to quantify the distorsion due to

the lossy compression is to calculate a spatial mean

square error for each sample n

MSE(n) = hε(X,n)i

X

. (10)

Temporal evolutions of MSE of Eq. (10) are given in

Fig. 6.

A

C

D

C

B

Figure 5: Panel A : uncompressed raw image I(X,n) of tem-

perature coded on 256 digital levels according to Eq. (8).

Panels (B,C,D) : error images ε(X, n) of Eq. 9 for decreas-

ing compression parameter CMP respectively equal to 100,

90, 25 and corresponding compression rates indicated in Ta-

ble 1.

0 200 400 600 800 1000

0

0.5

1

1.5

2

2.5

sample n

mean square error MSE

Figure 6: Mean square error MSE of Eq. (10) temporal

evolutions along the 999 images acquired with the setup of

Fig. 2 after JPEG compression. From bottom to up the com-

pression parameter CMP is respectively equal to 100, 90,

25.

It is possible from Fig. 5 and Fig. 6 to figurate how

both spatial and temporal noise will disturb the im-

age sequence. However, distorsion measured by the

mean square error does not assess the impact of the

compression on the useful information carried by the

sequence concerning the parameter to be estimated.

This type of questioning also arises when the per-

ceived distorsion due to a lossy compression is ap-

preciated by the human vision. Psychovisual experi-

ments are requested in this case. Here, since we are

in a measurement context, we can objectively address

IMAGAPP 2010 - International Conference on Imaging Theory and Applications

20

the quantitative impact of the distorsion on the qual-

ity of the measure. To this end, we now perform the

parameter estimation procedure of section 3 on the

sequence of images I

CMP

(X,n) for several values of

the compression rate controlled by the compression

parameter CMP. The results, visible in Table 1, show

how the quality of the estimate is affected by the lossy

compression. The CMP coefficient acts on the size of

the imagette used to perform the JPG compression.

For low values of parameter CMP (in Fig. 4D) some

discontinuities due to these imagette are clearly vis-

ible. Nevertheless, thermal images θ(X,n) are vary-

ing very smoothly in the spatial domain. JPEG al-

gorithm acts like a low-pass filter for spatial frequen-

cies which tends to preserve the low frequencies of

θ(X,n). Therefore, it appears that for sufficiently low

(up to 66%) compression rate the compression distor-

tion on each individual image barely has no effect on

the useful information carried by the whole sequence.

As demonstrated in Table 1, the estimation error by

comparison with raw datas increases slower than the

compression rate decreases. The measurement allows

to perform identification of the class of material in

terms of thermal properties even at very high com-

pression rate.

Table 1: Estimate of the conductivity λ of the ma-

terial sample of Fig. 2 in [W.m

−1

.K

−1

] performed af-

ter lossy JPEG compression at various rate (CR =

size(I

CMP

(X, n))/size(θ(X,n)). As a comparison, the typ-

ical λ for titanium is expected in the range 5 to 25

W.m

−1

.K

−1

depending on the purity of the material. As

an order of magnitude thermal conductivity of pure copper

is 401 W.m

−1

.K

−1

and pure aluminium is 237 W.m

−1

.K

−1

CR CMP estimate relative error

raw 21.42 0 %

66% 100 21.41 0.04%

88% 90 23.24 8.54%

94% 25 25.88 20.8%

5 CONCLUSIONS

In this report we have shown and analyzed quanti-

tatively the robustness of parameter estimation with

periodic active thermal imaging toward lossy JPEG

compression. An originality in our approach by com-

parison with the recent work of (Lugin, 2008) is that

we have not considered the distortion due to lossy im-

age compression on the thermal images but directly

on the quantitative information they carry. This ap-

proach is interesting in general for quantitative phys-

ical imaging since it shows the possibility of condi-

tions where lossy image compression can entail al-

most no loss in the information extracted form the im-

age.

Further development of this work is to consider

video-compression algorithms (Shi and Sun, 2000)

to compress the whole sequence of images. In-

stead of compressing each image separately, video-

compression treats groups of successive pictures.

This video compression would enable higher com-

pression rates and bring additional distortion on the

information carried on each pixel with time. Other

ways to reduce the amount of data required by peri-

odic active thermal imaging are also to decrease the

sampling frequency, the imaging sensor dynamic and

the number of pixels. It would then be interesting

to see how these configurations together with video

lossy compression degrade the quality of the estimate

of physical parameters. For illustration in this re-

port, the unknown parameter to be estimated was the

conductivity. The sensitivity to compression distor-

sion could also depend on the parameter to be esti-

mated and it would also be important to explore this

systematically while investigating other compression

schemes.

Typical limit to look for in terms of compression

would be in the direction of the technical character-

istics of the new portable thermal cameras which are

now available at relative low cost. An MPEG video

flux is usually available as an output of these cam-

eras. This facility is initially thought as a qualitative

tool enabling the display of thermal images on screens

larger than the screen of the camera itself. Yet, as il-

lustrated in this report, periodic active thermal imag-

ing only requires the relative spatial and temporal

variations of the gray levels to perform quantitative

measurement. An application of our results would

therefore be to evaluate the possible usefulness of

these portable thermal cameras for quantitative peri-

odic active thermal imaging.

ACKNOWLEDGEMENTS

Authors would like to thank Patrice BALCON and

Franck CARETTE from FLIR Systems for useful dis-

cussions.

REFERENCES

Bovik, A. C. (2000). Handbook of Image and Video Pro-

cessing. Academic Press, New York.

Breitenstein, O., Warta, W., and Langenkamp, M. (2003).

Lock-in Thermography. Springer, New York.

IMPACT OF A LOSSY IMAGE COMPRESSION ON PARAMETER ESTIMATION WITH PERIODIC ACTIVE

THERMAL IMAGING

21

Ghiglia, D. C. and Pritt, M. D. (1998). Two Dimensional

Phase Unwrapping : Theory, Algorithm and Software.

Wiley, New York.

Kay, S. M. (1993). Fundamentals of Statistical Signal Pro-

cessing: Estimation Theory. Prentice Hall, Engle-

wood Cliffs.

Lugin, S. (2008). Pulsed Thermography. VDM Verlag,

New York.

Perez, L. and Autrique, L. (2009). Robust determination of

thermal diffusivity values from periodic heating data.

Inverse problems, 25:2310–2313.

Shi, Y. Q. and Sun, H. (2000). Image and Video Compres-

sion for Multimedia Engineering. CRC Press, New

York.

IMAGAPP 2010 - International Conference on Imaging Theory and Applications

22