MANIPULATION OF PARAMETRIC SURFACES THROUGH A

SIMPLE DEFORMATION ALGORITHM

L. H. You

1

, H. Ugail

2

, X. Y. You

3

, E. Chaudhry

1

and Jian J. Zhang

1

1

National Centre for Computer Animation, Bournemouth University, U.K.

2

School of Computing, Informatics and Media, University of Bradford, U.K.

3

Faculty of Engineering and Computing, Coventry University, U.K.

Keywords: Surface Manipulation, Partial Differential Equation, Approximate Analytical Solution.

Abstract: In this paper, we present a novel but simple physics based method to manipulate parametric surfaces. This

method can deal with local deformations with an arbitrarily complicated boundary shape. We firstly map a

deformation region of a 3D surface to a circle on a 2D parametric plane. Then we derive an approximate

analytical solution of a set of fourth order partial differential equations subjected to sculpting forces and the

boundary conditions of the circle. With the obtained solution, we show how to create a deformed surface

and how sculpting forces and the shape control parameters affect the shape of a deformed surface. Finally,

we provide some examples to demonstrate the applications of our proposed method in surface manipulation.

1 INTRODUCTION

Surface manipulation is at the heart of geometric

modelling and has attracted a lot of research

attention.

Depending on whether physics of object

deformation is introduced or not, surface

manipulation can be divided into purely geometric

and physics based. Purely geometric surface

manipulation achieves the intended shapes by

manually changing the positions of surface points or

control points. Physics based surface manipulation

obtains different surface shapes by applying virtual

forces to deform the surfaces.

Directly manipulating surface points of

polygonal models or control points of NURBS

models is a commonly used method for purely

geometric surface manipulation. In addition,

extrusion, blending, sweeping, skinning, filleting,

chamfering, and Boolean operations etc. are also

frequently applied in shape manipulation (Fleming

1999; Maestri 1999).

In order to improve the efficiency and capability

of surface manipulation, free from deformation

methods were developed. By simulating the

deformations caused by twisting, bending, tapering,

or similar transformations of geometric objects, Barr

(1984) proposed new operations for shape

manipulation. Following Barr’s work, Sederberg and

Parry (1986) developed a more general approach

called free-form deformation (FFD). This method

embeds an object in a lattice and achieves the

deformations of the object by deforming the lattice.

By using the initial lattice points to define an

arbitrary trivariate Bézier volume, and allowing the

combination of many lattices to form arbitrarily

shaped spaces, Coquillart (1990, 1991) introduced

Extended Free-Form Deformations (EFFD). Free-

form deformation was also investigated by

Lamousin and Waggenspack (1994), MacCracken

(1996), Hirota et al. (2000), and Feng et al. (2002,

2006).

Purely geometric surface manipulation methods

are simpler and more efficient than the physics

based methods. However, purely geometric methods

do not follow any underlying physical laws.

Therefore, if an object is to be modelled by such

methods, the quality depends on the skills and

perception of modellers. For a same object, different

modellers may create somewhat different shapes.

This issue may be resolved by introducing the

underlying physics governing the deformation of

deformable materials. The surface manipulation

based on this consideration is called physics based.

It considers material properties and physical laws

relevant to surface deformation. This approach has a

potential to create more realistic looking objects.

Employing the elasticity theory, Terzopoulos and

his colleagues (1987) and (1988) introduced

dynamic differential equations for flexible materials

84

H. You L., Ugail H., Y. You X., Chaudhry E. and J. Zhang J. (2010).

MANIPULATION OF PARAMETRIC SURFACES THROUGH A SIMPLE DEFORMATION ALGORITHM.

In Proceedings of the International Conference on Computer Graphics Theory and Applications, pages 84-89

DOI: 10.5220/0002823100840089

Copyright

c

SciTePress

such as rubber, cloth and paper. This work was

extended from elasticity to viscoelasticity, plasticity

and fracture (Terzopoulos and Fleischer 1988). By

minimizing the energy functional under user

controlled geometric constraints and loads, Celniker

and Gossard (1991) presented a curve and surface

finite element method for shape manipulation. Based

on a primal formulation and a hybrid formulation

derived from the theory of pure elasticity, Güdükbay

and Özgüç (1994) investigated a physically based

modeling algorithm to animate deformable objects.

In order to deal with mass distributions, internal

deformation energies, and other physical quantities

of shape manipulation of NURBS, a dynamic

NURBS was developed by Terzopoulos and Qin

(1994). This method was further investigated to

tackle the surfaces with symmetries and topological

variability which leads to a dynamic NURBS swung

surface (Qin and Terzopoulos 1995). By extending

triangular B-splines to triangular NURBS and using

Lagrangian mechanics, Qin and Terzopoulos (1997)

developed the mathematical model of dynamic

triangular NURBS and manipulated the surfaces

defined over arbitrary, nonrectangular domains

through the finite element solution of the

mathematical model. Applying sculpting forces on a

surface and formulating and minimizing the energy

functional of the surface, Vassilev (1997) proposed a

method to manipulate deformable B-spline surfaces.

Using the model of a bar network, Léon and Veron

(1997) and Guillet and Léon (1998) dealt with the

deformation of free-form surfaces. Considering non-

homogeneous material properties and conducting the

finite element calculations of deformable objects in

local frames, McDonnell and Qin (2007) presented a

new, physics based shape manipulation method.

Surfaces can also be described by the solution to

a partial differential equation subjected to suitably

defined boundary conditions. Partial differential

equations (PDEs) based modelling was first

introduced by Bloor and Wilson (1989, 1990). In

order to cope with more complicated surface

modelling problems, Bloor and Wilson proposed a

spectral approximation method (1996) and a

perturbation method (2000). Using the partial

differential equation (PDE) method, Ugail et al.

(1999) examined how practical surfaces can be

constructed interactively in real time. Kubeisa et al.

(2004) addressed the problem of interactive design

of higher order PDEs. In the work carried out by

Ugail (2004), the generation of the spline of a PDE

surface and parameterization of the surface by using

the spline were investigated. By studying the so-

called harmonic and biharmonic Bézier surfaces,

Monterde and Ugail (2004) presented a new method

of surface generation. By defining the trim curves to

be a set of boundary conditions, Ugail (2006)

proposed a method to trim PDE surfaces. How

Bézier surfaces can be generated from boundary

information through a general 4th-order PDE was

tackled by Monterde and Ugail (2006). Generalizing

the governing partial differential equation to

arbitrary order, complex shapes were designed as

single patch by Ugail (2007). Incorporating dynamic

effects into a fourth order PDE, You and Zhang

studied creation of 3D deformable moving surfaces

(2003). Using a sixth order PDE and a semi-

analytical and semi-numerical solution, Zhang and

You (2004) presented a method for surface

modelling.

This paper will focus on surface manipulation

using an approximate analytical solution to fourth

order partial differential equations. It maps an

arbitrary deformation region in 3D coordinate space

to a circle in 2D parametric plane, achieves the

approximate analytical solution of the deformation

within the circle, and uses it to manipulate surfaces.

2 MATHEMATICAL MODEL

The deformations of a surface can be simulated

through those of a thin elastic plate. When subjected

a lateral load

q , the mathematical model describing

surface deformations is

),,(

2

4

4

22

4

4

4

zyx

D

q

vvuu

(1)

subjected to the following boundary conditions

),,(

0 ,0 ,0

zyx

vu

(2)

where

)1(12

2

3

Eh

D

(3)

and

E

and

are Young’s modulus and Poisson’s

ratio, and

h is the thickness of a surface.

3 SOLUTION

Since the analytical solution of Eq. (1) under the

MANIPULATION OF PARAMETRIC SURFACES THROUGH A SIMPLE DEFORMATION ALGORITHM

85

boundary conditions (2) on a circular boundary is

obtainable, we take the boundary defined by

parametric variables

u and v to be

01

22

vu

(4)

For the deformation which has both positional

and tangential continuities at boundary (2), we take

the following functions as the solution of Eq. (1)

),,(

)1(

222

zyx

vum

(5)

where

m is an unknown constant.

Substituting Eq. (5) into (2), boundary conditions

are satisfied exactly.

Substituting Eq. (5) into (1), we determine the

unknown constant

m and obtain the analytical

solution of Eq. (1).

4 APPLICATIONS

In order to use the above method to determine the

deformations of a 3D surface, we relate a

deformation region with an arbitrary boundary shape

to a circle.

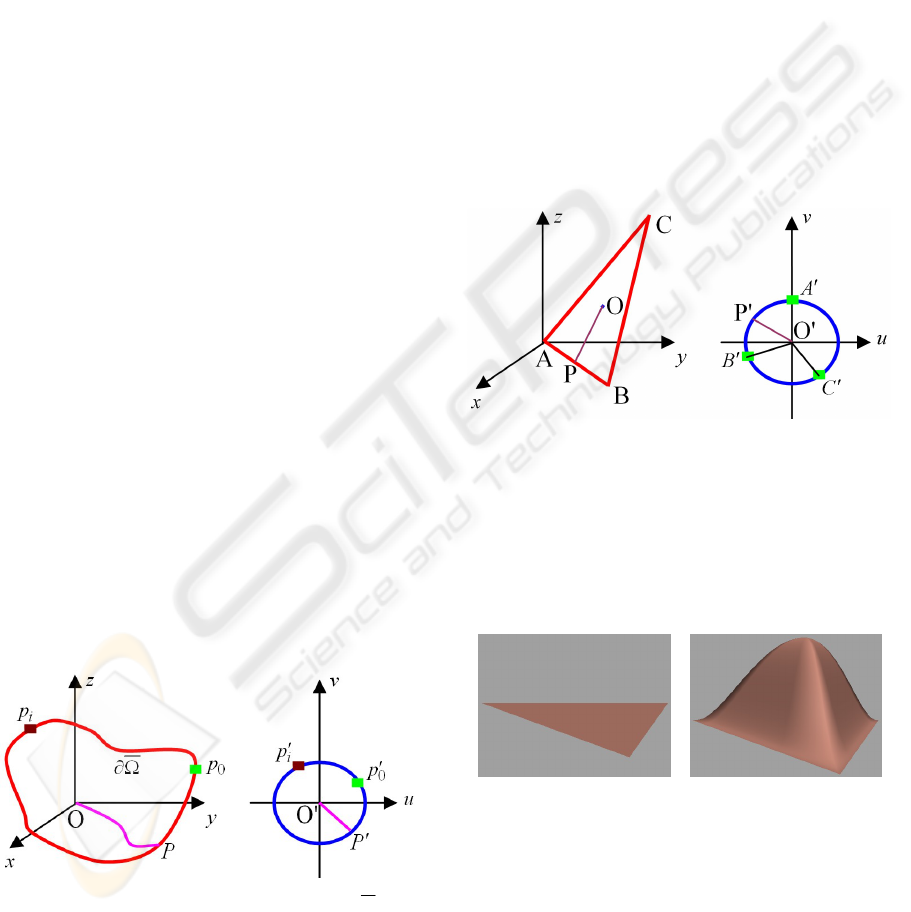

As shown in Figure 1, we use the length of the

boundary of the deformation region and the circle to

determine the corresponding points

P

and

P

between them. Then, we find a point

O on the 3D

surface which corresponds to the geometric centre of

the deformation region. The surface curve

OP is

related to the straight line

PO

. With such a

treatment, we obtain the one-to-one relationship

between all the points on the 3D surface and those

within the circle.

Figure 1: Parameterization of boundary

and

deformation region.

Finally, we apply a sculpting force

q , and use

the above method to calculate the deformations of

the 3D surface, and superimpose these deformations

to the original surface to create the deformed

surface. In the subsections below, we will

demonstrate this through a number of examples.

4.1 Surface Deformations within a

Triangle

In this subsection, we investigate how to deform a

triangle.

As indicated in Figure 2, by calculating the

length of the triangle and the circle, we find the

points

A

, B

and C

on the circle which correspond

to the three vertices A, B and C of the triangle,

respectively.

Then we calculate the geometric centre

O of the

triangle from its three vertices. This geometric

centre

O is related to the centre O

of the circle.

Figure 2: Parameterization of a triangle.

For an arbitrary point

P

on the boundary of the

triangle, we find its corresponding point

P

on the

circle. The points on the line

OP are related to the

points on the line

PO

. The same method is used to

determine the one-to-one relationship of the points

between the triangle and the circle.

a b

Figure 3: Surface deformation within a triangle region.

For a triangle deformation region indicated in

Figure 3a, we set Young’s modulus

10000E ,

Poisson’s ratio

3.0

, surface thickness 1.0

h

and the sculpting force

100

z

q . The deformation of

the triangle was obtained and depicted in Figure 3b.

GRAPP 2010 - International Conference on Computer Graphics Theory and Applications

86

4.2 Effect of Material and Geometric

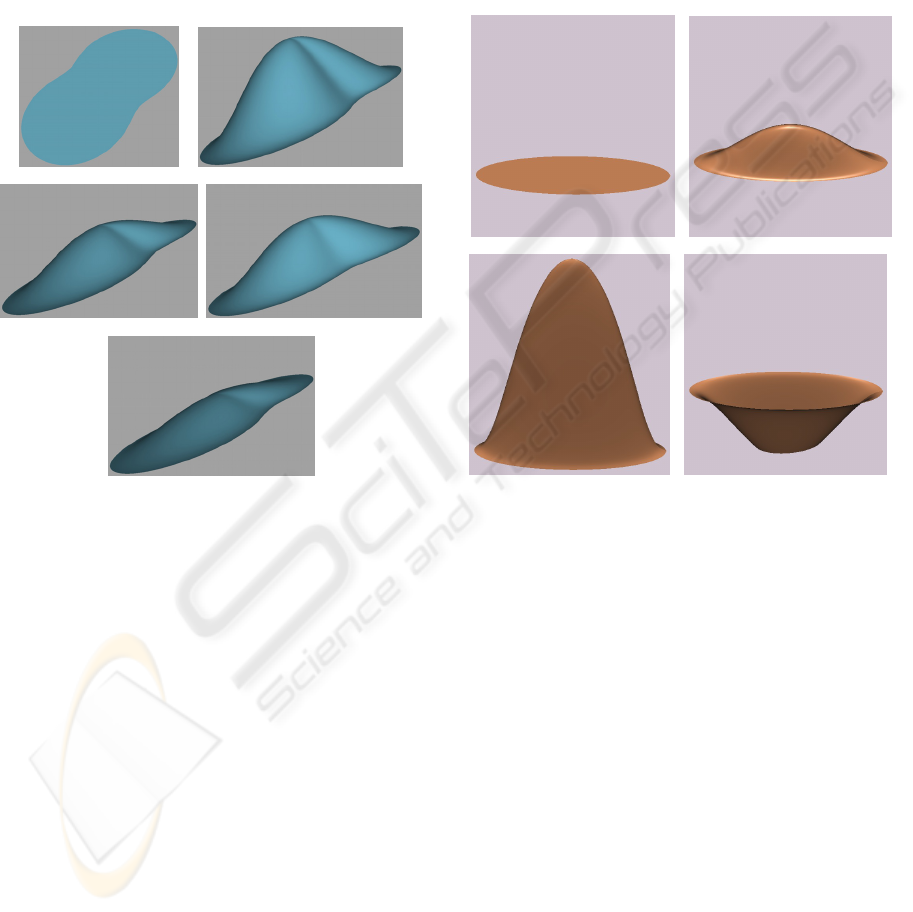

Properties

In this subsection, we examine how material and

geometric properties affect the shape of a surface.

The deformation region in a 3D coordinate space

was shown in Figure 4a. It was mapped into a circle.

Basic parameters are taken to be: the material

properties

10000E , 3.0

, geometric property

1.0h , and sculpting force 100

z

q .

a b

c d

e

Figure 4: Effect of material and geometric properties.

The deformed surface indicated in Figure 4b was

obtained. Only raising Young’s modulus to 20000

and keeping all other basic parameters unchanged,

the deformation was reduced and the deformed

shape in Figure 4c was generated. When Poisson’s

ratio of the basic parameters was increased to 0.6,

the deformation given in Figure 4b was dropped to

that in Figure 4d. Increasing the surface thickness to

0.15 also decreases the deformation and produces

the shape in Figure 4e.

4.3 Effect of Sculpting Forces

Here we study how sculpting forces affect surface

deformations. The deformation region in a 3D

coordinate space is an ellipse. The original surface

shape within the ellipse is depicted in Figure 5a. The

surface will be deformed in

z

direction. Young’s

modulus E is taken to be

30000E , Poisson’s ratio

is set to

3.0

. Applying a sculpting force 50

z

q

on the surface, the surface was pulled upwards and

the deformed shape was indicated in Figure 5b.

Raising the sculpting force to 200, the deformation

was greatly increased as indicated in Figure 5c.

Changing both the direction and size of the sculpting

force, i. e., setting the sculpting force to -120, the

surface was push downwards and the deformed

shape in Figure 5d was created. These images

indicate that sculpting forces are very useful in

surface manipulation.

a b

c d

Figure 5: Effect of sculpting force.

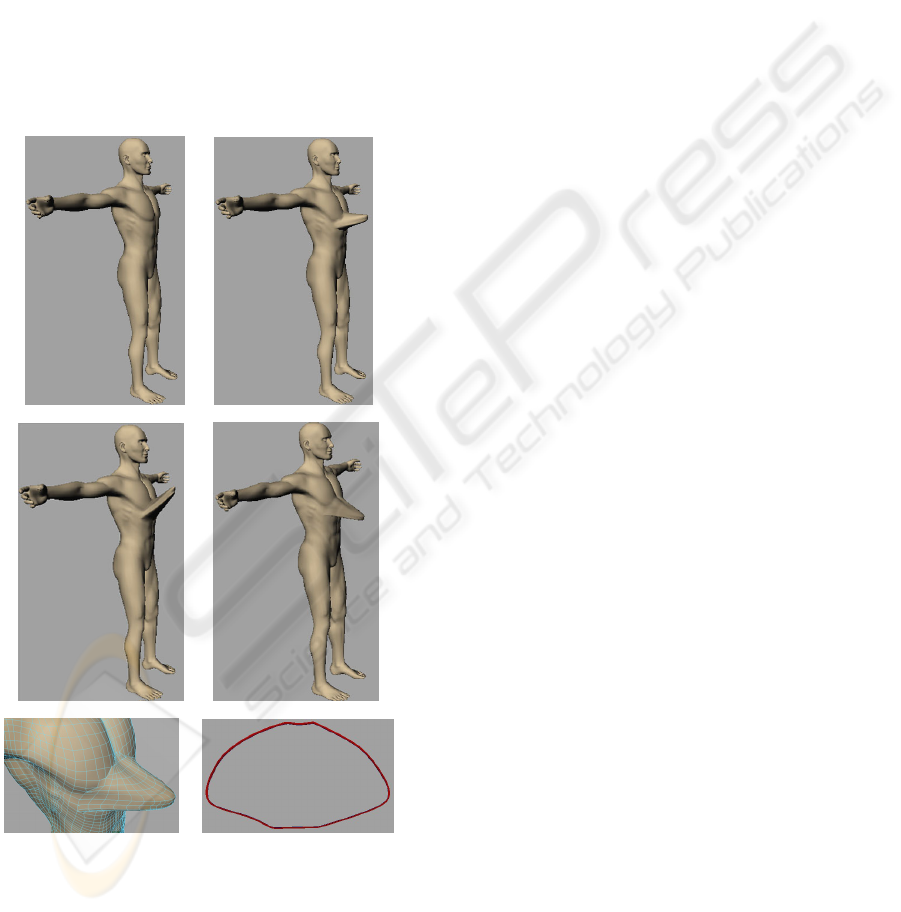

4.4 Local Deformations

In this subsection, we discuss how to use our

proposed method to achieve complex local

deformations of 3D models.

For a 3D surface model, we first interactively

specify the region which will be deformed. Then we

extract the boundary curve of the deformation

region. Finally, the above method is used to

determine the corresponding relationship between

the deformation region and a circle.

Here we give an example to deform a male chest.

The undeformed chest was shown in Figure 6a. The

boundary of the deformation region on the chest was

shown in Figure 6f. By applying different sculpting

forces to the deformation region, different deformed

shapes were obtained and depicted in Figures 6b, 6c

and 6d. A local view of the deformation shape in

Figure 6b was given in Figure 6e.

MANIPULATION OF PARAMETRIC SURFACES THROUGH A SIMPLE DEFORMATION ALGORITHM

87

5 CONCLUSIONS

A physics based surface manipulation method has

been proposed through the above work. For doing

this, we examined the relationship between a

deformation region in 3D coordinate space and a

circle in 2D parametric plane and formulated the

corresponding boundary conditions. By constructing

proper trial functions, we obtained an approximate

analytical solution which exactly satisfies both

positional and tangential continuities at the circle

and the partial differential equations. With the

application examples given in this paper, we

discussed how to use the solution to carry out

surface manipulation.

a b

c d

e f

Figure 6: Deformation of a male chest.

The method proposed in this paper can be easily

developed into an interactive software tool whereby

surface manipulation can be performed easily and in

real-time. We intend to develop such a tool in the

future.

REFERENCES

Fleming, B., 1999. 3D Modeling & Surfacing, Academic

Press.

Maestri, G., 1999.

Digital Character Animation, Volume

1: Essential Techniques

, New Riders Publishing.

Barr, A. H., 1984. Global and Local Deformations of Solid

Primitives,

Proceedings of SIGGRAPH ’84 and

Computer Graphics 18(3)

, 21-30.

Sederberg, T.W., Parry, S.R., 1986. Free-Form

Deformation of Solid Geometric Models,

Proceedings

of SIGGRAPH ’86 and Computer Graphics 20(4)

,

151-159.

Coquillart, S., 1990. Extended free-form deformation: a

sculpturing tool for 3D geometric modelling,

In

Computer Graphics (SIGGRAPH ’90 Proceedings) 24

,

187-196.

Coquillart, S., Janc´ene, P., 1991. Animated free-form

deformation: An interactive animation technique,

In

Computer Graphics (SIGGRAPH ’91 Proceedings) 25

,

23–26.

Lamousin, H., Waggenspack, W., 1994. NURBS-based

free-form deformation,

IEEE Computer Graphics and

Applications 14(6)

, 59-65.

MacCracken, R., 1996. Free-from deformations with

lattices of arbitrary topology,

In Proceedings of the

23

rd

Annual Conference on Computer Graphics and

Interactive Applications (SIGGRAPH 96)

, 181-188.

Hirota, G., Maheshwari, R., Lin, M.C., 2000. Fast volume-

preserving free-form deformation using multi-level

optimization,

Computer-Aided Design 32(8), 499-

512(14).

Feng, J., Nishita, T., Jin, X., Peng, Q., 2002. B-spline free-

form deformation of polygonal object as trimmed

Bézier surfaces,

The Visual Computer 18, 493-510.

Feng, J., Shao, J., Jin, X., Peng, Q., Forrest, A.R., 2006.

Multiresolution free-form deformation with

subdivision surface of arbitrary topology,

The visual

Computer 22(1)

, 28-42.

Terzopoulos, D., Platt, J., Barr, A., Fleischer, K., 1987.

Elastically deformable models,

Computer Graphics

21(4)

, 205-214.

Terzopoulos, D., Fleischer, K., 1988. Deformable models,

The Visual Computer 4, 306-331.

Terzopoulos, D., Fleischer, K., 1988. Modeling inelastic

deformation: viscoelasticity, plasticity, fracture,

Computer Graphics 22(4), 269-278.

Celniker, G., Gossard, D., 1991. Deformable curve and

surface finite-elements for free-form shape design,

Computer Graphics 25(4), 257-266.

Güdükbay, U., Özgüç, B., 1994. Animation of deformable

models,

Computer-Aided Design 26(12), 868-875.

Terzopoulos, D., Qin, H., 1994. Dynamic NURBS with

geometric constraints for interactive sculpting,

ACM

Transactions on Graphics 13(2)

, 103-136.

Qin, H., Terzopoulos, D., 1995. Dynamic NURBS swung

surfaces for physical-based shape design,

Computer-

Aided Design 27(2)

, 111-127.

Qin, H., Terzopoulos, D., 1997. Triangular NURBS and

their dynamic generations,

Computer Aided Geometric

GRAPP 2010 - International Conference on Computer Graphics Theory and Applications

88

Design 14, 325-347.

Vassilev, T. I., 1997. Interactive sculpting with

deformable nonuniform B-splines,

Computer Graphics

Forum 16

, 191-199.

Léon, J. C., Veron, P., 1997. Semiglobal deformation and

correction of free-form surfaces using a mechanical

alternative,

The Visual Computer 13, 109-126.

Guillet, S., Léon, J. C., 1998. Parametrically deformed

free-form surfaces as part of a variational model,

Computer-Aided Design 30(8), 621-630.

Mandal, C., Qin, H., Vemuri, B.C., 2000. Dynamic

modeling of butterfly subdivision surfaces,

IEEE

Transactions on Visualization and Computer Graphics

6(3)

, 265-287.

McDonnell, K. T., Qin, H., 2007. A novel framework for

physically based sculpting and animation of free-form

solids,

The Visual Computer 23(4), 285-296.

Bloor, M. I. G., Wilson, M. J., 1989. Generating blend

surfaces using partial differential equations,

Computer-Aided Design 21(3), 165-171.

Bloor, M. I. G., Wilson, M. J., 1990. Using partial

differential equations to generate free-form surfaces,

Computer-Aided Design 22(4), 202-212.

Bloor, M. I. G., Wilson, M. J., 1996. Spectral

approximations to PDE surfaces,

Computer-Aided

Design 28(2)

, 145-152.

Bloor, M. I. G., Wilson, M. J., Mulligan, S. J., 2000.

Generating blend surfaces using a perturbation

method,

Mathematical and Computer Modelling

31(1)

, 1-13.

Ugail, H., Bloor, M. I. G., Wilson, M. J., 1999.

Techniques for Interactive Design Using the PDE

Method,

ACM Transactions on Graphics 18(2), 195-

212.

Kubiesa, S., Ugail, H., Wilson, M. J., 2004. Interactive

design using higher order PDEs,

The Visual Computer

20

, 682-693.

Ugail, H., 2004. Spine based shape parameterisation for

PDE surfaces,

Computing 72, 195-206.

Monterde, J., Ugail, H., 2004. On harmonic and

biharmonic Bézier surfaces,

Computer Aided

Geometric Design 21(7)

, 697-715.

Ugail, H., 2006. Method of Trimming PDE Surfaces,

Computers & Graphics 30(2), 225-232.

Monterde, J., Ugail, H., 2006. A General 4th-Order PDE

Method to Generate Bézier Surfaces from the

Boundary,

Computer Aided Geometric Design 23(2),

208-225.

Ugail, H., 2007. Generalized Partial Differential Equations

for Interactive Design, International

Journal of Shape

Modeling 13(2)

, 225-226.

You, L. H., Zhang, J. J., 2003. Fast Generation of 3D

Deformable Moving Surfaces,

IEEE Transactions on

Systems, Man and Cybernetics, Part B: Cybernetics

33(4)

, 616-625.

Zhang, J. J., You, L. H., 2004. Fast surface modelling

using a 6

th

order PDE, Computer Graphics Forum

23(3)

, 311-320.

MANIPULATION OF PARAMETRIC SURFACES THROUGH A SIMPLE DEFORMATION ALGORITHM

89