A MORPHING WING USED SHAPE MEMORY ALLOY

ACTUATORS NEW CONTROL TECHNIQUE WITH

BI-POSITIONAL AND PI LAWS OPTIMUM COMBINATION

Part 2: Experimental Validation

Teodor Lucian Grigorie, Andrei Vladimir Popov, Ruxandra Mihaela Botez

École de Technologie Supérieure, Montréal, Québec H3C 1K3, Canada

Mahmoud Mamou, Youssef Mébarki

National Research Council, Ottawa, Ontario K1A 0R6, Canada

Keywords: Morphing Wing, Shape Memory Alloy Actuators Control, Experimental Validation, Bench Test, Wind

Tunnel Test.

Abstract: The paper represents the second part of a study related to the development of an actuators control system for

a morphing wing application, and describes the experimental validation of the control designed in the first

part. After a short presentation of the finally adopted control architecture, the physical implementation of

the control is done. To implement the controller on the physical model two Programmable Switching Power

Supplies AMREL SPS100-33 and a Quanser Q8 data acquisition card, were used. The inputs of the data

acquisition were two signals from Linear Variable Differential Transformer potentiometers, indicating the

positions of the actuators, and six signals from thermocouples installed on the SMA wires. The acquisition

board outputs channels were used to control power supplies in order to obtain the desired skin deflections.

The control validation was made in two experimental ways: bench test and wind tunnel test. All 35

optimized airfoil cases, used in the design phase, were converted into actuators vertical displacements which

were used as inputs reference for the controller. In the wind tunnel tests a comparative study was realized

around of the transition point position for the reference airfoil and for each optimized airfoil.

1 INTRODUCTION

The spectacular and continuous evolution of the

aerospace engineering domain was highlighted in

the last years especially through the boarded

equipments and systems technology development,

mainly those of avionics. But, in the same time, the

two related sub-domains, propulsion systems and

aircraft structures, in parallel registered very

important discoveries, sometimes notified to the

general public too little. Thus, the concept of green

aircraft launched major trends in the aerospace field

research, of which can be mentioned reduction of

noise and chemical pollution of the atmosphere,

reduction of fuel consumption and increase of

aircraft flight autonomy. This concept is a

consequence of the predictions for future according

with that the air traffic is seen to more than double in

the next 20 years. Therefore, both environmental and

economic pressures will strongly increase and

significant progress will need to be achieved in both

improving the efficiency and minimizing the

environmental impact of aircraft. In order to provide

these required changes, aircrafts in new concepts are

designed and will be developed. These suppose the

validation and after that the integration of new

technologies and solutions at the level of all major

aircraft components: cabin, wing, power plant

system, and fuselage; multidisciplinary

investigations already explore the different

associated aspects of aero-dynamics, acoustics,

materials, structure, engines and systems. The aims

of these investigations are to ensure an improved

quality and affordability, whilst meeting the

tightening environmental constraints (emission and

noise), with a vision of global efficiency of the air

13

Lucian Grigorie T., Popov A., Mihaela Botez R., Mamou M. and Mébarki Y. (2010).

A MORPHING WING USED SHAPE MEMORY ALLOY ACTUATORS NEW CONTROL TECHNIQUE WITH BI-POSITIONAL AND PI LAWS OPTIMUM

COMBINATION - Part 2: Experimental Validation.

In Proceedings of the 7th International Conference on Informatics in Control, Automation and Robotics, pages 13-19

DOI: 10.5220/0002878500130019

Copyright

c

SciTePress

transport system.

Within this context are developed our research

related to the morphing aircraft new challenge field,

precisely to the morphing wing concept in this field

(Chang, 2009, Smith, 2007, Hinshaw, 2009,

Gonzalez, 2005, Namgoong, 2006, Majji, 2007, and

Ruotsalainen, 2009). The presented work objective

is to develop an actuation control concept for a new

morphing mechanism using smart materials, like

Shape Memory Alloy (SMA), as actuators. These

smart actuators modify the upper surface of a wing

made of a flexible skin so the laminar to turbulent

transition point moves close to the wing airfoil

trailing edge. The final purpose of the research

project is to obtain a drag reduction as a function of

flow condition, by changing the wing shape.

The chosen wing model was a rectangular one,

with a reference airfoil WTEA-TE1, a chord of 0.5

m and a span of 0.9 m. The model was equipped

with a flexible skin made of composite materials

morphed by two actuation lines. Each actuation line

uses shape memory alloys wires as actuators.

In the first part of this paper a control for the

actuation lines of the morphing wing system was

designed. In this way, 35 optimized airfoils available

for 35 different flow conditions (five Mach numbers

(0.2 to 0.3) and seven angles of attack (-1˚ to 2˚)

combinations) were used.

From the developed actuation mechanism results

that each actuation line uses three SMA wires (1.8 m

in length) as actuators, and contains a cam, which

moves in translation relative to the structure (on the

x-axis in Fig. 1). The cam causes the movement of a

rod related on the roller and on the skin (on the z-

axis). The recall used is a gas spring. The horizontal

displacement of each actuator is converted into a

vertical displacement at a rate 3:1, which makes that

the horizontal stroke of x mm to be converted into a

vertical stroke z=x/3; results a cam factor c

f

=1/3,

therefore, for the approximately 8 mm maximum

vertical displacement, obtained from the optimized

airfoils numerical data, a 24 mm maximum

horizontal displacement must be actuated.

HeatingCooling

Three SMA wires

Flexible skin

Cam

Roller

Support plate for

actuation system

Rod

Compression

spring

x

z

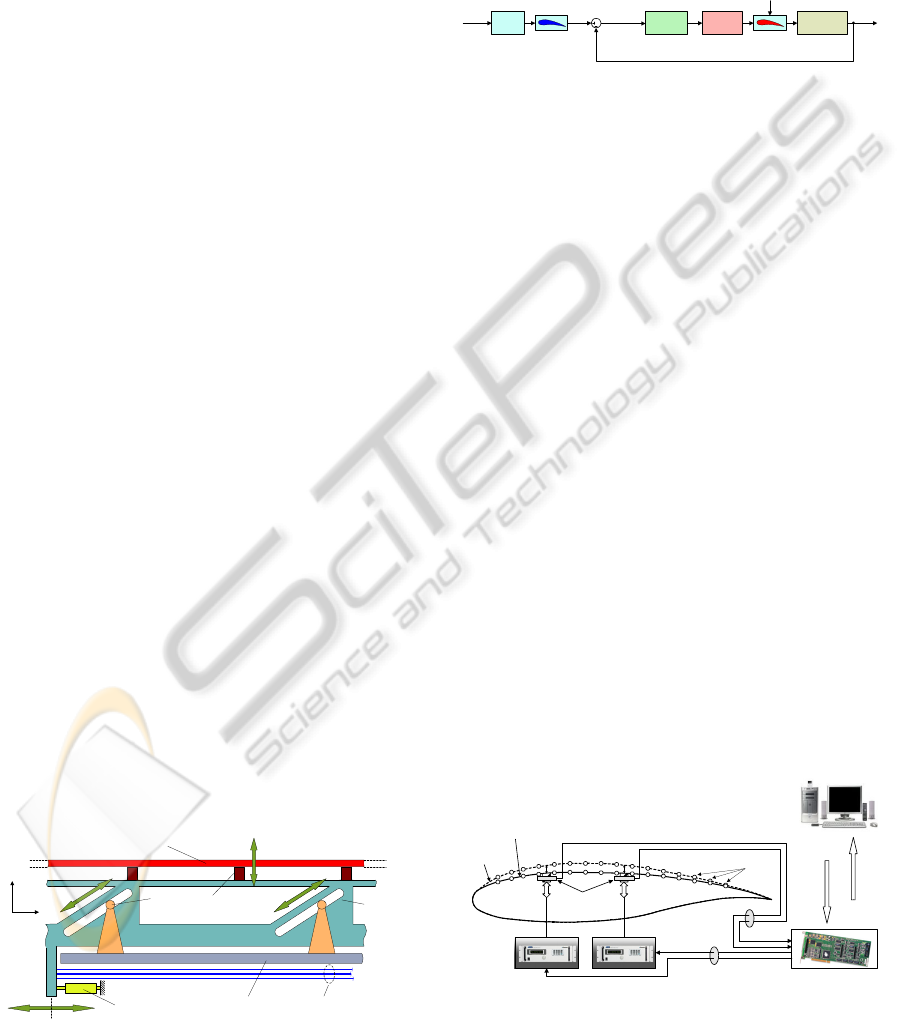

Figure 1: The actuation mechanism concept.

The designed controller controls the SMA

actuators in terms of supply electrical current so that

to cancel the deviation between the required values

for vertical displacements (corresponding to the

optimized airfoils) and the real values, obtained

from two position transducers (Fig. 2).

, M,

Re

Pilot

Control

Flight

conditions

Optimised

airfoils

database

dY

1opt

dY

2opt

Real airfoil

Integrated

controller

dY

1real

dY

2real

SMA

actuators

e=dY

opt

- dY

real

Airflow

perturbations

Current

Position

transducers

dY

1real

dY

2real

Figure 2: Operating schema of the SMA actuators control.

The finally numerical validated configuration (in

the first part of the paper) of the integrated controller

was a combination of a bi-positional controller

(particularly an on-off one) and a PI (proportional-

integral) controller, due to the two phases (heating

and cooling) of the SMA wires interconnection. The

resulted controller must behave like a switch

between cooling phase and heating phase, situations

where the output current is 0 A, or is controlled by a

law of PI type

.0if,d)(0061.787)(8.1792

,0if,0

)(

ettete

e

ti

(1)

e is the operating error (see Fig. 2).

2 PHYSICAL MORPHING WING

CONTROL IMPLEMENTATION

Starting from the theoretical and numerical

simulation resulted considerations to implement the

controller on the physical model two Programmable

Switching Power Supplies AMREL SPS100-33,

controlled by Matlab through a Quanser Q8 data

acquisition card, were used (Fig. 3) (Kirianaki, 2002,

Park, 2003, and

Austerlitz, 2003).

dY

1

dY

2

SMA#1 SMA#2

.

.

.

pressure sensors

Optimum

airfoil

Reference airfoil

Desired

dY

1

, dY

2

Analog output signal for

power supply control

AMREL SPS100-33

power supplies

Position

transducers

Quanser Q8 data

acquisition card

Analog input signal

from position

transducers

Real

dY

1

, dY

2

Figure 3: Physical model operating schema.

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

14

The power supplies have RS-232 and GPIB

IEEE-488 as standard features and the technical

characteristics: Power 3.3kW, Voltage (dc) 0÷100

V, Current (dc) 0÷33 A. The Q8 data acquisition

card has 8 single-ended analog inputs with 14-bit

resolution. All 8 channels can be sampled

simultaneously at 100 kHz, with A/D conversion

times of 2.4 µs/channel, simultaneous sampling and

sampling frequencies of up to 350 kHz for 2

channels. Also, the Q8 card is equipped with 8

analog outputs, with software programmable voltage

ranges and simultaneous update capability with an 8

µs settling time over full scale (20V).

The acquisition board was connected to a PC and

programmed through Matlab/Simulink R2006b and

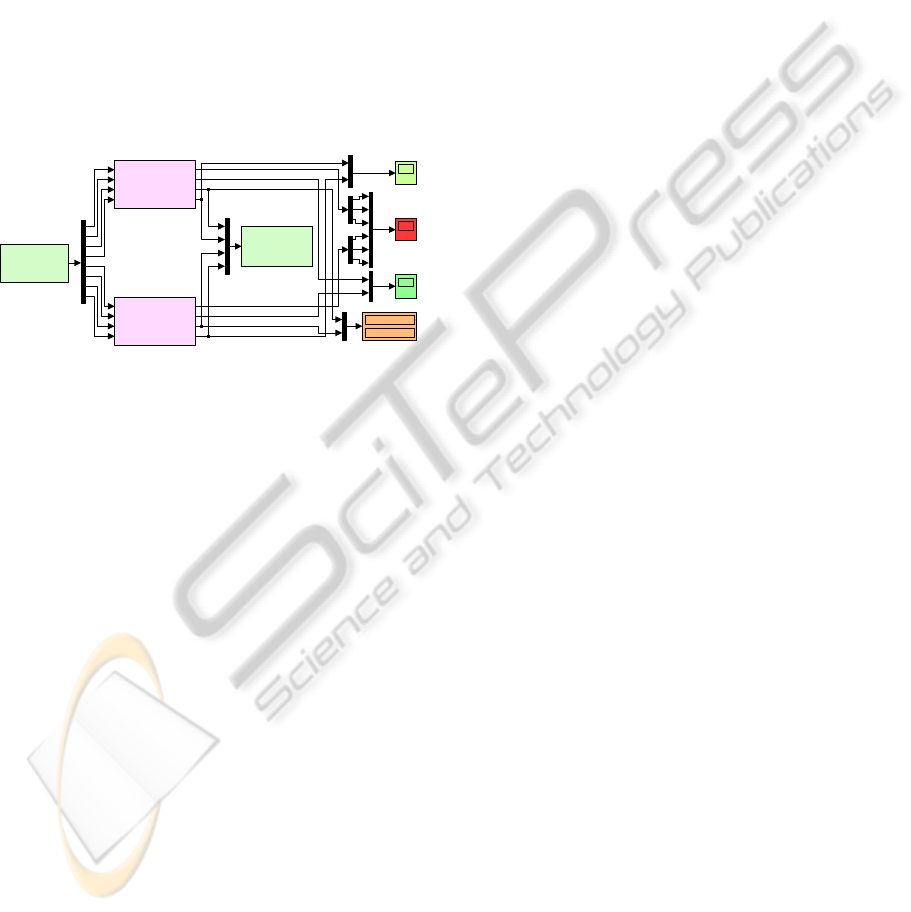

WinCon 5.2 (Fig. 4).

0

Volts

Temp

StartVolt

termocouple1

termocouple2

termocouple3

position 2

temp

amps

control V

start 5V

SMA2

termocouple1

termocouple2

termocouple3

position 1

temp

amps

control V

start 5V

SMA1

Q8

Quanser

Analog Output

Q8

Quanser

Analog Input

Amps

Analog Input

Analog Output

0

Figure 4: Simulink actuators control.

The input signals were two signals from Linear

Variable Differential Transformer potentiometers

that indicate the positions of the SMA actuators, and

six signals from thermocouples installed on all the

SMA wires components. The acquisition sampling

time was set to 0.01 second. The outputs channels of

the acquisition board were used to control each

power supply through analog/external control by use

of a DB-15 I/O connector. The current supplied to

the actuator was set to be limited at 10 A, and the

control signal was set to be 0÷0.6061V (maximum

voltage for the power supply is 2 V for 33 A current

supply).

The operation principle of the physically

implemented controller is relative simple. The initial

input, which is the optimized airfoil for any flow

condition, is chosen manually by the operator from

the computer database through a user interface. Then

the displacements (dY

1

, dY

2

) that are required to be

reproduced by the two control points on the flexible

skin are sent to the controller. This controller sends

an analog signal 0 – 2 V to the power supply that

provides a current to the SMA. The SMA will

respond accordingly and change its length according

to the temperature of the wire. This will result in a

change of the actuators positions, which are sensed

by the linear variable differential transducer

(LVDT). The signal position received from the

LVDT is compared to the desired position and the

error obtained is fed back to the controller. If the

realized position is greater than the desired position

the controller will disconnect the control current

letting the SMA wire to cool down. During the

cooling down process the SMA will maintain its

length due to the hysteretic behavior. This effect is

taken into account for actuators displacement. Also

the controller uses three thermocouples signals from

each SMA wire to monitor the temperature of the

wires and maintain it below 130˚C, as an upper

limit.

3 SMA ACTUATORS CONTROL

BENCH TEST VALIDATION

The morphing wing system in the bench test runs is

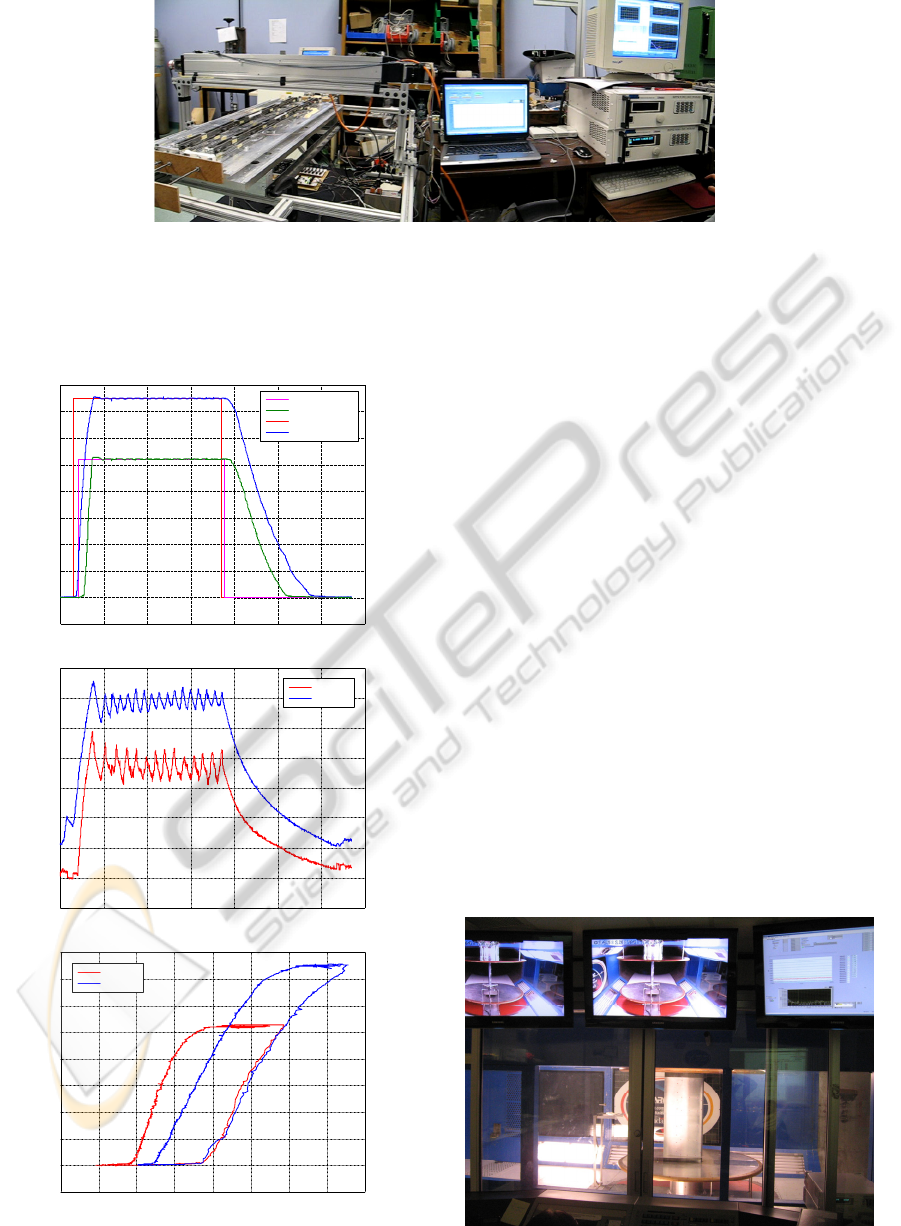

shown in Fig. 5.

The gas springs that maintain the SMA wires in

tension had a preloaded value of 225 lbs (1000 N)

since in the laboratory condition there is no

aerodynamic force.

After an initial calibration test the calibration

gains and constants were established for the two

LVDT potentiometers and for the six thermocouples.

The calibration test for LVDT potentiometers

consisted of several scans of airfoil using a laser

beam. On the calibration, the SMA actuators were in

“zero setting position” with no power supplied and

the skin coordinates were measured using the laser

beam that scanned the center line of the wing model.

The laser was set to scan the chord of the model on a

370 mm length with a speed of 5 mm per second.

In the bench test, the 35 optimized airfoil cases

were converted into SMA actuator #1 and #2

vertical displacements which were used as inputs

reference for the controller. A typical test run history

is shown in Fig. 6 for α=1°, Mach=0.3 flight

condition (dY

1

=5.22 mm, dY

2

=7.54 mm – vertical

displacements of the skin in the actuation points).

On observe that the controllers, in the two

actuation lines, work even in zero values of the

desired signal because of the gas springs pretension.

Also, small oscillations of the obtained deflection

are observed around the desired values of the

deflections. The amplitude of the oscillations in this

phase is due to the LVDT potentiometers

mechanical link and to the inertia of the SMA wires,

being smallest than 0.05 mm. The heating phase is

approximately 9 times more rapidly than the cooling

phase; heating time equals 8 s while the cooling time

A MORPHING WING USED SHAPE MEMORY ALLOY ACTUATORS NEW CONTROL TECHNIQUE WITH

BI-POSITIONAL AND PI LAWS OPTIMUM COMBINATION - Part 2: Experimental Validation

15

Figure 5: Morphing wing system in the bench test runs.

equals 70 s. There can be observed the differences

between the numerical model of the SMA actuators

and the physical model.

50 100 150 200 250 300 350

-1

0

1

2

3

4

5

6

7

8

0

Time [s]

20

30

40

50

60

70

80

90

100

50 100 150 200 250 300 3500

Time [s]

20 30 40 50 60 70 80 90 100

act #1

act #2

Displacements dY

1

, dY

2

(

v

) [mm]

Temperature [

o

C]

-1

0

1

2

3

4

5

6

7

8

Displacements dY

1

, dY

2

(

v

) [mm]

=1°, Mach=0.3

Temperature [

o

C]

act #1 desired

act #1 obtained

act #2 desired

act #2 obtained

act #1

act #2

Figure 6: Bench test for α=1°, M=0.3 flight condition.

The bench test results confirmed that the

experimental version of the designed integrated

controller woks well even in the lab conditions,

where no aerodynamic forces are loaded and the

preloaded gas springs force is 1000N.

4 SMA ACTUATORS CONTROL

VALIDATION IN WIND

TUNNEL TESTS

Once confirmed the well working of the designed

integrated controller through bench test, the next

step in our morphing wing project was to validate

the controller in a wind tunnel test simultaneously

with the transition point real time detection and

visualization for all 35 optimized airfoils. The model

was tested for all 35 theoretical studied flight

conditions, a comparative study being realized

around of the transition point position for the

reference airfoil and for each optimized airfoil. So,

simultaneously with the controller testing, a

validation study for the aerodynamic part of the

project was realized.

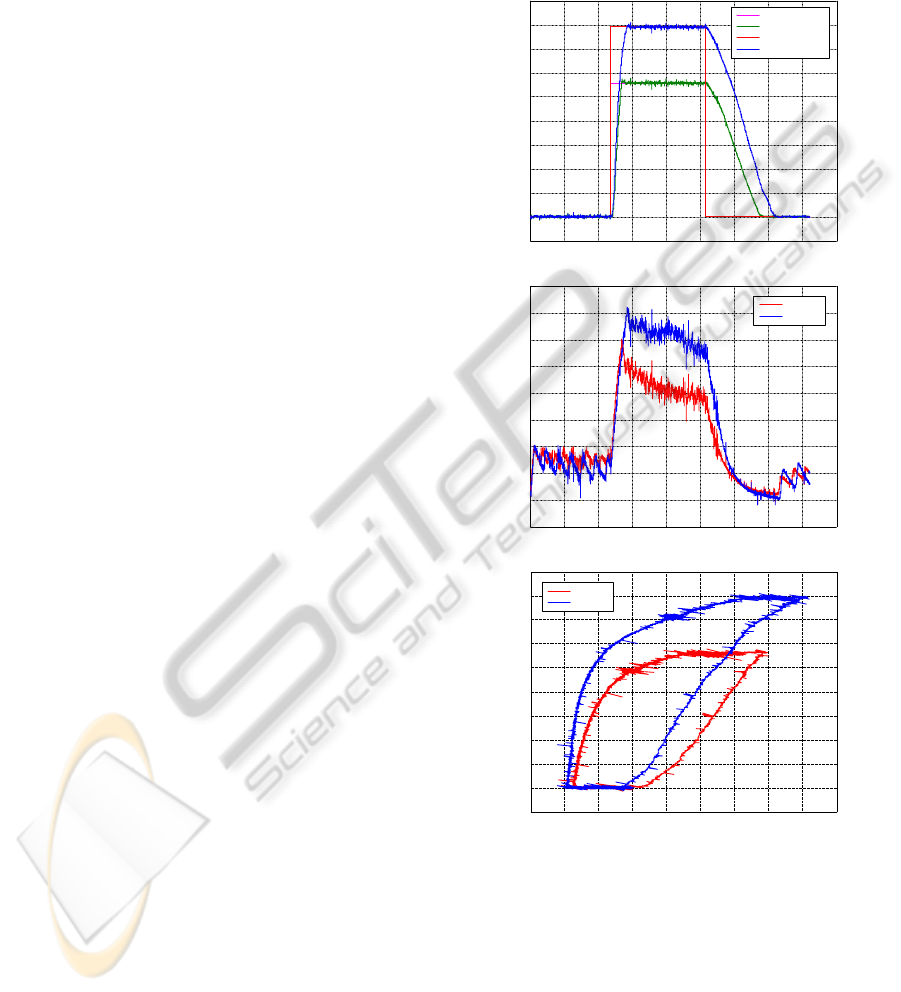

The morphing wing system in the wind tunnel

runs is shown in Fig. 7.

Figure 7: Wind tunnel morphing wing model.

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

16

The transition detection was made real time

using the pressure data obtained from the 32 Kulite

and optical pressure sensors. The pressure data

acquisition was performed using the IAR-NRC

analog data acquisition system which was connected

to the 32 sensors. The sampling rate of each channel

was 15 kS/s, which allowed a boundary layer

pressure fluctuations FFT spectral decomposition up

to 7.5 kHz for all channels. The signal was

processed by use of Simulink and visualized in real

time on the computer screen in dedicated windows.

The pressure signals were analyzed through Fast

Fourier Transforms (FFT) decomposition in order to

detect the magnitude of the noise in the surface air

flow. Subsequently, the data is filtered by means of

high-pass filters and processed by calculating the

Root Mean Square (RMS) of the signal in order to

obtain a plot diagram of the noise in the air flow.

This signal processing is necessary to disparate the

inherent electronically induced noise, by the

Tollmien-Schlichting that are responsible for

triggering transition from laminar flow to turbulent

flow. The measurements showed that in processed

data the transition appeared at frequencies between

3kHz - 5kHz and the magnitude of pressure

variations in the laminar flow boundary layer are of

the order 5e-4 Pa (7.25e-8 psi). The transition

between laminar flow and turbulent flow was shown

by an increase of the pressure variations, reflected

also by a strong variation of the pressure signal

RMS.

For the wind tunnel test the preloaded forces of

the gas springs were reconsidered to the 1500 N

because of the presence of the aerodynamic forces

on the flexible skin of the wing. In Fig. 8 are

presented the control results for test run α=2°,

Mach=0.225 (dY

1

=5.56 mm, dY

2

=7.91 mm).

The experimental results show a decrease of the

SMA wires work temperatures vis-à-vis of

numerically simulated and bench tested cases. An

explanation can be the appearing of the aerodynamic

forces with particular values for each flight

condition. The decrease of these temperatures is a

beneficial one taking into account the negative

impact of a strong thermal field on the other

component of the system, especially on the flexible

skin and on the pressure sensors. Also, from the

experimental results a high frequency noise

influencing the LVDT sensors and the

thermocouples instrumentation amplifiers can be

observed. The noise sources are the wind tunnel

vibrations and instrumentation electrical fields. With

this noise, the amplitude of the actuation error

(difference between the realized deflections and

desired deflections) is under 0.07 mm, but this don’t

affecting the transition, which is stable on a sensor

with a high RMS spike; Fig. 9 presents the results

obtained on the transition monitoring for the run test

in Fig. 8.

20 25 35 40 45 50 55 60

-1

0

1

2

3

4

5

6

7

9

Displacements dY

1

, dY

2

(

v

) [mm]

Temperature [

o

C]

act #1

act #2

30 65

8

20

30

35

40

45

50

55

65

Time [s]

Temperature [

o

C]

act #1

act #2

50 100 150 200 250 300 3500 400

25

60

450

-1

0

1

2

3

4

5

6

7

9

Displacements dY

1

, dY

2

(

v

) [mm]

8

Time [s]

50 100 150 200 250 300 3500 400 450

=2°, Mach=0.225

act #1 desired

act #1 obtained

act #2 desired

act #2 obtained

Figure 8: Wind tunnel test for α=2°, M=0.25 flight

condition.

The actuation line control obtained precision can

have some influence in the transition point position

detection only if the density of the chord disposed

pressure sensors becomes bigger; from the

experimental data evaluation one concluded that,

even the value of the error is 1 mm around the

optimized values, the transition point position on the

airfoil surface is not significantly changed.

A MORPHING WING USED SHAPE MEMORY ALLOY ACTUATORS NEW CONTROL TECHNIQUE WITH

BI-POSITIONAL AND PI LAWS OPTIMUM COMBINATION - Part 2: Experimental Validation

17

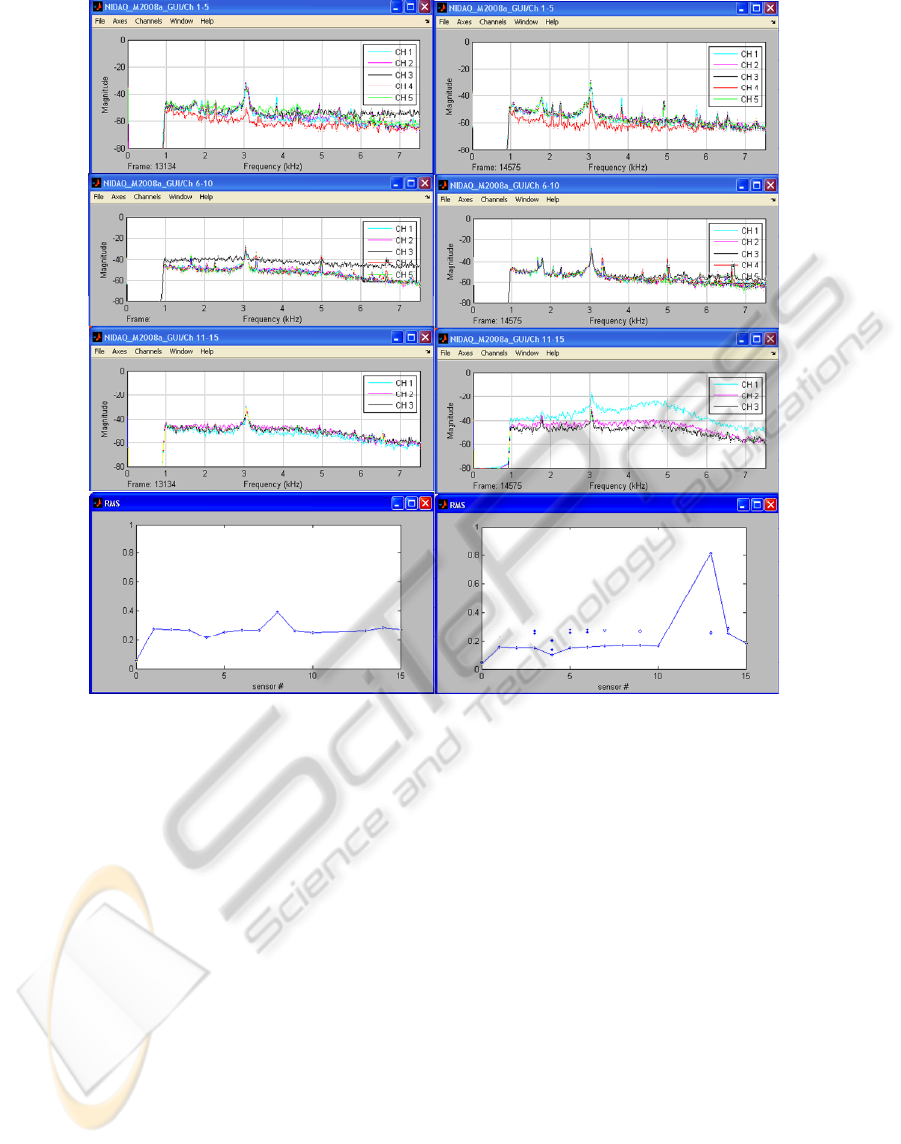

Figure 9: Results obtained on the transition monitoring for the run test in Figure 8.

In Fig. 9 are presented the outputs of the Kulite

pressure sensors in leading edge – trailing edge

sense of positioning (3 sensors are broken and was

not considered in the monitoring phase) and the real

time pressure signals RMS for each of these sensors.

The left hand column presents the results for

reference airfoil, and the right hand column the

results for optimized airfoil. The spike of the RMS

suggests that we have turbulence on the sensor no.

13, near the trailing edge.

So, the results obtained for the actuators control

are very good, the controller fully satisfying the

requirements imposed for the project purpose

achievement.

The future work on the project supposes the

development of the closed loop control, based on the

pressure information received from the sensors and

on the transition point position estimation.

Evidently, the closed loop control will include, as an

internal loop, the actuation lines here presented

controller.

5 CONCLUSIONS

The paper represents the second part of a study

related to the development of an actuators control

system for a morphing wing application, and

describes the experimental validation of the control

designed in the first part. The control validation was

made in two experimental ways: bench test and wind

tunnel test.

In the bench test phase, the 35 optimized airfoil

cases were converted into SMA actuator #1 and #2

vertical displacements which were used as inputs

reference for the controller. The characteristics in

Fig. 6 (α=1°, Mach=0.3 flight condition) show that

the controllers, in the two actuation lines, work even

in zero values of the desired signal because of the

gas springs pretension. Also, small oscillations of

the obtained deflection are observed around the

desired values of the deflections. The amplitude of

the oscillations in this phase is due to the LVDT

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

18

potentiometers mechanical link and to the inertia of

the SMA wires, being smallest than 0.05 mm. The

heating phase is approximately 9 times more rapidly

than the cooling phase; heating time equals 8 s while

the cooling time equals 70 s.

For the final experimental validation test (wind

tunnel test), with real aerodynamic forces load, the

1500 N preloaded forces of the gas springs was

reconsidered. From Fig. 8 (α=2°, Mach=0.225) a

decrease of the SMA wires work temperatures vis-à-

vis of numerically simulated and bench tested cases

is observed. The decrease of these temperatures is a

beneficial one taking into account the negative

impact of a strong thermal field on the other

component of the system, especially on the flexible

skin and on the pressure sensors. Also, a high

frequency noise influencing the LVDT sensors and

the thermocouples instrumentation amplifiers can be

observed. The noise sources are the wind tunnel

vibrations and instrumentation electrical fields. With

this noise, the amplitude of the actuation error

(difference between the realized deflections and

desired deflections) is under 0.07 mm, but this

doesn’t affecting the transition, which is stable on a

sensor with a high RMS spike like in Fig. 9.

So, the results obtained for the actuators control

are very good, the controller fully satisfying the

requirements imposed for the project purpose

achievement.

The designed controller is used for the open loop

development stage of a morphing wing project, but

the closed loop of the morphing wing system, based

on the pressure information received from the

sensors and on the transition point position

estimation, will include, as an internal loop, the

actuation lines here presented controller.

ACKNOWLEDGEMENTS

We would like to thank the Consortium of Research

in the Aerospatial Industry in Quebec (CRIAQ),

Thales Avionics, Bombardier Aerospace, and the

National Sciences and Engineering Research

Council (NSERC) for the support that made this

research possible. We would also like to thank

George Henri Simon for initiating the CRIAQ 7.1

project and Philippe Molaret from Thales Avionics

and Eric Laurendeau from Bombardier Aeronautics

for their collaboration on this work.

REFERENCES

Austerlitz, H., 2003, Data acquisition techniques using

PCs, Elsevier, USA

Chang, P., Shah, A., Singhee, M., 2009, Parameterization

of the Geometry of a Blended Wing Body Morphing

Wing, Project report, Georgia Institute of Technology,

April 2009, Atlanta, Georgia, USA

Gonzalez, L., 2005, Morphing Wing Using Shape Memory

Alloy: a concept proposal, Final research paper, Texas

A&M University, College Station, Texas, USA

Hinshaw, T. L., 2009, Analysis and Design of a Morphing

Wing Tip using Multicellular Flexible Matrix

Composite Adaptive Skins, Master of Science Thesis,

Virginia Polytechnic Institute and State University,

Virginia, USA

Kirianaki, N. V., Yurish, S. Y., Shpak, N. O., Deynega,

V.P., 2002, Data Acquisition and Signal Processing

for Smart Sensors. John Wiley & Sons

Majji, M., Rediniotis, O. K., Junkins, J. L., 2007, Design

of a Morphing Wing: Modeling and Experiments,

AIAA Atmospheric Flight Mechanics Conference and

Exhibit, Hilton Head, South Carolina, USA

Namgoong, H., Crossley, W. A., Lyrintzis, A. S., 2006,

Aerodynamic Optimization of a Morphing Airfoil

Using Energy as an Objective, 44th AIAA Aerospace

Sciences Meeting and Exhibit, Reno, Nevada, USA

Park, J., Mackay, S., 2003, Practical data acquisition for

instrumentation and control systems, Elsevier, UK

Ruotsalainen, P., et. al., 2009, Shape Control of a FRP

Airfoil Structure Using SMA-Actuators and Optical

Fiber Sensors. Journal of Solid State Phenomena,

Volume 144, pp. 196-201

Smith, K., Butt, J., Spakovsky, M. R., Moorhouse, D.,

2007, A Study of the Benefits of Using Morphing Wing

Technology in Fighter Aircraft Systems, 39th AIAA

Thermophysics Conference, Miami, Forida, USA

A MORPHING WING USED SHAPE MEMORY ALLOY ACTUATORS NEW CONTROL TECHNIQUE WITH

BI-POSITIONAL AND PI LAWS OPTIMUM COMBINATION - Part 2: Experimental Validation

19