MOBILE ROBOT OBSTACLE DETECTION USING

AN OVERLAPPED ULTRASONIC SENSOR RING

Sungbok Kim, Jaehee Jang and Hyun Bin Kim

Department of Digital Information Engineering, Hankuk University of Foreign Students, Korea

Keywords: Ultrasonic Sensor, Overlapped Beam Pattern, Positional Uncertainty, Obstacle Position, Sensor Model.

Abstract: This paper presents the obstacle detection of a mobile robot using an ultrasonic sensor ring with overlapped

beam pattern. Basically, it is assumed that a set of ultrasonic sensors are installed at regular intervals along

the side of a circular mobile robot of nonzero radius. First, by exploiting the overlapped beam pattern, it is

shown that the positional uncertainty inherent to an ultrasonic sensor can be significantly reduced for both

single and double obstacle detection. Second, given measured distances from adjacent ultrasonic sensors,

the geometric method of computing the position of the detected obstacle with respect to the center of a

mobile robot is described. Third, through experiments using our ultrasonic sensor ring prototype, the

validity and the performance of the proposed overlapped ultrasonic sensor ring are demonstrated.

1 INTRODUCTION

Since the mid 1980s, ultrasonic sensors have been

widely used for map building and obstacle

avoidance. Typically, an ultrasonic sensor equipped

at a mobile robot operates in reflective mode, rather

than in direct wave mode. Once the acoustic wave is

emitted by the transmitter, an ultrasonic sensor can

measure the obstacle distance using the elapsed time

until the reflected wave is sensed by the receiver,

which is called the time of flight. The detected

obstacle is present at a certain point along the arc of

radius given by the obstacle distance; however, the

exact position of an obstacle on the arc remains

unknown. This is called the positional uncertainty

inherent to an ultrasonic sensor.

To alleviate the problem of positional

uncertainty, we propose to overlap the cone shaped

beams of two ultrasonic sensors in part. With the

overlapped beam pattern, the entire sensing zone of

each ultrasonic sensor can be divided into two

smaller sensing subzones: the overlapped and the

unoverlapped subzones. If both ultrasonic sensors

detect an obstacle, the detected obstacle should

belong to the overlapped subzone. On the other

hand, if either ultrasonic sensor detects an obstacle,

the detected obstacle should belong to the

unoverlapped subzone. This indicates that the

positional uncertainty of an ultrasonic sensor can be

reduced by exploiting the overlapped beam pattern

of two ultrasonic sensors. In this paper, we present

the obstacle detection of a mobile robot using an

ultrasonic sensor ring with overlapped beam pattern.

2 POSITIONAL UNCERTAINTY

REDUCTION

Assume that N ultrasonic sensors of the same type

are arranged in a circle at regular intervals with their

beams overlapped. After numbering the ultrasonic

sensors from 1 to N in clockwise order, let S

, ..

1, , , denote the

ultrasonic sensor of an

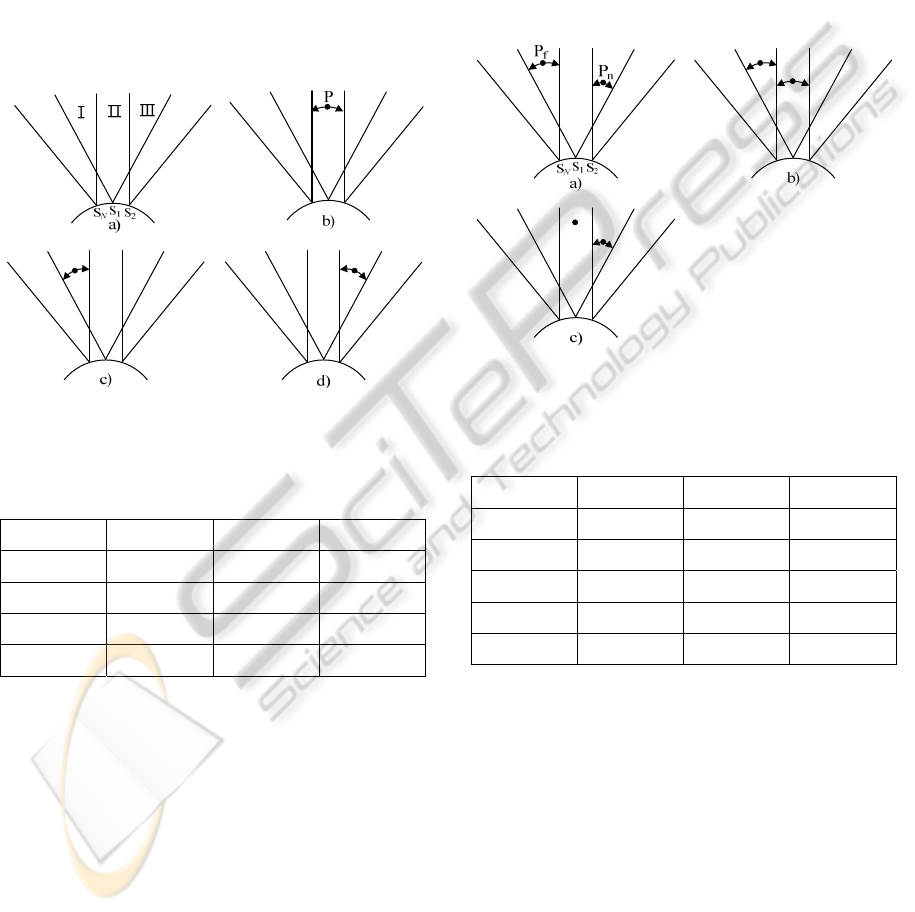

overlapped ultrasonic sensor ring. Fig. 1 shows three

adjacent ultrasonic sensors, S

, S

, and S

, which

are placed at the left, the center, and the right,

respectively. Due to beam overlapping, the entire

sensing zone of the ultrasonic sensor S

can be

divided into three sensing subzones, denoted by ‘I’,

‘II’, and ‘III’. In Fig.1, an obstacle P is depicted by a

bold.

First, let us consider the detection of a single

obstacle using three overlapped ultrasonic sensors.

Let ρ

, ρ

, and ρ

be the distances of the obstacle P

measured by three ultrasonic sensors, S

, S

, and

S

, respectively. Table 1 shows the distance

measurements of S

, S

, and S

, depending on to

the position of P among one of three sensing

340

Kim S., Jang J. and Kim H. (2010).

MOBILE ROBOT OBSTACLE DETECTION USING AN OVERLAPPED ULTRASONIC SENSOR RING.

In Proceedings of the 7th International Conference on Informatics in Control, Automation and Robotics, pages 340-343

DOI: 10.5220/0002878803400343

Copyright

c

SciTePress

subzones, either I, II, or III. In Table 1, ′∞′ indicates

the situation that P cannot be detected by the

corresponding ultrasonic sensor. Seen from Table 1,

the combination of three ultrasonic sensors which

return finite measured distances varies according to

where the obstacle belongs among three sensing

subzones. This implies that the sensing subzone to

which the obstacle belongs can be determined based

on the combination of three ultrasonic sensors

returning finite measured distances. It should be

noted that the beam overlapping between adjacent

ultrasonic sensors can lead to the significant

reduction in positional uncertainty.

Figure 1: Single obstacle detection using overlapped

ultrasonic sensors.

Table 1: Distance measurements of ultrasonic sensors in

the case of single obstacle detection.

2b) 2c) 2d)

P

II I III

S

∞

ρ

∞

S

ρ

ρ

ρ

S

∞ ∞

ρ

Next, let us consider the detection of double

obstacles using three overlapped ultrasonic sensors.

Note that the number of obstacles that can be

detected by two adjacent ultrasonic sensors is at

most two, regardless of how many obstacles are

present in front of them. Assume that one obstacle is

present at far distance, called the far obstacle and

denoted by P

, and the other obstacle is present at the

near distance, called the near obstacle and denoted

by P

. Fig. 2 shows three different cases of how the

far and near obstacles are located. Let ρ

,

and

ρ

,

ρ

,

, , 1,2, be the distances of the

obstacles, P

and P

, measured by three ultrasonic

sensors, S

, S

, and S

, respectively.

Table 2 shows the distance measurements of

three ultrasonic sensors, S

, S

, and S

, depending

on the relative positions of the far and the near

obstacles, P

and P

. Referring to Table 2, the

following decisions can be made on where P

and P

are positioned among three sensing subzones, I, II,

and III. For instance, if the left ultrasonic sensor

S

returns larger value than the other two ultrasonic

sensors, S

and S

, as shown in Fig. 2a), P

is

positioned within I and P

is positioned within III.

Figure 2: Double obstacle detection using overlapped

ultrasonic sensors.

Table 2: Distance measurements of ultrasonic sensors in

the case of double obstacle detection.

3a) 3b) 3c)

P

I I II

P

III II III

S

ρ

,

ρ

,

∞

S

ρ

,

ρ

,

ρ

,

S

ρ

,

∞

ρ

,

3 MOBILE ROBOT

REFERENCED OBSTACLE

DETECTION

Each ultrasonic sensor of an ultrasonic sensor ring

returns the distance of an obstacle that is measured

with reference to the vertex of its own, called the

sensor referenced obstacle distance. On the other

hand, it is the obstacle position with reference to the

center of a mobile robot, called the mobile robot

referenced obstacle position that should be known

for the obstacle detection/avoidance of a navigating

MOBILE ROBOT OBSTACLE DETECTION USING AN OVERLAPPED ULTRASONIC SENSOR RING

341

mobile robot.

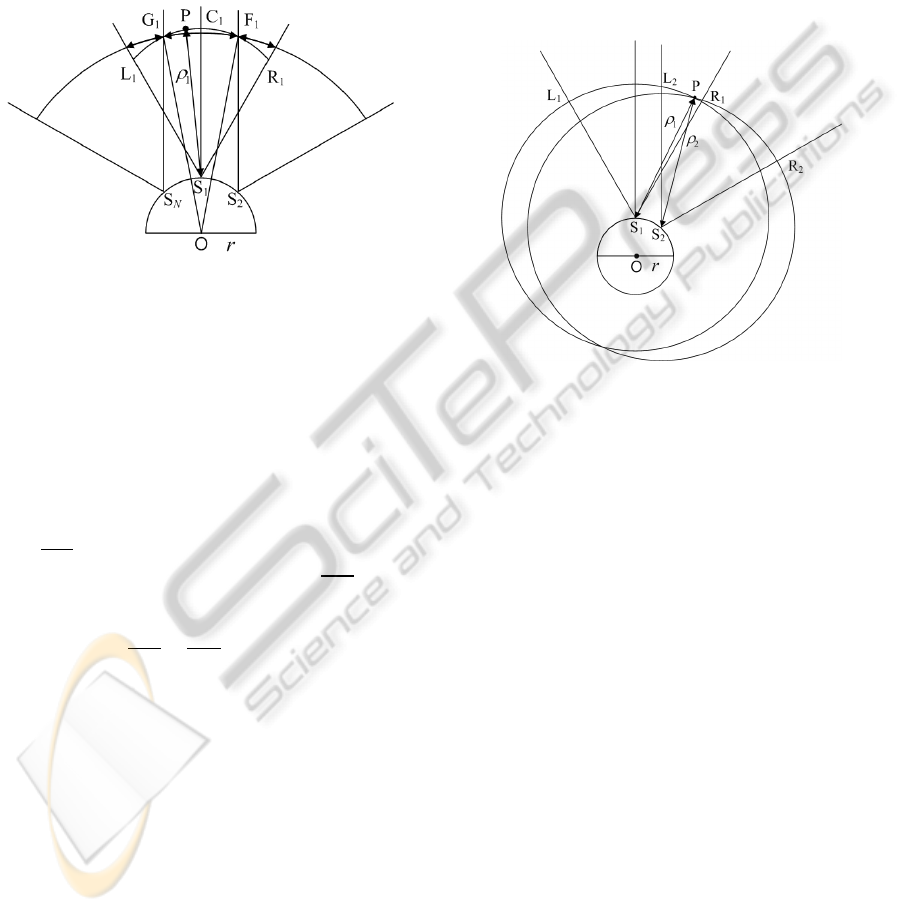

First, suppose that an obstacle P is present at the

distance ρ

within the unoverlapped sensing subzone

II of the ultrasonic sensor S

, as shown in Fig. 3. Let

G

and F

denote the intersecting points of the circle

of radius ρ

centered at the point S

, and the right

beam boundary of the ultrasonic sensor S

and the

right beam boundary of the ultrasonic sensor S

,

respectively.

Figure 3: The mobile robot referenced position of an

obstacle within the unoverlapped sensing zone.

Due to the positional uncertainty, an obstacle P

can exist at a certain point along the arc G

C

F

of

radius ρ

centered at the point S

, instead of the arc

L

C

R

. Considering that the ultimate goal of

obstacle detection is to prevent possible collision

with obstacles, it is reasonable to take conservative

stance in guessing the obstacle position. To prepare

for the worst case scenario, the collision free region

can be specified as the intersection of the circle of

radius OF

centered at the point O and the cone of

angle G

OF

centered along the line OC

. As a

result of the beam overlapping of an ultrasonic

sensor ring, 1) the radius of the collision free region

increases, that is, OF

OR

, and 2) the angle of the

collision free region decreases, that is, G

OF

L

OR

. The increased radius can allow a mobile

robot more room for obstacle avoidance, and the

decreased angle can improve the spatial resolution in

obstacle detection.

Next, suppose that an obstacle P is present at the

distance ρ

within the overlapped sensing subzone

III of the ultrasonic sensor S

, as shown in Fig. 7.

Let ρ

and ρ

be the distance of P from the vertices

of ultrasonic sensors, S

and S

, respectively. Owing

to the positional uncertainty of two ultrasonic

sensors, P exists along the arc L

R

of radius ρ

centered at the point S

, and it also exists along the

arc L

R

of radius ρ

centered at the point S

. As

shown in Fig. 4, the position of P can now be

obtained from the intersection of these two circles,

which results in two intersecting points in general.

Finally, the obstacle position can be uniquely

determined out of two intersecting points, based on

the relative locations of ultrasonic sensors, S

and

S

. It should be noted that the problem of

uncertainty does not exist anymore for an obstacle

within the overlapped sensing subzone, although the

measurement errors may still affect the accuracy in

computing the obstacle position.

Figure 4: The mobile robot referenced position of an

obstacle within the overlapped sensing subzone.

4 EXPERIMENTAL RESULTS

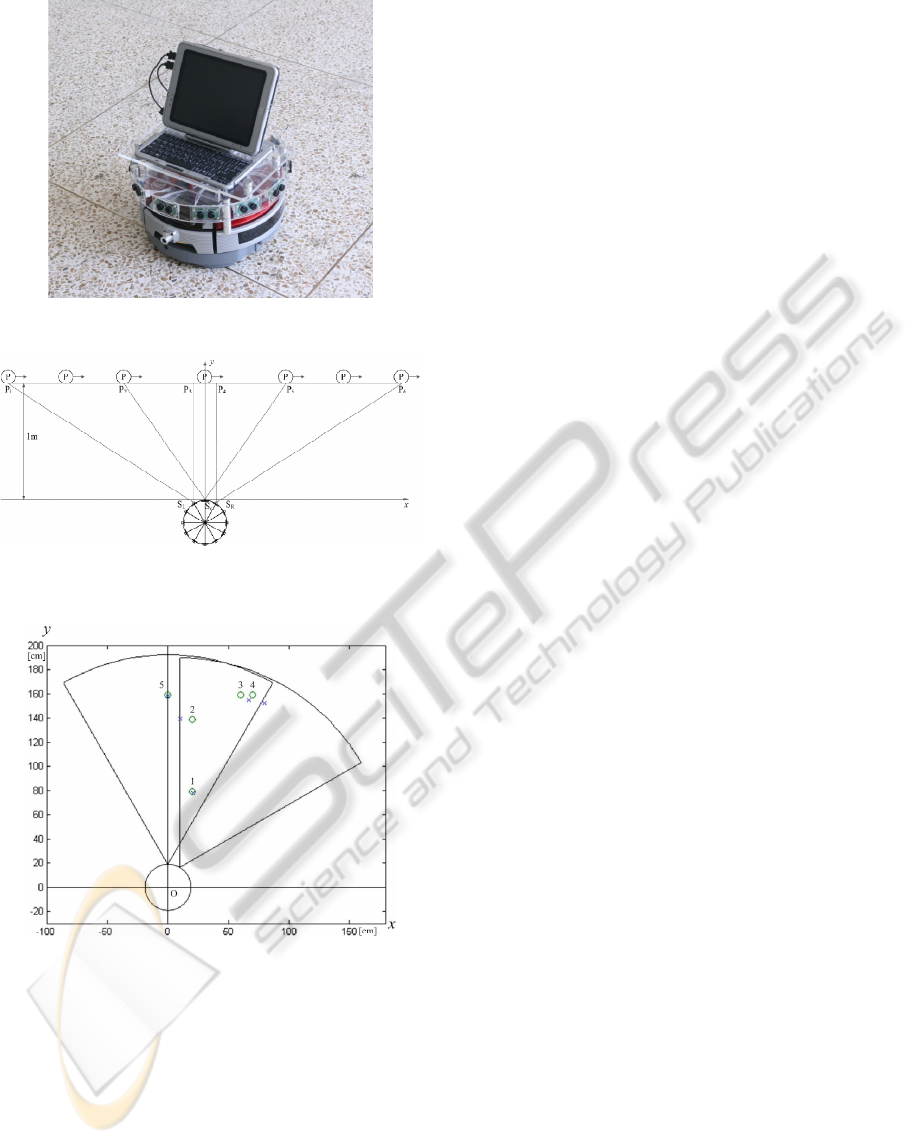

An omnidirectional overlapped ultrasonic sensor

ring prototype was built using the ultrasonic sensor

modules which contain MA40B8 of beam width

α 50° from Murata Inc. As shown in Fig. 5,

twelve ultrasonic sensor modules are first installed at

a regular spacing of β30° between two circular

acrylic plates of radius 19cm, which is then

fixed on top of a circular mobile robot

concentrically.

First, a mobile robot is commanded to move

along a straight line, which is 1 m apart from a

circular obstacle of diameter 12.5 cm. Fig. 6 shows

the division of the straight line depending on the

combination of ultrasonic sensors involved in

obstacle detection. It can be observed that the

distance from P

to P

is about 170 cm and the

distance from P

to P

is about 140 cm. Using these

data, the effective beam widths can be calculated:

70° for the center ultrasonic sensor and 60° for the

left and right ultrasonic sensors.

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

342

Figure 5: Our overlapped ultrasonic sensor ring prototype.

Figure 6: The experimental results for single obstacle

detection.

Figure 7: The experimental setting and results for

computing mobile robot referenced obstacle positions.

Next, for five different locations of an obstacle,

we compute the mobile robot referenced position of

an obstacle from the measured distances of three

ultrasonic sensors. Fig. 7 shows the actual and the

computed obstacle positions, which are marked by

'o' and 'x', respectively. The discrepancy between the

actual and the computed obstacle positions tends to

increase as an obstacle is located away from the

center of the overlapped ultrasonic sensor ring and

close to the boundary of the overlapped sensing

subzone. However, it is confirmed through repetitive

experiments that the maximum discrepancy is

bounded within 10 cm.

5 CONCLUSIONS

In this paper, we proposed an overlapped ultrasonic

sensor ring which consists of relatively small

number of low cost ultrasonic sensors with low

directivity, to reduce the positional uncertainty in

obstacle detection. The proposed ultrasonic sensor

ring made of low directivity ultrasonic sensors is

advantageous over its high directivity counterpart in

both sensor device and data processing requirements.

It is expected that the results of this paper can

facilitate early deployment of low cost mobile

platforms for personal service robots.

REFERENCES

Borenstein, J. and Koren, J., 1989. Real-Time Obstacle

Avoidance for Fast Mobile Robots. In IEEE Trans.

Sysems, Man, and Cybernetics, vol. 19, no. 5, pp.

1179-1187.

Choset, H., Nagatani, K., and Lazar, N. A., 2003. The

Arc-Traversal Median Algorithm: A Geometric

Approach to Increase Ultrasonic Sensor Azimuth

Accuracy. In IEEE Trans. Robotics and Automation,

vol. 19, no. 3, pp. 513-522.

Crowley, J. L., 1989. World Modeling and Position

Estimation for a Mobile Robot Using Ultrasonic

Ranging. In Proc. IEEE Int. Conf. Robotics and

Automation, pp. 674-680.

Elfes, A., 1987. Sonar-Based Real-World Mapping and

Navigation. In IEEE J. Robotics and Automation, vol.

RA-3, no. 3, pp. 249-265.

McKerrow, P. J., 1993. Echolocation-from Range to

Ontline Segments. In Robotics and Autonomous

Systems, vol. 11, no. 4, pp. 205-211.

Moravec, H., and Elfes, A., 1985. High Resolution Maps

for Wide Angles Sonar. In Proc. IEEE Int. Conf.

Robotics and Automation, pp. 116-121.

Murphy, R., 2000. Introduction to AI Robotics, The MIT

Press.

Thrun, S., Burgard, W., and Fox, D., 2005. Probabilistic

Robotics, The MIT Press.

Wijk, O. and Christensen, H. I., 2000. Triangulation-

Based Fusion of Sonar Data with Application in Robot

Pose Tracking. In IEEE Trans. Robotics and

Automation, vol. 16, no. 6, pp. 740-752.

MOBILE ROBOT OBSTACLE DETECTION USING AN OVERLAPPED ULTRASONIC SENSOR RING

343