SEGMENTATION OF THE SOLID BED IN

INFRARED IMAGE SEQUENCES OF ROTARY KILNS

Patrick Waibel, J¨org Matthes and Hubert B. Keller

Institute for Applied Computer Science, Karlsruhe Institute of Technology

Hermann-von-Helmholtz-Platz 1, 76344 Eggenstein-Leopoldshafen, Germany

Keywords:

Rotary kiln, Solid bed, Segmentation, Infrared camera.

Abstract:

This paper presents two novel methods for segmenting the solid bed in infrared image sequences of metal-

recycling rotary kilns. Exploiting the different dynamics and temperatures of gas phase, solid bed and kiln

wall, we developed filter chains for an image segmentation of the solid bed. For the image acquisition we

employed infrared cameras with a spectral filter. Two image processing algorithms were realized according to

the two most common camera positions (frontal and top-left view on the solid bed at the rear-end of the kiln).

Results show that both algorithms are capable to segment the solid bed in the image sequences accurately and

reliably. The work presented here provides a basis for the extraction of characteristic process state variables,

that can help to improve the process control with regard to product quality, energy consumption and emission

reduction.

1 INTRODUCTION

Rotary kilns are industrially used for processing ma-

terials at high temperatures. Reducing the energycon-

sumption, improving the product quality and lowering

pollutant emission are important goals for the opera-

tion of rotary kiln plants. A new approach to achieve

these goals is an advanced process control that uses

additional information from cameras that capture im-

ages from the inside of the kiln. An appropriate image

processing system is necessary to extract meaningful

information of the process state out of the camera im-

ages to be used for the process control.

A rotary kiln is a cylindrical vessel that is slightly

inclined to the horizontal. While the raw material is

mixed by the rotating movement the solids gradually

movetowards the kiln’s lower end. High temperatures

are attained by a burner inside the kiln and exothermic

reactions of the material. Infrared cameras are ca-

pable to capture the spatial arrangement of the solid

bed and the temperature distribution inside the kiln

all at once. An image processing system can enhance

the benefit of the acquired images by identifying spe-

cific process parameters, e.g. filling height, repose an-

gle or movement pattern of the solids (Henein et al.,

1983). Due to varying process conditions the robust-

ness of the applied image processing algorithms is an

important factor. In this paper we address the prob-

lem of segmenting the solid bed in infrared-images of

metal-recycling rotary kilns from the two most com-

mon camera positions (frontal and displaced to the

top-left).

(Zipser et al., 2006) describe a software tool for

monitoring and analyzing of video and infrared im-

ages of combustion processes. In (He et al., 2009) an

intensity-based Fuzzy-C-Means clustering algorithm

for segmenting the solid bed in video images of alu-

mina kilns is presented. (Sun et al., 2008) examine

the segmentation of the solid bed and burner flame

in video images based on texture information and

Fuzzy-C-Means clustering. Our segmentation algo-

rithms process infrared images and make use of in-

tensity as well as dynamic properties in a particular

filter chain to improve the overall segmentation re-

sults. After outlining the image acquisition in sec-

tion 2 the image segmentation method developed for

a frontal view position of the camera is described in

section 3. Section 4 depicts the segmentation algo-

rithm for a top-left view of the camera and section 5

concludes this paper.

2 IMAGE ACQUISITION

The analyzed image sequences were captured at a

metal-recycling rotary kiln located in Freiberg (Ger-

217

Waibel P., Matthes J. and Keller H. (2010).

SEGMENTATION OF THE SOLID BED IN INFRARED IMAGE SEQUENCES OF ROTARY KILNS.

In Proceedings of the 7th International Conference on Informatics in Control, Automation and Robotics, pages 217-220

DOI: 10.5220/0002880402170220

Copyright

c

SciTePress

many). The length of the kiln is 43m with an inner

diameter of 3.6m. We used two different infrared-

cameras, which were installed at the lower end of the

kiln. The first camera (scenario 1) with a a resolu-

tion of 256x128 pixels was located slightly below the

rotational axis of the kiln (Figure 1 left). The second

camera was installed at the top-left of the rotary axis

(scenario 2). It has a resolution of 320x240pixels

(Figure 1 right). Both cameras are equipped with a

spectral filter at 3.9µm where the absorbance of the

burning gas atmosphere is at a minimum. The in-

tensity values of the pixels correspond to absolute

temperatures (400 to 2000

◦

C) with an accuracy of

±5K. A developedimage preprocessing system guar-

antees the validity of the acquired images. In the ac-

quired image sequences the direction of rotation is

anti-clockwise. Therefore the solid bed is moved up-

wards the right side of the kiln with regard to its cur-

rent repose angle. On legal grounds, parts of the air

supply unit had to be blacked out in the presented im-

ages.

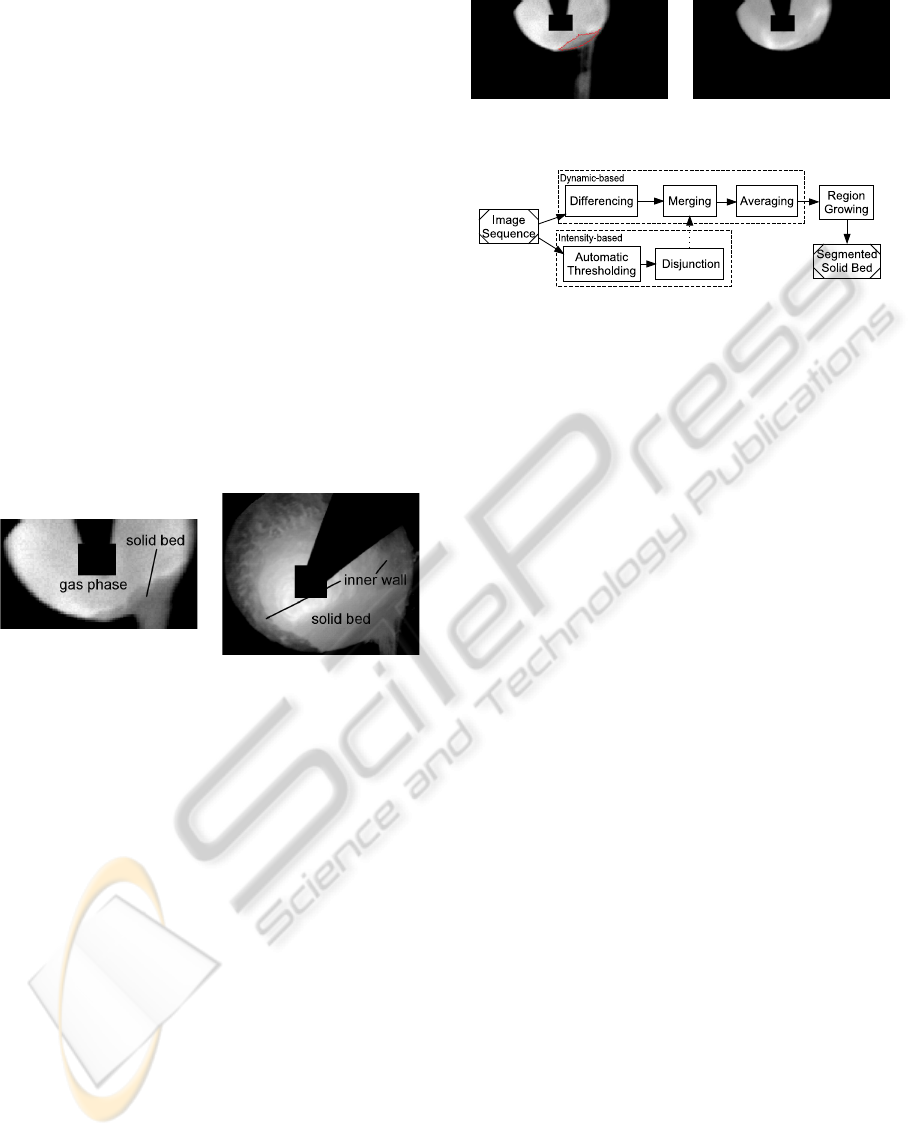

Figure 1: Scenario 1 (left) and Scenario 2 (right).

3 IMAGE SEGMENTATION -

SCENARIO 1

3.1 Method

At lower average kiln temperatures the solid bed can

easily be segmented via intensity differences, as the

solid bed is colder than the gas phase in such situa-

tions. However, with increasing temperature the in-

tensity differences of gas phase and solid bed vanish

and a solely intensity-based segmentation algorithm

fails (Figure 2). A robust filter algorithm has to han-

dle both situation in an adequate way. The algorithm

we developed makes use of different intensity proper-

ties as well as dynamic properties of the solid bed and

the gas phase (Figure 3).

In the intensity-based part of the algorithm at first

an automatic thresholding is performed on a region

of interest (ROI) containing the possible locations of

the solid bed. This method aims to find regions with

homogeneous intensity values via multiple threshold-

ing. Then all minimums in the intensity histogram of

Figure 2: Simple threshold segmentation at low (left) and

high (right) mean temperatures.

Figure 3: Solid bed segmentation algorithm for a frontal

camera view on the kiln.

the ROI of a single image are located. Each minimum

is used as a threshold segmentation. The segmented

regions are subsequently examined if their mean in-

tensity is below an offset (we used 30K) to the mean

intensity of the entire ROI. Regions with mean inten-

sities above this value are not further considered. The

region with the highest permitted threshold is subdi-

vided in connected pixel regions, whose areas (num-

ber of pixels) are computed. Connected regions with

small areas (we used 30 pixels as threshold) are re-

moved as fluctuations in the gas phase can generate

these regions. Consequently, the remaining connected

regions are defined as solid bed due to their mean in-

tensities and sizes. A grouping of these regions ide-

ally corresponds to the entire solid bed region. How-

ever, in many cases only a part of the solid bed is de-

tected or there is no valid segmentation result at all

(e.g. if the minimum search in the histogram is not

successful). Therefore the dynamic properties of the

solid bed and the gas phase are accounted for in the

segmentation algorithm. The dynamic-based part is

adapted from a modified calculation of the total vari-

ation (TV) of each pixel. Two temporally successive

images are used to compute a difference image (dif-

ferencing). The accumulated absolute differences of

an image sequence reflects the total variation for each

pixel which is an indicator for the fluctuation behavior

of the intensity values. In our algorithm we normal-

ize the total variation with the number of used frames

in order to simplify the comparison of different frame

limits. Therefore this step can be regarded as an av-

eraging of the differences. The intensity values of the

gas phase are usually more fluctuating then the solid

bed’s which leads to higher TVs in the gas phase re-

gion. Nevertheless it is possible that moving lumps

within the solid bed, which are colder than the sur-

rounding material, facilitate high TV values at their

contours even inside the solid bed region. To cir-

cumvent this problem and to improve the overall seg-

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

218

mentation result the intensity-based part is addressed

again. The merging step is the key element of the al-

gorithm. The preliminary segmentation result of the

intensity-based part is combined with the dynamic-

based computations. Cold lumps within the solid bed

are always either segmented solely or together with

the rest of the bed by the automatic threshold step due

to their low temperatures. The automatic threshold-

ing is done with both images which are used for the

respective differencing step. The pixels which are de-

fined as solid bed in at least one of the images are

approved as solid bed region in the disjunction step,

i.e. a relocation of a lump can be captured. Now,

all pixels included in the identified intensity-based

solid bed region are set to 0 in the current difference

image. This merging situationally leads to an en-

hanced distinguishability between the gas phase and

solid bed in the averaged difference images. If the

mean temperature of the kiln is high, the segmentation

algorithm is predominantly based on the dynamics-

based part since the intensity-based part rarely de-

tects the solid bed region. When there is a high con-

trast between solid bed and gas phase in the input im-

ages the intensity-based part boosts the results of the

dynamics-based part due to the merging step. Ad-

ditionally, high difference values at the contours of

moving lumps are prevented through this combina-

tion. For the final segmentation step a region growing

algorithm is implemented.

3.2 Results and Discussion

In figure 2 segmentation results at the frontal view

position with an fixed threshold segmentation are il-

lustrated. The intensity-based threshold segmentation

succeeds to detect the solid bed region in image se-

quences with low mean temperatures of the kiln. As

soon as the temperature rises this method fails. Even

an adaptive thresholding is not applicable at higher

mean temperatures, as there are no intensity differ-

ences between gas phase and solid bed. Figure 4

shows segmentation results with the combined seg-

mentation algorithm. They are each based on 200

frames. It can be seen that the modified averaged dif-

ference images possess high contrasts between solid

bed and gas phase regions also at high mean temper-

atures of the kiln. This enables an accurate final seg-

mentation with the region growing algorithm.

The developedcombinedsegmentation filter chain

proved to be a reliable and precise method to detect

the solid bed in scenario 1 infrared images. This al-

lows the extraction of process relevant solid bed fea-

tures in future works. It is e.g. possible to define a

circle segment with two parameters corresponding to

Figure 4: Segmentation with modified averaged difference

images at low (left) and high (right) mean temperatures.

filling height and repose angle. In an iterative opti-

mization process both parameters are adapted to find

the best-fit of circle segment and segmented solid bed.

Besides acquiring these two parameters, the remain-

ing error between circle segment and solid bed region

can be used to discriminate the bed movement (e.g.

slumping or rolling).

4 Image Segmentation - Scenario 2

Conversely to scenario 1 in this case the solid bed has

to be distinguished from the inner kiln wall instead of

the gas phase. Intensity values cannot be used for the

segmentation since the temperatures of kiln wall and

solid bed are similar. Especially at the upper border

of the solid bed, where solid parts stick to the wall,

an intensity-based segmentation has little prospect of

success. The filter chain we developed makes use of

the different dynamic properties of the kiln wall and

the solid bed. In particular we discriminate the steady

rotating movement of the wall from the specific mix-

ing movement of the solid bed.

4.1 Method

The first step of our segmentation process is a map-

ping. Two circles in the acquired images are set, in

order to define the geometry of the inner surface of

the kiln. Then a geometric mapping of the inner sur-

face to a rectangle is performed (Figure 5 left). With

the mapped intensity values a movement analysis is

conducted. An optical-flow algorithm (Brox et al.,

2004) computes a vector field out of two successive

mapped images (Figure 5 right). Each vector spec-

ifies the direction and the magnitude of the move-

ment of a pixel between two frames. Due to the map-

ping step the rotation of the kiln is transformed in a

rightward movement. Consequently, discriminating

the solid bed from the kiln wall corresponds to de-

tecting the image region that is not constantly mov-

ing to the right. Since the material of the solid bed is

also transported up along the kiln wall before it col-

lapses respectively slides back in the opposite direc-

tion, an discrimination via movement is not possible

at all times. Thus we implemented a moving aver-

age filter which averages the movements of the last

SEGMENTATION OF THE SOLID BED IN INFRARED IMAGE SEQUENCES OF ROTARY KILNS

219

200 frames. In the so computed image the solid bed

can be segmented with a simple threshold operator.

Afterwards the segmented region in the mapped rect-

angular is mapped back to the original image. The

single steps of the segmentation filter chain are illus-

trated in figure 6.

Figure 5: Mapping of kiln’s inner surface to a rectangle

(left) and vector field of mapped kiln’s inner surface (right).

Figure 6: Solid bed segmentation algorithm for a camera

view from top-left.

4.2 Results and Discussion

The averaged horizontal velocities of an image se-

quence are shown in figure 7left. Brighter gray val-

ues correspond to higher velocities. Whereas the dark

vertical stripe on the right side is due to the air supply

unit, the dark stripe more to the left is caused by the

dynamics of the solid bed. After a coarse definition

of the ROI the lower part of the mapped solid bed is

segmented via thresholding. The upper part is error-

prone at some sequences because of the mapping pro-

cess. Nevertheless the remapping of the segmented

region in the original image achieves accurate results

(Figure 7 right). In the next step extensions of the seg-

mentation method will be examined. For instance, the

best-fitting rectangular of the segmented region in the

mapped horizontal velocities will be determined. This

could improve the segmentation results in the more

distant region of the solid bed. Additionally, the dif-

ference between the segmented region and the best-

fitting rectangle could be used as an indicator for the

particular movement pattern of the solid bed.

Figure 7: Averaged horizontal velocity values (left) and seg-

mentation result (right).

5 CONCLUSIONS

The extraction of features from infrared image se-

quences of the inside of rotary kilns provides a high

potential to improve the process control. An impor-

tant requirement is the reliable and accurate segmen-

tation of the specific regions in the acquired images.

In this work we presented image segmentation filter

chains that were capable to segment the solid bed in

infrared images of a rotary kiln from the two most

common camera positions. Results show that the

combination of intensity-based and dynamic-based

features considerably enhance the segmentation re-

sults at a frontal view position of the camera. From a

top-left view on the solid bed the succession of a map-

ping process and an optical-flow computation enables

satisfying segmentation results. In future works the

correlation between extracted solid bed features with

process states will be examined, particularly with re-

gard to improvements for the process control.

REFERENCES

Brox, T., Bruhn, A., Papenberg, N., and Weickert, J. (2004).

High accuracy optical flow estimation based on a the-

ory for warping. In ECCV, pages 25–36.

He, M., Zhang, J., and Liu, X. (2009). Determination of the

repose angle of stuff in rotary kiln based on imaging

processing. In ICEMI, pages 4–97–4–101.

Henein, H., Brimacombe, J., and Watkinson, A. (1983). Ex-

perimental study of transverse bed motion in rotary

kilns. Metall. Trans. B, 14(2):191–205.

Sun, P., Chaia, T., and jie Zhou, X. (2008). Rotary kiln

flame image segmentation based on FCM and gabor

wavelet based texture coarseness. In WCICA, pages

7615–7620.

Zipser, S., Matthes, J., and Keller, H. (2006). Camera aided

control of combustion processes with the software tool

inspect. at - Automatisierungstechnik, 54:574–81.

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

220