PERFORMANCE OF HIGH-LEVEL AND LOW-LEVEL

CONTROL FOR COORDINATION OF MOBILE ROBOTS

Sisdarmanto Adinandra, Jurjen Caarls, Dragan Kostić and Henk Nijmeijer

Dept. of Mechanical Engineering, Eindhoven University of Technology, PO Box 513 5600MB, Eindhoven, The Netherlands

Keywords: Coordinated Control, Non-holonomic Systems, High-level and Low-level Control, Collision Avoidance,

Performance Evaluation.

Abstract: We analyze performance of different strategies for coordinated control of mobile robots. By considering an

environment of a distribution center, the robots should transport goods from place A to place B while

maintaining the desired formation and avoiding collisions. We evaluate performance of two collision

avoidance strategies, namely a high-level and low-level collision avoidance approach, each using different

feedback information and update rate. As performance measure we take into account the time to

accomplish the transportation task and the tracking errors of the robots. Evaluation is done in several

experiments with seven mobile robots.

1 INTRODUCTION

A group of mobile robots can be used to realize

spatially distributed transportation tasks in a

distribution center. When several robots are

employed in a shared environment, then motion

coordination and cooperation between these robots

can be introduced in order to increase robustness in

the execution of their tasks.

Transportation in a distribution center is typically

carried out by means of conveyors. Unfortunately, a

failure in a single conveyor can disable a part of the

transportation. To increase robustness of

transportation, one can introduce redundant

conveyers. This solution requires extra investments

and occupies additional space. An appealing

alternative is to substitute conveyers with mobile

robots (Giuzzo, 2008). Unlike conveyers, the robots

can dynamically alter their trajectories to avoid

obstacles and complete assigned tasks. In addition, if

one robot fails, its task can be delegated to another

one. While engaging a number of mobile robots

simultaneously, efficient robot coordination and

cooperation control strategies are required to achieve

high throughput in transportation of goods without

collisions.

In the distribution center, planning and

scheduling tasks are normally done in a centralized

way. A high-level planning system decides which

customers orders must be executed, together with

the decision on how the tasks must be accomplished,

see e.g. (van den Berg, 1999) and (Gu, et al., 2007).

Whereas this centralized approach can provide the

optimal throughput in the absence of uncertainties, it

can show quite some weaknesses in exceptional

situations, such as when unexpected obstacles

appear or when unknown disturbances start affecting

the robots. In such situations, re-planning must be

accomplished with time limitations that often lead to

transportation plans that are not optimal in terms of

the throughput. A viable alternative to the

centralized approach is to facilitate negotiations

among the robots and the supervisor which assigns

the tasks. Through negotiation, the robots and the

supervisor can dynamically adapt the transportation

plans such as to make them less sensitive to different

types of failures. The result might not have the

optimal throughput, but it will likely bring higher

robustness in comparison with the centralized

approach. The high level coordination can be

solved, for instance, using the holonic approach

(Giret and Botti, 2004), (Moneva, et al., 2009).

Another example of the high-level coordination is

decentralized control of Automated Guided Vehicles

for distribution centers (Farahvash and Boucher,

2004), (Weyns, et al., 2005). In both works, a multi

agent system is proposed for transportation planning,

distribution of tasks, and collision avoidance.

At the layer of low-level control of individual

63

Adinandra S., Caarls J., Kosti

´

c D. and Nijmeijer H. (2010).

PERFORMANCE OF HIGH-LEVEL AND LOW-LEVEL CONTROL FOR COORDINATION OF MOBILE ROBOTS.

In Proceedings of the 7th International Conference on Informatics in Control, Automation and Robotics, pages 63-71

DOI: 10.5220/0002943800630071

Copyright

c

SciTePress

mobile robots, various techniques of robot

coordination and cooperation can be used to realize

the transportation, such as leader-follower, behavior

based, virtual structure, etc, (Ren and Beard, 2004),

(Mastellone, et al., 2008), (Sun et al., 2009), (van

den Broek et al., 2009). In these approaches, the

motion controllers achieve tracking of individual

robot trajectories, on the one hand, and maintain the

desired spatial formation between the robots, on

another.

To the best of our knowledge, little research is

devoted to performance comparison between the

high-level and low-level control techniques. Some

research have been conducted on performance

comparison of different high-level techniques, see

e.g. (Vis, 2004), (Le-Anh and De Koster, 2006),

(Gu, et al., 2010) and references therein.

Furthermore, a quantitative evaluation of robustness

of high-level control is still lacking, and no data are

reported that illustrate how complicated it can be for

the high-level control to find the optimal solution.

Finally, there is scarce research on appropriate

combination of high- and low-level control that can

handle both effectiveness and robustness at the same

time.

The lack of information has motivated us to

quantitatively compare performance of high-level

and low-level control of a group of mobile robots

that perform a task which resembles coordinated

transportation of goods in a distribution center. An

ideal situation is simulated as a basis for

comparison. We evaluate performance using

relevant indicators, such as time to accomplish the

task and errors in tracking the desired robot

trajectories.

Two main contributions of this paper are: (i)

suboptimal solutions for motion coordination of

mobile robots, namely pure high-level and pure low-

level coordination and (ii) experimental performance

evaluation of these two strategies for completing

transportation tasks in distribution center like

environments.

This paper is organized as follows. In Section 2

we present necessary mathematical models and

tools. Section 3 explains strategies to coordinate the

motion of the mobile robots. Section 4 reports on

experimental results and highlights the main

findings of our performance analysis. Conclusions

and discussion on future work are given in Section

5.

2 PRELIMINARIES

2.1 Unicycle Mobile Robots

We consider a group of m mobile robots that are

described by the non-holonomic kinematic model of

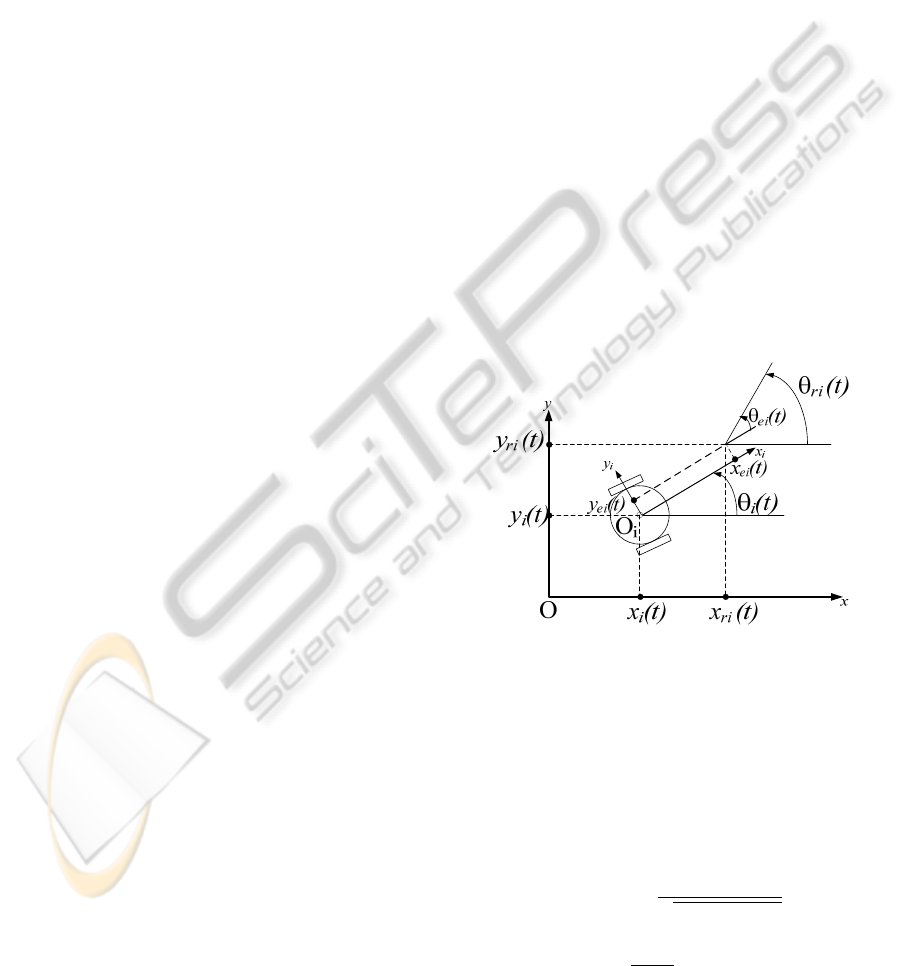

a unicycle, as depicted in Figure 1:

cos

sin

.

(1)

Here,

and

are the forward and steering

velocities, respectively,

and

are the Cartesian

coordinates of the robot midpoint O

i

in the world

coordinate frame O

xy

,

is the heading angle

relative to the x-axis of the world frame, and

∈1,2,3,…,. The reference trajectory of each

robot is given in the frame O

xy

:

.

(2)

The trajectories of all mobile robots constitute a

time-varying formation. An example is shown in

Figure 2, where a platoon-like formation is adopted.

Figure 1: Configuration and error coordinates of a

unicycle mobile robot.

2.2 Trajectory Tracking Control

To follow its own reference trajectory and to

maintain the assigned formation, for each robot we

propose the following control laws v

i

and

ω

i

cos

1

,

,

(3a)

(3b)

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

64

sin

,

sin

1

,

.

where

,

,

are the tracking errors

represented in the robot coordinate frame O

xiyi

cos

sin

0

sin

cos

0

001

,

(3c)

,

,

are the design parameters that influence

the performance of trajectory tracking, while

,

,

are the design parameters that influence

formation keeping. Furthermore,

,∈,, is

defined as follows:

sgn

|

|

sgn

|

|

.

(3d)

The control laws (3a,b) guarantee globally

asymptotic tracking of

and represent a non-

saturated version of the controller proposed in

(Kostić, et al., 2009) and (Kostić, et al., 2010).

Figure 2: An example of a convoy-like, time-varying

formation.

2.3 Penalty Functions

We introduce a set

of continuous, monotone and

bounded penalty functions indexed by a constant

parameter

(Kostić, et al., 2009):

:iscontinous,monotone,

,

i

f

,

,

,

i

f

,

,

i

f

.

(4)

An example of a function in

is

,

,

1Δ

sin

,

,

,

(5)

where Δ

γ

=

-

and = 2π / (

-

).

3 HIGH-LEVEL AND

LOW-LEVEL COORDINATION

To achieve transportation with high throughput and

increase robustness to uncertainties, such as

disturbances, all engaged robots have to cooperate.

These robots have to coordinate their motions such

as to avoid collisions and keep the sequence as

assigned by the given formation.

In this research, we investigate the performance

of two coordination methods, namely high-level

coordination and low-level coordination. The

coordination takes care of collision avoidance and

keeping the desired robot sequence. Both aspects are

very relevant for realization of transportation tasks

in a distribution center environment.

3.1 High-level Coordination

The high-level method of coordination is

implemented at the level of generating the reference

trajectory (2) for each robot. This method assumes

that the robots move from waypoint to waypoint

(nodes) on a network of fixed path segments (edges).

This network enables us to define spatial reference

trajectories.

To accomplish a given transportation task, a

timed desired trajectory along the desired path

segments is generated by each robot. For collision

avoidance it is needed to coordinate (predicted)

intervals of appearance of the robots at intersecting

segments. If these time intervals are well

coordinated, then the absence of collisions is

guaranteed as long as each robot accurately follows

its own reference trajectory. In this case, the

coupling gains

,

and

between robots in the

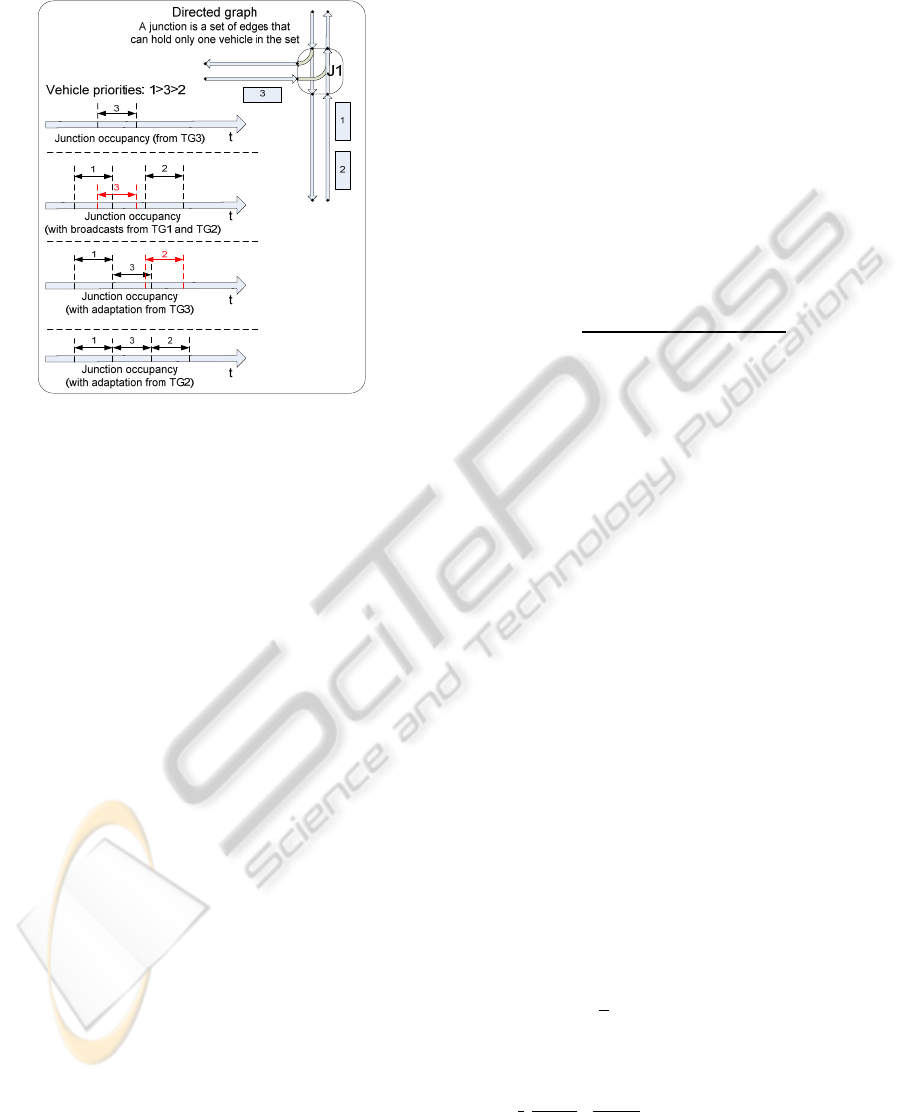

control laws (3) have to be set to zero. Figure 3

illustrates this coordination method in a situation

where trajectories of three robots intersect at

junction J1.

The junction is represented by a group of

intersecting path segments. Each segment brings a

robot from one side of the junction to another.

Therefore, the interval a robot occupies the junction

PERFORMANCE OF HIGH-LEVEL AND LOW-LEVEL CONTROL FOR COORDINATION OF MOBILE ROBOTS

65

is marked by passing the beginning and ending

waypoints of such a segment.

Figure 3: High-level coordination for collision avoidance.

At regular intervals, currently 1s, each robot

broadcasts its occupation interval to other robots

headed to J1. If overlap is detected, the robot of the

highest priority will rebroadcast its occupation

interval immediately to notify the other robots.

The robot of lower priority will postpone its

arrival time at the junction until the leaving time of

the robot of higher priority. Each robot adjusts its

speed immediately such as to reach the junction at

the correct time. The necessary speed is calculated

and all passing times at the waypoints between the

robot and the junction are adapted accordingly.

Similarly, the passing times after the junction

should be changed too. From the junction segment

on, the passing times are only adapted when the

robot would require to exceed its speed limits. Once

both the entering and leaving waypoint passing

times on the junction are known, the robot

broadcasts its new non-overlapping occupation

interval, and waits again for incoming occupation

intervals.

The priority of a robot is determined as the sum

of the total time this robot has to wait for other ones,

excluding those in front of it, and the expected time

to enter the junction. This is similar to the first come

first served priority scheme, which minimizes the

queues in front of the junctions as well as the

waiting times of the individual robots.

3.2 Low-level Coordination

The low-level coordination is implemented at the

level of trajectory tracking control. To keep the

correct robot sequence according to the desired

spatial pattern, the coupling gain

,

, and

are set to positive non-zero values. With such gains,

the control law (3) will be able to track the desired

formation, e.g. as shown in Figure 2. Due to this

coupling, the robots can recover their formation

faster than their individual desired paths, thereby

maintaining the desired sequence of robots better

than without the coupling.

To gain more robustness to uncertainties, the

reference forward velocity

,

1,2,3,…,

, of

each robot is also adjusted using the penalty

functions from the set

defined by (4). For each

robot we determine the distance between its

reference and actual position:

Δ

,

.

(6)

If Δ

,

, then the desired forward velocity

of each robot i is penalized as follows:

,

Δ

,

.

(7)

Here,

is a penalty function from the set (4)

and

,

is the desired forward velocity. Using (7),

if one robot is far from the assigned path, then the

forward velocities of all robots are decreased in

order to give the perturbed robot time to get back on

its track. In this way, it will be easier to keep the

correct sequence of the robots.

To avoid collisions, we make use of an Artificial

Potential Field (APF) (Latombe, 1991). The

reference trajectories of the robots facing collisions

are online adapted using the APF, mimicking the

approach in (Kostić, et al., 2010). If

,

and

,

, i,j∈ {1,2,...,m}, are the Cartesian

coordinates of the robots i and j, respectively, then

an APF of robot i is:

,

,

,

,

,

(8)

where

,

1

2

,

(9)

,

,

,

0, elsewhere.

.

(10)

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

66

Here, K

o

and K

a

are the gains of the repulsive and

attractive fields, respectively, and are positive

real numbers that determine the size of the detection

region for the repulsive function, rob

d

is the robot

diameter, and d

s

is the threshold of the detection

region. When all obstacles are outside the detection

region of robot i, its tracking controller tracks the

trajectory

. Inside the detection region, the

low-level coordination modifies the trajectory as

follows:

• Determine the Cartesian velocities that move the

robot in the direction of the steepest descent of V

i

(away from the obstruction):

,

,

,

,

,

.

(11)

• Update the reference trajectory such that

collision avoidance is achieved at time-instant t

k

:

,

,

atan

,

/

,

, if

0,

,if

0,

,

,

,

.

(12a)

(12b)

(12c)

(12d)

(12e)

4 EXPERIMENTS AND

PERFORMANCE ANALYSIS

4.1 Scenario

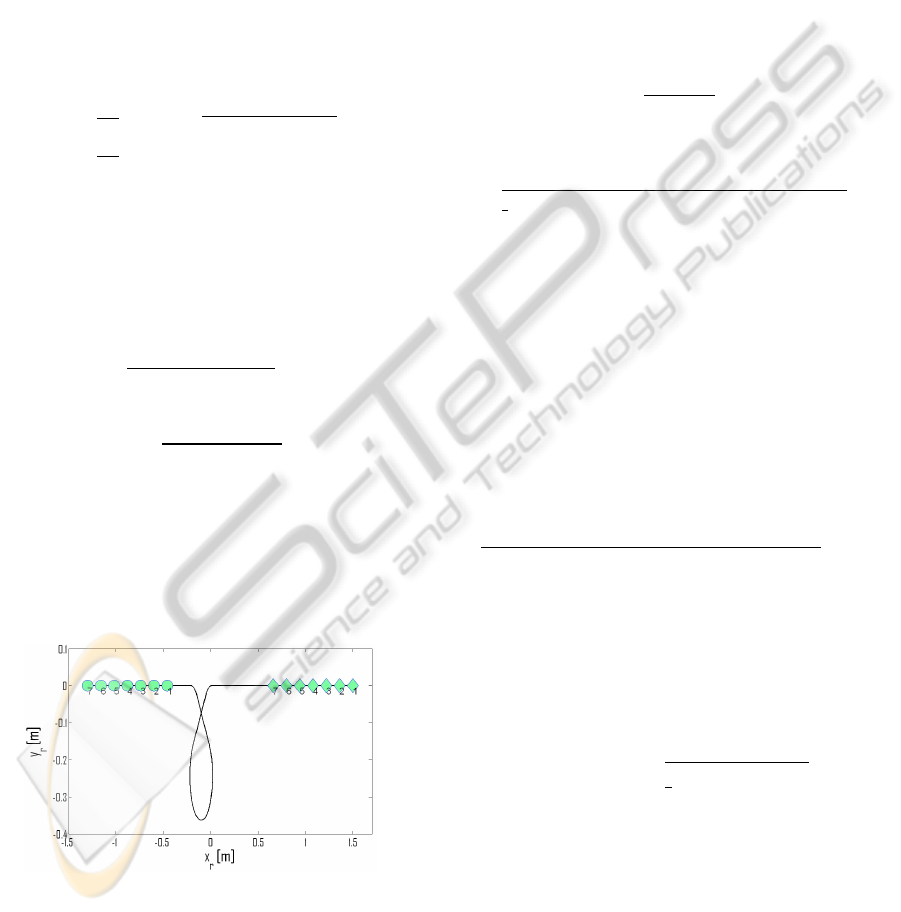

Figure 4: The experimental robot path. Symbols “o” and

“◊” indicate the start and end positions of the robots,

respectively.

To mimic a realistic transportation task in a

distribution center, experiments are conducted

according to the following scenario: a convoy of

seven robots delivers goods along a path depicted in

Figure 4. At one segment of this path, the front part

of the convoy intersects with the part at the back;

consequently, robot coordination is needed to avoid

collisions between the robots and to keep the correct

robot sequence. The desired forward velocity of

each robot is 0.08[m/s].

For performance evaluation, we use the

following indicators:

1. The average of the travel times,

, that the

robots consume to reach their target locations:

∑

,

.

(13)

2. The normalized total tracking error of all robots:

,

∑

∑

,

,

.(14)

where t

k

is the moment of collecting data, l is the

number of data points in the experiment,

,

and

,

are the originally assigned robot reference,

while x

i

and y

i

are the actual positions.

3. The normalized total formation error. In the

experiments we use a platoon-like formation, which

has a spatial pattern described by a time-varying

Euclidean distance between the neighboring robots.

For seven robots, the pattern can be described for

1,2,3,4,5,6 and 1, as follows:

Δ

,

,

,

,

.

(15)

We define the individual formation error by

Δ

Δ

,

(16)

where Δ

is the actual Euclidean distance

between the robots i and j. Thus, the normalized

total formation error is given by:

,

∑∑

1

∑

.

(17)

For a total performance indicator, we take the

summation of the three indicators proposed above

with equal weight:

∑

,

,

.

(18)

4.2 Experimental Set-up

Our experimental setup is depicted in Figure 5. We

PERFORMANCE OF HIGH-LEVEL AND LOW-LEVEL CONTROL FOR COORDINATION OF MOBILE ROBOTS

67

use mobile robots, model e-puck (Mondala and

Bonani, 2007), a camera as a localization device for

getting the position and orientation of all robots, and

a PC. The PC generates robot trajectories, processes

camera images to get the actual pose of the robots,

and runs the collision avoidance algorithms and

tracking control laws for all the robots. The PC

sends the control velocities to the robots via a

BlueTooth protocol. This way of implementation is

chosen due to the limiting processing power of the

onboard robot processors and due to the limited

bandwidth of the BlueTooth communication.

4.3 Experimental Results and Analysis

In the experiments, we use the following design

parameters:

0.4,

100,

0.5,

(19a)

0.06,

10,

0.00001,

(19b)

20,

10,0.05,

(19c)

0.03

m

,

0.14m,

(19d)

0.05

m

,

0.5

m

,

(19e)

,

0.3,

,

1.

(19f)

The values of

,

,

are chosen such that we

have an accurate trajectory tracking. As for

,

,

, the values will be zero if high-level

coordination is active. When low-level coordination

is active, the values are chosen such that we have

strong coupling between the robots, especially in x

and y direction.

As a basis for comparison, we simulate the case

where the coupling terms in the control law (3) are

enabled and collisions are allowed. In this unrealistic

case, all the robots can travel without perturbation

from the start to the end position, while keeping the

formation. To account for realistic imperfections of

the vision system used in experiments, we add

simulated noise, drawn from a normal distribution

with zero mean and standard deviation of ±0.005

[m] for x and y, and ±0.5

0

for

θ

, in accordance with

the measurement noise of the real camera. The

following results are obtained:

36.06

s

,

,

0.0024

m

,

(20a)

,

=0.0019

m

,

∑

36.0643-].

(20b)

Figure 5: The experimental set-up.

The simulation results are used as a reference for

comparison with data obtained from experiments.

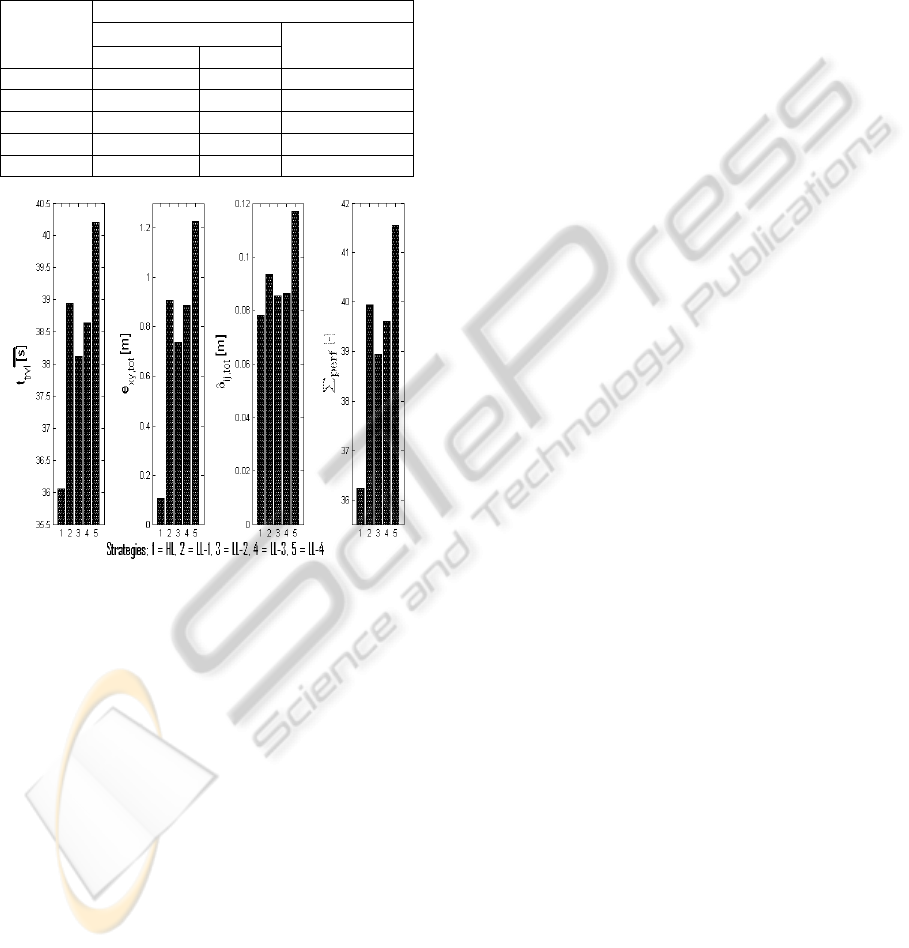

Tables 1a and 1b show statistics of all performance

indicators obtained in ten repeated experiments,

while Figure 6 shows a graphical representation of

these statistics.

ANALYSIS. From the second column of Table 1a

and Figure 6, we can see that the high-level

coordination achieves the shortest average travel

time with respect to other strategies. Thanks to

negotiations among the robots in the high-level

coordination, collision avoidance is achieved time-

efficiently, which leads to short travel times.

Table 1a: Mean value and standard deviation of

and

,

in ten repeated experiments.

Strategies

Indicators

s

,

m

mean Std mean Std

1

HL

36.06

0

0.105 0.00088

2

LL-1 38.939 1.920 0.907 0.4501

3

LL-2 38.110 1.184 0.737 0.3277

4

LL-3 38.633 1.024 0.885 0.2796

5

LL-4 40.204 2.277 1.228 0.3470

1

HL: high-level;

2

LL-1: low level, no coupling between robots

3

LL-2: low-level, all robots are mutually coupled;

4

LL-3: low-

level, each robot is coupled to the leader robot, i.e. the first robot

of the convoy, not vice versa;

5

LL-4: low-level, each robot is

coupled to the robot in front of it, not vice versa.

Two‐camerasystems

PC

E‐pucks

width

hei

g

ht

len

g

th

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

68

Moreover, the travel time is identical to the one

achieved under the ideal condition (20a). The given

experimental result suggests that the high-level

control yields time-optimal transportation while

taking care of collision avoidance.

Table 1b: Mean value and standard deviation of

,

in ten repeated experiments and Σ

perf

.

Strategies

Indicators

,

m

Σ

perf

mean std

1

HL

0.0782

0.00045 36.243200

2

LL-1 0.0934 0.04390 39.939400

3

LL-2 0.0853 0.02390 38.932299

4

LL-3 0.0862 0.00770 39.604199

5

LL-4

0.1170 0.05540 41.548999

Figure 6: The mean values of

,

,

,

,

from

different coordination strategies and Σ

perf

.

As for the low-level coordination, according to

the second column of Table 1a and Figure 6, in all

low-level coordination methods, the total travel time

is longer than achieved using the high-level

coordination. The online APF strategy does not

utilize negotiations; a robot facing an imminent

collision tries to move away from the obstacle.

Time-optimality of such a collision avoidance

algorithm is not guaranteed.

In our experiments, the lowest tracking errors are

achieved using the high-level coordination. With

modest uncertainties, this strategy ensures that each

robot follows its own collision-free reference

trajectory. Consequently, the difference between the

actual and the desired robot trajectories remains

small, which results in small tracking errors. This is

in line with the observation that the shortest travel

time is characteristic for the high level strategy. In

addition, the way the high-level strategy solves the

collision avoidance is also useful for formation

keeping, as depicted in Figure 6.

When comparing the tracking errors, the low-

level coordination strategies, all yield larger tracking

errors compared to the high-level coordination. As

expected, the tracking errors with coupling are

slightly larger than without coupling. Having the

couplings, a robot adapts its movement to other

perturbed robots. In this way, the tracking control

can keep the formation but by doing so, it decrease

its own tracking performance. Despite the poor

tracking error performance, as shown in Figure 6,

introducing correct coupling helps the robots keep

the formation.

If a decision needs to be made, a single measure

is needed to base it on. Comparing the values of the

total performance, we can observe that in our

experiments, option LL-2 turns out to be the most

suitable option for the low-level coordination

method.

Overall, it appears that the high-level control is

the most promising solution according to the total

performance measure. However, this solution may

fail in case of perturbations. The high-level strategy

requires all robots to be in the correct position for a

successful collision-free execution. If one robot is

not at the correct position at some time instant,

collisions may occur and the correct robot

sequencing cannot be guaranteed.

The low-level coordination is inherently more

robust to perturbations. Despite perturbations, the

low-level coordination achieves collision avoidance

and formation keeping. In the presence of

perturbations, from the comparison of the indicators

and considering the importance of formation, the

fully coupled option (LL-2) seems to be the most

appealing one. We show in Table 2 the minimum

distances between the center points of all robots,

measured from an experiment using the LL-2

strategy. During the experiment robot 4 was

manually displaced from the platoon. Since the

diameter of the robot is 0.07 [m], any value below

0.07 [m] implies a collision between robots. Table 2

shows no distances below 0.08 [m], so no collisions

occurred.

Given experimental analysis brings us to the

conclusion that it is not easy to find a single solution

that scores best in terms of all performance

indicators and is robust enough against uncertainties.

There will be a set of solutions that are best, i.e. no

better solutions exist in one performance indicator,

without being worse in another. These solutions are

called pareto-optimal solutions. One has to choose a

PERFORMANCE OF HIGH-LEVEL AND LOW-LEVEL CONTROL FOR COORDINATION OF MOBILE ROBOTS

69

weighing between all indicators, as in the total

performance indicator (18), to select the best one for

a certain application.

Table 2: Minimum distances between the centers of all

robots.

,

denotes the distance between robots i and j.

min

,

[m]

robot 1 2 3 4 5 6 7

1 - 0.08 0.08 0.09 0.16 0.09 0.08

2 - 0.08 0.17 0.23 0.19 0.14

3 - 0.08 0.17 0.20 0.18

4 - 0.08 0.09 0.17

5 - 0.08 0.08

6 - 0.08

The problem remains to find those pareto-

optimal solutions. The high-level and low-level

coordination strategies that we propose still can be

improved and optimized in terms of all performance

indicators, e.g. using larger safety distance for the

high level method or having a smoother transition

from normal to collision mode for the low level

methods. Finding the true pareto-optimal solutions is

probably not possible. However, from a set of

solutions one can always remove the non pareto-

optimal solutions, and choose from the remaining,

best, ones.

5 CONCLUSIONS

We have experimentally evaluated the performance

of different strategies for coordinated control of

mobile robots. We have proposed high-level and

low-level coordination methods and presented

experimental results that illustrate the superior

performance of the high-level method in terms of

time efficiency and accuracy of tracking the desired

robot trajectories. A serious limitation of the high-

level coordination is the requirement for accurate

tracking of the reference trajectories.

Even though the performance of the low-level

coordination method is worse than that of the high-

level coordination method, the low-level one is

inherently more robust against uncertainties.

Given the results of our analysis, it seems

interesting to analyze performance of combinations

of different strategies, e.g., of high-level and low-

level coordination methods. By combining more

strategies, we may optimize more performance

indicators and meet more requirements.

Consequently, it needs to be investigated which

combinations would lead to the pareto-optimal

solutions.

ACKNOWLEDGEMENTS

This work has been carried out as part of the

FALCON project under the responsibility of the

Embedded Systems Institute with Vanderlande

Industries as the industrial partner. This project is

partially supported by the Dutch Ministry of

Economic Affairs under the Embedded Systems

Institute (BSIK03021) program.

REFERENCES

Berg, J. P. van den, 1999, A literature Survey on Planning

and Control of Warehousing Systems, in IIE

Transactions, Vol.31, pp. 751-762.

Broek, T. H. A. van den, van de Wouw, N., Nijmeijer, H.

2009, Formation Control of Unicycle Mobile Robots:

a Virtual Structure Approach, in Proc. IEEE Conf. on

Decision and Control, pp. 8238-8333.

Farahvash, P., and Boucher, T. O., 2004, A Multi-agent

Architecture for Control of AGV Systems, in Robotics

and Computer Integrated Manufacturing, Vol.20, pp.

473-483.

Giret, A., and Botti, V., 2004, Holons and Agents, in J. of

Intelligent Manufacturing, Vol. 15, pp. 645-659.

Giuzzoa, E., 2008, Three Engineers, Hundred of Robots,

One Warehouse, in IEEE Spectrum, Vol. 45. No. 7,

pp. 26-34.

Gu, J., Goetschalckx, M., McGinnis, L. F., 2007, Research

on Warehouse Operation: A Comprehensive review, in

in European Journal of Operational Research, Vol.

177, pp. 1-21.

Gu, J., Goetschalckx, M., McGinnis, L. F., 2010, Reseach

on Warehouse Design and Performance Evaluation: A

Comrehensive review, in European Journal of

Operational Research, Vol. 203, pp. 539-549.

Kostić, D., Adinandra, S., Caarls, J., Nijmeijer, H., 2009,

Collision-free Tracking Control of Unicycle Mobile

Robots, in Proc. IEEE Conf. on Decision and Control,

pp. 5667-5672.

Kostić, D., Adinandra, S., Caarls, J., Nijmeijer, H., 2010,

Collision-free Tracking Control of Unicycle Mobile

Robots, Collision-free Motion Coordination of

Unicycle Multi-agent Systems, Accepted for American

Control Conference 2010.

Latombe, J. C., 1991, Robot Motion Planning, Kluwer

Academic Publishers, Boston, MA.

Le-Anh, De Koster, M. B. M., 2006, A review of Design

and Control of Automated Guided Vehicles Systems,

in European Journal of Operational Research, Vol.

171, pp. 1-23.

Mastellone, S., Stipanović, D. M., Graunke, C. R.,

Intlekofer, K. A., and Spong, M. W., 2008, Formation

Control and Collision Avoidance for Multi-agent Non-

holonomic Systems: Theory and Experiments, in Int.

Journal of Robotics Research, Vol.27, No. 1, pp. 107-

126.

ICINCO 2010 - 7th International Conference on Informatics in Control, Automation and Robotics

70

Mondala, F., Bonani, M., 2007, E-puck education robot,

www.e-puck.org.

Moneva, H., Caarls, J., and Verriet, J., 2009. A Holonic

Approach to Warehouse Control, in Int. Conf. on

Practical Applications of Agents and Multiagent

Systems, pp. 1-10.

Ren, W. and Beard, W., 2004, Decentralized Scheme for

Spacecraft Formation via The Virtual Structure

Approach, in IEEE Proc. Control Theory Application

2004, pp. 268-357.

Sun, D., Wang, C., Shang, W., Feng, G., 2009, A

Synchronization Approach to Trajectory Tracking of

Multiple Mobile Robots While Maintaining Time-

Varying Formations, IEEE Transactions on Robotics,

Vol.25, pp. 1074-1086.

Vis, I. F. A, 2004, Survey of Research in the Design and

Control of Automated Guided Vehicle Systems, in

European Journal of Operational Research, Vol. 170,

pp. 677-709.

Weyns, D., Schelfthout, K., Holvoet, T., and Lefever, T.,

2005, Decentralized Control of E’GV Transportation

Systems, in Autonomous Agents and Multiagent

Systems, Industry Track (Pechoucek, M. and Steiner,

D. and Thompson, S., eds.), pp. 67-74.

PERFORMANCE OF HIGH-LEVEL AND LOW-LEVEL CONTROL FOR COORDINATION OF MOBILE ROBOTS

71