MODELING LARGE SCALE MANUFACTURING PROCESS FROM

TIMED DATA

Using the TOM4L Approach and Sequence Alignment Information for Modeling

STMicroelectronics’ Production Processes

Pamela Viale

1,2

, Nabil Benayadi

1

, Marc Le Goc

1

and Jacques Pinaton

2

1

LSIS, Laboratory for Information and System Sciences,University of Marseille, Marseille, France

2

STMicroelectronics, Rousset, France

Keywords:

Process model discovery, Temporal knowledge discovering, Markov processes, Sequence alignment.

Abstract:

Modeling manufacturing process of complex products like electronic chips is crucial to maximize the quality of

the production. The Process Mining methods developed since a decade aims at modeling such manufacturing

process from the timed messages contained in the database of the supervision system of this process. Such

process can be complex making difficult to apply the usual Process Mining algorithms. This paper proposes

to apply the TOM4L Approach (Timed Observations Mined for Learning) to model large scale manufacturing

processes. A series of timed messages is considered as a sequence of class occurrences and is represented

with a Markov chain from which models are deduced with an abductive reasoning. Because sequences can

be very long, a notion of process phase is introduced. Sequences are cut based on the concept of class of

equivalence and information obtained from an appropiate alignment between the sequences considered. A

model for each phase can then be locally produced. The model of the whole manufacturing process is obtained

from the concatenation of the models of the different phases. This paper presents the application of this

method to model STMicroelectronics’ manufacturing processes. STMicroelectronics’ interest in modeling its

manufacturing processes is based on the necessity to detect the discrepancies between the real processes and

experts’ definitions of them.

1 INTRODUCTION

1

Modeling manufacturing processes for the construc-

tion of complex objects like electronic chips is crucial

for maximizing productivity. The methods and the

algorithms developed in the Process Mining domain

aims at modeling such manufacturing processes with

graphs of manufacturing steps (treatments, operations

or tasks) from the timed messages contained in the

database (Cook and Wolf, 1998). The proposed al-

gorithms generally generate complex models that are

difficult to read and interpret when the process con-

tains hundred of steps.

This paper proposes a modeling method and the

corresponding algorithms to model manufacturing

processes having hundreds of steps. The proposed

method is based on cutting the sequences in subse-

quences called process phases. The way of cutting

1

This work has been made possible thanks to the finan-

cial support of STMicroelectronics, Convention 642/2008.

the sequences is based on information obtained from

an alignment between them. However, finding an ap-

propiate sequence alignment is not a simple task.

The section 2 resumes the state of art on the pro-

cess mining area and it introduces some ideas about

sequence alignment. Section 3 defines the notions of

class of equivalence and process phase that we pro-

pose and describes the algorithms that are required

to this aim. Section 4 presents the application of the

algorithms to model STMicroelectronics’ manufac-

turing processes. These manufacturing processes are

used for creating electronics chips, micro-controllers,

etc. The resulting models will be useful to control that

the implemented process correspond to the experts’

ideas. Discrepancies found will be helpful to alarm

experts’ about possible problems in production. In

section 5 a summary of the proposed method is pre-

sented. The paper concludes in section 6 with the in-

troduction of our current works.

129

Viale P., Benayadi N., Le Goc M. and Pinaton J. (2010).

MODELING LARGE SCALE MANUFACTURING PROCESS FROM TIMED DATA - Using the TOM4L Approach and Sequence Alignment Information

for Modeling STMicroelectronics’ Production Processes.

In Proceedings of the 12th International Conference on Enterprise Information Systems - Artificial Intelligence and Decision Support Systems, pages

129-138

DOI: 10.5220/0002971801290138

Copyright

c

SciTePress

2 STATE OF ART

2.1 Process Mining Area

In the Process Mining framework, a series of mes-

sages is considered as an ordered set of events from

where a process model can be inferred and repre-

sented in some formalism (workflows, state charts or

Petri nets for examples) (van der Aalst and Weijters,

2004). One of the first algorithm was proposed in

(Agrawal et al., 1998). The algorithm aims at find-

ing workflow graphs from a set of series of events

contained in a workflow log. An event represents the

start time of a task. To avoid the problem of poten-

tial cycles (i.e. repeated events in a series), the algo-

rithm first renames the repeated labels of task before

enumerating the binary dependency relations between

the tasks. This set of relations is then reduced with the

use of the transitivity property of the binary relations.

Labels are again renamed to merge the tasks, making

possible the introduction of cycles in the model. Dif-

ficulties arise with this approach when (i) the tasks are

statistically independent and (ii) the number of tasks

is large (Agrawal et al., 1998). Nevertheless, Pinter

(Pinter and Golani, 2004) extends this algorithm no-

tably with the introduction of events marking the end

of the tasks. Similar issues in the context of software

engineering processes are investigated in (Cook and

Wolf, 1998) where the aim is to build a finite state

machine from the set of the most frequent event pat-

terns mined in a given log. In particular, the Markov

algorithm is based on a two order Markov chain that

is converted in states and state transitions. Cook and

Wolf (Cook and Wolf, 2004) extend this method to

concurrent processes and uses a first order Markov

chain for this aim. The difficulties come from the

pruning of the finite state machine to obtain a mini-

mal model and the sensibility of pruning metrics to

the ”noise” (van der Aalst and Weijters, 2004). Aalst

(van der Aalst et al., 2004) defines the class of process

that can be modeled with the α-algorithm but this al-

gorithm requires the series of events in the log to be

noise-free and complete.

There is a consensus to consider that finite state ma-

chines are difficult to understand and to validate. And

most of the proposed methods have difficulties when

(i) the process contains a lot of steps, (ii) the se-

ries in the log induce potential cycles in the models

and (iii) the sequences are not noise-free and com-

plete. The TOM4L Approach (Timed Observations

Mined for Learning, previously called Stochastic Ap-

proach Framework) (Le Goc et al., 2005) for discov-

ering temporal knowledge from timed observations

provides a general framework for modeling dynamic

processes that is based on a markovian representation

but uses abstract chronicle models (Ghallab, 1996) in-

stead of finite state machines. This framework consid-

ers that the timed messages of a series are written in

a database by a program, called a monitoring cogni-

tive agent MCA, that monitors a production process

Pr. A timed message is represented with an occur-

rence of a discrete event class C

i

= {e

i

} that is an

arbitrary set of discrete event e

i

= (x

i

, δ

i

), where δ

i

is one of the discrete value of the variable x

i

. When

the variable x

i

is not known, an abstract variable φ

i

is used to define the discrete event e

i

= (φ

i

, δ

i

) cor-

responding to the constant δ

i

. A discrete event class

is often a singleton because in that case, two discrete

event classes C

i

= {(x

i

, δ

i

)} and C

j

= {(x

j

, δ

j

)} are

only linked with the variables x

i

and x

j

when the con-

stants δ

i

and δ

j

are independent (Le Goc, 2006). This

condition is only concerned with the programs the

MCA is made with. A sequence of discrete event

class occurrences is then considered as the observ-

able manifestation of a series of state transitions in

a timed stochastic automaton representing the cou-

ple (Pr, MCA). The BJT4G algorithm represents a

set of sequences of discrete event class occurrences

with a one order Markov chain and uses an abduc-

tive reasoning to identify the set of the most proba-

ble timed sequential binary relations between discrete

event classes leading to a given class. A timed se-

quential binary relation R(C

i

,C

j

, [τ

−

i j

, τ

+

i j

]) is an ori-

ented relation between two discrete event classes C

i

and C

j

that is timed constrained with the interval

[τ

−

i j

, τ

+

i j

]. [τ

−

i, j

, τ

+

i, j

] is the time interval for observing an

occurrence of the C

j

class after an occurrence of the

C

i

class. The set of timed sequential binary relation

is an abstract chronicles model where the nodes are

discrete event classes and the links are timed sequen-

tial binary relations. This paper proposes to tackle the

two main problems of the Process Mining approaches

with the extension of the TOM4L Approach. The

first ideas of this approach has been presented in (Be-

nayadi et al., 2008).

2.2 Sequence Alignment

Before introducing the extension to the TOM4L Ap-

proach, it is necessary to introduce some ideas about

sequence alignment. These ideas are necessary to

understand the steps proposed in the algorithms for

modeling large scale manufacturing processes.

A sequence alignment consists in a way of ar-

ranging sequences to identify regions of similarity

between them. Aligned sequences are usually rep-

resented as rows within a matrix. Gaps (’-’) are in-

serted between the residues so that identical or simi-

ICEIS 2010 - 12th International Conference on Enterprise Information Systems

130

lar residues are aligned in successive columns. In our

problem, the residues are the discret event class oc-

currences.

One of the first issue that arise when compar-

ing sequences concerns the estimation of substitution

costs. These substitution costs provide useful infor-

mation that leads the algorithms to align or not the

residues of the sequences considered. The scores for

aligning the different characters in the alphabet Σ are

obtained from a matrix S = [s

x,y

]

x∈Σ,y∈Σ

, called simi-

larity matrix (it is also called substitution matrix). The

value s

x,y

represents the similarity between the ele-

ments of the pair (x, y), x ∈ Σ, y ∈ Σ. In biology, there

exists some well-known substitution matrices. How-

ever, this problem has also been encountered in many

other areas, for example, in social sciences where

there are no well known similarity matrices precal-

culated. The problem in social science is to compare

chronological sequences of various kind (e.g. profes-

sional or familial statuses) where there is no equiva-

lent to such a strong theoretical and empirical frame-

work like evolutionary theory. Thus the relationship

between the symbols constituting sequences of social

events remain at least partly uncertain. The ideas from

social science field can guide us towards to find a

strategy to build similarity matrices for any kind of

sequences. The idea is to find a way to construct the

similarity matrix S for any kind of sequence, deriving

costs empirically. An adaptation of the algorithm for

calculating substitution costs iteratively is necessary

(Gauthier et al., 2008).

3 EXTENSION OF THE TOM4L

APPROACH FOR PROCESS

MINING

3.1 Motivation

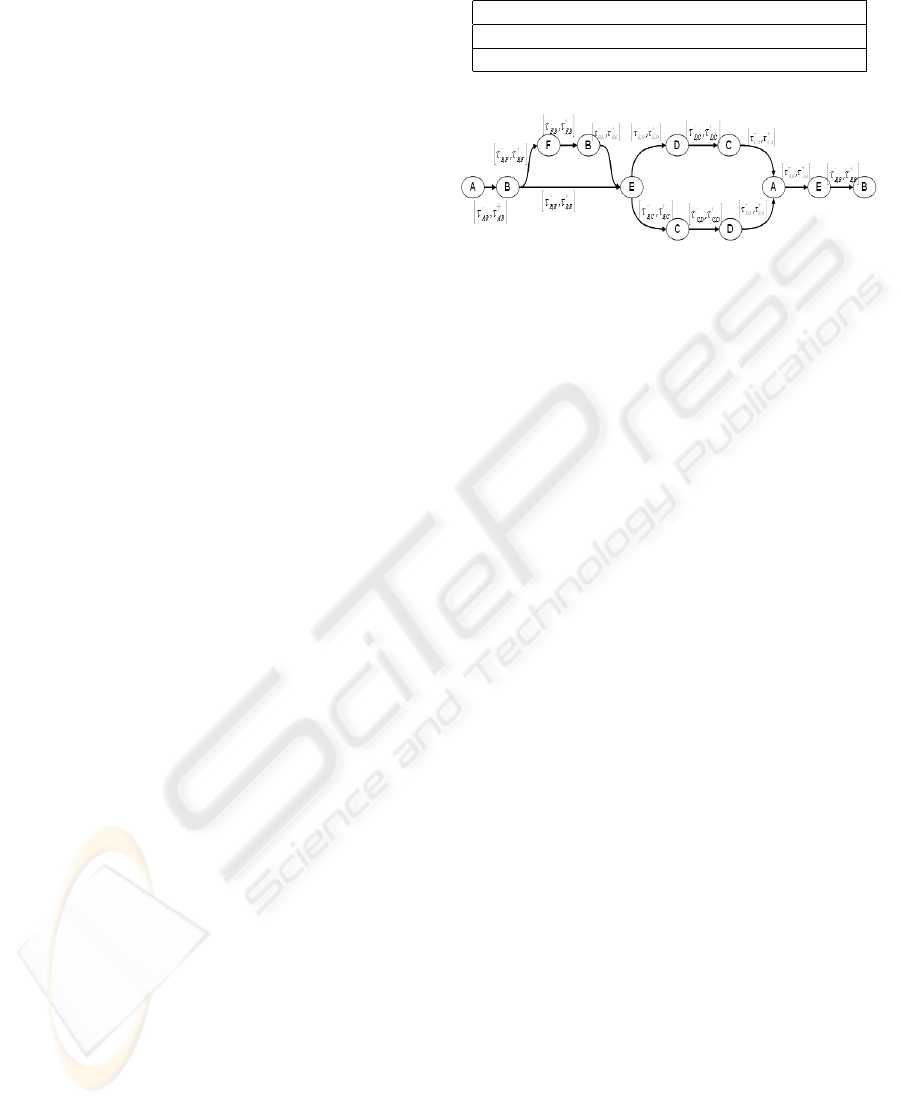

Let us take an example to illustrate the proposed ex-

tensions with a manufacturing process having a set

S = {A, B,C, D, E, F} of 6 manufacturing steps. Sup-

pose the supervision system records the execution of a

step with a message X(t

k

) denoting the time t

k

of the

beginning of the execution of the step X. The three

series of messages of table 1 are represented with the

abstract chronicle model of figure 1. In this model, if

nodes labeled with A denote the same manufacturing

step, then the nodes can be confused, introducing a

cycle in the model. The same reasoning can be done

over the other nodes, making the model difficult to

read and to understand.

This repetition of manufacturing steps can be due

Table 1: Three series of event.

A(t

1

)B(t

2

)F(t

3

)B(t

4

)E(t

5

)D(t

6

)C(t

7

)A(t

8

)E(t

9

)B(t

10

)

A(t

11

)B(t

12

)E(t

13

)C(t

14

)D(t

15

)A(t

16

)E(t

17

)B(t

18

)

A(t

19

)B(t

20

)E(t

21

)C(t

22

)D(t

23

)A(t

24

)E(t

25

)B(t

26

)

Figure 1: Model for the three Sequences.

to a situation that arrives frequently during the exe-

cution of a manufacturing process. When an object

is being manufactured, the object goes from one ma-

chine to another for making all the necessary treat-

ments on it. Nevertheless, usual controls in pro-

duction sometimes show that certain objects did not

achieved the expected characteristics. Some actions

(special actions) has to be done to correct the prob-

lem. These actions usually consist on performing spe-

cial treatments and/or the repetition of tasks.

This is the reason why we need to align the differ-

ent process execution sequences to identify equivalent

treatments over the different objects being produced

in each execution.

Given a set Ω = {ω

i

}

i={1,...,n}

of sequences ob-

tained from the execution of the same manufacturing

process, we need a ’good’ sequence alignment be-

tween them, SA(Ω) . By ’good’ we mean an align-

ment that aligns similar treatments made on the dif-

ferent objects on the same column and special tasks

(task performed to correct errors) with gaps (’-’).

Two possible ’good’ alignment for the sequences

shown in Table 1 are proposed in Table 2.

Suppose now that each of the three sequences are

cut when a label is aligned with exactly the same one

in all sequences and this alignment appears two times.

The model of the first part of the sequences will be

similar to the one of figure 1 but without the path

A − E − B at the end of the model. This fact moti-

vates the notion of process phase proposed in this pa-

per. But this notion is not sufficient to solve the cycles

that are introduced with the steps C and D. We con-

sider that this problem is due to the fact that the three

series of events provide no information about the or-

der of the steps C and D. Consequently, any solution

of this problem must take into account some a priori

knowledge about the process which we want to avoid

it. The notion of potential cycle is then defined to de-

tect this kind of situation to be able to make further

investigations (i.e. finding new series or discussing

MODELING LARGE SCALE MANUFACTURING PROCESS FROM TIMED DATA - Using the TOM4L Approach and

Sequence Alignment Information for Modeling STMicroelectronics' Production Processes

131

Table 2: Two Sequence Alignments proposed for sequences on Table 1.

Possible Sequence Alignments

SA

1

=

A(t

1

) B(t

2

) F(t

3

) B(t

4

) E(t

5

) D(t

6

) C(t

7

) − A(t

8

) E(t

9

) B(t

10

)

A(t

11

) B(t

12

) − − E(t

13

) − C(t

14

) D(t

15

) A(t

16

) E(t

17

) B(t

18

)

A(t

19

) B(t

20

) − − E(t

21

) − C(t

22

) D(t

23

) A(t

24

) E(t

25

) B(t

26

)

SA

2

=

A(t

1

) B(t

2

) F(t

3

) B(t

4

) E(t

5

) − D(t

6

) C(t

7

) A(t

8

) E(t

9

) B(t

10

)

A(t

11

) B(t

12

) − − E(t

13

) C(t

14

) D(t

15

) − A(t

16

) E(t

17

) B(t

18

)

A(t

19

) B(t

20

) − − E(t

21

) C(t

22

) D(t

23

) − A(t

24

) E(t

25

) B(t

26

)

with experts for examples).

To illustrate the notion of class of equivalence, let

us take the Edit activity of the ”writing a scientific pa-

per” process that can be made by different students

and professors. The Edit activities can then be la-

beled differently according to the performer with a set

of classes of the form: C = {C

E1

= {(s

1

, δ

1

)},C

E2

=

{(s

2

, δ

2

)}, . . .}, where the variables s

i

and p

i

denotes

respectively students and professors. In this case,

the resulting model of the process will be complex

without necessity. One of the interesting features of

the TOM4L Approach is the notion of discrete event

class. This notion can be used to define abstract

classes of the form C

φ

i

= {(φ

i

, δ

1

), . . . , (φ

i

, δ

n

)} where

φ

i

denotes an abstract variable and the set {δ

j

}, j =

1. . . n, is an arbitrary set of constants. This property

allows defining classes of equivalence that simplifies

a process model. For example, an abstract class C

φ

i

be defined as an equivalent class of the set of classes

C of the ”writing a scientific paper” process. Doing

this way allows constituting a set of sequences com-

ing from different students and professors.

3.2 Class of Equivalence

By definition, a large scale process consist on a lot

of steps. Some of these steps differs only with some

characteristics but realizes similar treatments.

Definition 1 . Given a model M =

{R(C

i

,C

j

, [τ

−

i j

, τ

+

i j

])} build with a set Ω = {ω

i

}

of discrete event class occurrences ω

i

, a class

C

φ

i

= {(φ

i

, δ

1

), (φ

i

, δ

2

), . . . , (φ

i

, δ

n

)} is an equiv-

alence class of a sub set of classes C = {C

j

},

j = 1 . . . n, C

j

= {(x

j

, δ

j

)}, of the set of classes C

M

of

a model M iff:

∀C

a

,C

b

∈ C

∀C

k

∈ C

M

,

(∃R(C

k

,C

a

, [τ

−

ka

, τ

+

ka

]) ∈ M ∧ ∃R(C

k

,C

b

, [τ

−

kb

, τ

+

kb

]) ∈ M)

∧ (1)

∀C

r

∈ C

M

,

(∃R(C

a

,C

r

, [τ

−

ar

, τ

+

ar

]) ∈ M ∧ ∃R(C

b

,C

r

, [τ

−

br

, τ

+

br

]) ∈ M)

This definition means that every classes C

j

of

the subset C ⊆ C

M

are linked with the same classes

in M. When this condition is verified, each oc-

currences C

j

(t

s

) of the classes C

j

in the sequences

ω

i

of Ω can be rewritten as occurrences C

φ

i

(t

s

)

of the equivalence class C

φ

i

. The abstract vari-

able φ

i

has no a priori meaning: φ

i

can be substi-

tuted with the corresponding concrete variable x

i

in

any occurrences C

φ

i

(t

s

). Consequently, the set of

uphill relations {R(C

i

,C

j

, [τ

−

i j

, τ

+

i j

])} of M will be-

come {R(C

i

,C

φ

i

, [τ

−

iφ

i

, τ

+

iφ

i

])} and the set of down-

hill relations {R(C

j

,C

k

, [τ

−

jk

, τ

+

jk

])} of M will become

{R(C

φ

i

,C

k

, [τ

−

φ

i

k

, τ

+

φ

i

k

])}. In practice, an equivalence

class can be used to represent related discrete event

classes. In the application presented in the next sec-

tion, a discrete event class represents a set of treat-

ments that can be made on an object using a particular

machine. Equivalence classes are then used to repre-

sent this set of treatments made by different machines:

in that case, the machines are equivalents because the

same set of treatments can be done on each of the ma-

chines.

Given a set of sequences Ω = {ω

i

}

i={1,...,n}

, the

algorithm for defining equivalence classes find all the

equivalence classes and rewrite the corresponding oc-

currences in each sequence ω

i

(Algorithm 1):

1. Build a model M given a set of sequences Ω =

{ω

i

}

i={1,...,n}

.

2. Find all the subset of classes C verifying the equa-

tion 1.

3. For all the subsets C.

• Create an equivalence class C

φ

i

.

• For all C

j

∈C, rewrite all the occurrences C

j

(t

s

)

in all the sequences ω

i

∈ Ω with the rewriting

rule: C

j

(t

s

) ≡ C

φ

i

(t

s

).

4. Build a new model M

0

with Ω.

3.3 Process Phase

The information contained in a series of manufactur-

ing messages is concerned with both the state of the

manufactured object and the manufacturing process

that makes evolving this state from an initial state up

to a final state. But generally, the state of the manufac-

tured object is not provided with the messages. So we

ICEIS 2010 - 12th International Conference on Enterprise Information Systems

132

propose to capture indirectly this dimension with the

notion of Process Phase. However, before introduc-

ing this new concept, we must define formally what is

called a Sequence Alignment.

3.3.1 Sequence Alignment

A sequence alignment consists in a way of arranging

sequences to identify regions of similarity between

them. Aligned sequences are usually represented

as rows within a matrix M = [m

i, j

]

i∈{1,...,n}, j∈{1,...,r}

.

Gaps (’-’) are inserted between the residues so that

identical or similar residues are aligned in successive

columns.

Definition 2 . Given a model M =

{R(C

i

,C

j

, [τ

−

i j

, τ

+

i j

])} build with a set Ω = {ω

i

}

of discrete event class occurrences. A sequence

alignment SA between all sequences ω

i

∈ Ω is

defined as follows:

SA(Ω) = {M

n×r

|

∀ω

j

∈ Ω, r ≥ card(ω

j

) ∧

∀m

i j

∈ M

n×r

, m

i j

∈ C

M

∪ {

0

−

0

} ∧

∀m

i j

, m

i( j+1)

∈ M

n×r

, (2)

(m

i j

= C

j

(t

k

),C

j

(t

k

) ∈ ω

i

∧

m

i( j+1)

= C

l

(t

x

),C

l

(t

x

) ∈ ω

i

∧

t

x

> t

k

)}

where:

- card(s) is the length of sequence s.

There are many possible alignments between n

sequences. There exists many algorithms for creat-

ing sequence alignments based on different objectives

and strategies (Thompson et al., 1994; Notredame

et al., 2000; Needleman and Wunsch, 1970; Smith

and Waterman, 1981). However, it is necessary to

provide a similarity matrix S to these algorithms so

that they are able to calculate when to align or not

residues of the different sequences. If we use the same

alignment algorithm over the same set of sequences

with different similarity matrices the resulting align-

ments will be probably not the same. So, it is very im-

portant to use a similarity matrix that agrees with the

semantics of the sequences treated. We will illustrate

this problem in section 4, over STMicroelectronics’

manufacturing process sequences.

Given a set of sequences Ω = {ω

i

}

i={1,...,n}

and a

sequence alignment SA(Ω), we propose an algorithm

for renaming classes.This algorithm traverses all se-

quences and renames a class if in the alignment it is

aligned with classes different from itself or with gaps

(Algorithm 2):

• ∀ω

i

∈ Ω, ∀C

j

(t

k

) ∈ ω

i

do:

– Rename the occurrence C

j

(t

k

) when:

- ∃C

i

(t

s

) ∈ w

m

, w

m

∈ Ω,C

j

(t

k

) is aligned with

C

i

(t

s

) in SA(Ω) and C

i

6= C

j

; or

- C

j

(t

k

) is aligned with a gap (’-’) in SA(Ω).

In Table 3 we will show the corresponding series

from Table 1 after applying Algorithm 2 on them,

considering sequence alignment SA

1

.

3.3.2 Process Phase Concept

As it was said before, the concept of process phase

will be used to capturate the different stages that an

object must go through in the manufacturing process

to achieve the final expected state. For this task we

need to count with a ’good’ sequence alignment of the

sequences that we use to build the model. The reason

is that this alignment provides a guideline to distin-

guish normal treatments from special tasks performed

in particular executions of the process. Aligned tasks

are supposed to be regular tasks whereas not aligned

tasks are not.

Definition 3 . Given a set of sequences

Ω = {ω

i

}

i={1,...,n}

and a sequence alignment

SA(Ω), a process phase of the model M con-

structed using Algorithm 2 is a submodel

M

0

= {R(C

i

,C

j

, [τ

−

i j

, τ

+

i j

])|C

i

,C

j

∈ C

M

0

} ⊆ M, so

that there is no path P = {R(C

i

,C

i+1

,

[τ

−

ii+1

, τ

+

ii+1

])} ∈ M

0

, i = 1 . . . n, where:

∀ j, k ∈ N, 1 ≤ j < k ≤ n,C

j

= C

k

(3)

Algorithm 3 aims at cutting a set Ω =

{ω

i

}

i={1,...,n}

of sequences in subsequences ω

i

k

that

respects the equation 3 (i.e. ω

i

k

does not contain two

occurrences of the same class):

1. ∀ω

i

∈ Ω do

• Remove ω

i

from Ω.

• Cut up ω

i

in a set Ω

i

= {ω

i

k

} of sub sequences

ω

i

k

verifying the equation 3.

2. ∀ω

i

k

∈ Ω

i

do

• Add an occurrence of the C

0

and C

1

classes at

the beginning and the end of ω

i

k

.

3. Ω =

S

Ω

i

.

An occurrence of an abstract start class C

0

and

an occurrence of an abstract final class C

1

are

added at the beginning and the end of each sub

sequences ω

i

k

so that the BJT 4G algorithm auto-

matically identifies the process phases. For exam-

ple, when applying the algorithm 3 on the three

sequences of Table 1, the BJT 4G algorithm will

find two process phases. The second process phase

MODELING LARGE SCALE MANUFACTURING PROCESS FROM TIMED DATA - Using the TOM4L Approach and

Sequence Alignment Information for Modeling STMicroelectronics' Production Processes

133

Table 3: Series of event after renaming with Algorithm 2.

A(t

1

) B(t

2

) F

1,3

(t

3

) B

1,4

(t

4

) E(t

5

) D

1,6

(t

6

) C(t

7

) A(t

8

) E(t

9

) B(t

10

)

A(t

11

) B(t

12

) E(t

13

) C(t

14

) D

2,15

(t

15

) A(t

16

) E(t

17

) B(t

18

)

A(t

19

) B(t

20

) E(t

21

) C(t

22

) D

3,23

(t

23

) A(t

24

) E(t

25

) B(t

26

)

will be: { R(C

0

,C

A

, [τ

−

0A

, τ

+

0A

]) , R(C

A

,C

E

, [τ

−

AE

, τ

+

AE

]),

R(C

E

,C

B

, [τ

−

EB

, τ

+

EB

]), R(C

B

,C

1

, [τ

−

B1

, τ

+

B1

]) }.

It can be easily deduced from the definition of pro-

cess phase that process phases are dependent on the

sequence alignment chosen. It is necessary to count

with a ’good’ sequence alignment for being able to

correctly identify the different stages in the process.

3.4 Potential Cycles

When looking the model of figure 1, it is clear

that the classes C and D introduce a cycle. Cycles

present a strong problem of interpretation, making

hard to understand the resulting models. This explains

why there is a lot of works aiming at avoiding cy-

cles in process models (cf. (Cook and Wolf, 2004),

(Schimm, 2004) (van der Aalst et al., 2004), (Pin-

ter and Golani, 2004), (Weijters and van der Aalst,

2003) or (Agrawal et al., 1998) for examples). But

these works make assumptions about the process or

impose constraints about the constitution of the se-

quences. In all the case, this consists in having some

a priori knowledge about the process to be modeled

or the set of programs that write the messages in the

process data base.

The aim of the TOM4L Approach is to provide

models of sequences without any a priori knowledge

about the process and the set of programs that have

generated the occurrences. One difficulty is that cy-

cles often appear when mining a process because of

the transitivity property of the sequential binary rela-

tions.

Property 1 . The timed sequential binary relations

R(C

i

,C

j

, [τ

−

i j

, τ

+

i j

]) of a given abstract chronicle model

M = {R(C

i

,C

j

, [τ

−

i j

, τ

+

i j

])} are transitives.

∀R(C

i

,C

j

, [τ

−

i j

, τ

+

i j

]) ∈ M ∧ ∀R(C

j

,C

k

, [τ

−

jk

, τ

+

jk

]) ∈ M

R(C

i

,C

j

, [τ

−

i j

, τ

+

i j

]) ∧ R(C

j

,C

k

, [τ

−

j,k

, τ

+

j,k

])

⇒ ∃R

T

(C

i

,C

k

, [τ

−

ik

, τ

+

ik

]) (4)

Definition 4 . Given a process model M, two discrete

event classes C

i

and C

j

are not ordered when:

M ` R

T

(C

i

,C

j

, [τ

−

i j

, τ

+

i j

]) ∧ M ` R

T

(C

j

,C

i

, [τ

−

ji

, τ

+

ji

]) (5)

Two classes C

i

and C

j

that can not be ordered in a

model will be denoted C

i

kC

j

≡ C

j

kC

i

.

For examples the three sequences of the Table 1

do not provide any order between the classes C

C

and

C

D

(Figure 1). Consequently: C

C

kC

D

≡ C

C

kC

D

.

Property 2 . The set of discrete event classes C

k

=

{C

1

,C

2

, . . . ,C

n

} can not be ordered when:

∀C

i

∈ C

k

, ∀C

j

∈ C

k

,C

i

kC

j

. (6)

In the theory of graphs, the classes of a set C

k

are strongly connected components. The algorithm

4 aims at detecting a potential cycle (i.e. a set C

k

is

defined):

1. Build a process model M from Ω with the BJT 4G

algorithm.

2. Build the set Ck = {C

k

i

} of the sets C

k

i

of classes

without order with the equation 5

3. ∀C

k

i

∈ Ck do

• Remove the relations R(C

i

,C

j

, [τ

−

i j

, τ

+

i j

]) of M

where C

i

∈ C

k

i

or C

j

∈ C

k

i

.

• Generate all the pathes P = {P

k

} with P

k

=

{R(C

i

,C

i+1

, [τ

−

ii+1

, τ

+

ii+1

])} where C

i

∈ C

k

i

and

C

i+1

∈ C

k

i

• Insert the relations of the pathes P in M.

To avoid the adding of a priori knowledge about the

process or the programs, the algorithm 4 computes

all the paths linking the classes in C

k

(cf. model of

Figure 1 with the classes C and D). It is clear that if

Card(C

k

) = n, there is n! possible paths. But it is a

simple way to put the emphasis on potential cycles.

3.5 Modeling a Large Scale Process

The algorithm 5 aims at modeling a large scale man-

ufacturing process. It simply uses the four algorithms

provided in the preceding subsections. Given a set

of sequences Ω = {ω

i

}

i={1,...,n}

and a sequence align-

ment SA(Ω), the algorithm 5 finds a process model M

with the BJT 4G algorithm:

1. Rewrite the sequences of Ω with the algorithm 1.

2. Rewrite the sequences of Ω with the algorithm 2

using information from SA(Ω).

3. Produce the sets Ω

k

of subsequences ω

i

k

with the

algorithm 3.

4. ∀Ω

k

do

• Build a process model M

k

of the phase k with

the algorithm 4.

5. M =

S

M

k

ICEIS 2010 - 12th International Conference on Enterprise Information Systems

134

Applied to the sequences of the Table 1, this al-

gorithm provides the model of the Figure 1. This al-

gorithm has also been used to model the wafer manu-

facturing process of the Rousset (France) plant of the

STMicroelectronics company.

4 APPLICATION

The aim of STMicroelectronics Company is to im-

prove the control of the wafer manufacturing pro-

cesses through the definition of human scale process

models and a better knowledge of the timed con-

straints between the different steps of manufacturing.

A ”wafer” is a silicon plate used for the construc-

tion of STMicroelectronics’ products. A wafer manu-

facturing process is a series of elementary treatments

called ”recipes” that are executed on machines called

”equipments”. An ”operation” is a particular serie

of recipes and each recipe is associated with differ-

ent equipments, those that are qualified for perfom-

ing the treatment. A complete series of operations is

called ”manufacturing route”. The STMicroelectron-

ics’ plant situated in the south of France, in Rousset,

counts with more than 10.000 different recipes, each

manufacturing route is composed of about 400 oper-

ations and there are actually more than 300 equip-

ments in the plant. The supervision system of the

wafer manufacturing process describes a manufac-

turing route with messages providing the name of a

recipe, the machine on which the recipe is executed,

the corresponding operation and the start and finish

times of the recipe.

For validating the approach presented in this

paper, a set Ω containing 5 sequences ω

i

, i =

{1, . . . , 5}, has been extracted from STMicroelectron-

ics’ databases. These sequences contain data from

real production of the Company. For the construc-

tion of this example we considered an extract of each

of these 5 sequences ω

i

, i = {1, . . . , 5}. Only the 200

first executed recipes were used.

The Algorithm 5 has been applied at the equip-

ment level so that a process model M represents a

manufacturing route by a serie of equipments. Even

though we worked with extracts of real routes, we

found a large volume of data. In the example con-

structed, 127 discret event classes have been found.

A class is defined with a singleton C

i

= {(φ

i

, i)}

where the constant i is a natural number in the inter-

val [1000, . . . , 1126]. Each of these classes represent

a particular equipment in STMicroelectronics’ plant.

We will illustrate the application of the approach

proposed in this paper showing how it works over two

subsequences of sequences ω

1

and ω

2

used for the

example construction. These two subsequences can

be seen in Figure 2.

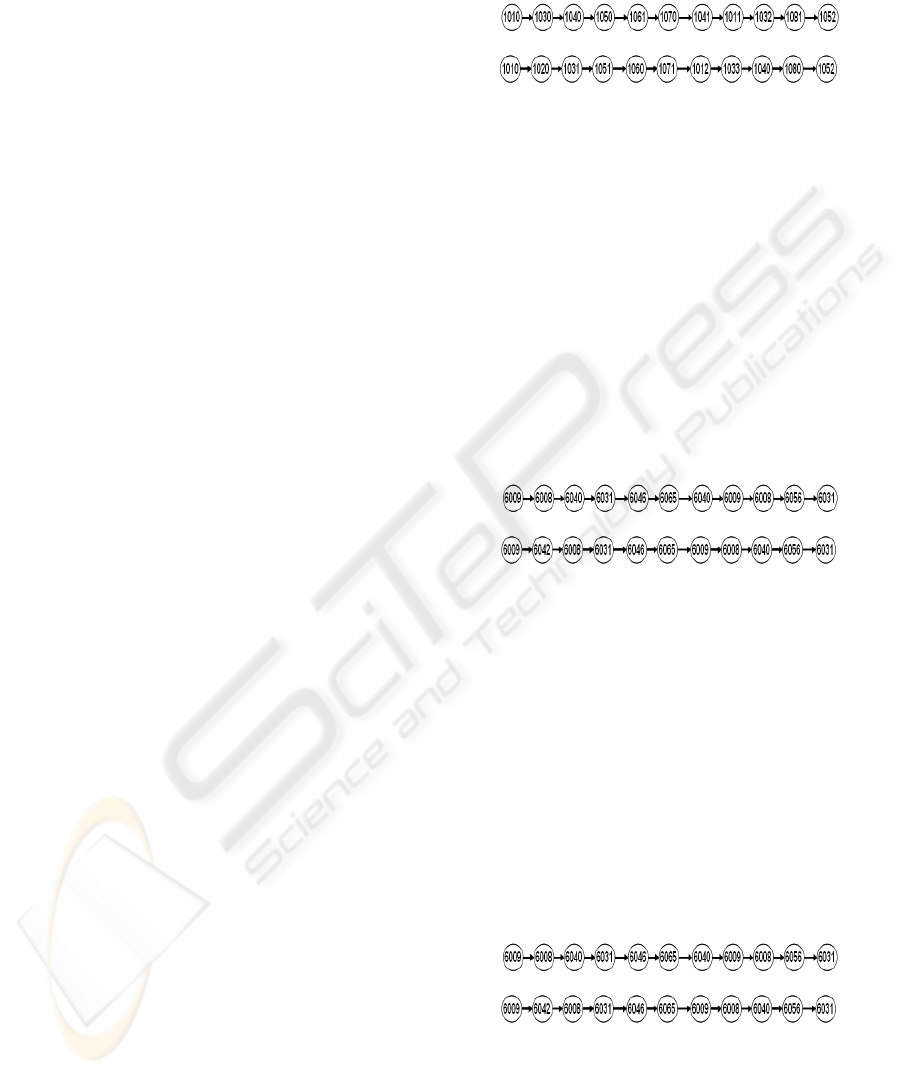

Figure 2: Subsequence of ω

1

(up) and subsequence of ω

2

(down).

During the example construction, 67 differ-

ent equivalent classes have been found. The

equivalent classes created using Algorithm

1 are singletons of the form C

j

= {(φ

j

, j)}

with j ∈ [6000, 6066]. Consider the equiva-

lent class C

6008

= {(φ

6008

, 6008)} contains the

discret event classes {C

1031

,C

1032

,C

1033

} and that

{C

1010

,C

1011

,C

1012

} ⊆ C

6009

, {C

1050

,C

1051

,C

1052

} ⊆

C

6031

, {C

1040

,C

1041

} ⊆ C

6040

, {C

1020

} ⊆ C

6042

,

{C

1060

,C

1061

} ⊆ C

6046

,{C

1080

,C

1081

} ⊆ C

6056

,

{C

1070

,C

1071

} ⊆ C

6065

. The algorithm 1 rewrites

the two subsequences of Figure 2 and produces the

subsequences of Figure 3.

Figure 3: Subsequences of ω

1

and ω

2

rewritten with Algo-

rithm 1.

Suppose now that we construct alignments be-

tween the two subsequences of ω

1

and ω

2

, using an

optimal algorithm (Needleman and Wunsch, 1970)

and two different similarity matrices S

1

and S

2

shown

in table 4. The main difference between these two

matrices is that S

2

penalizes the alignment of differ-

ent residues wherereas S

1

does not. A ’-1’ penalty is

used for the introduction of gaps.

The alignment corresponding to the two subse-

quences using the similarity matrix S

1

is shown in

Figure 4. The alignment for similarity matrix S

2

can

be seen in Figure 5.

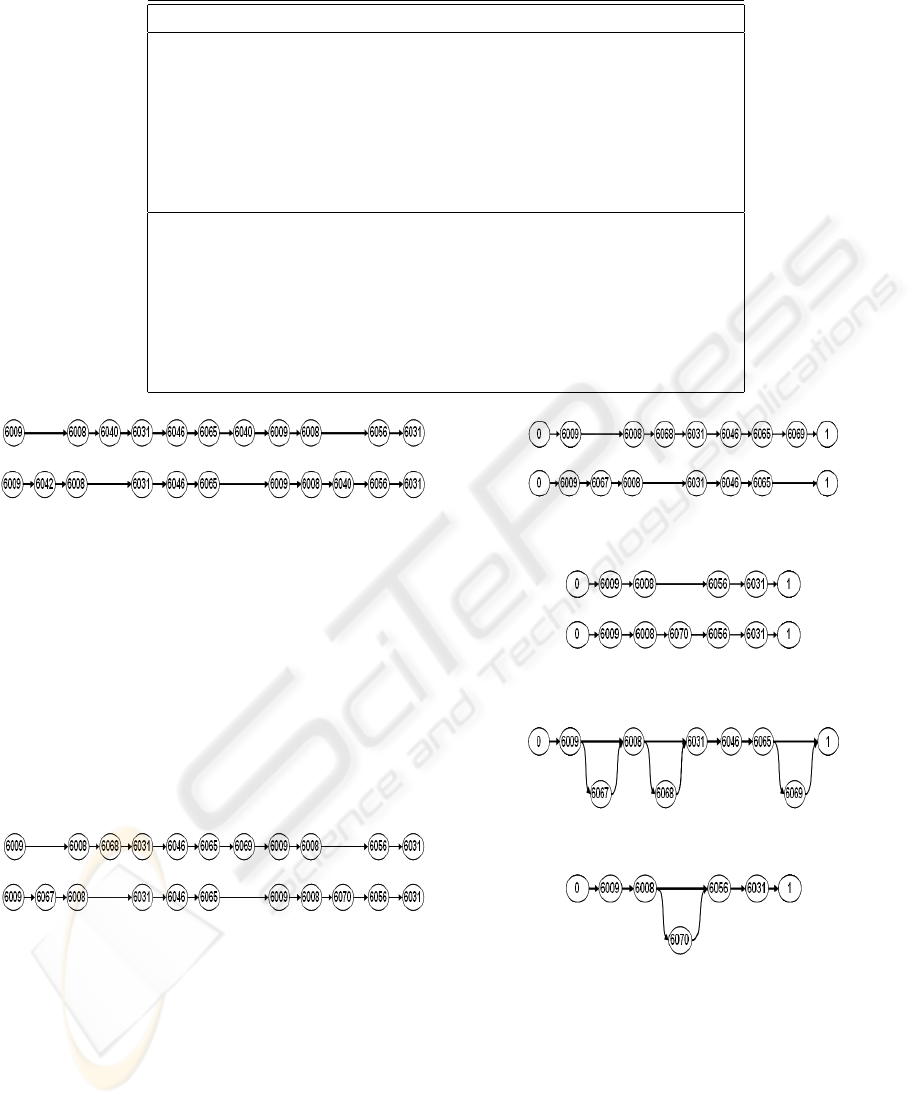

Figure 4: Subsequences of ω

1

and ω

2

aligned using simi-

larity matrix S

1

.

After analysing the alignment with STMicroelec-

tronics’ experts we could corroborate that only the

alignment constructed using matrix S

2

respects the se-

mantics of the sequences. This tiny example shows

MODELING LARGE SCALE MANUFACTURING PROCESS FROM TIMED DATA - Using the TOM4L Approach and

Sequence Alignment Information for Modeling STMicroelectronics' Production Processes

135

Table 4: Two possible similarity matrices for residues of subsequences of ω

1

and ω

2

considered.

Similarity matrices

S

1

=

− 6008 6009 6031 6040 6042 6046 6056 6065

6008 1 0 0 0 0 0 0 0

6009 0 1 0 0 0 0 0 0

6031 0 0 1 0 0 0 0 0

6040 0 0 0 1 0 0 0 0

6042 0 0 0 0 1 0 0 0

6046 0 0 0 0 0 1 0 0

6056 0 0 0 0 0 0 1 0

6065 0 0 0 0 0 0 0 1

S

2

=

− 6008 6009 6031 6040 6042 6046 6056 6065

6008 1 −1 −1 −1 −1 −1 −1 −1

6009 −1 1 −1 −1 −1 −1 −1 −1

6031 −1 −1 1 −1 −1 −1 −1 −1

6040 −1 −1 −1 1 −1 −1 −1 −1

6042 −1 −1 −1 −1 1 −1 −1 −1

6046 −1 −1 −1 −1 −1 1 −1 −1

6056 −1 −1 −1 −1 −1 −1 1 −1

6065 −1 −1 −1 −1 −1 −1 −1 1

Figure 5: Subsequences of ω

1

and ω

2

aligned using simi-

larity matrix S

2

.

the importance of choosing the right matrix to calcu-

late the alignment between all sequences considered.

An error in this step will introduce a problem that will

be carried over the following steps. Working with a

wrong sequence alignment will probably conduce to

errors when cutting sequences in process phases.

After applying Algorithm 2 for renaming classes

according to the alignment shown in Figure 5, the sub-

sequences of ω

1

and ω

2

are rewritten as it is shown in

Figure 6.

Figure 6: Subsequences of ω

1

and ω

2

rewritten using Algo-

rithm 2.

Algorithm 3 finds two process phases (i and i +

1) for the subsequence considered of ω

1

and for the

subsequence considered of ω

2

. Process phase i can

be seen in Figure 7 and process phase i + 1 is shown

in Figure 8.

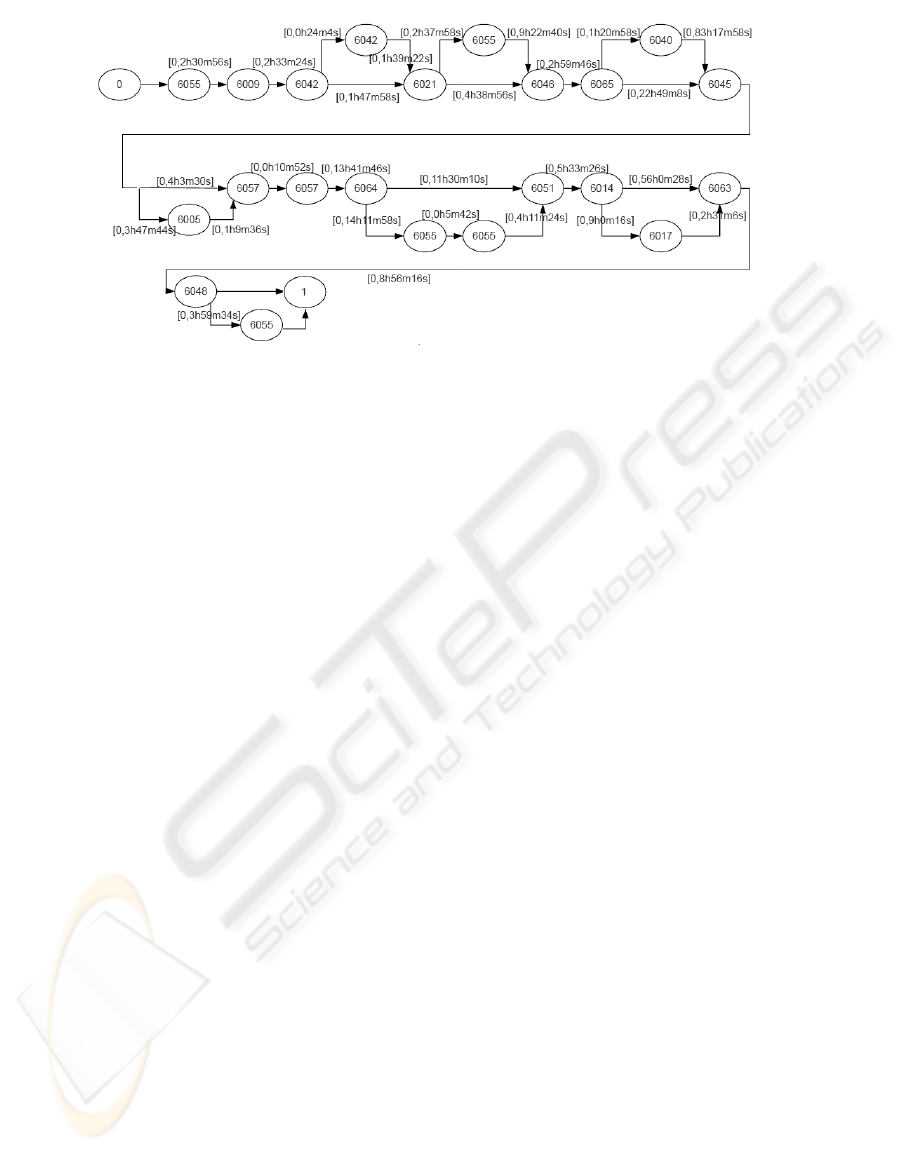

Using Algorithm 4 over the phases found, the cor-

responding models were constructed. Following the

two subsequences used for illustrating the approach,

we construct the models shown in Figures 9 and 10.

During the construction of the hole example

Figure 7: ω

i

1

(up) and ω

i

2

(down).

Figure 8: ω

i+1

1

(up) and ω

i+1

2

(down).

Figure 9: Model for phase i obtained from ω

i

1

and ω

i

2

.

Figure 10: Model for phase i + 1 obtained from ω

i+1

1

and

ω

i+1

2

.

model, 19 process phases were found. The resulting

model contains a total of 302 nodes.

In Figure 11 the resulting model constructed for

the 5th phase found is shown. The volume of data in

this small example is large even though we worked

with extracts of manufacturing routes. The model ob-

tained using this method is, however, simple and easy

to understand. The resulting model has already been

ICEIS 2010 - 12th International Conference on Enterprise Information Systems

136

Figure 11: Phase 5 of the model.

validated by STMicroelectronics’ experts.

The next step is to build a model of for com-

plete sequences and for bigger sets (more than 5 se-

quences). Afterwards, it would be valuable to con-

struct models for other levels of granularity (level of

operations or recipe level are some options).

5 CONCLUSIONS

This paper presents the TOM4L Approach for mod-

eling manufacturing processes from timed data con-

tained in a supervision system database. One of the

interesting features of this approach is the notion of

discrete event class. This notion is used to define a

process phase concept and discrete event classes of

equivalence that are required for large scale manu-

facturing processes. The definition of these concepts

leads to a global algorithm that has been applied to

modeling STMicroelectronics’ (Rousset) manufactur-

ing processes. This concrete application shows the

operational flavor of the extensions of the TOM4L

Approach. The importance of calculating a simi-

larity matrix that corresponds to sequence semantics

has also been shown in the applicative section. The

construction of these models will be a valuable tool

for STMicroelectronics to control production and to

alarm experts when the real activity of the Company

does not follow their theoretical definitions.

6 CURRENT WORKS

Current works are devoted to find an analogy of the

work presented in (Gauthier et al., 2008), works done

on the social science field. Our idea is to find a way

to calculate the similarity values between different

events classes in any kind of sequence, without in-

troducing experts knowledge about their contents.

REFERENCES

Agrawal, R., Gunopulos, D., and Leymann, F. (1998). Min-

ing process models from workflow logs. In Sixth In-

ternational Conference on Extending Database Tech-

nology, pages 469–483.

Benayadi, N., Le Goc, M., and Bouch

´

e, P. (2008). Using the

stochastic approach framework to model large scale

manufacturing processes. Proceedings of the 3rd In-

ternational Conference on Software and Data Tech-

nologies (ICSoft 2008).

Cook, E. J. and Wolf, A. L. (1998). Discovering models

of software processes from event-based data. ACM

Transactions on Software Engineering and Methodol-

ogy, 7:215–249.

Cook, E. J. and Wolf, A. L. (2004). Event-based detec-

tion of concurrency. In Proceedings of the 6th ACM

SIGSOFT international symposium on Foundations of

software engineering, volume 53, pages 35–45.

Gauthier, J. A., Widmer, E. D., Bucher, P., and Notredame,

C. (2008). How much does it cost? optimization of

costs in sequence analysis of social science data. So-

ciological Methods and Research.

Ghallab, M. (1996). On chronicles: Representation, on-line

recognition and learning. Proc. Principles of Knowl-

edge Representation and Reasoning, Aiello, Doyle

and Shapiro (Eds.) Morgan-Kauffman, pages 597–

606.

Le Goc, M. (2006). Notion d’observation pour le diagnostic

des processus dynamiques: Application

`

a Sachem et

`

a la d

´

ecouverte de connaissances temporelles. Hdr,

Facult

´

e des Sciences et Techniques de Saint J

´

er

ˆ

ome.

Le Goc, M., Bouch

´

e, P., and Giambiasi, N. (2005). Stochas-

tic modeling of continuous time discrete event se-

MODELING LARGE SCALE MANUFACTURING PROCESS FROM TIMED DATA - Using the TOM4L Approach and

Sequence Alignment Information for Modeling STMicroelectronics' Production Processes

137

quence for diagnosis. 16th International Workshop on

Principles of Diagnosis (DX’05) , California, USA.

Needleman, S. B. and Wunsch, C. D. (1970). A general

method applicable to the search of similarities in the

amino acid sequence of two proteins. J. Mol. Biol.,

48:443–453.

Notredame, C., Higgins, D. G., and Heringa, J. (2000). T-

coffee: A novel method for fast and accurate multiple

sequence alignment. J. Mol. Biol., 302:205–217.

Pinter, S. and Golani, M. (2004). Discovering workflow

models from activities’ lifespans. In Special issue:

Process/workflow mining, volume 53, pages 283–296.

Schimm, G. (2004). Mining exact models of concurrent

workflows. In Computers in Industry, volume 53(3),

pages 265–281.

Smith, T. F. and Waterman, M. S. (1981). Identification

of common molecular subsequences. J. Mol. Biol.,

147:195–197.

Thompson, J. D., Higgins, D. G., and Gibson, T. J. (1994).

Clustal w: improving the sensitivity of progres-

sive multiple sequence alignment through sequence

weighting, position-specific gap penalties and weight

matrix choice. Nucleic Acid Research, 22:4673–4680.

van der Aalst, W., Weijters, T., and Maruster, L. (2004).

Workflow mining: Discovering process models from

event logs. In IEEE Transactions on Knowledge and

Data Engineering, volume 16, pages 1128–1142.

van der Aalst, W. M. P. and Weijters, A. J. M. M. (2004).

Process mining. Special issue of Computers in Indus-

try, 53:231–244.

Weijters, A. and van der Aalst, W. (2003). Rediscovering

workflow models from event-based data using little

thumb. In Integrated Computer-Aided Engineering,

volume 10(2), pages 151–162.

ICEIS 2010 - 12th International Conference on Enterprise Information Systems

138