A GREEN DECISION SUPPORT SYSTEM FOR INTEGRATED

ASSEMBLY AND DISASSEMBLY SEQUENCE PLANNING

USING A PSO APPROACH

Yuan-Jye Tseng, Fang-Yu Yu and Feng-Yi Huang

Department of Industrial Engineering and Management, Yuan Ze University

135 Yuan-Tung Road, Chung-Li, Taoyuan 320, Taiwan

Keywords: Decision Support System, Product Life Cycle Management, Green Product Life Cycle, Assembly Sequence

Planning, Disassembly Sequence Planning, Particle Swarm Optimization.

Abstract: A green decision support system is presented to integrate assembly and disassembly sequence planning and

to evaluate the two costs in one integrated model. In a green product life cycle, it is important to determine

how a product can be disassembled before the product is planned to be assembled. For an assembled

product, an assembly sequence planning model is required for assembling the product at the start, whereas a

disassembly sequence planning model is needed for disassembling the product at the end. In typical

assembly and disassembly sequence planning approaches, the two sequences and costs are independently

planned and evaluated. In this research, a new integrated model is presented to concurrently generate and

evaluate the assembly and disassembly sequences. First, graph-based models are presented for representing

feasible assembly sequences and disassembly sequences. Next, a particle swarm optimization (PSO)

method with a new encoding scheme is developed. In the new PSO encoding scheme, a particle is

represented by a position matrix defining an assembly sequence and a disassembly sequence. The assembly

and disassembly sequences can be simultaneously planned with an objective of minimizing the total of

assembly costs and disassembly costs. The test results show that the presented method is feasible and

efficient for solving the integrated assembly and disassembly sequence planning problem. An example

product is implemented and illustrated in this paper.

1 INTRODUCTION

In a complete product life cycle of an assembled

product, both an assembly sequence and a

disassembly sequence are required. An assembly

sequence is required to locate and fix the

components in an ordered sequence to construct the

product at the start of the product life cycle. An

assembly sequence can be defined as an ordered

sequence of components and assembly operations

required to produce the final product. The purpose of

assembly sequence planning is to arrange the

assembly sequences based on the assembly

constraints and cost objectives.

On the other hand, a disassembly sequence is

required to disconnect the components of the

product at the end of the product life cycle. A

disassembly sequence can be defined as an ordered

sequence of components and disassembly operations

with which the product can be decomposed into

separated modules or components. The purpose of

disassembly sequence planning to arrange the

disassembly sequences based on the disassembly

constraints and cost objectives.

In a green product life cycle, it is essential to

plan how a product can be disassembled, reused, or

recycled, before the product is actually assembled

and produced. In a green product life cycle, although

the disassembly operations occur at the end, it is

important to plan in advance at the start. Therefore, a

green decision support system is required in a green

product life cycle management system to integrate

assembly sequence planning and disassembly

sequence planning.

In the traditional concept of sequential product

life cycle activities, the assembly sequence planning

and the disassembly sequence planning are

considered as two independent tasks. As a result, the

cost factors in the assembly sequence planning

model may sometimes contradict the cost factors in

444

Tseng Y., Yu F. and Huang F. (2010).

A GREEN DECISION SUPPORT SYSTEM FOR INTEGRATED ASSEMBLY AND DISASSEMBLY SEQUENCE PLANNING USING A PSO APPROACH

.

In Proceedings of the 5th International Conference on Software and Data Technologies, pages 444-449

DOI: 10.5220/0003005504440449

Copyright

c

SciTePress

the disassembly sequence planning model, or vice

versa. Therefore, a good assembly sequence for

constructing a product may result in adding more

costs in the corresponding disassembly sequence. In

this situation, if a product is assembled with an

assembly sequence with a low cost, it may cost more

to disassemble the product. Therefore, the assembly

and disassembly sequences must be concurrently

planned with an integrated model.

In this research, a green decision system is

proposed. The assembly and disassembly sequences

can be analyzed and evaluated with an integrated

planning model. A new PSO encoding scheme is

developed by defining the position of a particle

using a position matrix. The position matrix of a

particle defines an assembly sequence and a

disassembly sequence. In this way, the assembly

sequence and disassembly sequence can be

simultaneously planned by optimizing the position

matrix of a particle. The major contributions lie in

the new concept of integrated assembly and

disassembly sequence planning model and the new

PSO encoding and solution scheme to optimize the

two costs.

In this paper, Section 2 presents a literature

review Section 3 presents the graph-based

representation models for representing the assembly

and disassembly sequences. Section 4 presents the

PSO method for finding the solutions. Section 5

discusses the test results with an example. Finally,

section 6 concludes this study.

2 LITERATURE REVIEW

In the related research in assembly planning, it can

be summarized that assembly planning can be

performed in three stages: (1) assembly modelling

and representation, (2) assembly sequence

generation, and (3) assembly evaluation and

optimization. A recent review can be found in

Abdullah et al. (2003). The previous research in

assembly planning can be classified into three

categories. The first category uses rules or

knowledge bases to perform generation of different

assembly sequences. The second category presents

automatic generation of feasible assembly

sequences using graph representation forms

including the research presented in de Mello and

Sanderson (1991), Lin and Chang (1993), and Choi

et al. (1998). The third category focuses on

assembly analysis and evaluation for searching the

better or the optimal assembly sequence. The

research in this class includes Laperriere and

ElMaraghy (1996), Gottipolu and Ghosh (1997),

and Chen et al. (2004).

The recent research by Su (2007) introduced a

geometric constraint analysis method to generate

assembly precedence relations and evaluate feasible

assembly sequences. Dong et al. (2007) presented a

connection-semantics-based assembly tree hierarchy

to analyze geometric and non-geometric

information.

In the related research in disassembly sequence

planning, a review has been presented by Lambert

(2003). The concept of disassembly precedence

matrix has been applied by Huang and Huang

(2002) and Gungor and Gupta (2001) to evaluate

precedence relationships between components and

to generate disassembly sequences. Torre et al.

(2003) presented disassembly sequence planning

based on precedence relations among components,

sub-assemblies, and product. Kongar and Gupta

(2006) presented a disassembly sequence planning

method using GA.

The PSO has been successfully applied to many

continuous and discrete optimizations (Kennedy and

Eberhart, 1997). Banks et al. (2008) reviewed and

summarized the related PSO research in the areas of

hybridization, combinatorial problems, multiple

objectives and constrained optimization areas.

In this research, a green decision support system

for a complete life cycle management by integrating

assembly and disassembly planning is presented. A

PSO method is developed for finding the solutions

with an objective of minimizing the cost functions.

3 REPRESENTATION MODELS

Two graph-based models are presented to represent

the integrated assembly and disassembly sequences.

(1) Assembly precedence diagram (APD),

(2) Disassembly precedence diagram (DPD).

An assembly precedence diagram (APD) is a

directed graph showing the precedence of the

components and the associated assembly operations.

In this research, the concept of APD is applied to

represent the spatial connectivity relationship and

precedence between two components. The concept is

expanded for use in disassembly planning by

defining the disassembly precedence diagram (DPD).

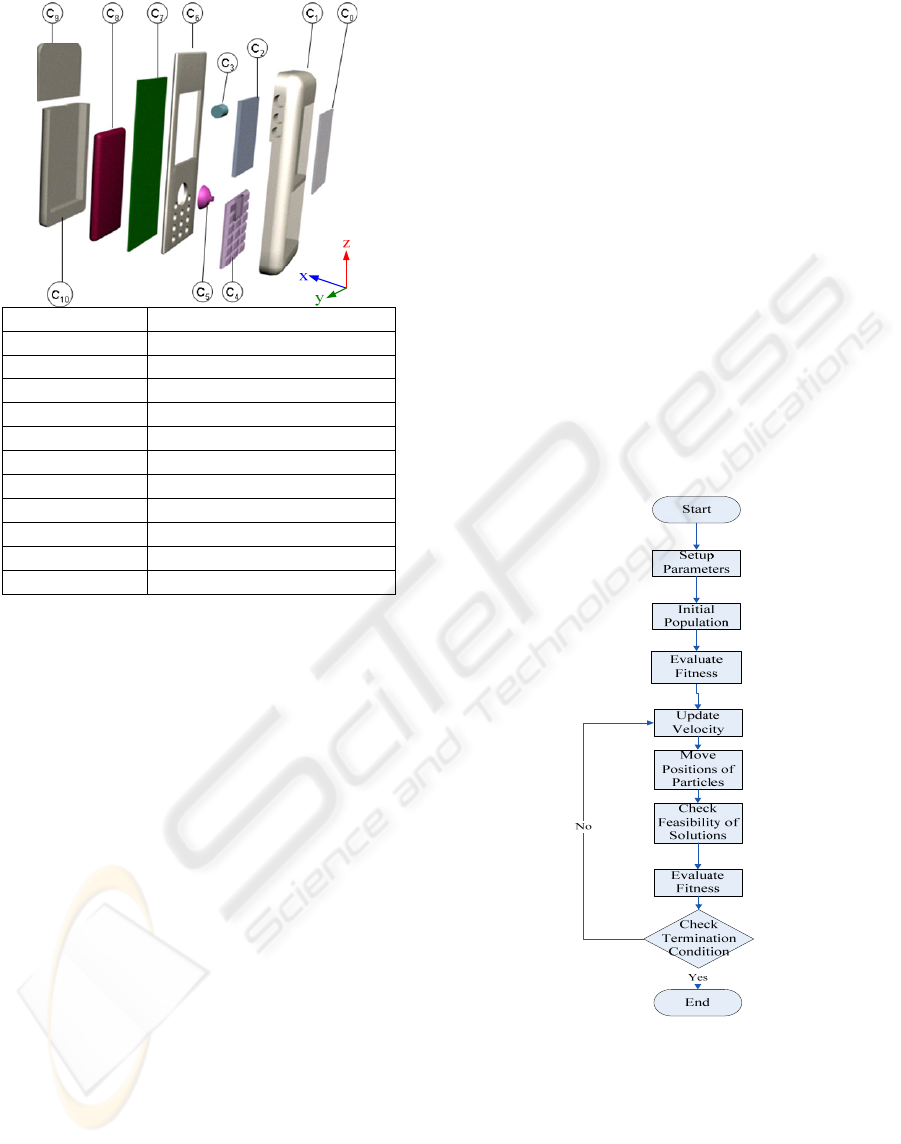

An example product A is shown in Figure 1. The

APD and DPD of the product A are shown in Figure

2.

A GREEN DECISION SUPPORT SYSTEM FOR INTEGRATED ASSEMBLY AND DISASSEMBLY SEQUENCE

PLANNING USING A PSO APPROACH

445

Component Name

0 Screen cover plate

1 Top case

2 LCD panel

3 Side button

4 Keyboard

5 Front button

6 Frame

7 Printed circuit board

8 Battery

9 Bottom case

10 Battery case

Figure 1: Illustration of the example product A.

Two new matrices forms, assembly precedence

matrix (APM) and disassembly precedence matrix

(DPM), are developed for integrated assembly

planning and disassembly planning. The two matrix

models are shown as follows.

APM =

nnnn

ij

n

ni

i

i

njjj

aaa

a

aa

aaa

p

p

p

ppp

21

2221

12111

2

1

21

(1)

where p

i

and p

j

are components, and n is the number

of components, a value of a

ij

= 0 represents that

there is no precedence between two the components

p

i

and p

j

, a value of a

ij

= 1 indicates that component

p

j

must be assembled before component p

i

.

DPM =

nnnn

ij

n

ni

i

i

njjj

ddd

d

dd

ddd

p

p

p

ppp

21

2221

12111

2

1

21

(2)

where p

i

and p

j

are components, and n is the number

of components, a value of d

ij

= 0 represents that

there is no precedence between two components p

i

and p

j

, a value of d

ij

= 1 indicates that component p

j

must be disassembled before component p

i

.

4 SOLUTION USING PARTICLE

SWARM OPTIMIZATION (PSO)

The overall flow of the PSO method is illustrated in

Figure 2. The PSO algorithm is an evolutionary

computation method introduced by Kennedy and

Eberhard (1997). In PSO, each particle moves

around in the multi-dimensional space with a

position and a velocity. The velocity and position

are constantly updated by the particle’s own

experience and the experience of the whole swarm.

Given a problem, a particle can be encoded to

represent a solution. Each solution, called a particle,

flies in the search space towards the optimal

position.

Figure 2: The overall flowchart of the PSO method.

In a general form, a particle is defined by its

position and velocity. The position of a particle i in

the D-dimension search space can be represented as

X

i

=[x

i1

, x

i2

, …, x

id

, …, x

iD

]. The velocity of the

particle i in the D-dimension search space can be

represented as V

i

=[v

i1

, v

i2

, …, v

id

, …, v

iD

]. Each

particle has its own best position P

i

=[p

i1

, p

i2

, …, p

id

,

…, p

iD

] representing the particle’s personal best

ICSOFT 2010 - 5th International Conference on Software and Data Technologies

446

objective (pbest) at time t. The global best particle is

denoted as p

g

and the best position of the entire

swarm (gbest) is denoted as P

g

=[p

g1

, p

g2

, …, p

gd

, …,

p

gD

] at tie t. To search for the optimal solution, each

particle adjusts its velocity according to the velocity

updating equation and position updating equation.

idgdidid

old

idi

new

id

xprcxprcvwv

2211

,

(3)

where d =1, …, D, i =1, …, E (number of particles),

new

id

v

: the new velocity of i in the current iteration t,

old

id

v

: the velocity of i in the previous iteration (t - 1),

c

1

and c

2

: constants called acceleration coefficients,

w

i

: the inertia weight,

r

1

and r

2

: two independent random numbers with a

uniform distribution [0, 1],

p

id

: the best position of each individual particle i,

p

gd

: the best position of the entire swarm.

new

id

old

id

new

id

vxx

,

(4)

where

new

id

x is the new position in the current

iteration t,

old

id

x is in the previous iteration (t - 1).

4.1 Cost Function

A cost function by integrating the assembly costs

and disassembly costs is formulated and used as an

objective function. The cost items are described as

follows.

(1) Assembly and disassembly operation cost (AOC

and DOC).

(2) Assembly and disassembly instability cost (AIC

and DIC).

(3) Assembly and disassembly directional

accessibility cost (ADC and DDC).

(4) Assembly and disassembly tool setup cost (ATC

and DTC).

(5) Assembly and disassembly weight effect cost

(AWC and DWC).

The value of each of the cost functions is

measured on a consistent scale with a unit in dollars.

The total cost function (TC) is the sum of all the

operation cost functions and can be described using

the following equation:

TC = (AOC+AIC+ADC+ATC+AWC) +

(5)

(DOC+DIC+DDC+DTC+DWC)

4.2 Encoding

In the developed encoding scheme, a particle is

represented by a position matrix. A position matrix

presents an integrated assembly and a disassembly

sequence. The position of particle i, i = 1, …, E, is

represented by a position matrix, denoted as X

ijk

, j =

1, 2, and k = 1, …, N, where N is the number of

components.

The first row, where j = 1, represents an

assembly sequence. In the heuristic sequencing rule,

the values in the first row represent the ranked order

values of the N components in an assembly

sequence. The second row, where j = 2, represents a

disassembly sequence. In the heuristic sequencing

rule, the values in the second row represent the

ranked order values of the N components in an

assembly sequence.

X

ijk

=

11 12 13 1

21 22 23 2

n

n

x

xx x

x

xx x

,

(6)

where i = 1, …, E, j =1, 2, and , k =1, …, N.

In the heuristic rule for decoding an assembly

sequence, the values in the first row [X

11

, X

12

, …,

X

1n

] are sorted in an ascending order. The ranked

order values represent the ordered position of the

component in the assembly sequence. For example,

if the ranked order values of row 1 of (C

1

, C

2

, C

3

, C

4

,

C

5

) are [4.5 1.1 3.2 7.6 5.3], then the ordered

positions of (C

1

, C

2

, C

3

, C

4

, C

5

) are (third, first,

second, fifth, fourth). The assembly sequence is

decoded as (C

2

, C

3

, C

1

, C

5

, C

4

). The heuristic rule

for decoding a disassembly sequence can be

interpreted in the same way.

4.3 The PSO Method for

Integrated Assembly and

Disassembly Planning

The flowchart the PSO method is shown in Figure 3.

Step 1. Setup parameters.

(1) Set iteration t = 0.

(2) T

Number

: the iteration (generation) number.

(3) P

Size

: the number of particles.

Step 2. Initialize a population of particles i = 1, …,

E,with random positions and velocities.

(1) A particle i is defined by a multi-dimensional

position matrix of (2)*(N).

(2) The position of particle i is defined by X

ijk

.

(3) The velocity of particle i is defined by V

ijk

.

Step 3. Evaluate the fitness function.

(1) t = t + 1.

A GREEN DECISION SUPPORT SYSTEM FOR INTEGRATED ASSEMBLY AND DISASSEMBLY SEQUENCE

PLANNING USING A PSO APPROACH

447

(2) Fitness = TC.

Step 4. Update the velocity of each particle i.

idgdidid

old

idi

new

id

xprcxprcvwv

2211

,

new

id

v

is the new velocity in the current iteration t,

old

id

v is the velocity in the previous iteration (t-1),

Step 5. Move the position of each particle i.

new

id

old

id

new

id

vxx

,

where

new

id

x is the new position in the iteration t,

old

id

x is the position in the iteration (t - 1).

Step 6. Check the feasibility of the solution and the

number of iteration t.

(1) The precedence is checked by APM and

DPM.

(2) If (t

> T

Number

), then go to Step 7, else go to

Step 2.

Step 7. Decode the best particle position and

interpret the solution.

5 IMPLEMENTATION AND TEST

RESULTS

In the presented green decision support system, the

models were implemented and tested by developing

software on a personal computer. The example

product A is illustrated in Figure 1. There are 11

components, C

0

, C

1

, …, C

10

. The APD and DPD are

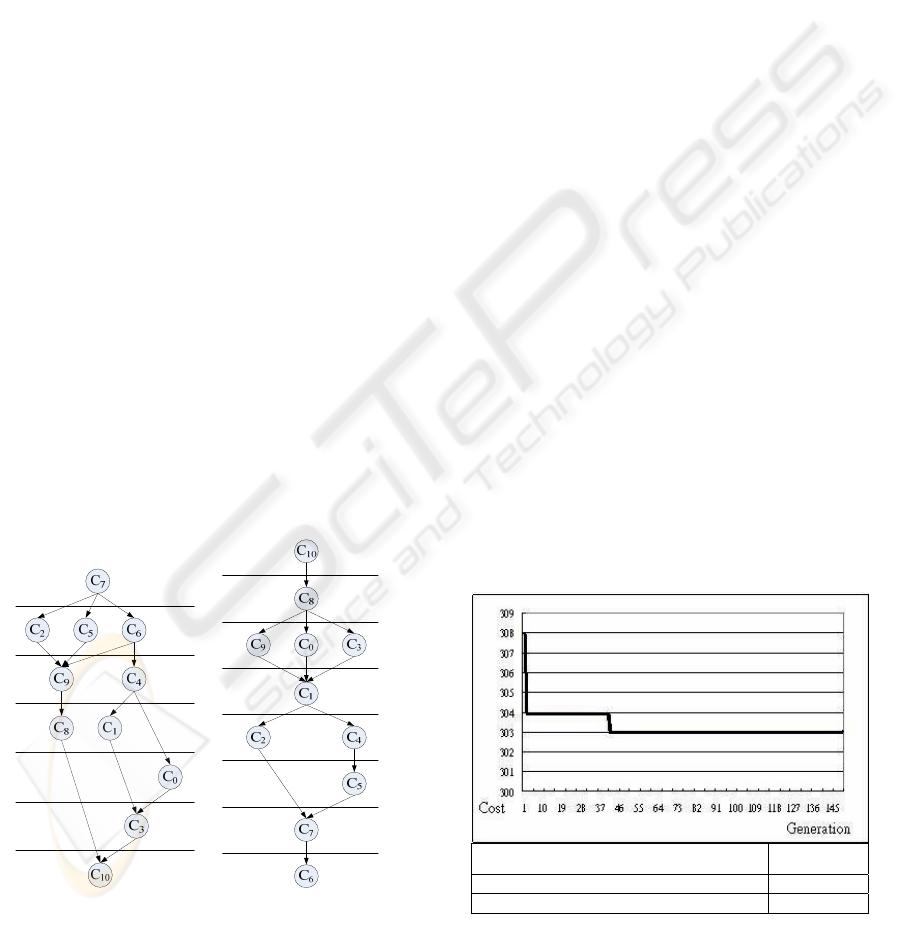

shown in Figure 3.

(a) APD (b) DPD

Figure 3: The APD and DPD of the example product A.

The APM and DPM are shown in the following

forms.

0123 45 6789 10

0

1

2

3

4

5

6

7

8

9

10

00001011000

00001011000

00000001000

11001011000

00000011000

00000001000

00000001000

00000000000

00100111010

00100111000

11111111110

CCCCCCCCCCC

C

C

C

C

C

APM C

C

C

C

C

C

0123 45 6789 10

0

1

2

3

4

5

6

7

8

9

10

00000000101

10010000111

11010000111

00000000101

11010000111

11011000111

11111101111

11111100111

00000000001

00000000101

00000000000

CCCCCCCCCCC

C

C

C

C

C

DPM C

C

C

C

C

C

Finally, the PSO method is applied for finding

the solutions. The test result is shown in Figure 4.

Figure 4 shows that the computation converges after

40 generations. After 150 generations, a solution

with the near optimized low cost of $302.968 can be

obtained. The numerical values of the position

matrix of the solution are shown in Figure 5. The

position matrix can be decoded to show the

integrated assembly and disassembly sequence.

Figure 6 describes the assembly and disassembly

sequence. The 11 components can be assembled and

disassembled with a near optimized low cost.

Cost (dollars) 302

Iterations (Generations) 150

Computer time (seconds) 1.281

Figure 4: The test result of the cost and generation number

of the PSO method.

ICSOFT 2010 - 5th International Conference on Software and Data Technologies

448

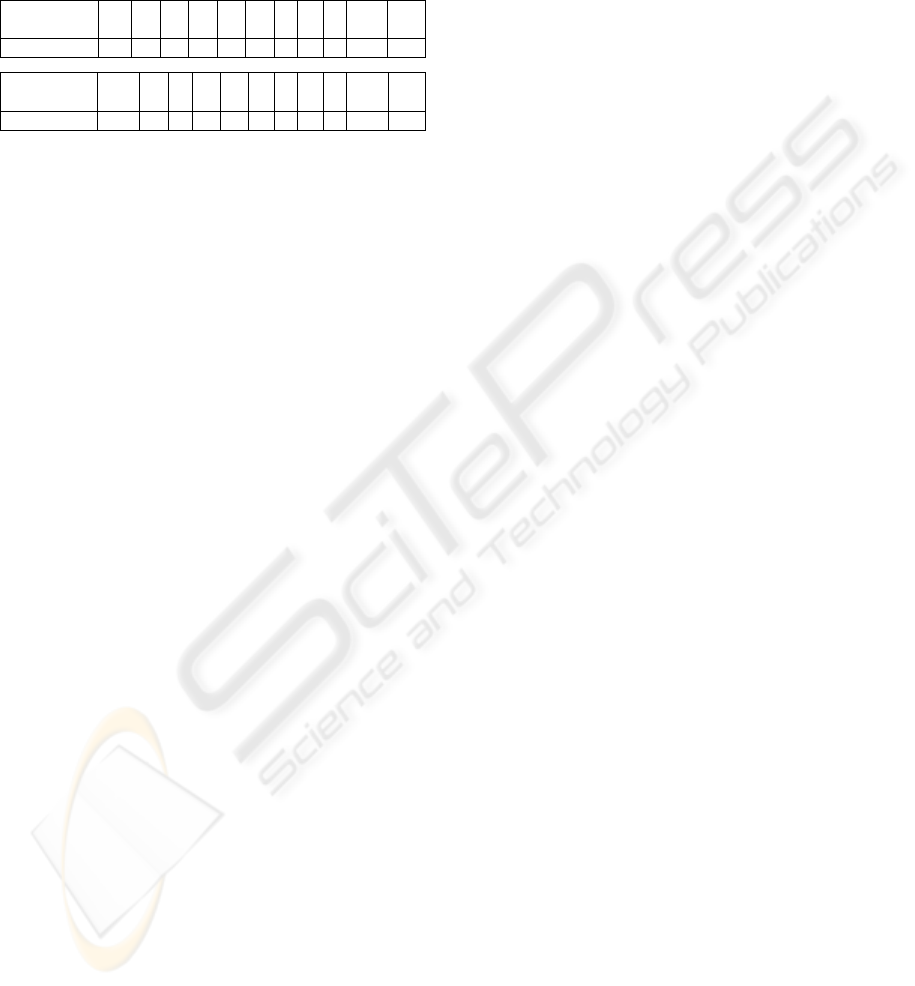

00 01 02 03 04 05 06 07 08 09 10

1.44 1.85 1.64 3.71 0.58 2.76 3.46 3.00 1.82 3.55 1.51

1.90 3.15 2.34 0.86 2.52 1.49 1.86 2.88 1.14 1.62 3.22

CCCCCCCCCCC

PM

Figure 5: The Numerical values of the position matrix of

the PSO solution.

Assembly

sequence

1 2 3 4 5 6 7 8 9 10 11

Component 7 2 5 6 4 1 0 9 8 3 10

Disassembly

sequence

1 2 3 4 5 6 7 8 9 10 11

Component 10 8 3 9 0 1 4 5 2 7 6

Figure 6: The final test results of the integrated assembly

and disassembly sequences.

It is observed that the combinatorial number of

sequences increases as the component number

grows. It can be concluded in general, the PSO

method can be considered an efficient and effective

method for find the solutions of integrated assembly

and disassembly sequences. Although the presented

methods can be useful for generating and evaluating

feasible sequences with good solutions, much

remains to be done to manage more complicated

products with a large number of components.

Further research on the complexity issues need to be

conducted.

6 CONCLUSIONS

In this research, a green decision support system is

presented to integrate assembly and disassembly

sequence planning models. First, graph-based

models are built by analyzing the spatial

relationships of the components and the operations.

Second, a solution method using a PSO approach is

applied to search for the good assembly sequence

and disassembly sequence. A new encoding scheme

of position matrix is developed for representing a

particle. A cost function by integrating the assembly

costs and disassembly costs is formulated. An

example product is illustrated in this paper. The test

results show that the PSO method converges within

a small number of generations with a near optimized

low cost. It can be generally concluded that the

developed model in the decision support system is

feasible and efficient for integrating assembly and

disassembly sequence planning. The green decision

support system is capable of finding complete

assembly and disassembly sequences with a near

optimized low cost. In further research, more

detailed assembly and disassembly cost functions

can be further explored. The solution method can be

refined to enhance the solution speed.

REFERENCES

Abdullah, T. A., Popplewell, K., and Page, C. J. (2003). A

review of the support tools for the process of assembly

method selection and assembly planning, International

Journal of Production Research, 41(11), pp. 2391–

2410.

Banks, A., Vincent, J., and Anyakoha, C. (2008). A review

of particle swarm optimization. Part II: hybridization,

combinatorial, multicriteria and constrained

optimization, and indicative applications, Natural

Computing, 7, 109-124.

Chen, R. S., Lu, K.-Y., and Tai, P. H. (2004). Optimizing

assembly planning through a three-stage integrated

approach, International Journal of Production

Economics, 88, pp. 243-256.

Gottipolu, R. B., and Ghosh, K. (1997). Representation

and selection of assembly sequences in computer-aided

assembly process planning, International Journal of

Production Research, 35(12), pp. 3447-3465.

Gungor, A., and Gupta, M. (2001). Disassembly sequence

plan generation using a branch-and-bound algorithm,

International Journal of Production Research, 39(1),

pp. 481-509.

Homem de Mello, L. S., and Sanderson, A. C. (1991).

Two criteria for the selection of assembly plans:

maximizing the flexibility of sequencing the assembly

tasks and minimizing the assembly time through

parallel execution of assembly tasks, IEEE Transactions

on Robotics and Automation, 7(5), pp. 626-633.

Huang, Y. M. and Huang, C. T. (2002). Disassembly

matrix for disassembly processed of products,

International Journal of Production Research, 40(2),

pp. 255- 273.

Kennedy, J., and Eberhart, R. C. (1997). A discrete binary

version of the particle swarm algorithm, Proceedings of

the International Conference on Systems, Man and

Cybernetics, Piscataway, NJ, 4104-4109.

Kongar, E., and Gupta, S. M. (2006). Disassembly

sequencing using genetic algorithm, International

Journal of Advanced Manufacturing Technology, 30,

pp. 497-506.

Lambert, A. J. D. (2003). Disassembly sequencing: a

survey, International Journal of Production Research,

41(16), pp. 3721- 3759.

Laperriere, L., and ElMaraghy, H. A. (1996). GAPP: A

Generative Assembly Process Planner, Journal of

Manufacturing Systems, 15(4), pp. 282-293.

Lin, A. C., and Chang, T. C. (1993). An integrated

approach to automated assembly planning for three-

dimensional mechanical products, International Journal

of Production Research, 31(5), pp. 1201-1227.

Torres, F., Puente, S. T., and Aracil, R. (2003).

Disassembly planning based on precedence relations

among assemblies, International Journal of Advanced

Manufacturing Technology, 21, pp. 317-327.

A GREEN DECISION SUPPORT SYSTEM FOR INTEGRATED ASSEMBLY AND DISASSEMBLY SEQUENCE

PLANNING USING A PSO APPROACH

449