RFID-assisted Product Delivery in Sustainable Supply

Chains: A Knowledge-based Approach

M. Ruta, F. Scioscia, E. Di Sciascio, F. Gramegna, S. Ieva and G. Loseto

Politecnico di Bari, via Re David 200, I-70125, Bari, Italy

Abstract. The paper proposes an integrated framework which uses knowledge

representation theory and languages to annotate relevant product information in

a semantically rich and unambiguous fashion so disclosing several added-value

services in multiple supply chain stages, without depending on a back-end in-

frastructure. EPCglobal RFID protocol standard has been extended and further

applied in an innovative supply chain model where production, packaging and

logistics have a reduced ecological impact. Particularly, on-product information

are leveraged in a more general Intelligent Transport System (ITS) framework

enabling advanced delivery scheduling and product tracking.

1 Introduction

Supply chains are articulated organisms involving organizations aimed at transferring

either products or services from a supplier to a customer. Nowadays, a successful supply

chain should more and more rely on an extended collaboration and integration among

component actors belonging to the productive and/or logistic network. Hence, infor-

mation has assumed an increasing strategic role in production, logistics and marketing.

From this standpoint, Radio-Frequency IDentification (RFID) is seen as a perspective

key technology. RFID enables radio interconnection of transponders –hosting informa-

tion associated to the goods to be identified– with interrogators able to extract carried

data. EPCglobal consortium

1

is one of the most active subjects involved in the mission

of a worldwide diffusion of RFID standards. Goods management during the delivery

stage of a supply chain is a complex process with criticisms tied to the packaging of

different and possibly incompatible products over multiple vehicles. Several systems

for product tracking which also enable integrity check have been proposed to improve

process quality in supply chains exploiting RFID technology [10]. Nevertheless, the

original identification mechanism –exclusively providing “true/false” replies– appears

as too restrictive for advanced applications. Furthermore, RFID-based technology usu-

ally relies on a stable and fixed back-end which makes every solution only partially

applicable to intrinsically volatile contexts such as the transportation and delivery ones.

On the contrary, given the increased storage availability (up to several kBs [1]) modern

transponders provide, RFID could provide further automation of actions and processes

1

EPCglobal, http://www.epcglobalinc.org

Ruta M., Scioscia F., Di Sciascio E., Gramegna F., Ieva S. and Loseto G.

RFID-assisted Product Delivery in Sustainable Supply Chains: A Knowledge-based Approach.

DOI: 10.5220/0003029100530065

In Proceedings of the 4th International Workshop on RFID Technology - Concepts, Applications, Challenges (ICEIS 2010), page

ISBN: 978-989-8425-11-9

Copyright

c

2010 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

related to item sorting and shipment, helping to prevent human errors and assist users

in decision making.

The paper presents a framework which exploits knowledge representation theoreti-

cal studies to annotate tagged objects which can so describe themselves in several sup-

ply chain stages, without depending on a back-end infrastructure and adhering to the

Ubiquitous Computing paradigm [22]. Canonical EPCglobal RFID identification has

been extended [16,7], providing semantic-based value-added services whose deploy-

ment and outcomes have been grounded in an advanced “green supply chain” setting.

Semantic Web languages such as OWL

2

and DIG [3] are used for building the lin-

guistic and semantic infrastructure underlying a networked and capillary exchange of

information among chain actors aimed at overcoming restrictions imposed by exist-

ing RFID solutions. Key features are: (i) to leverage a hybrid wireless communication

platform for enabling a distributed, backward compatible data management system; (ii)

to provide decision support exploiting semantic-based annotations accompanying and

describing goods aimed at optimizing the reliability and sustainability of the whole sup-

ply process. Case studies and simulations have evidenced usefulness and feasibility of

the framework. Distinctive features of this model enabled it to support several RFID-

based applications integrating Knowledge Representation techniques and technologies

to improve data management and business processes. The proposed approach has been

applied and tested in an innovative RFID-enabled supply chain model. On-product in-

formation have been exploited in a more general Intelligent Transport System (ITS)

framework enabling advanced context-aware delivery and tracking of fruits and veg-

etables. Integrity checks have been also introduced for process analyses, according to

the total quality management vision. Noteworthy is the capability to enable pollution-

aware dynamic path calculation, fully automated goods compatibility management in

delivery, truck fleet intelligent routing.

The remaining of the paper is structured as follows. In the next section relevant

related work is surveyed. Section 3 outlines the framework, explaining the followed

approach, Section 4 illustrates the system architecture thanks to a reference scenario

and finally conclusion and future work terminate the paper.

2 Related Work

This section surveysessential related work concerning RFIDtechnology in supply chain

management and ITS for building more efficient and sustainable goods delivery.

2.1 RFID

Benefits of RFID technology in supply chain management include timeliness, accu-

racy and completeness [9]. In latest years, they are becoming widely acknowledged not

only in distribution and warehousing, but also in the retail and post-sales domains. The

largest retail groups are mandating the adoption of interoperable technology solutions

2

OWL Web Ontology Language, version 2, W3C Recommendation 27 October 2009,

http://www.w3.org/TR/owl2-overview/

4

to commercial partners [18]. De et al. [6] first introduced a system for real time tracking

of items in a ubiquitous context. That work can be considered a reference for current

technological architectures for supply chain management, endorsed by worldwide spe-

cial interest groups such as the EPCglobal consortium [19].

Nevertheless, RFID has received relatively little attention as an information con-

veyor that can directly increase business process awareness and thus improve both

performance analysis and support to decision processes. Most current approaches for

run-time processing of RFID data in supply chains [21,2] manage only very basic in-

formation, namely raw (EPC, location, time) triples produced by RFID readers, where

EPC (Electronic Product Code) is the unique product identifier, while location and time

mark each RFID reading event.

In order to improve decision-making capabilities and information sharing across

boundaries of partner organizations, it is important to enable RFID-based run-time ob-

ject/group discovery facilities in decentralized and pervasive contexts. In each supply

chain node, it should be possible to process expressive requests –in terms of shared

and formal domain vocabularies– without depending on a central fixed information in-

frastructure. In our proposal, we adapt Semantic Web techniques and formalisms to

RFID-based supply chains. The basic goal is to fully characterize products equipped

with RFID tags by means of annotations in semantic languages such as RDF

3

, OWL

and its equivalent DIG. By means of formal ontologies, knowledge about a specific do-

main can be modeled, shared and exploited to derive new implied information from the

one stated within metadata associated to each resource.

Our proposal for semantic-enabled RFID [16] allows tags to contain a structured

and detailed description of product features, endowed with unambiguous and machine-

understandable semantics. Semantically annotated information is encoded in a compact

way by means of an algorithm aimed at efficient compression of XML-based ontolog-

ical languages [17]. Tag memory structure is extended in order to store the additional

information required for semantic-based object discovery. Additional TID (Tag Iden-

tification) memory space stores a 16-bit word for optional protocol features (currently

only the most significant bit is used to indicate whether the tag is semantic-enabled or

not, other bits are reserved for future uses) and a 32-bit Ontology Universally Unique

Identifier (OUUID) marking the ontology with respect to the description stored in the

tag is expressed. The encoded product annotation and contextual parameters (depend-

ing on the specific application) are stored, instead, within the User memory bank. This

is possible by adopting increasingly available models of passive EPCglobal UHF Class

1 Generation 2 RFID tags with several kilobits of available memory, such as TEGOTag

4

or Intelleflex IF602

5

. The air interface protocol for Gen 2 RFID systems is exploited but

neither new commands nor modifications to existing ones are introduced, thus keeping

full backward-compatibility with current RFID readers. In our simulations, we obtained

a reading rate of about 10 tags/s, which is comparable with products Gen 2 standard.

Further efficiency considerationsin terms of data compression, response time and mem-

3

RDF (Resource Description Framework) Primer, W3C Recommendation, 10 February 2004,

http://www.w3.org/TR/rdf-primer/

4

TEGOTag, http://www.tegoinc.com/products/products tegotag.php

5

Intelleflex Integrated RFID Tags, http://www.intelleflex.com/pdf/datasheet.c1g2ic.pdf

5

ory usage are reported in [17,7]. In this way goods auto-expose their description to

any RFID-enabled computing environment is reached. This enables decentralized ap-

proaches for context-aware application solutions, based on less expensive and more

manageable mobile ad-hoc networks. Furthermore, by combining standard and non-

standard inference services in Description Logics [4], several semantic-based match-

making schemes can be designed to meet goals and requirements of specific processes

and applications within a supply chain.

Few other proposals for semantic-based annotation of physical products can be

found in the literature. In [20] the adoption of the Part Libraries (PLIB) standard ISO

13584 was proposed and an XML Schema for data-on-tag storage was developed. Even

though the benefits of standardization are clear, the chosen standard provides only a

very rudimentary taxonomy, lacking explicit semantics for product characteristics. A

solution based on Semantic Web languages was proposed in [12] for ubiquitous com-

merce environments.In that case, however,RFID tags stored only a productcode, which

was used as a key to retrieve the corresponding RDF annotation from a central back-end

information system. This approach, inherited from traditional RFID applications, poses

major architectural and organizational challenges for information sharing in complex

multi-party supply chains. Conversely, our core idea is that, as physical products flow

among supply chain partners, ipso facto relevant high-level information about them is

conveyed [16] and can be exploited for meaningful business analysis at different lev-

els [7]. Recent studies [8, 23] highlighted factors in favor of data-on-tag approaches

w.r.t. traditional data-on-network ones. Mainly, fast data access is essential when the IT

infrastructure must meet real-time requirements, avoiding bottlenecks related to back-

end queries. Other benefits include: avoiding single points of failure; additional security

controls over information by consumer and companies; cost reductions in establishing

and maintaining network infrastructures.

2.2 Supply Chain and ITS

One of the most important factors in supply chain management is efficient control of

product delivery through vehicle routing. Vehicle routing problem (VRP) has always

been a fundamental problem in network optimization research and it is an important

objective of Intelligent Transport Systems (ITS). It was first introduced by Dantzig and

Ramser [5] and it can be defined as the problem of finding the fleet route planning that

serves as many jobs as possible at the least cost. Since that, many VRP types were

studied and classified based on additional problem constraints required by different

applications, and many algorithms and methods have been developed.

Ramachandran [15] developed an integer linear programming (ILP) model for the

design of routes that satisfy the load compatibility constraints for a fleet of vehicles,

transporting different types of goods. ILP and MILP (mixed integer linear program-

ming) are –along with Markov processes and genetic algorithms– the most widespread

approaches to solve this kind of optimization problems. Nevertheless, these methods

require that modeling and execution are performed in off-line mode. It is hard to adapt

the model to real-time applications and whenever constraints change.

In [11] an optimal solution was proposed for a VRP based on real-time environ-

ment information of perishable goods, exploiting continuous monitoring of RFID tags

6

located in the refrigerated cargo and of road traffic flow information. The approach,

however, requires large resources to compute the optimal solution. A further common

shortcoming of purely mathematical and statistical methods is that they cannot provide

explanation for outcomes, which is important to strengthen user trust in the system.

Mahr et al. [13] introduced a distributedarchitecture based on truck agents andorder

agents (containers) in a real world scenario constrained by uncertain job arrival time.

The system does not need any central monitoring and delegates decision making at local

level. Benefits of the distributed approach include better handling of local information

and quicker adaptive reaction to unpredictable order arrivals. They apply to our current

proposal as well.

Approaches at semantic-enhanced route planning have recently been attempted.

Niaraki et al. [14] introduced a technique which uses ontologies to annotate each road

segment with both user preferences and context point of view, in order to find cus-

tomized routes that best match specific needs. The solution was focused on personal

route planning, hence the model and the process are not easily adaptable to the require-

ments of supply chain VRP scenarios.

3 Framework and Approach

We propose an RFID-based delivery managementsystem extending classic supply chain

organization and shipment models using techniques and technologies for smart tagging

[16] and a semantic-based decision support [4]. Due to space constraints, the reader

is referred to cited works for an explanation of used Descritpion Logic languages and

algorithms. Product packages (tagged with RFID transponders conforming to the EPC-

global Class 1, Generation II UHF standard) and vehicles are accompanied by an OWL-

DL compressed annotation [17] which include relevant object properties/purposes and

vehicle features, according to a reference ontology. Product characteristics comprise

relevant item properties, delivery requirements (e.g., micro-climate and storage needs

or possible security measures) and potential incompatibility constrains referred to other

nearby products. Vehicle descriptions will contain general truck specifications along

with freight equipment information and the remaining load availability.

Starting from a single logistic unit where delivery of available goods has to be

planned, a semantic-based matchmaking process allows a smart allocation process aim-

ing at maximizing vehicle carrying capability also minimizing travel distance. In order

to take into account item-item and item-vehicle constraints in shipment schedule we

make use of a lightweight version of non-monotonicinferences[4], which automatically

detect the best load-truck associations by taking into account semantic compatibility de-

gree of goods among them and with vehicles. Such a system aims to reduce response

times in delivery decisions and improve efficiency of product allocation. Particularly,

the proposed approach can be effectively integrated into existing supply chain man-

agement systems extending already supported technology. It allows to solve on-truck

product allocation issues, ensuring products quality to destination (minimizing risks

due to incompatibility among closely delivered goods and reducing delivery times).

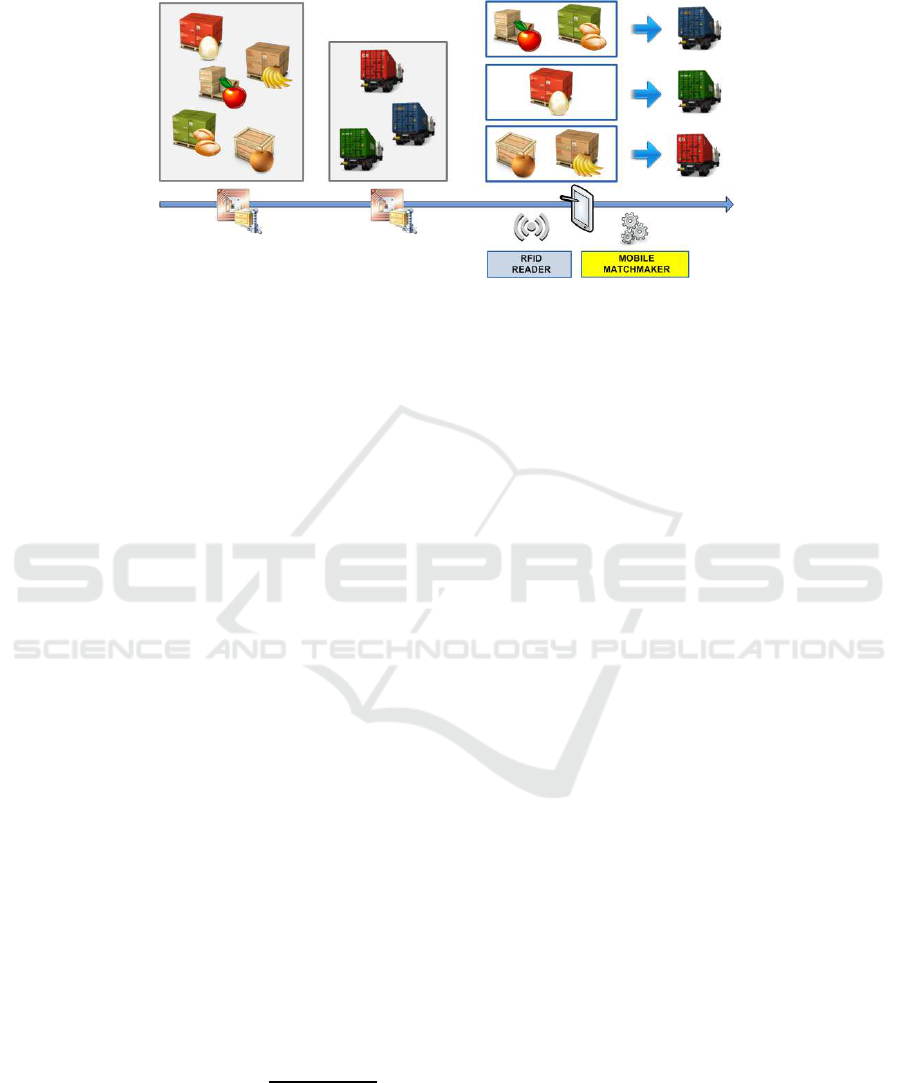

A system architecture schema is shown in Figure 1. Each tag is tracked within a

warehouse by either fixed RFID readers deployed in strategic locations or handheld

7

Fig.1. System Architecture.

ones. Truck informationcan be read when vehicles arrive at the stocking center, whereas

product tags are scanned individually before storage. Data extracted from RFID tags are

decompressed and sent to a mobile matchmaker which performs inference services.

Given a shipment order,the warehouse unit can automatically build a set of products

to be sent to each customer by means of a on-the-fly semantic matchmaking between

product information and truck features. The matchmaking process has to satisfy the

following goals.

– Products can be allocated only to trucks fulfilling their transportation requirements,

in terms of needed loading/unloading equipment, containers and internal environ-

mental conditions (e.g., temperature, humidity, lighting).

– Different products cannot travel together if they have negative mutual effects. A

typical case concerns climateric fruits (e.g., apples), which can influence ripening

of other fruits and vegetables.

– Product destinations must be taken into account, in order to avoid inefficient route

planning.

We suppose all goods which will compose a shipment are available in a single ware-

house and a delivery request has been addressed to retail endpoints, including different

items to be delivered with related destination and required quantity. A semantic-based

product allocation process is performed in the warehouse. Elements of the optimization

problem can be formalized as follows:

– The set of stored products P = {p

1

, p

2

, . . . p

n

}. In addition to semantically anno-

tated description referring to an ontology T , quantity q

i

and destination location l

i

are associated to each product, based on orders received from partner supply chain

nodes (e.g., retail stores).

– The set of available vehicles V = {v

1

, v

2

, . . . v

m

}. Besides the semantically anno-

tated description, the freight capacity is associated to each vehicle.

– l

0

is the warehouse location.

– A set T = {θ

1

, θ

2

, . . . θ

n

} is derived from P . For each product p

i

∈ P , the approx-

imated angle θ

i

of the line connecting the warehouse to the destination is computed

as θ

i

= ar ctan(

lat(l

i

)−lat(l

0

)

lon(l

i

)−lon(l

0

)

).

8

– A threshold semantic distance value 0 < s < 1 and a threshold angle θ

max

are de-

fined. The latter allows to avoid grouping products that have to be delivered toward

very different directions.

Algorithm 1: Greedy algorithm for product clustering.

Algorithm: clustering (hP, T, L, T i)

Require: L Description Logic, acyclic T , p

i

∈ P, i = 1, 2, . . . n concept expressions in L satisfiable in T .

Ensure: G = {G

1

, G

2

, . . . G

k

} set of product compatibility groups.

1: G := ∅

2: k := 0

3: while P 6= ∅ do

4: k := k + 1

5: pick p

i

∈ P

6: G

k

:= {p

i

}

7: C

k

:= p

i

8: for all p

j

∈ P, i 6= j do

9: δ

θ

= min

(p

q

∈G

k

)

(|θ

j

− θ

q

|)

10: if δ

θ

<= θ

max

AND (p

j

⊓ C

k

) is satisfiable in T AND

rankPotential (

h

L,p

j

,C

k

,T

i

)

rankPotential (

h

L,p

j

,⊤,T

i

)

<= s then

11: G

k

:= G

K

∩ {p

j

}

12: C

k

:=

d

p

q

∈G

k

(p

q

)

13: end if

14: end for

15: P := P \ G

k

16: G := G ∩ {G

k

}

17: end while

18: return G

The optimization strategy divides the problem into the following steps.

1. Product Clustering. For all available goods, the system verifies compatibility be-

tween product descriptions to cluster items in different compatibility groups. All prod-

ucts within each group present similar storage requirements and no compatibility con-

straints with other items are violated. The greedy bottom-up clustering Algorithm 1 is

exploited. Remarks follow.

– As a preliminary route optimization feature, a product cannot join a group if its

delivery direction is too different from all the other group elements. This check is

implemented by comparing the minimum angle distance δ

θ

to the threshold θ

max

.

– The algorithm exploits rankPotential [4] to discover semantic conflicts between

productcharacteristics/requirementsand to evaluate product similarity among mem-

bers of each cluster. It is important to note that the description of a group is seman-

tically expressed as the logical conjunction of individual item descriptions (which

is satisfiable by construction). Compatibility level is calculated by normalizing the

semantic distance between each new element p

j

and the current product group, as

returned by rankPotential , w.r.t. the maximum possible rankPotential value for p

j

,

which is rankPotential (hL, p

j

, ⊤, T i) and depends only on axioms in the reference

ontology. The interested reader is referred to [4] for details.

– It is easy to see that the algorithm requires O(n

2

) rankPotential calculations.

2. Cluster Allocation. Properties of product groups are subsequently matched with de-

scriptions of the delivery trucks, in order to find the most suitable vehicles for transport:

rankPotential inference service is exploited again to measure the semantic distance of

9

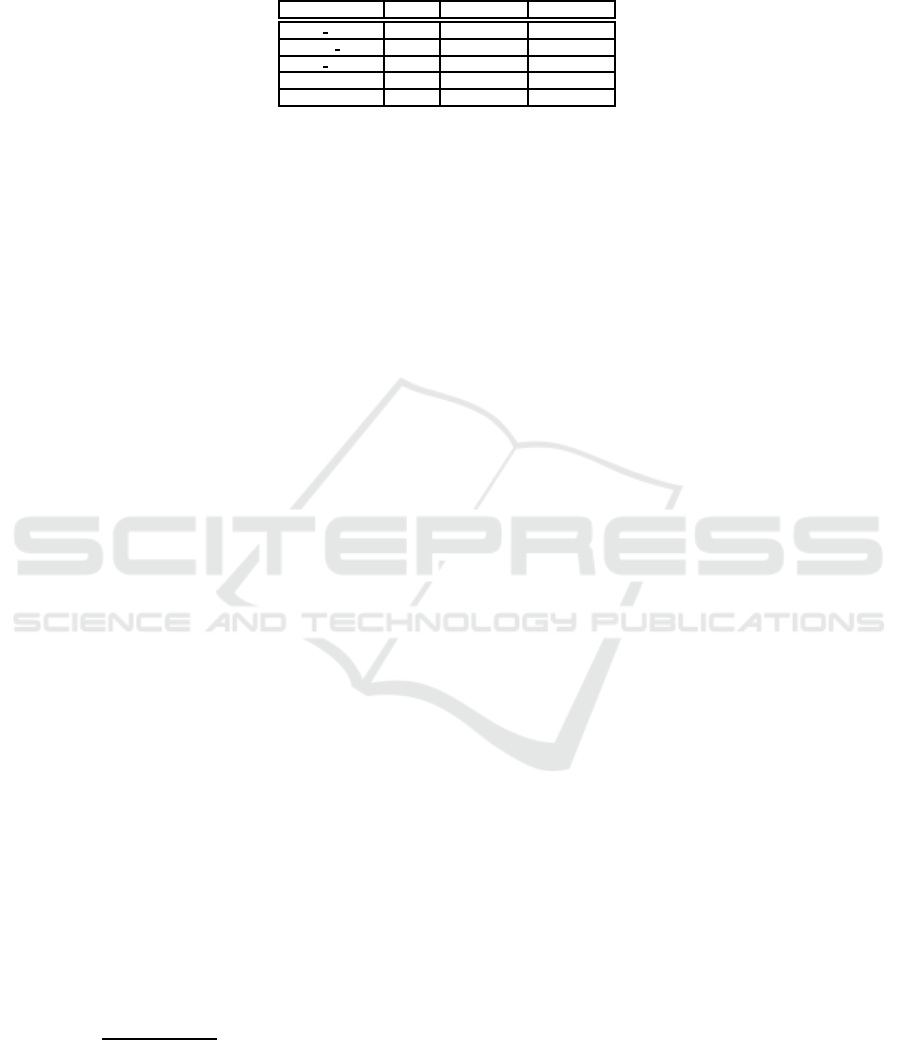

Table 1. Orders list.

Orders Delivery Distance (km) Quantity (kg)

Golden Delicious Barletta 53.75 500

Altamura Bread Foggia 117.06 300

Ostrich Egg Brindisi 105.30 200

Navelina Lecce 139.67 300

Cavendish Taranto 79.37 300

descriptions. At most nm rankPotential calculations are performed at this stage. The

product group with lowest score (i.e., the most compatible) is selected and inserted in

the suggested vehicle.

3. Storage Optimization. Now a refinement process can be performed to maximize ve-

hicle carrying capacity. If a vehicle is overfull (e.g., because the product group total

volume is larger than the vehicle storage space), the system splits the group and re-

allocates the exceeding portions to the vehicle with second best match score. Dually,

the most empty vehicles are gradually unloaded and products are reallocated to par-

tially full trucks, according to compatibility scores. Processing ends when all goods are

allocated and vehicles have minimum carrying space waste.

4. Route Planning. Detailed route planning is executed at the beginning of the deliv-

ery trip. Mobile device on board of a vehicle acts as a navigation system. Since the

previous step has grouped products with destinations along the same direction, in this

step the route is planned by means of a very simple algorithm: delivery point are sorted

according to increasing distance from the starting point. This approach resembles the

well-known SCAN algorithm for hard disk drive access scheduling: it is very quick and

simple to implement and, in our case, its approximation w.r.t. the optimal static route

improves when destinations span a narrower angle w.r.t. the source.

More sophisticated route planning algorithms can be plugged into the framework,

in order to minimize a cost estimation function that considers the overall economic

and environmental impact of route distance, trip duration, road type, traffic estima-

tion and truck load. Inference services upon semantically annotated information can be

leveraged also in this step. Using openly available and editable map data such as Open-

StreetMap

6

, maps can be customized with additional metadata about road segments and

points of interest, in order to better suit supply chain goals.

4 Case Study: Do not Compare Apples and Oranges!

In order to better explain the proposed framework and algorithms, let us consider a

practical example. A food cooperative in Apulia has adopted semantic-based supply

chain management process. Each production center ships goods to a distribution center,

located in Bari. From there products have to be delivered to shopping centers located

in different towns. The orders list is showed in Table 1. Figure 2 provides a visual

representation of the geographic area.

The problem is determining the most efficient method to ship the products so that

they are delivered without quality loss. As described previously, our proposed frame-

work uses mobile devices equipped with RFID reader. Warehouse operators, endowed

6

OpenStreetMap project, http://www.openstreetmap.org/

10

Fig.2. Map of supply chain nodes in our case study.

High Temperature ⊑ Controlled Temperature Medium Temperature ⊑ Controlled Temperature

Low

Temperature ⊑ Controlled Temperature Controlled Temperature ⊑ Temperature

Room

Temperature ⊑ Temperature High Humidity ⊑ Controlled Humidity

Medium

Humidity ⊑ Controlled Humidity Low Humidity ⊑ Controlled Humidity

Controlled

Humidity ⊑ Humidity Natural Humidity ⊑ Humidity

High

Oxygen ⊑ Controlled Oxygen Medium Oxygen ⊑ Controlled Oxygen

Low

Oxygen ⊑ Controlled Oxygen Controlled Oxygen ⊑ Oxygen

Natural

Oxygen ⊑ Oxygen Direct Lighting ⊑ Lighting Source

Indirect

Lighting ⊑ Lighting Source ISO Pallet Rack ⊑ Pallet Rack

Pallet

Rack ⊑ Stocking Equipment Plastic Shelving ⊑ Shelving

Shelving ⊑ Stocking

Equipment Stocking Equipment ⊑ Equipment

Hydraulic

Drill ⊑ Transport Equipment Transport Equipment ⊑ Equipment

High

Maturity ⊑ Maturity Low Maturity ⊑ Maturity

High

Fragrance ⊑ Fragrance Low Fragrance ⊑ Fragrance

disj(High

Oxygen, Medium Oxygen, Low Oxygen) disj(Controlled Temperature, Room Temperature)

disj(Controlled

Humidity, Natural Humidity) disj(Controlled Oxygen, Natural Oxygen)

disj(Direct

Lighting, Indirect Lighting) disj(Shelving, Pallet Rack)

disj(High

Maturity, Low Maturity) disj(High Fragrance, Low Fragrance)

Ripe

Product ⊑ ∃Has Climateric Maturation Degree ⊓ ∀Has Climateric Maturation Degree.High Maturity

Unripe

Product ⊑ ∃Has Climateric Maturation Degree ⊓ ∀Has Climateric Maturation Degree.Low Maturity

disj(High

Temperature, Medium Temperature, Low Temperature)

disj(High

Humidity, Medium Humidity, Low Humidity)

Fig.3. Axioms in the food transport ontology used in the case study

with RFID-enabled handheld devices, can locally manage the allocation problem and

they can also monitor automated system process behavior. For each tagged product,

the following information is retrieved via RFID: EPC code, unique identifier of the ref-

erence ontology [16], semantic-based annotation in compressed OWL-DL format and

delivery information, expressed with geographic coordinates.

In our supply chain case study, goods and vehicles are described according to an

example ontology devised for product management. Figure 3 shows a relevant excerpt

of it. Each RFID tag contains a semantic description w.r.t. the reference ontology,

summarizing both quality characteristics and storage and transport requirements.

Descriptions corresponding to Table 1 follow:

Golden Delicious: A pple ⊓ ∀ Has Colour.Y ellow ⊓ ∃ Has Colour ⊓

∀ Has Quality.Ordinary Quality ⊓ ∃ Has Quality ⊓

∀ Storage T emperature.Room T emperature ⊓ ∃ Storage T emperature ⊓

∀ Storage Humidity.M edium Humidity ⊓ ∃ Storage Humidity ⊓

∀ Storage Oxygen.N atural Oxygen ⊓ ∃ Storage O xygen ⊓ U nripe P roduct.

Altamura Bread: Bread ⊓ ∀ Has Quality.Ordinary Quality ⊓ ∃ Has Quality ⊓

∀ Storage T emperature.Room T emperature ⊓ ∃ Storage T emperature ⊓

11

∀ Storage Humidity.M edium Humidity ⊓ ∃ Storage Humidity ⊓

∀ Storage Oxygen.N atural Oxygen ⊓ ∃ Storage O xygen ⊓ Low F ragrance.

Ostrich Egg: Egg ⊓ ∀ Has Col our.W hite ⊓ ∃ Has Colour ⊓ ∀ Has Quality.T op Quality ⊓

∃ Has Quality ⊓ ∀ Storage T emperature.Low T emperature ⊓ ∃ Storage T emperature ⊓

∀ Storage Humidity.Low Humidity ⊓ ∃ Storage Humidity ⊓ ∀ Storage Oxygen.Low Oxygen ⊓

∃ Storage Oxygen ⊓ Low F ragrance.

Navelina: Orange ⊓ ∀ Has Co l our.Or a nge ⊓ ∃ Has Colour ⊓

∀ Storage T emperature.Room T emperature ⊓ ∃ Storage T emperature ⊓

∀ Storage Humidity.Medium Humidity ⊓ ∃ Storage Humidity ⊓ High F rag rance.

Cavendish: Banana ⊓ ∀ Has Co l our.Y ellow ⊓ ∃ Has Colour ⊓∀ Has Quality.Ordinary Quality ⊓

∃ Has Quality ⊓ ∀ Storage T emperature.Room T emperature ⊓ ∃ Storage T emperature ⊓

∀ Storage Humidity.M edium Humidity ⊓ ∃ Storage Humidity ⊓

∀ Storage Oxygen.N atural Oxygen ⊓ ∃ Storage O xygen ⊓ Ripe P roduct.

Warehouse operator uses the mobile logic-based matchmaker embedded in her de-

vice to identify groups of compatible products. As previously said, each cargo should

be composed of products that do not interfere with each other, causing a general quality

loss. In order to accomplish this, the system adopts a greedy approach, applying the

algorithm presented in the previous section. We better explain this process seeing how

it is applied to our example.

1. At the beginning, Golden Delicious is added to cargo

1

group.

2. Its semantic description is compatible with Altamura Bread, because all atomic

concepts, universal quantifiers and unqualified number restrictions on roles are

compatible. Furthermore, products are also compatible in terms of truck direction,

because the angle difference between delivery locations is about 10 degrees (with

a supposed threshold of 60 degrees). For this reason it is added into cargo

1

group.

3. Then Ostrich Egg is matched against cargo

1

: a semantic incompatibility is re-

turned, because some storage requirements are in conflict, e.g., storage temperature

is different.

4. Next, cargo

1

is semantically compatible with Navelina, but they are not compati-

ble w.r.t. truck direction, because the angle between destinations is more than 160

degrees. Finally, it is not compatible with Cavendish, because both are climacteric

and so they can travel in the same cargo only if they are in the same ripening stage,

but in this case apples are ripe while bananas are unripe.

If needed, the system can show inconsistencies to operator by means of the Concept

Contraction inference service offered by the reasoning engine [4]. Outcome explanation

is a very important feature and a unique advantage of approaches based on knowledge

representation.

The same process is repeated with remaining products to build other groups.

The system finally returns the following groups: cargo

1

= { Golden Delicious, Alta-

mura Bread} ; cargo

2

= {Ostrich Egg}; cargo

3

= {Navelina, Cavendish}.

Next phase consists of the allocation of each cargo on a compatible truck. The

RFID reader retrieves the semantic descriptions stored on tags associated with trucks

and begins a matchmaking process. For example, let us consider the following truck

descriptions in the warehouse:

12

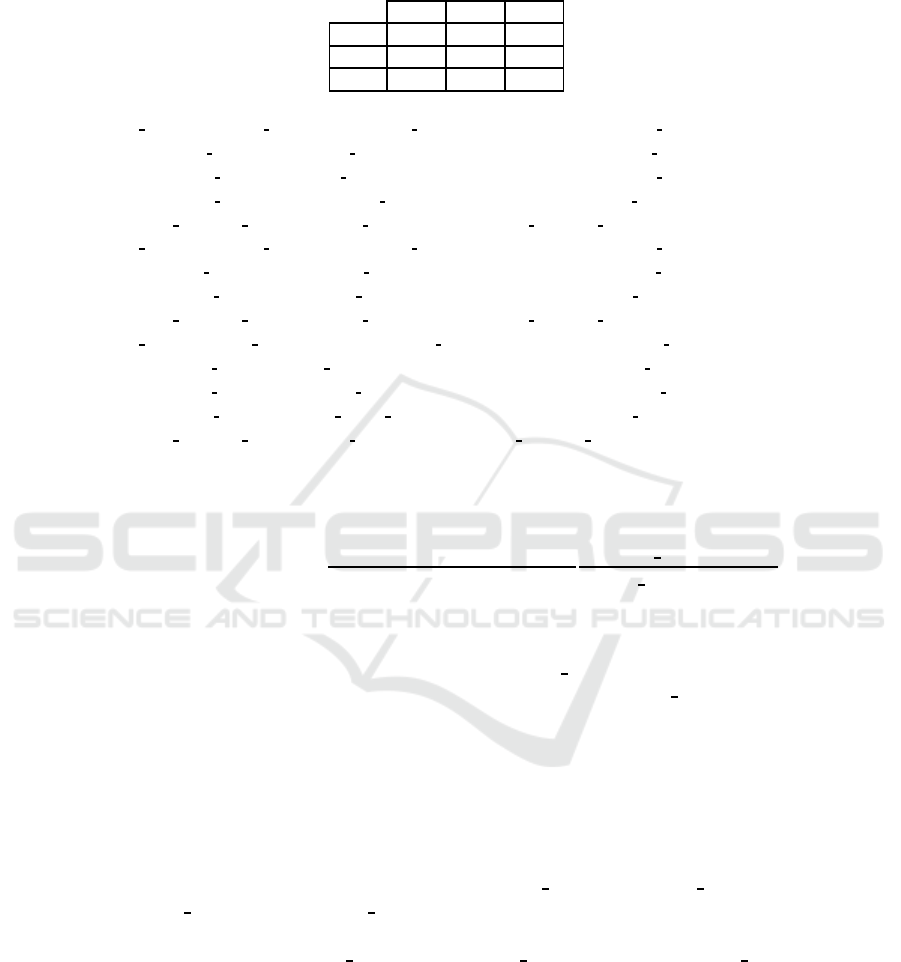

Table 2. Matchmaking results between cargoes and trucks.

cargo

1

cargo

2

cargo

3

truck

1

0.132 n.c. 0.284

truck

2

0.154 n.c. 0.324

truck

3

n.c 0.432 n.c

Truck 1: ∀ Storage T emperature.Room T emperature ⊓ ∃ Storage T emperature ⊓

∀ Storage Humidity.M edium Humidity ⊓ ∃ Storage Humidity ⊓

∀ Storage Oxygen.N atural Ox ygen ⊓ ∃ Storage Oxygen ⊓

∀ Storage Equipment.Hydraulic Drill ⊓ ∃Storage Equipment ⊓

∀ Storage Lighting Source.Indirect Lighting ⊓ ∃ Storage Lighting Source.

Truck 2: ∀ Storage T emperature.Room T emperature ⊓ ∃ Storage T emperature ⊓

∀ Stor a ge Humidity.Controlled Humidity ⊓ ∃ Storage Humidity ⊓

∀ Storage Equipment.P lastic Shelving ⊓ ∃Storage Equipment ⊓

∀ Storage Lighting Source.Indirect Lighting ⊓ ∃ Storage Lighting Source.

Truck 3: ∀ Storage T emperature.Controlled T emperature ⊓ ∃ Storage T emperature ⊓

∀ Storage Humidity.Low Humidity ⊓ ∃ Storage Humidity ⊓

∀ Storage Oxygen.Controlled Oxygen ⊓ ∃ Storage Oxygen ⊓

∀ Storage Equipment.ISO P allet Rack ⊓ ∃Storage Equipment ⊓

∀ Storage Lighting Source.Direct Lighting ⊓ ∃ Storage Lighting Source.

Only if a truck is compatible, for each cargo the semantic distance is evaluated,

exploiting the rankPotential algorithm. The results obtained are ranked using the utility

function:

Rank(cargo

i

, truck

i

) =

rankPotential (cargo

i

, truck

i

)

rankPotential (cargo

i

, ⊤)

res idual space(truck

i

)

total space(truck

i

)

where: rankPotential (cargo

i

, truck

i

) is the semantic distance from cargo

i

to truck

i

;

rankPotential (cargo

i

, ⊤) is the maximum semantic distance from cargo

i

, which

depends on axioms in the domain ontology; residual spa c e(tru ck

i

) is the avail-

able space in the truck

i

after the allocation of the cargo

i

and total space(truck

i

)

is the overall space in truck

i

. The pair with lowest score will be selected. In

this way each cargo will be allocated to the truck that better satisfies its trans-

port requirements and that maximizes the truck load. Table 2 shows the results

of the computation, in case that each truck has a maximum capacity of 1 ton.

Results denote that, for example, cargo

1

is not compatible with truck

3

, due to

storage requirements not fulfilled by the truck. Also in this case, an explana-

tion of the causes for incompatibility can be obtained exploiting the Concept

Contraction inference service (give up: ∀Storage Oxygen.N atural Oxygen ⊓

∀Stora ge T emperature.Room T emperature).

At the end of the matchmaking process the cargoes will be arranged on the trucks

as follows: truck

1

: {Golden Delicious, Altamura Bread}; truck

2

: {Ostrich Egg};

tru c k

3

: {Navelina, Cavendish}.

The mobile system now performs optimization of storage space on different trucks.

Referring to previous example, truck

2

results partially empty. In this case, the sys-

tem can rearrange products moving them in other vehicle after checking compatibility

13

with truck features and already stored product descriptions. A possible approach could

exploit rankPartial and Concept Contraction algorithms to establish contrasting char-

acteristics. In this way, weakly incompatible products can be delivered on the same

truck to minimize unused carrying space.

Finally, products are loaded and a delivery schedule is planned for each truck.

Using the simple algorithm outlined in the previoussection, vehicle routes are computed

as follows: truck

1

: (Barletta, Foggia); truck

2

: (Brindisi); truc k

3

: (Taranto, Lecce).

5 Conclusions

The paper presented a novel supply chain model where semantic-enhancements to

RFID allows information exchange among actors involved in various stages of the good

life cycle. Benefits deriving from the adoption of such an approach have been proved

with reference to the environmental sustainability of products delivery in a generic fruit

and vegetable market. An RFID-assisted ITS relies on tagged goods information to per-

form: (i) fully automated goods compatibility management in load composition, (ii)

pollution-aware routing, (iii) intelligent delivery. Further work will be performed to

extend and improve the proposed approach. Future developments include studying so-

lutions to security issues specific of data-on-tag RFID approaches, whereas the current

framework uses the simple security methods provided by EPCglobal standards.

Acknowledgements

The authors acknowledge partial support of Apulia Region Strategic Project PS 025 -

Processes and technologies supporting quasi-markets in logistics.

References

1. B. R. Ayoub Khan M., Manoj S. A Survey of RFID Tags. International Journal of Recent

Trends in Engineering, 1(4):68–71, 2009.

2. Y. Bai, F. Wang, P. Liu, C. Zaniolo, and S. Liu. RFID data processing with a data stream

query language. In Proceedings of the 23nd International Conference on Data Engineering,

ICDE, pages 1184–1193, 2007.

3. S. Bechhofer, R. M¨oller, and P. Crowther. The DIG Description Logic Interface. In Pro-

ceedings of the 16th International Workshop on Description Logics (DL’03), volume 81 of

CEUR Workshop Proceedings, Rome, Italy, September 2003.

4. S. Colucci, T. Di Noia, A. Pinto, A. Ragone, M. Ruta, and E. Tinelli. A non-monotonic

approach to semantic matchmaking and request refinement in e-marketplaces. International

Journal of Electronic Commerce, 12(2):127–154, 2007.

5. G. B. Dantzig and J. H. Ramser. The truck dispatching problem. Management Science,

6(1):80–91, 1959.

6. P. De, K. Basu, and S. Das. An ubiquitous architectural framework and protocol for object

tracking using RFID tags. In The First Annual International Conference on Mobile and Ubiq-

uitous Systems:Networking and Services (MOBIQUITOUS 2004), pages 174–182, August

2004.

14

7. R. De Virgilio, E. Di Sciascio, M. Ruta, F. Scioscia, and R. Torlone. Semantic-based RFID

Data Management. In D. Ranasinghe, Q. Sheng, and S. Zeadally, editors, Unique Radio

Innovation for the 21st Century: Building Scalable and Global RFID Networks. Springer,

2010. to appear.

8. T. Diekmann, A. Melski, and M. Schumann. Data-on-network vs. data-on-tag: Managing

data in complex rfid environments. In HICSS ’07: Proceedings of the 40th Annual Hawaii In-

ternational Conference on System Sciences, page 224a, Washington, DC, USA, 2007. IEEE

Computer Society.

9. M. Karkkainen. Increasing efficiency in the supply chain for short shelf life goods using

RFID tagging. International Journal of Retail & Distribution Management, 31(10):529–536,

2003.

10. F. Li. Impact of rfid technology on supply chain: A simulation approach. In Management

and Service Science, 2009. MASS ’09. International Conference on, pages 1 –4, sept. 2009.

11. F. Li and Y. Wei. A real-time vehicle routing system for rfid-tagged goods transportation. In

Service Operations and Logistics, and Informatics, 2008. IEEE/SOLI 2008. IEEE Interna-

tional Conference on, volume 2, pages 2892 –2897, oct. 2008.

12. W. Maass and A. Filler. Towards an infrastructure for semantically annotated physical prod-

ucts. Informatik, 94:544–549, 2006.

13. T. Mahr, J. Srour, M. M. de Weerdt, and R. Zuidwijk. Agent performance in vehicle routing

when the only thing certain is uncertainty. In Proceedings of the workshop on Agents in

Traffic and Transportation (ATT), 2008.

14. A. S. Niaraki and K. Kim. Ontology based personalized route planning system using a multi-

criteria decision making approach. Expert Systems with Applications, 36(2, Part 1):2250 –

2259, 2009.

15. P. Ramachandran. Vehicle routing problem with load compatibility constraints. In Industrial

Engineering and Engineering Management, 2009. IEEM 2009. IEEE International Confer-

ence on, pages 339 –343, dec. 2009.

16. M. Ruta, T. Di Noia, E. Di Sciascio, F. Scioscia, and G. Piscitelli. If objects could talk:

A novel resource discovery approach for pervasive environments. International Journal of

Internet and Protocol Technology (IJIPT), 2(3/4):199–217, 2007.

17. F. Scioscia and M. Ruta. Building a Semantic Web of Things: issues and perspectives in

information compression. In Semantic Web Information Management (SWIM’09). In Pro-

ceedings of the 3rd IEEE International Conference on Semantic Computing (ICSC 2009),

pages 589–594. IEEE Computer Society, 2009.

18. M. Tajima. Strategic value of RFID in supply chain management. Journal of Purchasing and

Supply Management, 13(4):261–273, 2007.

19. K. Traub, G. Allgair, H. Barthel, L. Bustein, J. Garrett, B. Hogan, B. Rodrigues, S. Sarma,

J. Schmidt, C. Schramek, R. Stewart, and K. Suen. EPCglobal Architecture Framework.

Technical report, EPCglobal, July 2005.

20. C. Tribowski, K. Spin, O. G¨unther, and O. Sielemann. Storing Data On Rfid Tags: A

Standards-Based Approach. In Proceedings of the 17th European Conference on Information

Systems (ECIS 2009), 2009.

21. F. Wang, S. Liu, P. Liu, and Y. Bai. Bridging physical and virtual worlds: complex event

processing for RFID data streams. Lecture Notes in Computer Science, 3896:588, 2006.

22. M. Weiser. The computer for the 21st century. SIGMOBILE Mob. Comput. Commun. Rev.,

3(3):3–11, 1999.

23. K. Werner, E. Grummt, S. Gro, and R. Ackermann. Data-on-tag: An approach to privacy

friendly usage of rfid technologies. In Proceedings of the 3rd European Workshop on RFID

Systems and Technologies (RFID SysTech ’07), Duisburg, Germany, June 2009.

15