NEURAL NETWORKS IN COMBUSTION SIMULATIONS

Lars Frank Große and Franz Joos

Power Engineering, Laboratory of Turbo Machinery, Helmut-Schmidt-University

University of the Federal Armed Forces Hamburg, Holstenhofweg 85, D-22043 Hamburg, Germany

Keywords: Computational Fluid Dynamics (CFD), Combustion simulation, Furnace, Finite-volume-model.

Abstract: The design process of commercially available combustion engines is often based on real experiments which

is expensive concerning to fuel consumption, men power and environmental pollution. It is possible to

replace complex experiments by computer simulations. The prediction of the velocity field, the mixing

process of fuel and oxidiser and the temperature field is a wide range of research subjects. In case of

turbulent flow simulations with combustion the chemical reactions and the coupling have to be calculated at

the same time. With regard to computer time the used chemical reaction mechanism has a big influence on

the performance of the whole simulation. Therefore optimisation procedures often improve the

representation of the chemistry. The suggestion made in this paper, is the use of artificial neuronal networks

for approximation of complex chemistry in turbulent combustion simulations.

1 INTRODUCTION

The prediction of minority species in the flow field

of a turbulent combustion simulation like CO- or

NO

x

-formations depend on the used reaction

mechanism. Often more complex chemical reaction

mechanism contain hundreds of reactions and fifty

or more species. Only optimised mechanisms

contain these species of interest and in general the

evaluation is computer time intensive. Further

information can be found in Große and Joos (2009).

Former studies by Blasco, Fueyo, Dopazo and

Ballester (1998) and Chen, Blasco, Fueyo and

Dopazo (2000) show the use of ANN for

representation of reduced chemical systems. Further

studies by Große and Joos (2009, 2010) show the

feasebility of the use of ANN for complex chemistry

representation.

2 COMPLEX CHEMISTRY

REPRESENTATION

A complex chemical reaction mechanism like the

Gas Research Institute Mechanism 3.0

(GRIMech3.0) which consists of 325 reactions with

53 species is optimised for methane combustion in a

wide pressure and temperature range. So the use of

the GriMech3.0 means to solve the ordinary

differential equation (ODE) system with 53

variables, which are the species, for each statistic

representation (particle) in the flow field. The

smallest eigenvalue of the Jacobian matrix of the

ODE system is fixing the integration step, which

means practically to integrate the system in smallest

steps until the solution is reached:

i

i

dy

r(y,T,p)

dt

.

(1)

In equation (1)

i

r

denotes the chemical reaction

rate of species i,

y

the mass fraction vector, T the

temperature and p the pressure. In general it is

computer time intensive to evaluate this system of

ODE for each species.

When the effects of turbulent flow are calculated

at the same time during a simulation process the

required CPU-time limits the evaluation of the stiff

ODE system to simple problems with less finite-

volume-elements in the model approximation.

3 TURBULENT

FLOW SIMULATION

WITH COMBUSTION

Turbulent flow is characterised by continuous

velocity fluctuations, the resulting fluctuations of

406

Große L. and Joos F..

NEURAL NETWORKS IN COMBUSTION SIMULATIONS.

DOI: 10.5220/0003073904060410

In Proceedings of the International Conference on Fuzzy Computation and 2nd International Conference on Neural Computation (ICNC-2010), pages

406-410

ISBN: 978-989-8425-32-4

Copyright

c

2010 SCITEPRESS (Science and Technology Publications, Lda.)

scalars lead to complex interactions between the

turbulent flow field and the chemical reactions.

Therefore deterministic approaches describe the

interaction with probability density functions (PDF)

as stated in Harder (2007).

Figure 1: Picture of the Flame (Sandia, 2003) with

description (added).

For this study a stochastically equivalent system

in a Lagrangian framework is used. A high number

of stochastic particles which is called stochastic

particle ensemble represents the real distribution of

scalars. The particles have the same initial

distribution as the physical scalar values and are

calculated in the flow field. For a piloted

methane/air flame (Barlow and Frank, 1998;

Barlow, Frank, Karpetis and Chen, 2005) the

calculation was performed by connecting a three

dimensional CFD solver with a PDF approach and

the use of the commercially available computer

program CHEMKIN for calculating the progress in

complex chemical reactions with GRIMech3.0.

A calculation using the PDF approach presented

in this work was conducted with 8 particles per

finite-volume-element. The whole model has 1000

elements. The model is a rotational symmetric slice

of the whole flame. Figure 1 depicts the flame

(Sandia, 2003). Because of CPU-Time reasons a

more detailed model with more volume-elements or

the increase of the stochastic particles is limited. 8

particles with 1000 elements require 8000

integrations of the ODE system per iteration step.

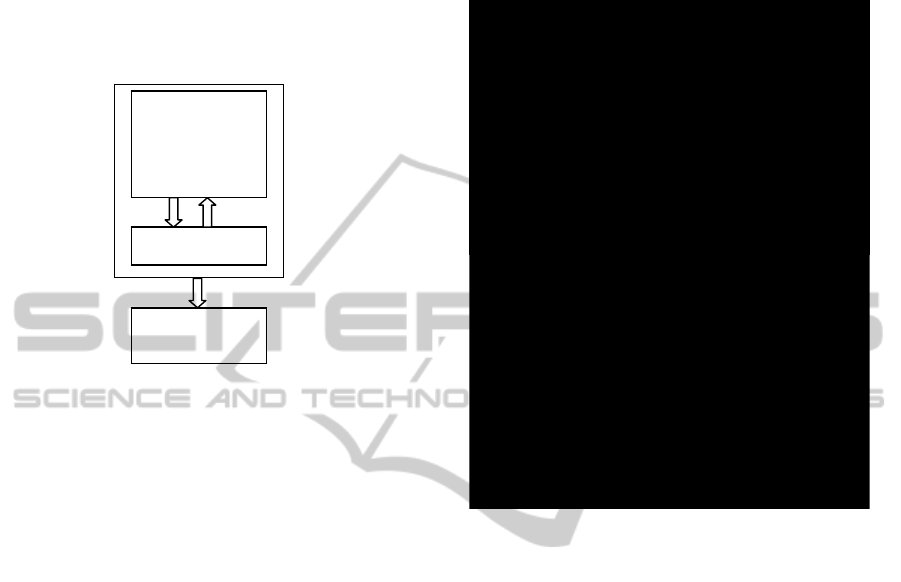

3.1 PDF CFD Simulation

The general approach for the calculation is shown in

figure 2.

The convergence in the probability distribution

of the particle is reached after 1700 iteration steps.

The input and output chemical states of the

stochastic particle ensemble were saved. So the

species mass concentrations in the flow field and

their change in the 53 dimensional state during the

simulation is known. A complete dataset of about

1.000.000 in and output samples in the form

(

y

(t),T(t);

y

(t+dt),T(t+dt)) where t is the absolute

time and dt the time of the reaction progress which

is calculated with the complex chemistry mechanism

is the basis for the training of the ANNs. A simple

chess-board cluster algorithm is used for clustering

the dataset in six dimensions. The data in each

cluster consists of the training base for one ANN.

Chemistry,

GRIMech3.0

Turbulent Flow

Simulation CFX

Finite-Volume

Model 1000

Elements

Solution (CPU-

time 168h

)

Chemistry

sam

p

les

Training

ANNs

Figure 2: Approach for the PDF CFD simulation.

168h of CPU-time is needed for the calculation

of the solution and the chemistry samples for the

whole finite-volume-model (CPU Q6850, 8 GB,

WIN XP64bit).

Former studies (Große und Joos, 2010) show that

the calculation with ANNs yields a good

approximation of the ODE system solution.

Furthermore the ANNs solution requires only 1/14

th

of the CPU time, which is about 12h for the 1000

finite-volume-element model. So several parameter

studies with ANNs are applicable during a full ODE

simulation. Moreover the possibility of more precise

calculations is given.

3.2 CFD Simulation with ANNs

The clustered dataset is used to train ANNs which

are able to reproduce the change in species mass

concentrations during the simulation. The ANNs are

simple feed-forward-nets with two hidden layers

with up to 50 neurons and six in- and output neurons

for four main species (CH

4

, CO

2

, H

2

O, O

2

), the

temperature and one important minority species

(CO). Because of complexity reduction only five of

the saved dataset of 53 species were analysed. The

stoichiometric global reaction of complete

methane/air combustion is given in equation (2).

pilot

air

air

flame

x- direction

r

-

direction

nozzle -

diameter d

NEURAL NETWORKS IN COMBUSTION SIMULATIONS

407

CH

4

+2(O

2

+3,76N

2

)CO

2

+2H

2

O+7,52N

2

. (2)

With the closure condition that sum of mass

fractions of the species has to be one, N

2

is the

closure condition species. A more detailed

combustion description includes hundreds of

reaction steps with several intermediate species like

the GRIMech3.0 with more than 50 species.

TrainedANNs

Turbulent Flow

Simulation CFX

Finite-Volume

Model 6500

Elements

Solution

(CPU‐time12h)

Figure 3: Approach for the PDF Simulation with ANNs.

For each ANN a bias neuron is set for the hidden

layers and for the output neurons. As learning

algorithm the Resilent-Backpropagation by Igel and

Husken (2003) with weight-backtracking and the

mean squared error was used.

The rerun of the simulation with ODE replaced

by 1500 ANNs (figure 3) show the ability of ANNs

for complex chemistry representation (Große and

Joos, 2010).

The reduction of CPU-time in comparison to the

ODE calculation makes it possible to simulate a high

resolution model of the flame with about 6500

finite-volume-elements and up to 26 stochastic

particles per element to describe the stochastic

particle ensemble. Precise simulation solutions allow

the comparison with measurements and are therefore

a tool for optimisation tasks.

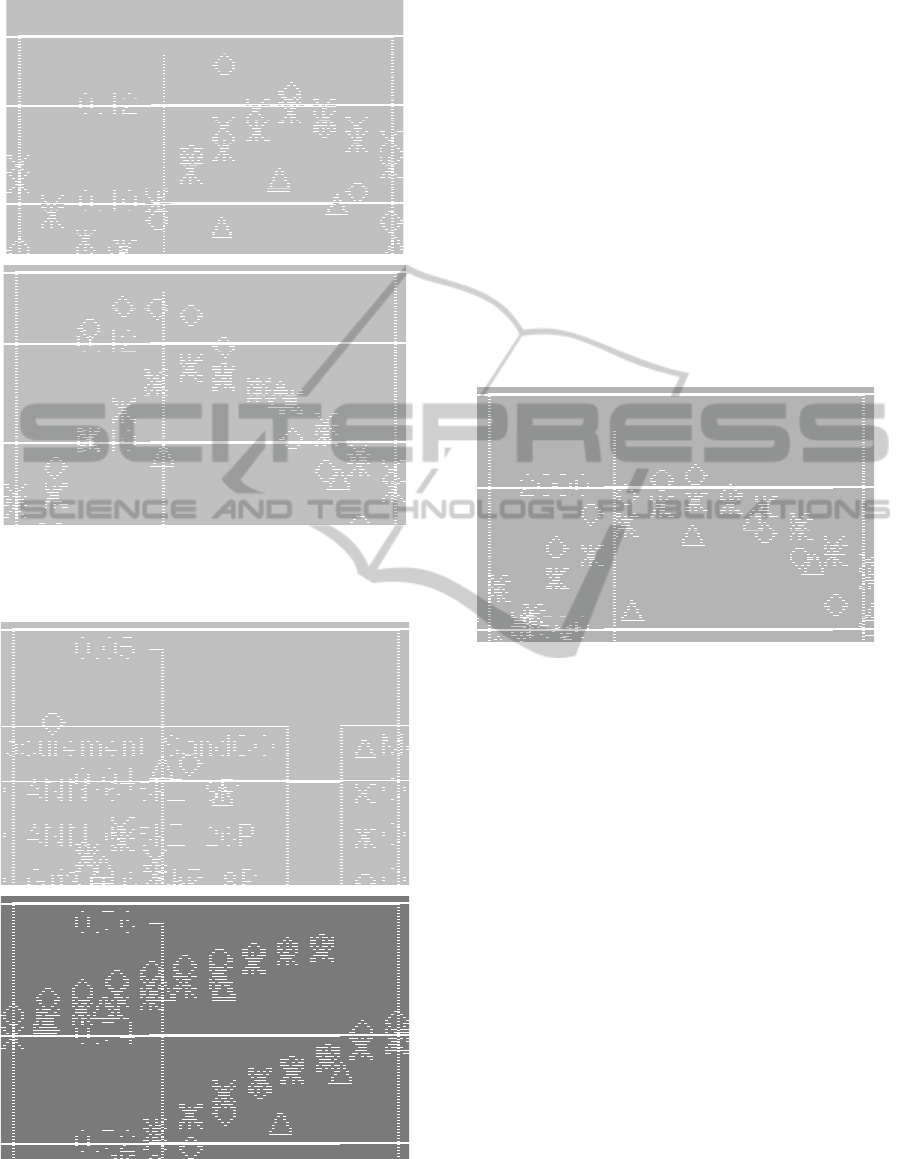

3.3 Results

The comparison of measurements and simulation

solutions of the calculation with ANNs and the ODE

system on the main axis (r=0mm, see figure 1) is

shown in figures 4-7, with d=7,2mm as nozzle

diameter. The high resolution finite-volume-model

of the flame with 6500 elements was used with

different numbers of particles (8 or 26) per element.

The configuration and the boundary conditions

of the flame and the scalar measurements are

adopted by (Barlow and Frank, 1998). The

calculation with the ODE system is used as

reference application but in general it is not

analysable because of a summarized calculation time

of 100 days as well as convergence problems during

the solution iterations.

Figure 4: Comparison of measurements, ANNs and ODE

system simulation solutions of the educts of the flame.

The educts in figure 4 show a good

approximation of the measurements. There is a small

downstream shift of methane and oxygen. The

maximum and minimum is within the range of the

measurements. The calculations with 8 (8P) and 26

(26P) particles for representation of the stochastic

particle ensemble of the ANNs simulation are almost

similar. Using a finite volume-model with a higher

resolution will probably yield further improvement.

The calculation with the ODE system and the high

resolution model with 8 particles show the same

trend. The extreme points became apparent and the

drop of the species is marginal faster. Physical

observed the strong gradient of educts between 15 to

40[x/d] is an indicator for the position of the flame.

The products shown in figure 5 show also a

matching behaviour. Measurements and calculation

diverge only in form of a small shift, which is

connected with the shift of the educts. The values of

carbon dioxide are slightly higher with a maximum

difference of 0,02. The calculation with the ODE

system shows the same behaviour. Only the extreme

points have a higher difference to measurement

values.

ICFC 2010 - International Conference on Fuzzy Computation

408

Figure 5: Comparison of measurements, ANNs and ODE

system simulation solutions of exhaust gas components of

the flame.

Figure 6: Comparison of measurements, ANNs and ODE

system simulation solutions of carbon monoxide and

nitrogen.

Carbon monoxide is an import minority species.

Several reduced mechanisms can not calculate the

values of that specific species. In comparison the

values in figure 6 are within the same range. The

maximum point for the ODE system is about 0,008

higher and the CO oxidation is faster than for the

ANNs simulation. The measurements show a small

shift to higher [x/d]-values which is in good

correlation to the former discussed species values.

Nitrogen is the closure condition. The mass

fractions of the species have to sum up to one, so

that the CFD solver is able to compute the density

for the flow field calculation. Therefore the overall

error of the calculation results can be seen in the

values of nitrogen in figure 6. In comparison of the

ANNs and ODEs solution the error is marginal.

Figure 7: Comparison of measurements, ANNs and ODE

system simulation solutions of the flame temperature.

In summary measurements and calculations of

the examined species show good results. In physical

description the flame front of the calculation with

ANNs is shifted to lower x-values. But the same

solution is also generated by the full GriMech3.0

solution.

Figure 7 depicts the temperature which shows

the same shift in flame front position and the good

trend in comparison of ANNs and ODE calculation.

Further comparison of the flow field and

turbulence values show the performance of the

ANNs simulation solutions. Because of the coupling

of the turbulent flow field and the reactions, minor

changes can result in convergence problems and

species mass concentrations which are not physical.

Whereas the ODE system is a physical model ANNs

only represent the learned dataset within the given

limits.

3.4 Future Prospects

In order to reach an improvement the chemistry

samples which are generated with a model of about

NEURAL NETWORKS IN COMBUSTION SIMULATIONS

409

1000 finite-volume-elements should be replaced by

samples of the high resolution model. Further the

use of a more fitting cluster algorithm will improve

the performance regarding the number of used

ANNs. The forecast of further minority species like

NO

x

or unburnt hydrocarbons can help to fulfil

current exhaust emission directives.

ACKNOWLEDGEMENTS

The investigations were conducted as part of the

joint research programme

COOREFF-

T/COORETEC-turbo

in the frame of AG Turbo.

The work was supported by the Bundesministerium

für Wirtschaft und Technologie (BMWi) as per

resolution of the German Federal Parliament under

grant number

0327716L. The authors gratefully

acknowledge AG Turbo and

MAN Diesel & Turbo

SE

for their support and permission to publish this

paper. The responsibility for the content lies solely

with its authors.

REFERENCES

Barlow, R. S. and Frank, J. H. (1998). Proc. Combust.

Inst. 27:1087-1095. The Combustion Institute.

Pittsburgh.

Barlow, R. S., Frank, J. H., A. N. Karpetis, and Chen, J.-

Y. (2005). Piloted Methane/Air Jet Flames: Scalar

Structure and Transport Effects, 143:433-449.

Combustion Flame.

Blasco J. A., Fueyo N., Dopazo C., Ballester J. (1998).

Modelling the Temporal Evolution of a Reduced

Combustion Chemical System With an Artificial

Neural Network, 113:38-52. Combustion and Flame.

Chen J.-Y., Blasco J. A., Fueyo N., Dopazo C. (2000). An

economical strategy for storage of chemical kinetics:

Fitting in situ adaptive tabulation with artificial

neural networks, 28:115-121. Proceedings of the

Combustion Institute, Baltimore: Port City Press.

Harder, S., Joos, F. (2007). Modelling a Non-Premixed

Industrial 18 MW Gas Turbine Combustor, GT2007-

27370 GTI/ASME. Turbo Expo, Montreal: Canada.

Gregory P. Smith, David M. Golden, Michael Frenklach,

Nigel W. Moriarty, Boris Eiteneer, Mikhail

Goldenberg, C. Thomas Bowman, Ronald K. Hanson,

Soonho Song, William C. Gardiner, Jr., Vitali V.

Lissianski, and Zhiwei. (n.d.). GRI-Mech 3.0. from

http://www.me.berkeley.edu/gri_mech/.

Große, L., Joos, F. (2008). Usage of Artificial Neural

Networks for Data Handling, GfKL 2008. German

Classification Society, Hamburg: Germany.

Große, L., Joos, F. (2009). The use of ANN for turbo

engine applications, 17

th

European Symposium on

Artificial Neural Networks, 207-212. ESANN 2009,

Bruges: d-side publications.

Große, L., Joos, F. (2010). Approximation of chemical

reaction rates in turbulent combustion simulation ,

18

th

European Symposium on Artificial Neural

Networks, 195-200. ESANN 2010, Bruges: d-side

publications.

Igel, C., Husken, M. (2003). Empirical Evaluation of the

Improved RPROP Learning Algorithms, 105-123.

Neurocomputing 50C.

Reaction Design, CHEMKIN. (n.d.). from

http://www.reactiondesign.com/.

Sandia/TUD Piloted/CH4/Air Jet Flames (2003). from

http://www.sandia.gov/TNF/DataArch/FlameD.html.

Zell, A. (1997). Simulation Neuronaler Netze. Oldenburg:

Wissenschaftsverlag.

ICFC 2010 - International Conference on Fuzzy Computation

410