OPTIMIZATION OF A STEAM TURBINE GUIDE VANE BY END

WALL CONTOURING USING EVOLUTIONARY ALGORITHMS

Nils Moser and Franz Joos

Power Engineering, Laboratory of Turbomachinery, Helmut-Schmidt-University

University of the Federal Armed Forces Hamburg

Holstenhofweg 85, D-22043, Hamburg, Germany

Keywords: CFD, Control stage, Evolutionary algorithm, Guide vane, Optimization, Steam, Turbine.

Abstract: The subject of this paper is the optimization of a guide vane of steam turbine control stage by end wall

contouring. The investigated control stage is derived from an existing industrial steam turbine design. The

end wall contour is varied in rotational direction within specified restrictions by an evolutionary algorithm.

The algorithm is directly connected to a mesh generator and a Computational Fluid Dynamics (CFD) solver.

The optimization goal is the reduction of the total pressure loss over the guide vane. The geometry of the

rotor blade has been retained unchanged. The flow field of the varied stage is compared with the baseline

geometry. The optimum candidates are further investigated with CFD simulations for different operating

point scenarios. Numerical results show that the axisymetric end wall contouring of the nozzle has a

considerable effect on the loss behavior of the nozzle over a wide range of pressure ratios. Due to end wall

contouring the boundary layer in the nozzle is significantly affected which results in a significant reduction

of the secondary flow effects in the guide vanes.

1 NOMENCLATURE

nozzle chord

number of individual

isentropic coefficient of air

static pressure at guide vane outlet

,

total pressure at guide vane inlet

,

total pressure at guide vane outlet

pressure ratio

,

shroud radius of shroud point i

∗

transformed coordinates

,

max. shroud radius

,

min. shroud radius

hub radius

2 INTRODUCTION

Secondary losses, in addition to profile losses, are

one of the most important loss mechanisms in turbo

machines. Their influence emerges in particular at

blade profiles with high aerodynamic loads, high

pressure ratio, high flow velocity and low aspect

ratio. Secondary loss can constitute up to 30% of the

overall loss. The effect of secondary flows has been

intensively investigated by Langston (2001),

Sieverding (1985) and Gregory-Smith (1997). Dejc

and Zarjankin (1960) have shown that secondary

losses and boundary layer effects can be reduced by

an axisymetric end wall contour. They used a cubic

function to define the end wall contour. Moustapha

and Williamson (1985) investigated rotational

constrictions in the meridian plane. They asserted

that a streamwise downward constriction exhibits a

lower loss than a linear constriction. Rose (1994)

achieved a significant influence of the static pressure

at the profiled wall by a three-dimensional

contouring of a high pressure gas turbine. Harvey,

Rose, Taylor, Shapar, Hartland and Gregory-Smith

(2000) examined a 3D hub contour of a turbine. The

contour was described with a divergence from the

reference contour at six axial positions in

circumferential direction by a Fourier function. The

static pressure distribution at the hub surface and the

exit flow angle variation were selected as

optimization target. Harvey et al. asserted the

passage vortex and the overall losses were reduced

by the 3D profiled hub. Furthermore, they

discovered a new vortex near the hub. Experiments

327

Moser N. and Joos F..

OPTIMIZATION OF A STEAM TURBINE GUIDE VANE BY END WALL CONTOURING USING EVOLUTIONARY ALGORITHMS.

DOI: 10.5220/0003074603270331

In Proceedings of the International Conference on Evolutionary Computation (ICEC-2010), pages 327-331

ISBN: 978-989-8425-31-7

Copyright

c

2010 SCITEPRESS (Science and Technology Publications, Lda.)

by Hartland, Gregory-Smith, Harvey and Rose

(2000) validated these results. Eymann, Foersterm

Beversdorff, Reinmoeller, Niehuis and Gier (2002)

experimentally investigated an axisymmetric end

wall contour simultaneous with a blade profile

optimization in the first stage of a gas turbine. They

asserted that the vortex system behind the first guide

vane was dislocated near the end walls.

Additionally, Eymann observed a reduction of the

passage and the trailing edge vortex as a result of the

optimization.

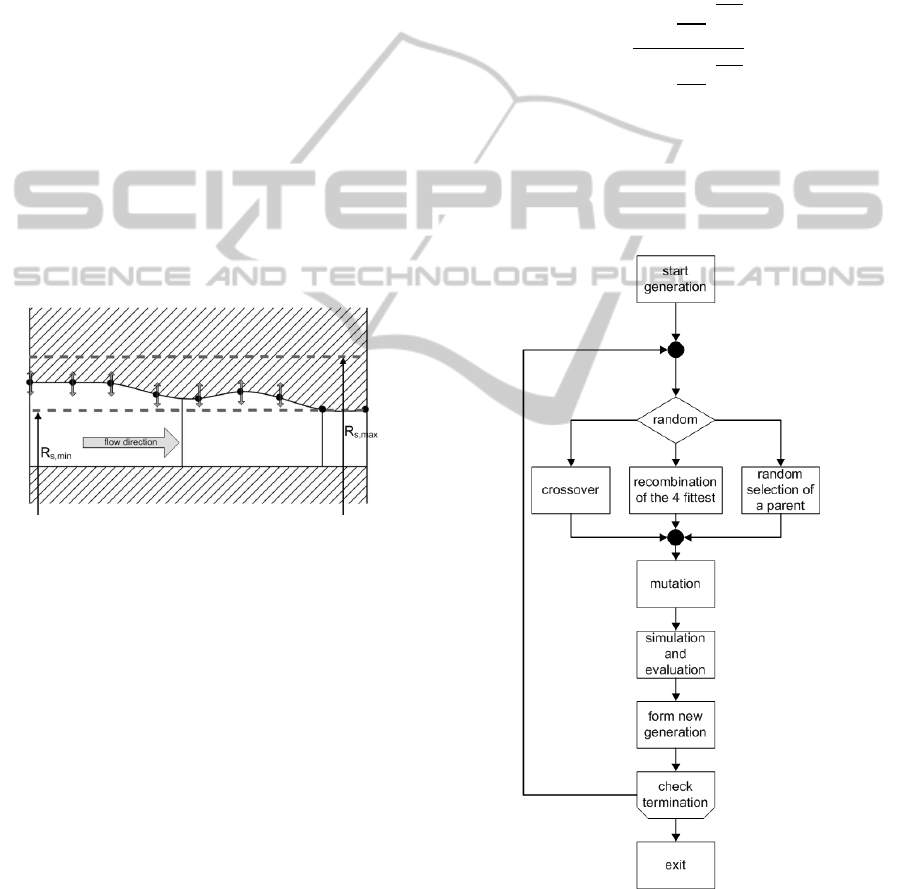

3 GEOMETRY RESTRICTION

The control stage investigated is derived from an

existing industrial steam turbine design. Due to the

production process of guide vanes for control stages

of steam turbines the end wall contour has to be

axisymmetric. The shroud contour is defined by an

equidistant distribution of seven points which define

a b-spline as shown in Fig. 1.

Figure 1: Illustration of geometry restriction.

These seven points are varied in radial direction

within the following restriction of R

s

:

,

=

+0.25∗

≤

,

(1)

,

=

+0.5∗

≥

,

(2)

By virtue of undisturbed flow conditions at the

inlet and outlet of the guide vane channel the radial

shroud contour gradient equals zero. The cross

section of the outlet remains unchanged for all

geometry variants.

4 EVOLUTIONARY ALGORITHM

The optimization of the shroud contour is a complex

multi dimensional problem. The optimization

parameters are the radial positions of the seven

points, which describe the contoured shroud. Due to

the seven degrees of freedom a simple analytic

solution is not suitable. In order to achieve a

systematic optimization of the contoured end wall an

evolutionary algorithm has been used. The main loss

mechanism in guide vanes is the total pressure loss

due to secondary flow regimes. Hence the total

pressure loss of the guide vane is selected as fitness

function for the evolutionary algorithm. It is

evaluated as shown in Equation (3). The evaluated

pressure is mass flow averaged.

=1−

1−

,

1−

,

(3)

An evolutionary optimization algorithm is based

on the technique of adaption and evolution as shown

by Rechenberg (1994) and Weicker (2002). The

workflow of the used evolutionary algorithm is

shown in Fig. 2.

Figure 2: Workflow.

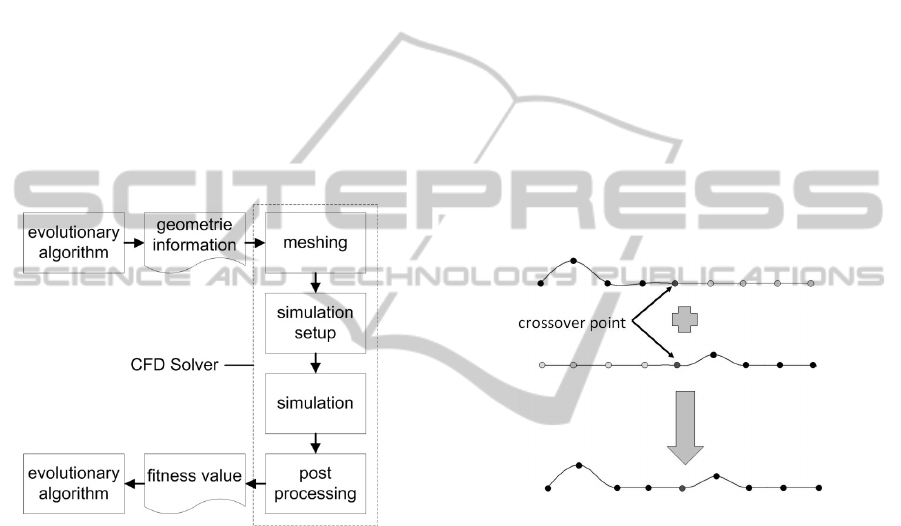

4.1 Evaluation of the Fitness

After gaining the geometry information for the child

ICEC 2010 - International Conference on Evolutionary Computation

328

individual the pressure loss is evaluated. Due to the

influence of the end wall contouring on the

secondary flow phenomena every single individual

must be simulated by means of 3D-CFD. For this

reason the evolutionary algorithm is directly

connected to a commercial mesh generator and a

CFD solver. ANSYS CFX 11.0 is used as CFD

solver. The mesh generator creates the three-

dimensional numerical model and hands it over to

the CFD solver which simulates and evaluates every

single child individual. The numerical mesh of the

guide vane has a resolution of about 1 mio. control

volumes. The ”Shear Stress Transport Model” is

used as turbulence model. The convergence criterion

of the CFD solver is an overall residual below 10

-5

.

Figure 3 shows the scheme of the evaluation

process. One single evaluation process needs about

30 minutes.

Figure 3: Evaluation process.

After evaluating each individual, the next

generation is formed. It is based on Darwin‘s

principal ”survival of the fittest”. This means only

the fittest individual of the parent generation and the

child individuals are transferred to the next

generation. The optimization is looped until a certain

number of simulations is reached or a stagnation

over 50 loops in the optimization process is noticed.

4.2 Evolution Strategy

(μ+λ)-strategy is selected as evolutionary strategy.

This means that from μ parental individuals λ child

individuals are generated and the μ fittest of the

(μ+λ) individuals are passed onto the next

generation. Parental individuals can be transferred to

the next generation, too. One problem of this

strategy is that the algorithm tends to hang up on a

local optimum but on the other side the algorithm is

quite fast and robust. This is the reason why the

(μ+λ)-strategy is selected. Due to the fact that the

evaluation of the fitness by CFD consumes about 30

min. per individual, the number of the parental

individuals (μ) is set to 20 and the number of the

child individuals (λ) is set from 1 to 5. For the

creation of the child individuals 3 different

mechanisms are required:

simple mutation

recombination of the four fittest

crossover.

The simple mutation slightly varies the shroud

geometry of a randomly selected parental individual.

The recombination mechanism averages the shroud

geometry of the four fittest parental individuals and

mutates this average value. The crossover

mechanism crosses two randomly selected parental

individuals at a random position as shown in Fig. 4.

Afterwards this new geometry is also mutated.

Figure 4: Scheme of crossover.

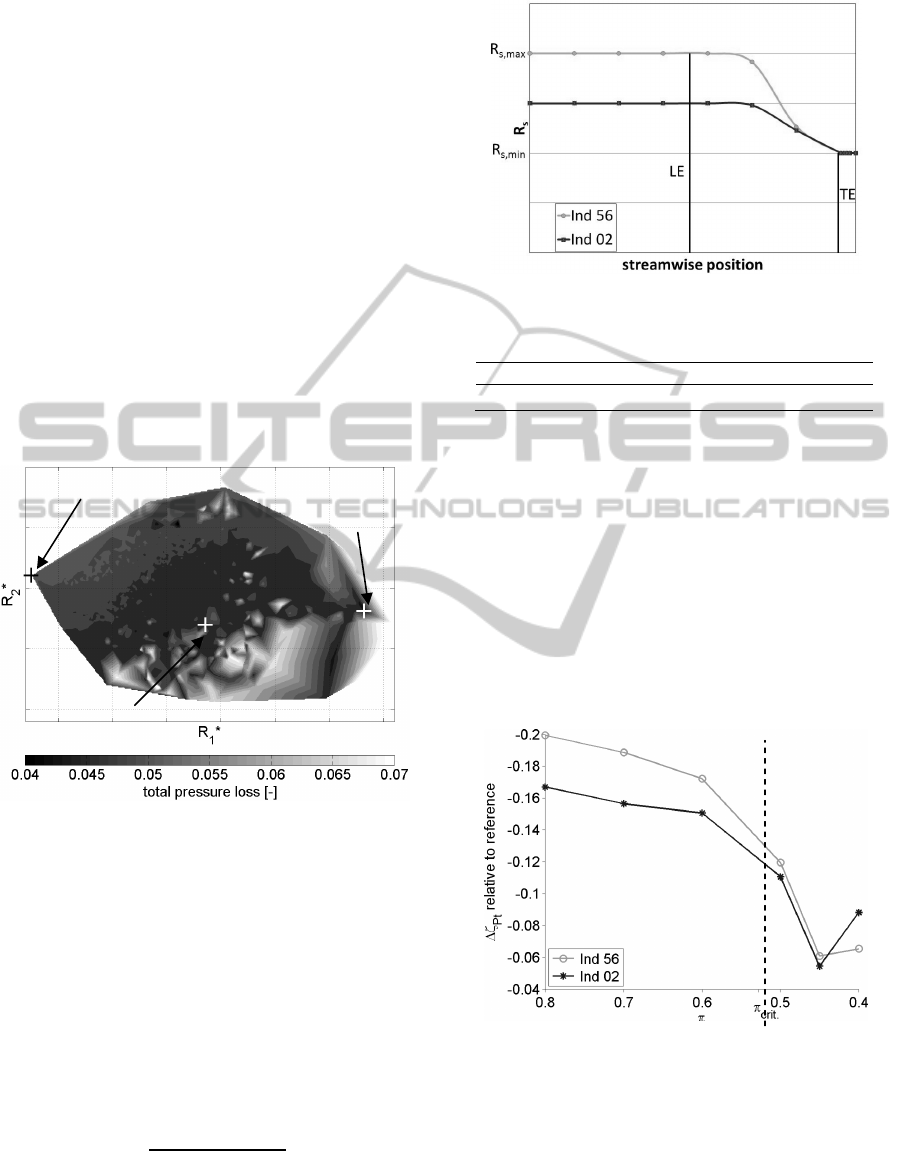

4.3 Results

In the first step the operating point of the guide vane

is kept constant during optimization. The optimum

candidate is further investigated with CFD

simulations for different operating point. The design

pressure ratio over the nozzle is π = 0.5. Air is the

chosen fluid because in a further step the result will

be compared with measurements of an air turbine

test rig. The original shroud contour with a constant

shroud radius

,

=

,

is used as the reference

geometry.

In order to properly visualize the target function

of the shroud variation a multidimensional scaling is

used to project the eight-dimensional space on a

three-dimensional space. The Euclidean distances

between the individuals in the three dimensional

space are approximately calculated as a

monotonically transformation of the corresponding

dissimilarities in the eight-dimensional space. The

OPTIMIZATION OF A STEAM TURBINE GUIDE VANE BY END WALL CONTOURING USING EVOLUTIONARY

ALGORITHMS

329

transformation scheme is given in Equation (4).

,

⋮

,

∗

∗

(4)

Elements which are close to each other in the

eight-dimensional space are also close in the three-

dimensional space. As goodness-of-fit criterion for

the approximately calculated transformation the

minimum of the squared standardized residual sum

of squares (stress), normalized with the sum of

fourth powers of the dissimilarities, is used. Further

information can be found at Seber (1984), Borg and

Groenen (1997) and Backhaus, Erichson, Plinke and

Weiber (2006). Figure 5 shows the total pressure

loss

over the transformed coordinates

∗

and

∗

.

The map was generated using the information of

over 2500 individuals.

Figure 5: Multidimensional scaling.

4.4 Guide Vane Simulation Results

For comparison a shroud contour according to Dejc

and Trojanovskij (1973) was also simulated and

evaluated (Ind 02). The optimum contour of the

evolutionary algorithm is named Ind 56. The

investigated contours are shown in Figure 6.

Table 1 shows the difference of the pressure loss

of the both end wall contours in relation to the

reference contour. It is calculated as shown in

Equation (5).

∆

,

=

,

−

,

,

(5)

Figure 6: Illustration of the investigated contours.

Table 1: Total pressure loss relative to reference.

Ind 02 Ind 56

∆

,

-0.1106 -0.1196

In a further step the three geometries are

investigated at different pressure ratios over the

nozzle. Figure 7 shows the characteristic of ∆

relative to the reference contour. The dashed line

marks the critical pressure ratio of air. It is

noteworthy that the advantage of contouring over the

straight contour increases as pressure ratio increases.

Especially at subcritical pressure ratios the total

pressure loss is reduced by end wall contouring. It

can be observed that the optimized contour has an

significant advantage over the straight and the Ind

02 contour.

Figure 7: Total pressure loss relative to reference over

pressure ratio.

5 CONCLUSIONS

A new axisymmetric end wall design has been

designed for a guide vane of a control stage. This

end wall design has been gained by an evolutionary

reference

Ind 56

Ind 02

ICEC 2010 - International Conference on Evolutionary Computation

330

optimization algorithm. This algorithm has been

successfully connected to a commercial CFD solver.

The aim of the end wall contouring was to reduce

the total pressure loss and the secondary flow

regimes in the guide vane. A significant reduction of

the total pressure loss was achieved. This

investigation shows that the optimization of the

shroud contour is not a simple problem. It shows

that an evolutionary algorithm is a suitable

optimization method for this problem. However it

also shows that the evaluation of the fitness function

has to be speed up. One method would be an

approximated one dimensional calculation of the

flow field in the guide vane. In order to include the

influence of the guide vane contour on the efficiency

of the control stage, the whole stage will be

simulated during the further optimization. In a

further step the results of this investigation will be

compared with measurements of an air turbine test

rig with different end wall configurations.

ACKNOWLEDGEMENTS

The investigations were conducted as part of the

joint research program COOREFF-T/COORETEC-

turbo in the frame of AG Turbo. The work was

supported by the Bundesministerium für Wirtschaft

und Technologie (BMWi) as per resolution of the

German Federal Parliament under grant number

0327716Q. The authors gratefully acknowledge AG

Turbo and MAN Diesel & Turbo SE for their

support and permission to publish this paper. The

responsibility for the content lies solely with its

authors.

REFERENCES

Backhaus, K., Erichson, B., Plinke, W., and Weiber, R.

(2006). Multivariate Analysemethoden. Springer.

Borg, I., and Groenen, P., 1997. Modern Multidimensional

Scaling. Springer.

Dejc, M. E., and Zarjankin, A. E. (1960). Methods of

Increasing the Efficiency of Turbine Stages.

Teploenergetika, 2, pp. 18–24.

Dejc, M. E., and Trojanovskij, B. M. (1973).

Untersuchung und Berechung axialer Turbinenstufen.

Berlin: VEB Verlag Technik.

Eymann, S., Foerster, W., Beversdorff, M., Reinmoeller,

U., Niehuis, R., and Gier, J. (2002). Improving 3D

flow characteristics in a multistage LP turbine by

means of endwall contouring and airfoil design

modification part 1: design and experimental

investigation. In Proceedings of ASME Turbo Expo.

ASME Paper GT2002-30352.

Gregory-Smith, F. G. (1997). Secondary and Tip-

Clearance Flows in Axial Turbines. VKI LS, 1997-01.

Von Karman Institute for Fluid Dynamics, Rhode St.

Genese, Belgium.

Hartland, J. C., Gregory-Smith, D. G., Harvey, N. W., and

Rose, M. G. (2000). Nonaxisymmetric Turbine End

Wall Design: Part II - Experimental Validation. ASME

Journal Turbomachinery, 122, 286–293.

Harvey, N. W., Rose, M. G., Taylor, M. D., Shapar, S.,

Hartland, J. C., and Gregory-Smith, D. G. (2000).

Nonaxisymmetric Turbine End Wall Design: Part I -

Three-Dimensional Linear Design System. ASME

Journal Turbomachinery, 122, 278–285.

Langston, L., 2001. Secondary Flows in Axial Turbines -

A Review. Annals of New York Academy Sciences,

934.

Moustapha, S. H., and Williamson, R. G. (1985).

Investigation of the Effect of two Endwall Contours

on the Performance of an Annular Nozzle Cascade.

Proceedings of AIAA. AIAA-85-1218.

Rechenberg, I. (1994). Evolutionsstrategie ’94. Stuttgart:

Frommann-Holzboog.

Rose, M. G. (1994). Non-axisymmetric Endwall Profiling

in the HP NGVs of an Axial Flow Gas Turbine.

Proceedings of ASME Turbo Expo. ASME Paper No.

94-GT-249.

Seber, G. A. F. (1984). Multivariate Observations. Wiley.

Sieverding, C. H. (1985). Recent progress in the

understanding of basic aspects of secondary flows in a

turbine blade cascade. ASME Journal of Engineering

Gas Turbines and Power, 107(2), 248–252.

Weicker, K. (2002). Evolutionaere Algorithmen. Teubner

Verlag.

OPTIMIZATION OF A STEAM TURBINE GUIDE VANE BY END WALL CONTOURING USING EVOLUTIONARY

ALGORITHMS

331