OPTIMIZATION OF A SOLID STATE FERMENTATION

BASED ON RADIAL BASIS FUNCTION NEURAL NETWORK

AND PARTICLE SWARM OPTIMIZATION ALGORITHM

Badia Dandach-Bouaoudat, Farouk Yalaoui, Lionel Amodeo

University of Technology of Troyes, 12 rue Marie Curie, Troyes, France

Franc¸oise Entzmann

Ets J.Soufflet, Quai Sarrail, Nogent sur Seine, France

Keywords:

Solid state fermentation, Enzyme production, Optimization, Response surface methodology, Neural network,

Particles swarm optimization algorithm.

Abstract:

Radial basis function neural network (RBF) and particle swarm optimization (PSO) are used to model and

optimize a solid state fermentation (SSF) for production of the enzyme. Experimental data reported in the lit-

erature are used to investigate this approach. The response surface methodology (RSM) is applied to optimize

PSO parameters. Using this procedure, two artificial intelligence techniques (RBF-PSO) have been effec-

tively integrated to create a powerful tool for bioprocess modelling and optimization. This paper describes the

applications of this approach for the first time in the solid state fermentation optimization.

1 INTRODUCTION

Fermentation processes are used to produce various

substances in the pharmaceutical, chemical and food

industries. The performance of fermentation pro-

cesses depends on many factors, including pH, tem-

perature, ionic strength, agitation speed, and aera-

tion rate in the aerobic fermentation (Kennedy and

Krouse, 1999). To achieve the best performance

of fermentation processes, various process optimiza-

tion strategies were developed by scientists. The

most frequently used optimization is response sur-

face methodology (RSM), which includes factorial

design and regression analysis, seeks to identify and

optimize significant factors to maximize the response

(cell density, high yields of the desired metabolic

products or enzyme levels in the microbial system).

RSM yields a model, which describes the relationship

between the independent and dependent variables of

the processes. The most widely used simulating mod-

els are second order polynomials (Ceylan et al., 2008)

and (Chang et al., 2008), and now RSM has been

widely applied in the bioprocess optimization (Ku-

namneni and Singh, 2005) and (Ustok et al., 2007).

In recent years, a limited number of studies have

investigated the possibility of using non-statistical

techniques, such as artificial intelligence (AI), for de-

veloping non-linear empirical models. The most com-

monly used AI are artificial neural networks (ANNs).

ANNs are superior and more accurate modelling tech-

niques when compared to RSM and represent the non-

linearities in a much better way (Dutta et al., 2004).

The most frequently used ANNs is a radial basis func-

tion (RBF) neural network. As a universal function

approximator under certain general conditions (Wil-

son et al., 1999).

One type of evolutionary technique used in com-

puter science is particle swarm optimization (PSO).

This technique allows one approximate optimization

and search problem solutions. Kennedy and Eberhart

were the first to propose the PSO algorithm (Kennedy

et al., 1995). This algorithm is based on the premise

that evolution of a species is advanced by the so-

cial sharing of information among members of the

said species. PSO is a perfect candidate of optimiza-

tion tasks based on a number of advatages compared

to other algorithms. The PSO algorithm is strong

enough to handle complex situations such as non-

linear and non-convex design spaces with discontinu-

ities. Also continuous, discrete and integer variable

287

Dandach-Bouaoudat B., Yalaoui F., Amodeo L. and Entzmann F..

OPTIMIZATION OF A SOLID STATE FERMENTATION BASED ON RADIAL BASIS FUNCTION NEURAL NETWORK AND PARTICLE SWARM

OPTIMIZATION ALGORITHM.

DOI: 10.5220/0003136202870292

In Proceedings of the International Conference on Bioinformatics Models, Methods and Algorithms (BIOINFORMATICS-2011), pages 287-292

ISBN: 978-989-8425-36-2

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

types can be handled easily. Also, the PSO optimiza-

tion method is more efficient than other equally robust

designs. There are fewer function evaluations yet the

results are of equal or better quality than competitors

(Hu et al., 2003) and (Hassan et al., 2005).

In this work, RBF neural network coupling PSO

algorithm (RBF-PSO) was used to model and opti-

mize the mixing performance of solid state fermenta-

tion. Three independent process variables including

temperature, agitation, and inoculums size were con-

sidered for optimization. The optimization objective

was to achieve the maximum alpha-amylase activity

at an optimal combination of three independent vari-

ables. The RBF neural network was used to develop

the mathematical function of alpha-amylase activity

with temperature, agitation, and inoculums size. Then

PSO algorithm was used to execute the optimization

task to achieve the maximum alpha-amylase activity.

The response surface methodology (RSM) is applied

to optimize PSO parameters.

2 MODELIZATION

2.1 RBF Neural Network

RBF neural network is structured by embedding ra-

dial basis function with a two-layer feed-forward neu-

ral network. Such a network is characterized by a set

of input and set of outputs. In between the inputs and

outputs there is a layer of processing units called hid-

den units. Each of them implements a radial basis

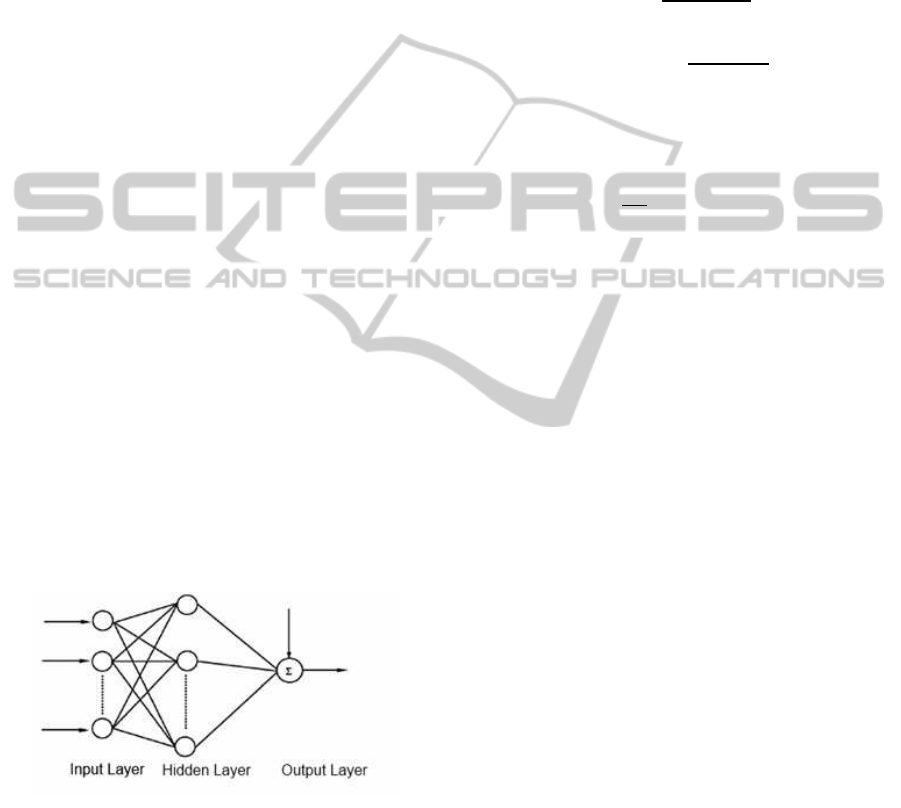

function. The architecture of RBF network is shown

in Figure 1.

Figure 1: structure of RBF neural network for process mod-

eling.

Mathematically RBF neural network can be for-

mulated as:

g(x) =

m

∑

k=1

λ

k

ϕ

k

(kx

i

− c

k

k) (1)

Where m is the neuron number of hidden layer, which

is equal to cluster number of training set. kx

i

− c

k

k

represents the distance between the data point x

i

and

the RBF center c

k

.λ

k

is the weight related with RBF

center c

k

. Therefore, the output of RBF neural net-

work is a weighted sum of the hidden layer’s activa-

tion functions. Various functions have been tested as

activation functions for RBF networks. Here we adopt

the most commonly used Gaussian RB functions as

basis functions shown in equation (2):

ϕ

k

(x

i

) =

R

k

(x

i

)

∑

m

i=1

R

i

(x

i

)

(2)

R

k

(x

i

) = exp(−

kx

i

− c

k

k

2

2σ

2

k

) (3)

In equation (3), σ

k

indicates the width of the kth

Guassian RB functions. One of the σ

k

selection meth-

ods is shown as follows.

σ

2

k

=

1

M

k

∑

x∈θ

k

kx

i

− c

k

k

2

(4)

here θ

k

the kth cluster of training set, and M

k

is

the number of sample data in the kth cluster.

3 OPTIMIZATION

3.1 PSO Algorithm

Stochastic in nature, the particle swarm process up-

dates the position of each particle in the swarm using

the velocity vector. This vector is updated using the

memory of each particle and the entire swarm. This

allows the position of each individual particle to be

updated based on the entire swarm. As the swarm

adapts to its environment each particle can return to

regions of space that are promising and also search

for better positions.

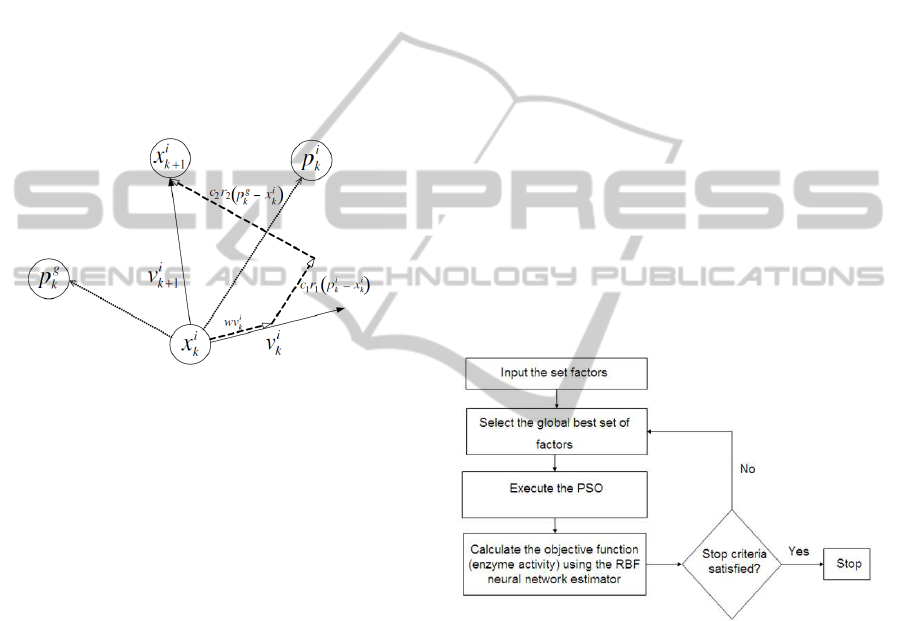

Numerically, the position x of a particle i at iter-

ation k + 1 is updated as shown in equation (5) and

illustrated in figure 2.

x

i

k+1

= x

i

k

+ v

i

k+1

(5)

Where v

i

k+1

is the corresponding updated velocity

vector, the velocity vector of each particles is calcu-

lated as shown in equation (6),

v

i

k+1

= wv

i

k

+ w

1

r

1

(p

i

k

− x

i

k

) + w

2

r

2

(p

g

k

− x

i

k

(6)

Where v

i

k

is the velocity vector at iteration k, r

1

and r

2

represents random numbers between 0 and 1;

p

i

k

represents the best ever particle position of particle

i, and p

g

k

corresponds to the global best position in the

swarm up to iteration k.

BIOINFORMATICS 2011 - International Conference on Bioinformatics Models, Methods and Algorithms

288

Terms that remain are parameters that depend on

the problem. These include w

1

, w

2

and w, which stand

for the particles confidence in itself (cognitive param-

eter) and in the swarm (social parameter) and also

inertial weight, respectively. The PSO convergence

behavior, which is used to control the exploration ca-

pabilities of the swarm, relies largely on the inertial

weight of the particle. The inertial weight impacts the

current velocity, which is based on previous veloci-

ties. Therefore, as the inertial weight changes, so does

the ability of the particle to roam. If inertial weight is

large, the particle can explore the design space in a

broader manner, while small inertial weights limit the

updates of velocity to local regions within the design

space.

Figure 2: PSO position and velocity update.

3.2 Response Surface Methodology

(RSM)

Response surface methodology combines statistical

experimental designs and empirical model building

by regression for the purpose of process or prod-

uct optimization. Statistical experimental design is

a powerful method for accumulating informations

about a process efficiently and rapidly from a small

number of experiments, there by minimizing exper-

imental costs. An empirical model is then used to

relate the response of the process to some indepen-

dent variables. This usually entails fitting a quadratic

polynomial to the available data by regression anal-

ysis. The general from of the quadratic polynomial

is:

Y = b

0

+

∑

b

i

X

i

+

∑

b

i

X

2

i

+

∑

b

ij

X

i

X

j

+ e (7)

WhereY is the predicted response, X

i

and X

j

stand

for the independent variables, b

0

is the intercept, b

i

and b

i, j

terms are regression coefficients, and e is a

random error component. A near-optimum solution

can then be deduced by calculating the derivatives of

equation (7) or by mapping the response of the model

into a surface contour plot.

4 RESULTS AND DISCUSSION

4.1 RBF Modeling

In the RBF estimator for the fermentationexample ex-

amined in this work, there are three nodes (x

1

: tem-

perature (

◦

C), x

2

: agitation (rpm) and x

3

: Log

10

of

inoculums size (spore/ml) in the input layer and an

output node for alpha-amylase activity (Y). with the

given structure, the RBF neural network is trained by

the sampling data imported from (Kammoun et al.,

2008) to obtain a desired estimator.

Here the R

2

of 99.8% indicates that the experi-

mental and predicted values are in a good agreement.

4.2 Optimization by PSO Algorithm

In the present work, we used the RBF neural net-

work to produce the fitness function. We developed

a (RBF-PSO) algorithm with Matlab software, this

algorithm has 2 steps: modeling and optimization,

various steps involved in this study were represented

schematically in Figure 3.

Figure 3: Schematic representation of RBF-PSO algorithm

for bioprocess optimization.

Based on the particle and velocity updates as ex-

plained in equation (6), the PSO algorithm is con-

structed as follows:

1. Initialize a set of particles positions x

i

0

and veloci-

ties v

i

0

randomly distributed throughout the design

space bounded by specified limits, and set p

i

k

=x

i

k

.

2. Evaluate the objective function values f(x

i

k

using

the design space positions x

i

k

. That is, employ the

particle’s position vector as the the input of RBF

estimator.

3. Update the optimum particle position p

i

k

at current

iteration (k) and global optimum particle position

p

g

k

.

OPTIMIZATION OF A SOLID STATE FERMENTATION BASED ON RADIAL BASIS FUNCTION NEURAL

NETWORK AND PARTICLE SWARM OPTIMIZATION ALGORITHM

289

4. Update the position of each particle using its pre-

vious position and update velocity vector as spec-

ified in equation (5) and equation (6).

5. Repeat steps 2-4 until the stopping criteria is met.

For the current implementation the stopping cri-

teria is defined based on the number of iterations

reached.

4.3 Tuning PSO Parameters

The role of the inertia weight w, plays a critical role in

the PSO’s convergence behavior in equation (6). The

inertia weight should consist of a trade-off between

global and local exploration abilities of the swarm

to therefore control the impact of previous veloci-

ties on the current velocity. Large inertia weight re-

sults in particles searching new areas, while a small

inertia weight results in particles exploring locally.

By finding a suitable value of inertia weight, a bal-

ance between wide-range and local exploration can

be acheived. By doing this, the optimum solution can

be found the most efficiently and with the fewest itera-

tions. Through experimentation, it was found that set-

ting the inertia weight to a high level results in global

exploration, which in turn produces more results (Shi

and Eberhart, 1998). This value can then be lowered,

refining the solutions. Therefore, a value of w start-

ing at 1.2 and gradually declining towards 0 can be

considered as a good choice for w.

The algorithm can be further improved by fine-

tuning the parameters w

1

and w

2

, in equation (6).

the results could be converged on faster and the lo-

cal explorat alleviated. In (Kennedy, 1998) an ex-

tensive study of the acceleration parameter in PSO’s

first version can be found. Recent work has also come

up with further suggestions for choosing w

1

and w

2

.

This work suggests that it may be in one’s best inter-

est to choose w

1

, the cognitive parameter, to be larger

than w

2

, the social parameter, with the limitation that

w

1

+ w

2

≤ 4 (Carlisle and Dozier, 2001).

The parameters r

1

and r

2

are used to maintain the

diversity of the population, and they are uniformly

distributed in the range [0, 1].

In this work, optimization of the parameters of the

PSO algorithm:

• N: swarm size ,

• w

1

: cognitive parameter,

• w

2

: social parameter,

was done by Box-Behnken design especially

made to require three levels coded as (-), (0) and

(+) (N = 13) (13 experiments and three factors at

three levels) under the response surface methodology

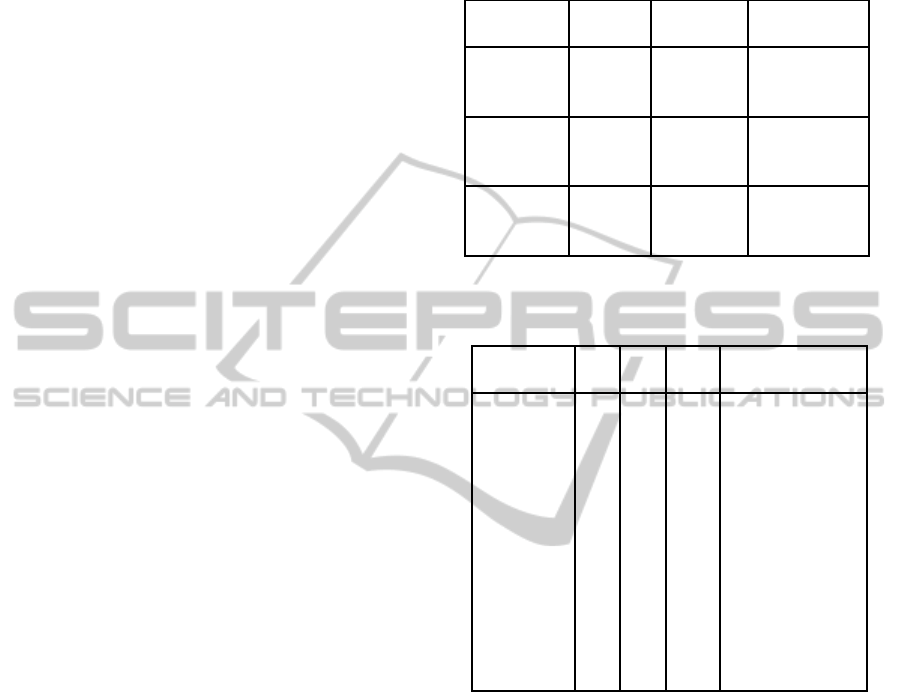

(RSM). Table 1 shows the different levels of each of

the parameters.

Table 1: Parameters values for Box-Behnken design.

Factors Basical Variation Value

level interval of the factor

w

1

: 2 2 0

Cognitive 2

parameter 4

w

2

: 2 2 0

Swarm 2

parameter 4

N: 65 35 30

Swarm 65

size 100

Table 2: Box-Behnken experimental design used to opti-

mize parameters of PSO algorithm.

PSO code w

1

w

2

N Alpha-amylase

activity (U/ml)

PSO 1 0 2 30 40.3668

PSO 2 0 2 100 40.3478

PSO 3 4 2 30 39.0155

PSO 4 4 2 100 40.3694

PSO 5 2 0 30 24.0529

PSO 6 2 0 100 29.7599

PSO 7 2 4 30 39.2980

PSO 8 2 4 100 40.0989

PSO 9 0 0 65 27.9151

PSO 10 4 0 65 27.4070

PSO 11 0 4 65 40.3685

PSO 12 4 4 65 35.0228

PSO 13 2 2 65 40.3731

Box-Behnken design is a fractional factorial de-

sign obtained by combining two-level factorial de-

signs with incomplete block designs. The response

surface methodology was used to analyses the exper-

imental design data. In order to be correlated to the

independent variables, the response variable was fit-

ted by a second order model.

Table 2 illustrates the Box-Behnken experimental

design of the three independent variables together

with the experimental result. By applying multiple

regression analysis on the experimental data, the

following second-order polynomial equation was

developed to clarify the relationship of the optimal

solution (Y), swarm size (N), cognitive parameter

(w

1

) and social parameter (w

2

):

Y = 40.374+ 0.980N− 0.898w

1

+ 5.707w

2

+

0.137N

2

− 0.487w

2

1

− 7.209w

2

2

+

0.343Nw

1

− 1.227Nw

2

− 1.209w

1

w

2

(8)

BIOINFORMATICS 2011 - International Conference on Bioinformatics Models, Methods and Algorithms

290

The R

2

of 98% indicates that the experimental and

predicted values are in a good agreement.

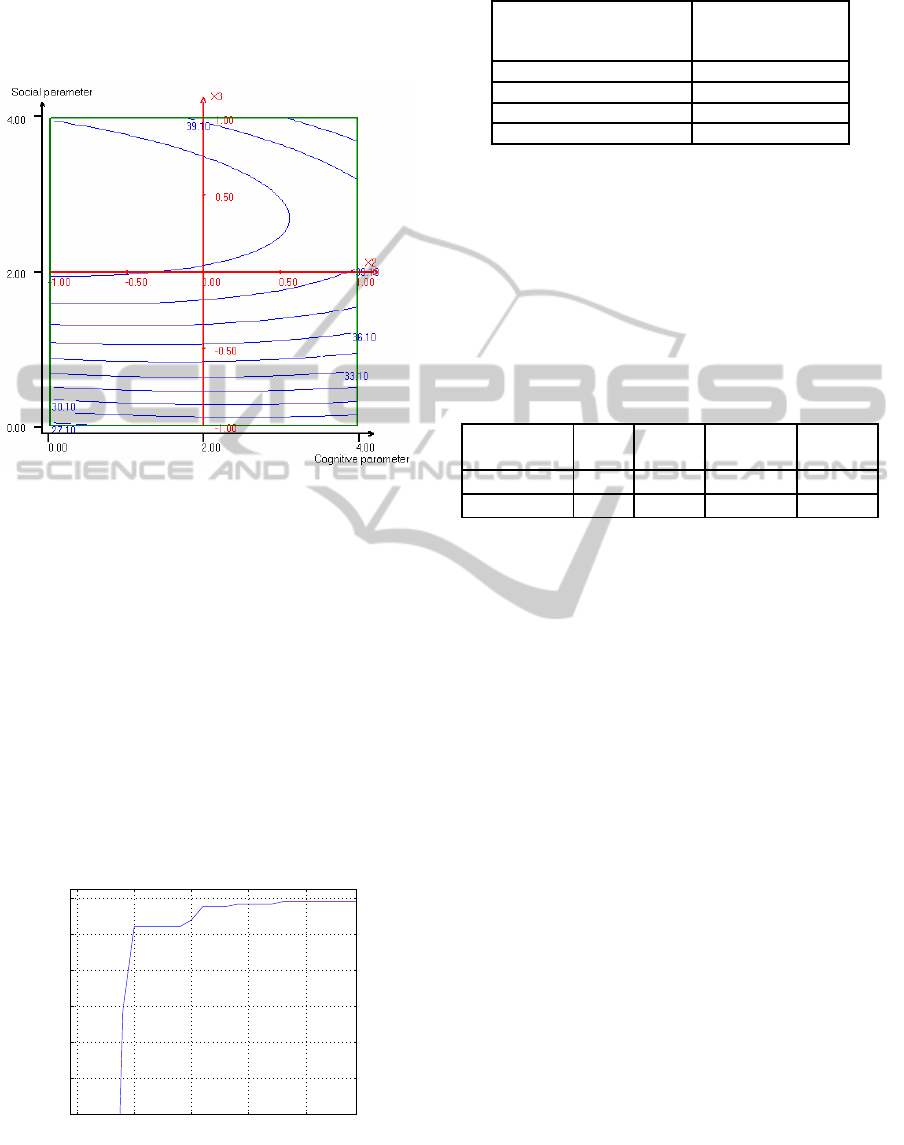

The response surface curves described by regres-

sion model are shown in figure 4.

Figure 4: Responses surface plot of cognitive parameter

(w

1

), social parameter (w

2

) and their mutual interaction on

alpha-amylase activity (Y), with an optimum level of swarm

size (N) of 65.

For equation derived from the differentiation of

equation (8), the optimal values of N, w

1

and w

2

in

coded units were found to be 0, -0.980 and 0.509 re-

spectively. Correspondingly, we can obtain the op-

timal combination of three parameters 65, 0.04 and

3.02 respectively.

In order to determine the maximum number of

generations, we have plotted the response curve in

function of number iteration, and we have presented

the results in figure 5. From figure, we deduce that

the maximum number of generations to reach the bet-

ter solution (Y = 40.3739U/ml) is 18 generations.

0 5 10 15 20

1.39

1.4

1.41

1.42

1.43

1.44

1.45

No. of iterations

Normalized alpha−amylase activity (U/ml)

Figure 5: Convergence process of solving optimization task

with PSO algorithm.

Table 3: Results after tuning parameters of PSO algorithm.

w: inertia parameter starting at 1.2 and

gradually declining

towards 0

N: Swarm size 65

w

1

:cognitive parameter 0.04

w

2

: Social parameter 3.02

G: Number of generation 18

4.4 Optimization Bioprocess Example

The result obtained are shown in the first row of table

4. As it is shown in the last column of the table, the

maximum value for alpha-amylase activity by RBF-

PSO algorithm is 40.3739U/ml which is much better

than the valueobtained by SM-GA algorithm reported

in (Dandach-Bouaoudat et al., 2010).

Table 4: Results after tuning parameters of PSO algorithm.

Approaches x

1

x

2

x

3

Y

(

◦

C) rpm spore/ml U/ml

RBF-PSO 21.88 303.22 7 40.3739

SM-GA 25.14 249.36 7.23 31.7

5 CONCLUSIONS

This work found that RBF neural network provided

good fits to experimental data. The hybrid RBF-PSO

approach described in this work serves as a viable al-

ternative for the modelling and optimization of fer-

mentation process. Alpha-amylase activity rises up to

40.37U/ml under the optimal culture conditions ob-

tained by RBF-PSO approach. This work indicates

that the coupling of RBF neural networks with PSO

algorithm has good predictability and accuracy in op-

timizing the multi-factor, non-linear, and time-variant

bioprocess. The knowledge and information obtained

here may be also helpful to the other industrial bio-

process to improve productivity.

Perspectives on work is conducting more expere-

ments, espacially for those data that have more pa-

rameters need to be optimized. We will also test

other artificial intelligence techniques for modelling

and optimization bioprocess and compared with the

proposed method.

OPTIMIZATION OF A SOLID STATE FERMENTATION BASED ON RADIAL BASIS FUNCTION NEURAL

NETWORK AND PARTICLE SWARM OPTIMIZATION ALGORITHM

291

REFERENCES

Carlisle, A. and Dozier, G. (2001). An off-the-shelf PSO.

In Proceedings of the workshop on particle swarm op-

timization. Indianapolis, IN: Purdue School of Engi-

neering and Technology, IUPUI.

Ceylan, H., Kubilay, S., Aktas, N., and Sahiner, N. (2008).

An approach for prediction of optimum reaction con-

ditions for laccase-catalyzed bio-transformation of 1-

naphthol by response surface methodology (RSM).

Bioresource technology.

Chang, S., Shaw, J., Yang, K., Chang, S., and Shieh, C.

(2008). Studies of optimum conditions for cova-

lent immobilization of Candida rugosa lipase on poly

([gamma]-glutamic acid) by RSM. Bioresource tech-

nology.

Dandach-Bouaoudat, B., Yalaoui, F., Amodeo, L., and

Entzmann, F. (2010). Optimization of a solid state

fermentation using Genetic Algorithm. In 5th Interna-

tional Symposium on Hydrocarbons and Chemistry-

Sidi Fredj, Algiers.

Dutta, J., Dutta, P., and Banerjee, R. (2004). Optimization

of culture parameters for extracellular protease pro-

duction from a newly isolated Pseudomonas sp. using

response surface and artificial neural network models.

Process biochemistry.

Hassan, R., Cohanim, B., De Weck, O., and Venter, G.

(2005). A comparison of particle swarm optimization

and the genetic algorithm. In Proceedings of the 1st

AIAA Multidisciplinary Design Optimization Special-

ist Conference.

Hu, X., Eberhart, R., and Shi, Y. (2003). Engineering op-

timization with particle swarm. In Proceedings of

the 2003 IEEE Swarm Intelligence Symposium, 2003.

SIS’03.

Kammoun, R., Naili, B., and Bejar, S. (2008). Applica-

tion of a statistical design to the optimization of pa-

rameters and culture medium for [alpha]-amylase pro-

duction by Aspergillus oryzae CBS 819.72 grown on

gruel (wheat grinding by-product). Bioresource tech-

nology.

Kennedy, J. (1998). The behavior of particles. In Evolu-

tionary Programming VII. Springer.

Kennedy, J., Eberhart, R., et al. (1995). Particle swarm op-

timization. In Proceedings of IEEE international con-

ference on neural networks. Piscataway, NJ: IEEE.

Kennedy, M. and Krouse, D. (1999). Strategies for im-

proving fermentation medium performance: a review.

Journal of Industrial Microbiology and Biotechnol-

ogy.

Kunamneni, A. and Singh, S. (2005). Response surface op-

timization of enzymatic hydrolysis of maize starch for

higher glucose production. Biochemical Engineering

Journal.

Shi, Y. and Eberhart, R. (1998). Parameter selection in par-

ticle swarm optimization. In Evolutionary Program-

ming VII. Springer.

Ustok, F., Tari, C., and Gogus, N. (2007). Solid-state

production of polygalacturonase by Aspergillus sojae

ATCC 20235. Journal of biotechnology.

Wilson, D., Irwin, G., and Lightbody, G. (1999). RBF prin-

cipal manifolds for process monitoring. IEEE Trans-

actions on Neural Networks.

BIOINFORMATICS 2011 - International Conference on Bioinformatics Models, Methods and Algorithms

292