A MULTI-PIN DROPLET ROUTING

ALGORITHM FOR DIGITAL MICROFLUIDIC BIOCHIPS

Pranab Roy, Hafizur Rahaman

School of VLSI Technology, Bengal Engineering and Science University, Shibpur, India

Parthasarathi Dasgupta

Indian Institute of Management Calcutta, India

Keywords: Digital Microfluidics, Algorithms, Placement and Routing, Biochips.

Abstract: Digital microfluidic biochips have emerged as a major area of attention in the fields of Clinical Research,

Medical diagnostics and are destined to revolutionize the biological laboratory procedure in coming years.

As the use of Digital microfluidic biochips becomes widespread in safety critical biomedical applications –

the need for enhanced automation for the complex biological procedures become more pronounced. In this

paper, we attempted to design a high performance routing procedure applicable for multi-pin digital

microfluidic biochips that deals with multiple source target routing in a concurrent manner using

hierarchical approach. The avoidance of cross contamination is a key challenge in the design of a biochip.

Our paper attempts to minimize this problem while parallel routing of droplets with an aim to optimize the

cell utilization and minimize the overall routing time as well. The proposed method uses a special technique

for clustering the sub-problems together and uses a hierarchical scheme to optimize the routing process.

Empirical results obtained are quite encouraging.

1 INTRODUCTION

A biochip is a collection of miniaturized test sites

(microarrays) arranged on a solid substrate that

permits many tests to be performed at the same time

in order to achieve higher throughput and speed.

The idea of low cost and reliable chip model that

resembles an electronic chip that performs thousands

of biological reactions within a very small area

gained huge interest among scientists and

biotechnologists in recent times. Because these chips

can automate highly repetitive laboratory tasks by

replacing cumbersome equipment with miniaturized,

microfluidic assay chemistries, they are able to

provide ultra-sensitive detection methodologies at

significantly lower costs per assay than traditional

methods—and in a significantly smaller amount of

space.

One of the most advanced technologies to build a

biochip is based on microfluidics where micro- or

nano-liter droplets are controlled or manipulated to

perform intended biochemical operations on a

miniature lab, commonly known as a lab-on-a-chip

(LOC).The major advantages of using microfluidics

are i) Surface effects become prominent with high

surface area to volume ratio, ii) Low thermal mass

and high heat transfer, and iii) Low value of

Reynolds number and thus laminar flows which only

result in diffusional mixing.

The earlier generation of microfluidic biochips

was based on continuous fluid flow in permanently

etched microchannels using micropumps and

microvalves for actuation. These devices relied on

electrical methods such as electrokinetics to control

the sample flows.

A major alternative is to manipulate liquid

samples as discrete droplets. The second generation

of microfluidic biochips is based on this approach

and is referred to as Digital microfluidic biochips.

Discrete droplets of the nanoliter volume are

manipulated on a patterned array of electrodes. On a

digital microfluidic biochip (DMFB), the electro-

hydrodynamic force generated by the electrodes

216

Roy P., Rahaman H. and Dasgupta P..

A MULTI-PIN DROPLET ROUTING ALGORITHM FOR DIGITAL MICROFLUIDIC BIOCHIPS.

DOI: 10.5220/0003164402160223

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2011), pages 216-223

ISBN: 978-989-8425-37-9

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

controls movements of the droplets. The electrodes

in the microfluidic array are controlled by

independent control pins, which actuate free

movement of the droplets on the array. By assigning

time-varying voltage values to turn on/off the

electrodes on the digital microfluidic biochip, it is

possible to move the droplets around the entire 2D

array and perform fundamental microfluidic

operations (such as, mixing reactions) for different

bioassays. The applied voltages are changed

according to the need for moving the droplets from

one electrode to the other, and the process can be

controlled by a processor of predefined clock

frequency that determines the velocity of movement

of the droplets (Su and Chakraborty, 2004). These

operations performed under the control of the

electrodes are reconfigurable operations because of

their flexibility in area (electrodes involved) and in

execution time. Digital microfluidic biochips allow

continuous sampling and analysis capabilities for

online and real-time chemical/biological sensing.

Digital microfluidic biochips have a vast

multitude of applications including clinical

diagnosis, environmental studies, and military

operations. Due to their digital nature, any operation

on droplets can be accomplished with a set of library

operations like VLSI standard library, controlling a

droplet by applying a sequence of preprogrammed

electric signals (actuation sequences) (Zeng, Liu,

Wue and Yue, 2007).Therefore, a hierarchical cell-

based design methodology can be applied to a

DMFB.

The first top down methodology for a DMFB

proposed by (Su and Chakraborty, 2004) mainly

consists of architecture level synthesis and

geometry-level synthesis. The geometry-level

synthesis in DMFBs broadly involves placement of

modules (source, mixer and target) and droplet

routing. During module placement, the location of

each module is determined to minimize chip area or

response time. In droplet routing, the path of each

droplet transports it without any unexpected or

accidental mixing under design requirements.

In this paper, attempts are made to route 2-pin

and multi-pin nets (which imply number of droplet

samples moving to the same target is greater than or

equal to two) in digital microfluidic biochip using a

hierarchical approach. The objectives are to optimize

(i) the number of electrodes used to route all the

droplets from source to target (via the mixer in case

of multi-pin droplets) and (ii) the overall droplet

routing time. This, in turn, optimizes the area,

routabilty and throughput.

The organization of the remaining paper is

arranged as follows. Section 2 deals with existing

works on droplet routing. Section 3 depicts the

fundamentals of droplet routing. Section 4

introduces the problem formulation with multi-pin

droplet routing. Section 5 discusses the algorithm for

clustering the sub-problems together to deal with

maximum parallel routability. Section 6 describes

the routing algorithm using hierarchical approach

.Section 7 depicts the final results for the given test

cases along with graphical representation of the

clusters showing sub-problem connectivity. Finally,

section 8 provides the conclusion with analysis of

results.

2 EXISTING WORKS

A critical step in biochip automation is droplet

routing, which provides an overall estimation of the

net performance time as well as resource utilization.

Numerous techniques are proposed for optimization

of droplet routing in biochips. A graph coloring

approach was proposed by (Akela, Griffith and

Goldberg, 2006), which is applied to each successive

cycle of direct addressing solution. In this work

direct addressing was defined as the control

mechanism of droplet movement over the electrodes

by direct addressing of the micro-controller control

unit. An acyclic graph was generated based on the

movement time of the droplets and coloring was

done based on concurrent routing of droplets. DMFB

arrays with hardware limited row-column addressing

are considered, and a polynomial-time algorithm for

coordinating droplet movement under such hardware

limitations was developed. Direct addressing method

was also used by (Xu and Chakraborty, 2007) where

the droplet routing problem is mapped into graph

clique model. Droplet routing time is optimized by

optimal partitioning of the clique model. (Lin, Yang,

Wen, Ping and Sapnetkar, 2008) explored the use of

direct addressing mode in their work of routing for

biochip, using integer linear programming (ILP) to

solve the problem. In works of (Hwang, Su and

Chakraborty, 2006) dynamic reconfigurability of the

microfluidic array is exploited during run-time. The

proposed method starts with an initial placement

technique. A series of 2-D placement configurations,

in different time spans, is obtained in the module

placement phase. Then appropriate routing paths are

determined to complete droplet routing. The authors

decompose a given problem into a series of sub-

problems, based on their initial placement and solve

them sequentially to find the ultimate solution. (Cho

A MULTI-PIN DROPLET ROUTING ALGORITHM FOR DIGITAL MICROFLUIDIC BIOCHIPS

217

and Pan, 2008) proposed a high performance droplet

routing algorithm using a grid based representation.

Their proposed algorithm initially checks which

droplets can be routed freely (without any obstacle

or blockage due to other droplets). Then the droplets

are arranged to route in parallel without considering

blockage. Routing of the remaining droplets is

considered in presence of blockage and a concession

zone was introduced to ascertain feasibility of the

routing. Finally a compaction based algorithm was

run to optimize the solution. In works of (Yang, Yuh

and Chang, 2007) a network flow based method was

proposed for droplet routing. The proposed method

was based on non-intersecting bounding box

technique. The bounding box of each net was first

obtained. Then a set of nets having non-intersecting

bounding boxes were chosen for routing. The

remaining nets were routed using min-cost max-flow

algorithm. An A* search algorithm was proposed by

(Boahringer, 2006). The states of the source-target

pairs at different times are differentiated using a

graph representation. Then optimal path from source

to target was chosen using the A* search algorithm.

(Xu and Chakraborty, 2007) presented a droplet-

routing-aware automated synthesis tool for

microfluidic biochips. Droplet routability, defined as

the ease with which droplet pathways can be

determined, is first estimated and integrated in the

synthesis flow. (Zhao and Chakraborty, 2009)

proposed a droplet-routing method that avoids cross-

contamination in the optimization of droplet flow

paths. This approach targets disjoint droplet routes

and minimizes the number of cells used for droplet

routing. (Roy, Rahaman and Dasgupta, 2010)

proposed a simple algorithm for concurrent path

allocation to multiple droplets, based on the

Soukup’s routing algorithm proposed by (Soukup,

1978) together with the use of stalling, and possible

detouring of droplets in cases of contentions.

Selection of the droplets was based on the lengths of

the respective source to target Manhattan paths. A

partition-based algorithm for pin-constraint based

design was proposed in (Xu and Chakraborty, 2006).

3 DROPLET ROUTING IN

DMFBS

The primary objective of droplet routing was to

transmit all the droplets from source to target within

a 2D grid array while fulfilling all the necessary

constraints. In this regard an efficient schedule has

to be developed that provides an optimized routing

both in terms of timing as well as electrodes

utilization.

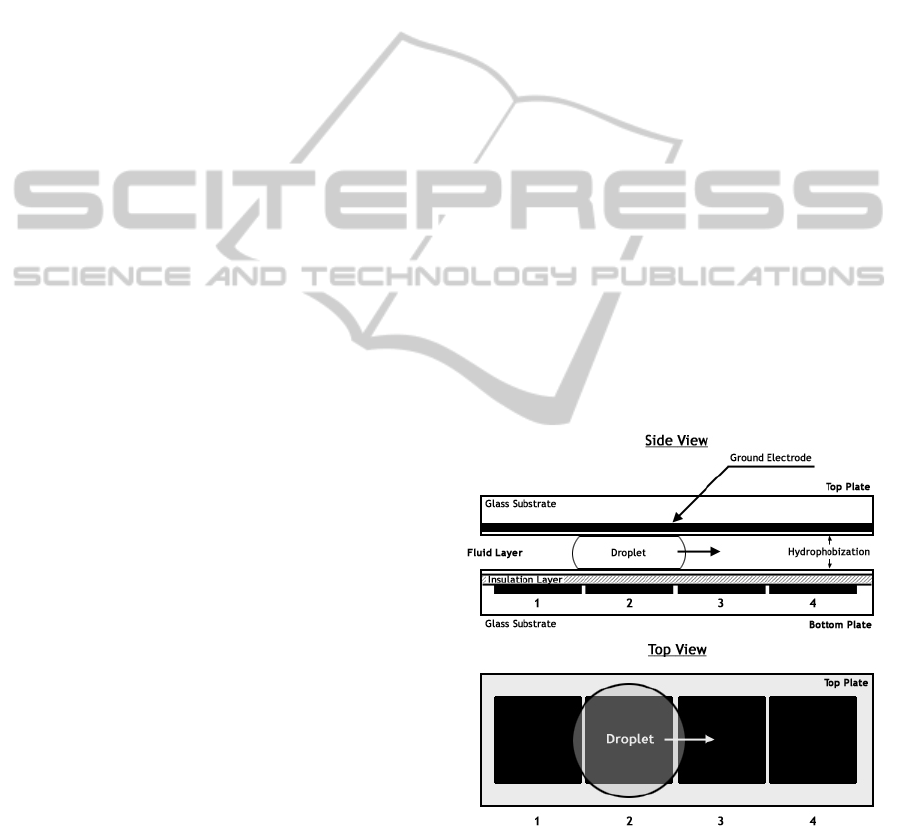

The droplets are sandwiched between two

electrodes (Fig 1) and the motion is actuated from

one electrode grid to another using the principle of

Electrowetting on dielectrics. We model the droplet

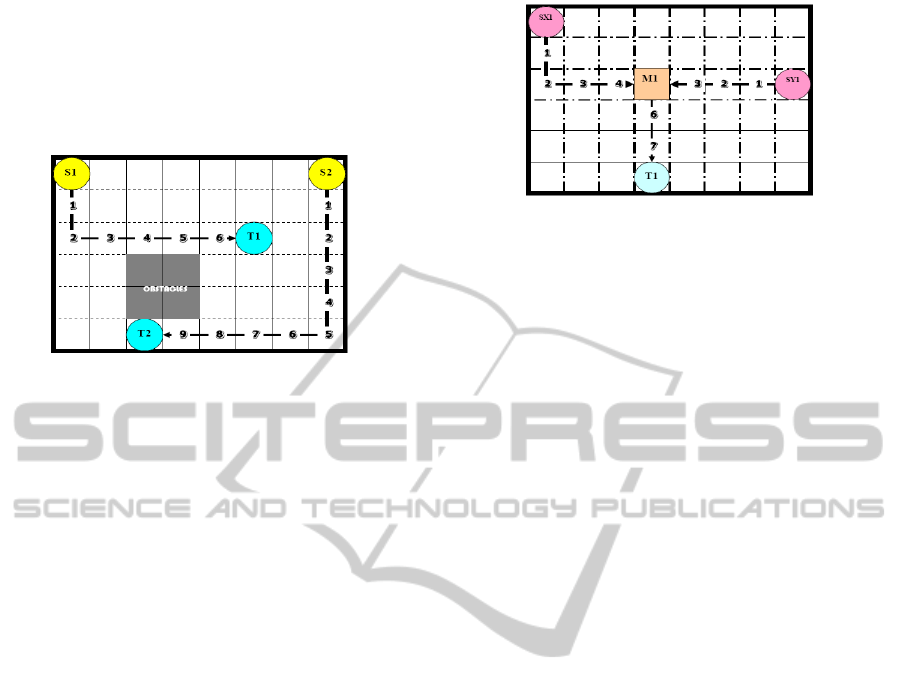

routing problem in DMFBs as a 2D-grid (Fig 2). For

each droplet, there exists a set of source grid

locations, and a set of target grid locations. Each

source to target combination is referred to as a net. If

only one source and one target are involved in a

given net, it is a 2-pin net. If multiple sources,

mixers and a single target are involved, it is a multi-

pin net. Two Sources, one Mixer and one Target

combination is referred to as a 3-pin net (Fig 3). Our

goal is to route every droplet, if feasible, from its

source location to its target location possibly through

mixers, subject to several constraints.

The constraints generally applied for droplet

routing are defined as follows. For a successful

droplet routing, a minimum spacing between

droplets must be maintained to prevent accidental

mixing. In cases of 3-pin nets or multi-pin nets,

droplet merging is desired at specific locations

termed as mixers. Several microfluidic modules

required for mixing, splitting, storage and other

operations are placed on the array. These are

considered as obstacles in droplet routing.

Figure 1: Droplet actuation principle in DMFB using

EWOD (Hwang, Su and Chakraborty, 2006).

In order to avoid conflicts between droplet routes

and assay operations, a segregation region is defined

around the functional region of microfluidic

modules. In this way, droplet routing can easily be

isolated from active microfluidic modules. During

BIODEVICES 2011 - International Conference on Biomedical Electronics and Devices

218

routing of multiple droplets concurrently in time-

multiplexed manner, there are possibilities of

intersection or overlapping of droplets coming in

collision course. Certain fluidic constraints are

introduced in order to avoid such undesirable

behavior.

Figure 2: Droplet routing in a 2D Grid where S1, S2

represents. Sources; T1, T2 represent Targets along with

timestamps and Obstacles (Latest arrival time = 10).

Let d

id

at (x

t

i,

y

t

i

) and d

j

at (

x

t

j

, y

t

j

) denote two

independent droplets at any given timestamp t.

Then, the following constraints, generally called

Fluidic Constraint should be satisfied for any time t

during routing: (Roy, Rahaman and Dasgupta, 2010)

• Static constraint: | x

t

i

– x

t

j

| >1 or | y

t

i

– y

t

j

|

>1

• Dynamic constraint: | x

t+1

i

– x

t

j

| >1 or |

y

t+1

i

– y

t

j

| >1

Or | x

t

i

– x

t+1

j

| >1 or | y

t

i

– y

t+1

j

| >1

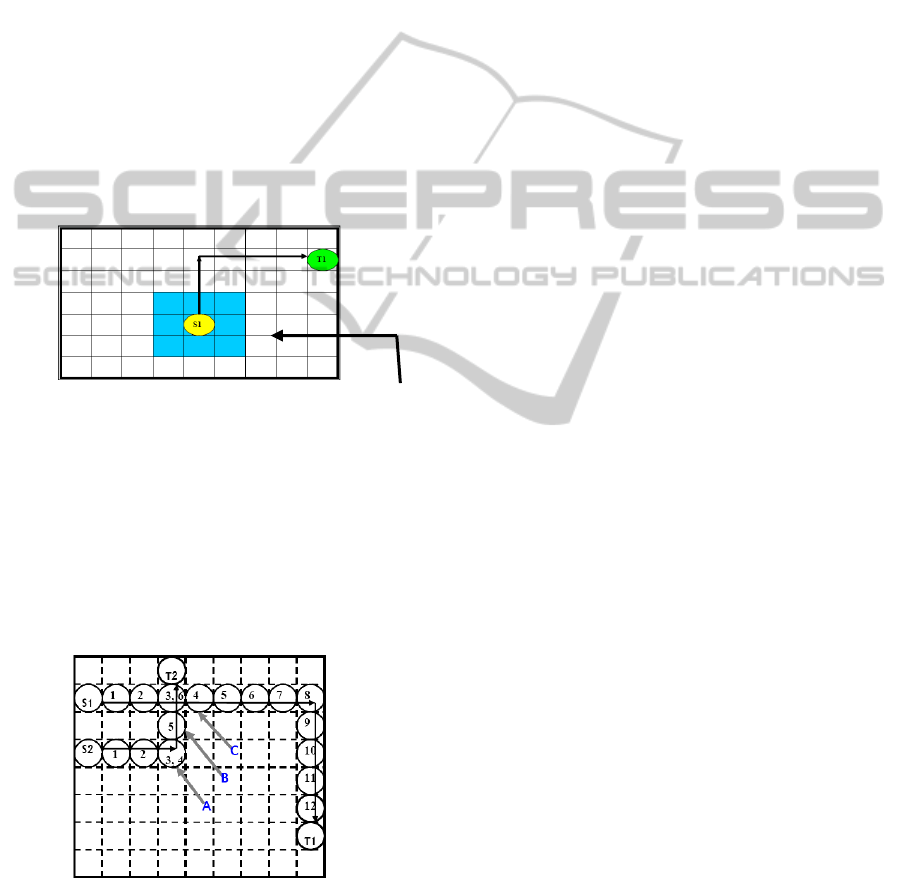

This implies that for any droplet at location

(x,y)- all the locations (x+1,y),(x-1,y),(x,y+1),(x,y-

1),(x+1,y+1),(x+1,y-1),(x-1,y-1),(x-1,y+1) are

prohibited for any other droplet to enter at

timestamp t and t + 1 in order to maintain the above

mentioned fluidic constraints. Hence, all the

locations neighboring (x,y) as referred to above

comprise the Critical Zone (Fig. 4) for any droplet at

(x,y) at time t.

The Timing Constraint provides the maximum

allowed transportation time of a droplet in the given

set.

4 PROBLEM FORMULATION

Parallel routing of droplets are necessary to optimize

the latest arrival time. In most of the approaches

described in Section 2, concurrent routing has been

attempted for those droplets whose paths are free of

obstacles. Then remaining droplets are taken care of

for their routing to respective targets sequentially

Figure 3: 3-Pin droplet routing with hierarchical approach

with two sources SX1 and SY1, One Target T1; Latest

arrival time (1

st

Generation – 5), Latest arrival Time (2

nd

Generation – 8).

using stalling and detour. In (Roy, Rahaman and

Dasgupta, 2010) however an overall concurrent

routing approach is adopted to obtain a virtual route

plan depending on relative locations of modules,

samples and targets. The results show encouraging

improvements for both time and resource

utilizations. However, no attempt has been made so

far to address the issue for multi-pin droplets as only

2-pin cases were resolved in (Roy, Rahaman and

Dasgupta, 2010) .Our work specifically attempts to

resolve the issue of 2-pin and multi-pin droplets

concurrently using a hierarchical approach for multi-

pin droplets.

The routing problem can be formulated as

follows: Given a two-dimensional array of

electrodes placed over a square microfluidic biochip

(a square layout area) as shown in Fig. 2 and Fig. 3.

A set of module locations is given in a grid. A

number of sub-problems clustered in different

subsets provide the source, target locations for 2-pin

nets and multiple source, mixer and corresponding

target locations for multi-pin nets. The objective is

to find the possible shortest path for each source to

target (via mixer, if any) taking into consideration of

the fluidic constraints mentioned in previous section

and thereby route each droplet to its destination with

optimum arrival time as well as minimal utilization

of electrodes.

In the process, we have to cluster the sub-

problems that comprise a total set into separate

subsets to maximize the number of droplets in the

individual subsets to be routed concurrently. The

reason is that it is not possible to place all the sub-

problems in a given test set at the same grid as it

violates fluidic constraints for placement. Each

cluster (subset of nets) is routed concurrently,

whereas the different clusters are routed one after

another in a sequence with clusters with largest

number of samples being routed first and so on.

A MULTI-PIN DROPLET ROUTING ALGORITHM FOR DIGITAL MICROFLUIDIC BIOCHIPS

219

5 METHOD OF CLUSTERING OF

SUB-PROBLEMS

Given a test case with n sub-problems. The fluidic

constraints for placement of source target and mixers

are as follows:

1. No two source location should coincide or

be placed at critical zone (adjacent cell) of

each other.

2. No Target location should coincide with

other or with any other mixer or in any

critical zone of mixer.

3. No Mixer should coincide with any other

mixer, source, or target or in any critical

zone of other mixer, source or target.

It is found that not all the sub-problems conform to

the placement fluidic constraints. Hence, the aim is

to cluster

Critical Zone

Figure 4: Critical zone around a droplet S1 in a moving

state (Roy, Rahaman and Dasgupta, 2010).

maximum number of sub-problems in a subset

together that do not violate the previously mentioned

constraints and route them together. Then go for the

next cluster, which contains next largest number of

sub-problems, which are not already routed in the

previous cluster. The process is continued until all

sub-problems have been considered.

Figure 5: Example of droplet routing with time stall (Roy,

Rahaman and Dasgupta, 2010).

5.1 The Clustering Algorithm

Input: A test case with n number of sub-problems,

compatibility_list[i] for each sub-problem

number i

initialized to null.

Step1: find the compatibility list for each sub-

problem

for i = 1 to n

Add i to compatibility_list[i]

for j = 1 to n

check compatibily with i (if j ≠ i)

if compatible add j to

compatibility_list[i]

end for

sort compatibility_list[i] in ascending

order of

Sub-problem Number.

end for

Step 2: Find the final set of clusters

for i = 1 to n-1

for j = i+1 to n

find intersection of compatibility_list[i]

and compatibility_list[j]

let number of elements in the

intersection set be m

for k = 1 to m

if (k ≠ i) and (k≠ j)

check compatibility of k with

other members

of the set from

compatibility_list[k]

if any member is not compatible,

exclude

them from the set comprising i, j

and k

end for

end for

end for

finally x number of sets comprising all the

numbers of

sub-problems are formed.

Step 3: Find out the set with largest number of sub-

problems.

Step 4: Exclude these members from other sets.

Step 5: Check if all sub-problems are exhausted.

Step 6: If some sub-problems are yet to be routed

repeat step 2 with remaining sets after the previously

mentioned exclusion.

Compatibility of nets may be represented as a graph,

with each node representing a net, and presence of

an edge between a pair of nets indicating their

compatibility (no violation of module placement

constraints).

BIODEVICES 2011 - International Conference on Biomedical Electronics and Devices

220

6 PROPOSED METHOD OF

ROUTING FOR EACH

CLUSTER

In this approach, we attempt an overall concurrent

routing of the droplets grouped in individual clusters

formed according the method stated in Section 5.

The method is described below:

1. The overall time is measured in terms of

timestamps for each source. For each source, the

start time is initialized to zero and a timestamp

increment of one is considered for each transition

from one cell to its adjacent cell.

2. The Manhattan distance between each source,

mixer, target combination is computed. For a 2-pin

source S

i

(x,y) and Target T

i

(x,y) the distance D

i

is

computed as [S

i

(x) ~ T

i

(x)]+ [S

i

(y) ~ T

i

(y)].For a 3-

pin source SX

i

(x,y),SY

i

(x,y) and Mixer M

i

(x,y)along

with target T

i

(x,y) -- the distance D

i

is computed as

[{SX

i

(x) ~ M

i

(x)}+ {SX

i

(y) ~ M

i

(y)}] + [{SY

i

(x) ~

M

i

(x)}+ {SY

i

(y) ~ M

i

(y)}]+ [{M

i

(x) ~ T

i

(x)}+

{M

i

(y) ~ T

i

(y)}]. Same ordering of nets is used for

multi-pin nets as well.

3. The Manhattan distance thus obtained for each

droplet set is sorted in descending order. The routing

of each droplet set (2- pin or 3-pin) is carried out in

the same order.

4. Routing of the droplets is carried out using

Soukup’s routing algorithm. For 2-pin nets each

source is routed directly towards the corresponding

target. However, for 3-pin nets each source SX and

SY is routed parallel to the corresponding mixer.

This is termed as 1

st

Generation route. The largest

arrival time T

SM

among (SX Æ M) and (SY ÆM) is

noted. Then the final mixed droplet from Mixer M is

routed to Target T. This is termed as 2

nd

Generation

route. In case of 2

nd

generation route, the timestamp

starts from T

SM

as determined earlier.

5. In case there is a clear path for any source to

target or source to mixer or mixer to target route,

then routing is completed easily. Detouring is

required in the presence of obstacles.

6. Consider the case when droplet from a source

arrives at a cell such that in the same timestamp

droplet from another source is also reaching the

same cell or in an adjacent cell within the critical

zone. In such a case, any one of the two sources is

stalled for a certain amount of time until the

difference of timestamps between the two sources

becomes at least two (Fig 5). The source with larger

Manhattan distance among the two is allowed to

route and the other one is stalled. However if it is

found that there remains a scope of detour through a

path which has been utilized before by some other

droplet – if stalling takes too long (empirically if it

is greater than 4 timestamps approximately) –

detouring through utilized path is favorable – as it

optimizes the utilization of resources in terms of

electrodes.

7. Finally, one more possibility may be encountered

while routing of droplets: deadlock. In this situation,

a droplet S

x

is stalled as it is in a collision course

with another droplet S

y

that has a higher routing

preference due to larger Manhattan distance.

However the second droplet S

y

may also get stalled

due to the movement of a Third droplet S

z

which in

turn can not move due to current position of S

x

or S

y

or any other blockage .In such cases it is necessary

to identify the specific droplet which is responsible

for deadlock – thereby detour it to a safe

position(this phenomenon is known as

retreat)through a different path and stall it to that

safe position for a certain amount of time – which

allows other two droplet to steer clear towards their

respective destinations.

In this approach we resorted to route the droplets

in an order of longest Manhattan distance first – the

reason behind this is as follows: the one expected to

take maximum time (approximately) is routed first

without any chance of stalling, thereby the critical

time, which tentatively defines the maximum arrival

time remains unaffected. This technique provided

encouraging improvement in Latest arrival time.

As already stated, during routing, attempt is

made to have a trade off between stalling and detour.

This is to optimize both time as well as total number

of unit cells utilized for routing.

7 RESULTS

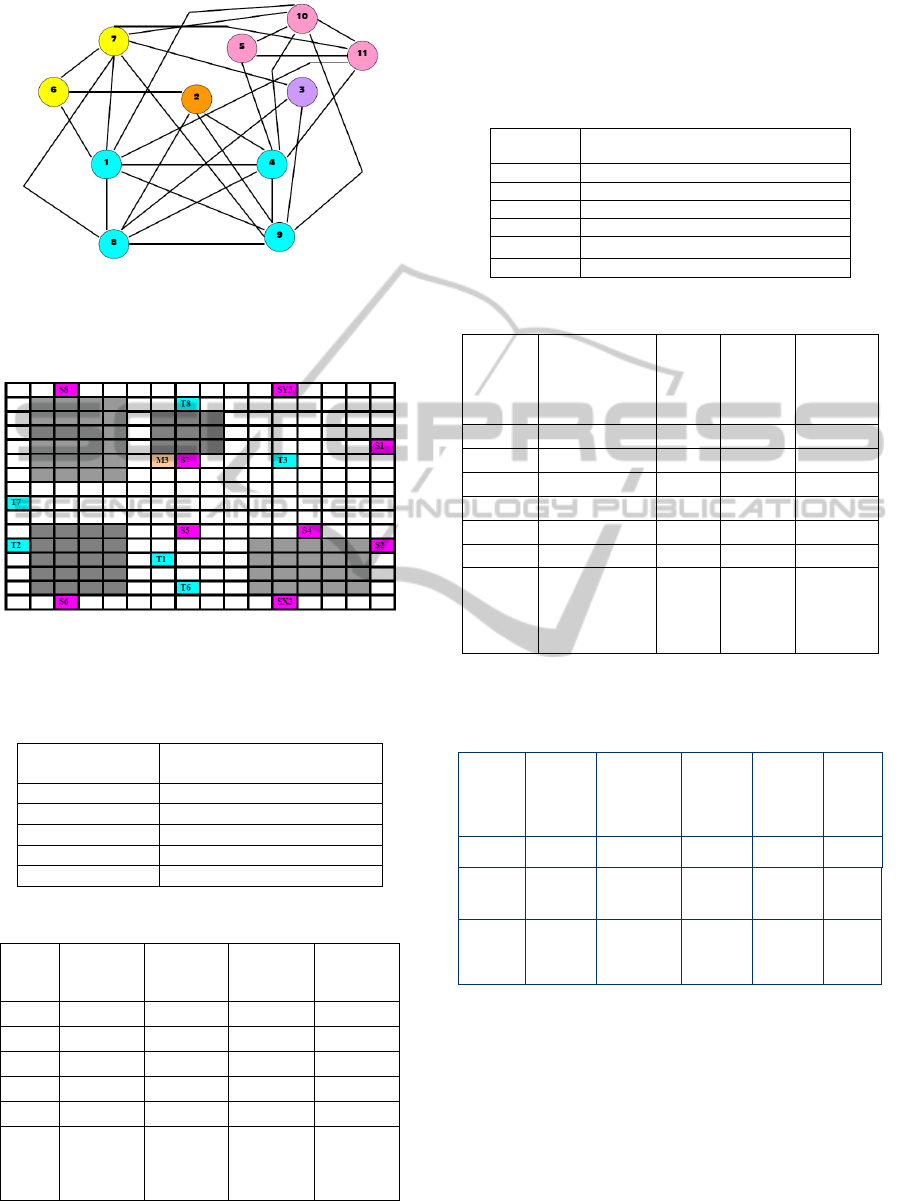

The two testbenches considered are In_Vitro_1 and

In_Vitro_2. In_Vitro_1 contains twenty 2-pin

droplets and six 3-pin Droplets with eleven sub-

problems on a 16 x 16 grid. In_Vitro_2 contains

twenty-six 2-pin droplets and six 3-pin droplets with

15 sub-problems on a 14 x 14-grid electrode.

7.1 Results for In_Vitro_1

Number of Sub-problems = 11

Figure 6 represents a compatibility graph In vitro 1.

Each node of the graph represents a sub-problem,

and nodes of same color belong to the same cluster.

A MULTI-PIN DROPLET ROUTING ALGORITHM FOR DIGITAL MICROFLUIDIC BIOCHIPS

221

Figure 6: The sub-problem connectivity graph for

In_Vitro_1 (based on compatibility with each other) Each

color representing one cluster and each circle representing

one sub-problem.

Figure 7: Sample placement diagram for Cluster 1 for

In_vitro_1 (Source ÆPink; Target ÆBlue, Mixer

ÆOrange, Blockage ÆGray).

Table 1a: Final set of clusters obtained for In Vitro_1.

Cluster Number

Set of sub-problems in

cluster

1 {1,4,8,9}

2 {5,10,11}

3 {6,7}

4 {2}

5 {3}

Table 1b: Final Route table for all clusters for In_Vitro_1.

Grid

Cluster

No{Set}

Number of

droplets

(2pin+3pin)

Latest

Arrival

Time

Electrode

Utilization

16 X 16 1{1,4,8,9} 7+1 = 8 24 59

16 X 16 2{5,10,11} 2+2 = 4 21 51

16 X 16 3{6,7} 6+0 = 6 10 36

16 X 16 4{2} 2+1 = 3 26 47

16 X 16 5{3} 3+2 = 5 20 47

Total - 5

Total – 2-

pin – 20

3-pin – 6

Total Time

– 101

Net

Electrode

Utilization

- 131

7.2 Results for In_Vitro_2

Number of Sub-problems = 15

Table 2a: Final set of clusters obtained for In vitro_2.

Cluster

Number

Set of sub-problems in cluster

1 {1,2,7,10,14,15}

2 {5,11,12}

3 {6,9,13}

4{3}

5{4}

6{8}

Table 2b: Final Route table for all clusters for In_Vitro _2.

Grid

Cluster

No {Set}

Number

of

droplets

(2-pin +

3 - pin)

Latest

Arrival

Time

Electrode

Utilization

14 X 14 1{1,2,7,10,14,15} 7+1 = 8 16 57

14 X 14 2{5,11,12} 6+1 = 7 15 37

14 X 14 3{6,9,13} 4+2 = 6 29 49

14 X 14 4{3} 4+1 = 5 23 50

14 X 14 5{4} 3+0 = 3 12 16

14 X 14 6{8} 5+1 = 6 16 37

Total - 6

Total –

2-pin –

26

3-pin – 6

Total Time

–

111

Net

Electrode

Utilization

- 95

Table 3: A comparative result for total Electrode

Utilization With other algorithms for two test sets –

In_Vitro_1 and In_Vitro_2.

Test

Design

Prioritized

A*

Boahringer

(2006)

Two Stage

Hwang, Su,

Chakraborty

(2006)

Network

Flow

Yang, Yuh,

Chang

(2007)

Cho

Pan

Algorithm

Cho, Pan,

(2008)

Our

Algorithm

Name

Cell

Utilization

Cell

Utilization

Cell

Utilization

Cell

Utilization

Cell

Utilization

In

Vitro 1

(16 X 16)

269 263 237 258 131

In

Vitro2

(14 X14)

failed Failed 236 246 95

8 CONCLUSIONS

Here we have taken two specific test sets In_Vitro_1

(having 20 2-pin droplets and 6 3-pin Droplets with

11 sub-problems on a 16 x 16 grid) and In_Vitro_2

(having 26 2-pin droplets and 6 3-pin droplets with

15 sub-problems on a 14 x 14 grid). We attempted to

cluster the sub-problems as shown in Table 1.a and

table 2.a so as to handle as many sub-problems

BIODEVICES 2011 - International Conference on Biomedical Electronics and Devices

222

concurrently as possible taking care of the fluidic

constraints for placement (as stated in Section 5).

The results of routing giving individual latest arrival

time for each cluster as well as overall route time for

each Test set is shown in Table 1.b and Table 2.b.

The overall electrode utilization is also shown for

each test case. A comparative study with other

algorithms shows major improvement in terms of

Cell Utilization for each test case as evident from the

table 3.

Hence, in terms of resource utilization this

algorithm shows remarkable improvement and is

able to route maximum droplet as allowed by the

placement constraints concurrently. This algorithm

can be extended to more than three pins to be routed

hierarchically. Also as the routing technique used

here does not guarantee the shortest path, hence

there remains further scope of improvement

regarding this area, which may enhance the latest

arrival time further.

ACKNOWLEDGEMENTS

This work has been supported in part by VLSI

Design Project, DIT, Govt. of WB,INDIA and

SMDP-II project, DIT, MCIT, Government of

India.

REFERENCES

Huang W., Su F., Chakraborty K., 2006 “Automated

design of pin-constrained digital microfluidic arrays

for lab-on-a- chip applications”— In Proceedings of

the 43rd annual Design Automation Conference, San

Francisco, CA, USA Pages: 925 – 930.

Su F., Chakrabarty K., 2004. “Architectural-Level

synthesis of digital microfluidics-based biochips”. In

Proceedings of IEEE International Conference on

CAD, pages 223-228.

Zeng X., Liu L., Wu J., Yue R., 2007 “ Droplets Actuating

Chip Based On EWOD”. Springer-Verlag.

Akella A., Griffith E. J., Goldberg M. K., 2006

“Performance characterization of a reconfigurable

planar-array digital microfluidic system.” IEEE

Transactions Computer-Aided Design of Integrated

Circuits and Systems, 25(10):340-352, February.

Xu T., Chakrabarty K., 2007 “A cross-referencing-based

droplet manipulation method for high-throughput and

pin-constrained digital microfluidic arrays.” In

Proceedings of Design Automation and Test in

Europe, pages 552 - 557, April.

Lin, Chang Yang Chia, Wen Yeo, Ping-Hung Y.,

Sapatnekar S., 2008 “A progressive-ilp based routing

algorithm for Crossreferencing biochips.” In

Proceedings of Design Automation Conference, pages

284 - 289, June.

Hwang W., Su F., Chakrabarty K., 2006 “Droplet routing

in the synthesis of digital microfluidic biochips.” In

Proceedings of Design Automation and Test in

Europe.

Cho M. and Pan D. Z., 2008“A high-performance droplet

routing algorithm for digital microfluidic biochips.”

IEEE Transactions Computer-Aided Design of

Integrated Circuits and Systems, 27(10):406-419,

October.

Yang C. L., Yuh P. H. and Chang. Y. W., 2007 “Bioroute:

A network flow based routing algorithm for digital

microfluidic biochips.” In Proceedings of IEEE/ACM

International Conference on Computer Aided Design,

pages 752-757.

Boahringer K. F., 2006 “Modeling and controlling parallel

tasks in Droplet based microfluidic systems”. IEEE

Transactions Computer Aided Design of Integrated

Circuits and Systems, 25(2):334 - 344, February.

Xu T. and Chakrabarty K., 2007 “Integrated Droplet

Routing in the Synthesis of Microfluidic Biochips”,

Proceedings of the Design Automation Conference,

June 4-8, San Diego, California, U.S.A.

Zhao Y. and Chakrabarty K., 2009 – “Cross-

Contamination avoidance for Droplet Routing in

Digital Microfluidic Biochips”, Proceedings of the

DATE.

Roy P., Rahaman H., Dasgupta P., 2010 “A Novel Droplet

Routing Algorithm for Digital Microfluidic Biochips”,

GLSVLSI, Providence, Rhode Island, USA.

Xu T. and Chakrabarty K., 2006 “Droplet-trace-based

array Partitioning and a pin assignment algorithm for

the automated design of digital microfluidic biochips.”

Proceedings of IEEE/ACM InternationalConference

on Hardware/Software Codesign and System

Synthesis, Pages 112-117.

Soukup J., 1978 “Fast Maze Router” Proceedings of the

15

th

ACM/ IEEE Design Automation Conference, pages

100-102.

A MULTI-PIN DROPLET ROUTING ALGORITHM FOR DIGITAL MICROFLUIDIC BIOCHIPS

223