OPTIMUM CORE-WINDING RATIO FOR A RECEIVER

COIL IN A BIOMEDICAL INDUCTIVE POWER SYSTEM

Furqan Noor

1

and Maeve Duffy

2

1

Bioelectronics Research Cluster, National University of Ireland Galway, Galway, Ireland

2

Power Electronics Research Centre, National University of Ireland Galway, Galway, Ireland

Keywords: Biomedical inductive power systems, Transplants, coils, Maximum power transfer, Magnetic cores.

Abstract: The relation of the structure of a cylindrical coil used on the receiver side of an inductive power system to

the level of power that can be delivered is investigated. It is found that for a given fixed receiver coil size,

an optimum design can be defined in which the cross sectional area of the core equals that of the winding.

Results of circuit simulation, Finite Element Analysis and measurements of five test coils are presented to

verify the proposed theory for the case of coils having 5 mm diameter and 10 mm length.

1 INTRODUCTION

Wireless power links have been widely applied in

biomedical applications, for their advantages of

reduced infection, reduced size and simplified or

reduced surgical procedures. However, in proven

systems it is generally true that power transmitter

and receiver coils are located in close proximity and

the power requirements are relatively low

(Clements, Vichienchom et al. 1999; Ahmadian,

Flynn et al. 2005; Atluri and Ghovanloo 2005;

Fotopoulou and Flynn 2006; Harrison, Watkins et al.

2006; Ali, Ahmad et al. 2009). Furthermore, most of

the biomedical inductive power transfer (IPT)

systems developed so far do not have such strict

constraints of physical dimensions of the transmitter

and receiver coils and the spacing between them

(Clements, Vichienchom et al. 1999; Atluri and

Ghovanloo 2005; Hmida, Dhieb et al. 2006; Furse,

Harrison et al. 2007; Mounaim, Sawan et al. 2009).

In this work, transmitter and receiver coils that have

significantly different sizes (50 mm vs. 5 mm

diameter), and which are located at a large distance

apart (when compared to the size of the received

coil) are investigated. Both primary and receiver

coils are assumed to be located inside the body, with

the battery powered transmitter coil located so that it

can provide power to a receiver coil located in a

more inaccessible part of the body.

Initially, the case of air-core coils was

investigated, but it was found that low coupling

between transmitter and receiver coils seriously

limits the power transfer capability. The inclusion of

a magnetic core in the receiver coil was found to

enhance the power transfer efficiency by increasing

the mutual coupling between the coils (Noor and

Duffy 2009). Cores have been used in the receiver

coils of biomedical applications like BION implants

(J. H. Schulman 2004; Djordje Popovic 2007),

biomedical sensors (Flynn), and wireless powering

of implantable devices (Kihyun Jung 2008).

However, no detail is available on how the design of

receiver coils with cores should be optimised, and

therefore this work addresses this issue.

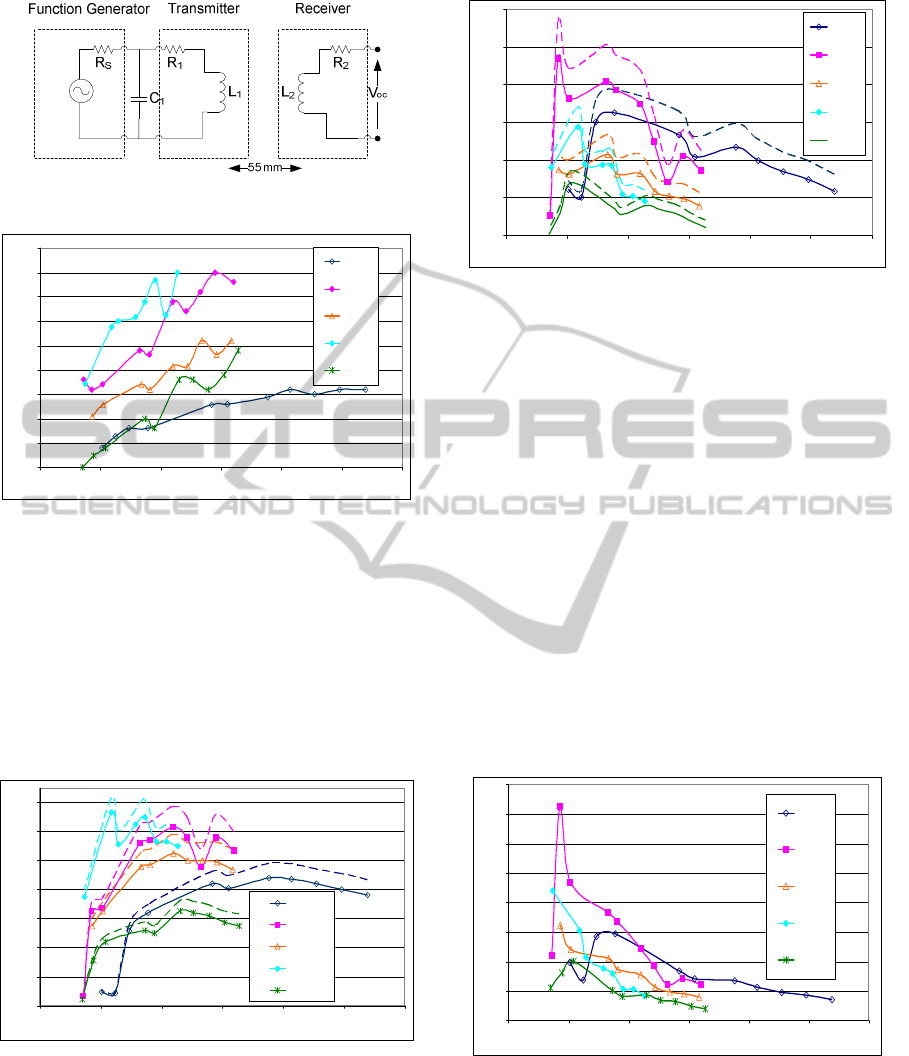

The design and construction of 5 test receiver

coils for a given air-core transmitter coil is described

in section 2. Resonant circuits used to compensate

for the high leakage inductance associated with a

loosely coupled system are described in section 3.

The design of a suitable resonant circuit in terms of

the inductances, resistances and coupling factor for a

given pair of transmitter and receiver coils is

described so that the results can be investigated for

other systems. Results of power and voltage levels

are predicted for the five test coils over frequencies

from 100 – 600 kHz. It is found that the maximum

power is provided with a coil in which the core and

winding cross sectional areas are approximately

equal, where the increase in coupling factor

provided by the core is offset by the reduction in

winding turns that can be fit for larger core areas.

The translation of power levels achieved in terms of

electromagnetic field regulations for safe human

74

Noor F. and Duffy M..

OPTIMUM CORE-WINDING RATIO FOR A RECEIVER COIL IN A BIOMEDICAL INDUCTIVE POWER SYSTEM.

DOI: 10.5220/0003169500740086

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2011), pages 74-86

ISBN: 978-989-8425-37-9

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

50

51

5

10

OD

exposure (IEEEStandard 1999) is discussed in

section 4. Both cases of continuous and pulsed

powering are considered. Finally, measurement

results of power and voltage produced for the test

coils are presented in section 5, where it is shown

that continuous power levels of up to 3.6 μW can be

provided within the electromagnetic field

regulations, thereby also confirming predicted pulse

power levels of up to 12 mW.

2 TRANSMITTER & RECEIVER

COILS

It was previously confirmed that the placement of a

magnetic core in the receiver coil of the inductive

power system provides amplification in the power

transfer (Noor and Duffy 2009). The application of

ferrite rod cores is investigated in this paper, where

the main aim is to identify an optimum core-winding

combination for the receiver coil that maximizes

power delivery to the load within the

electromagnetic field regulations. In all cases, a

transmitter coil with outer diameter of 51 mm and

N

tx

= 10 turns is assumed; practically the coil was

wound using wire with a diameter, d

wtx

, of 0.5 mm

over an axial length of 5 mm.

Power available from a receiver coil in an

inductive power system is proportional to the square

of the voltage induced on it, V

ind

2

= (jωMI

tx

)

2

, and

inversely proportional to the coil resistance, R

2

,

where M is the mutual inductance between the

transmitter and receiver coils and I

tx

is current

flowing in the transmitter coil. In terms of a

cylindrical receiver coil with a rod shaped core, the

induced voltage may be given as:

4/BCDNjV

2

rxind

πω=

(1)

where N

rx

is the number of receiver turns, CD is

the diameter of the core and B is the magnetic flux

density established in the area of the core for a given

transmitter current, I

tx

. Similarly, the DC resistance

of the coil can be given in terms of the physical

parameters of the winding as:

4/d

2/)CDOD(N

R

2

wrx

rx

2

π

+

π

ρ

=

(2)

Where ρ is the resistivity of the coil wire, OD is the

outer diameter of the coil and d

wrx

is the wire

diameter. Combining (1) and (2), a relationship

between the available output power, P

avail

, and the

coil parameters is found as:

)CDOD(N

d)BCDN(

P

rx

2

wrx

22

rx

avail

+ρ

ω

∝

(3)

For the purpose of comparing different receiver coil

geometries, it is assumed that ω, d

wrx

, B and ρ are all

constant. Furthermore, the coils are compared for a

fixed outer coil diameter, OD, and a fixed coil

length. Finally, recognising that there is a

proportional relationship between the number of

winding turns and the space available in a given

winding width, (OD – CD)/2, (3) can be expressed

entirely in terms of the coil radial dimensions:

)CDOD(

CD)CDOD(

P

4

avail

+

−

∝

(4)

Differentiating P

avail

in terms of CD, the

condition for an optimum receiver coil design is

identified as:

CD = 0.781 OD (5)

Further investigation confirms that this condition is

approximately the same as found by equating the

cross sectional areas of the core, πCD

2

/4, and the

winding, π(OD

2

– CD

2

)/4; i.e. there is a trade off

between the number of winding turns that can be fit

and the flux linkage area provided by the core.

In order to confirm this theory, wire with a

diameter, d

wrx

= 0.16 mm, was used to wind five

receiver coils over a length, l

rx

, of 10 mm. The coils

were wound on five different ferrite rod cores with

diameter, CD, varying from 4 mm to 1.5 mm. All

windings were wound to produce an overall coil

diameter OD = 5 mm. The corresponding number of

turns, N

rx

, ranges from 106 to 330 respectively. The

core material has an initial magnetic permeability of

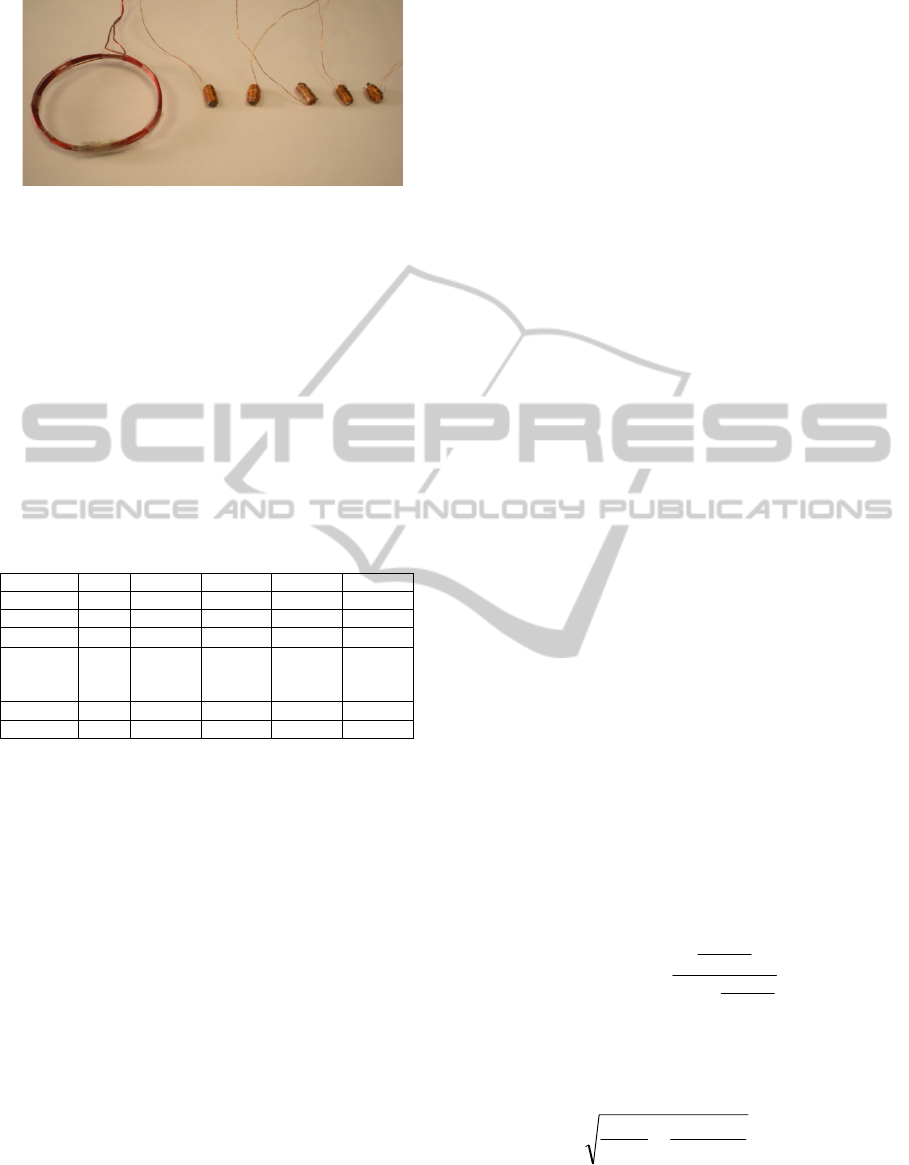

2300 (fair-rite) in all cases. A cross section of the

coils is shown in Figure 1 and a photograph of the

transmitter and receiver coils is shown in Figure 2.

CD

Figure 1: Cross section of test transmitter and receiver

coils. (Dimensions in mm, not to scale).

OPTIMUM CORE-WINDING RATIO FOR A RECEIVER COIL IN A BIOMEDICAL INDUCTIVE POWER SYSTEM

75

Figure 2: Transmitter Coil (large) with 5 (small) receiver

coils of different turn-core ratio.

The core dimensions and turns specifications of

the five receiver coils are compared in Table 1,

along with predicted and measured inductance

values. Predicted values L

FEA

, were found using

Finite Element Analysis (FEA) (Maxwell2d), and

measurements, L

meas

, were performed using an

impedance analyser (Agilent 4395A). Results of DC

winding resistance and coupling factor, k, are also

included in Table I, where FEA modelling was used

to predict k between transmitter and receiver coils

when separated by an axial distance of 5.5 cm.

Table 1: Receiver Coils’ Specifications.

Coil # 1 2 3 4 5

CD 4 3 2.5 2 1.5

N 106 208 231 285 330

L

FEA

(μH)

134 410 430 800 590

L

meas

(μH)

@ 200

kHz

146 425 420 873 396

R

DC

(Ω)

2.5 3.8 4.2 4.4 4.8

k 0.0041 0.0032 0.0031 0.0027 0.0025

There is generally agreement among the two

methods used for determining receiver coil

inductance, L

2

. Predicted values are generally higher

and this may be explained by the tolerance of the

core permeability and by the difference between

modelled and practical winding dimensions. As

might be expected, coupling factor increases with

increasing core diameter. These values will be

compared with measurements later in section 3.

3 RESONANT CIRCUIT DESIGN

In order to investigate the maximum power transfer

capability of an inductive link it is necessary to

determine the relationship between different circuit

parameters. These expressions eventually lead to an

optimum load resistance for a given coil operating at

a given frequency. In the case of links with low

coupling it is found that it’s more appropriate to first

aim for a maximum level of power transfer, and then

to try to optimize for maximum efficiency.

The impedance of the receiver leakage

inductance is quite large at weak coupling, and

therefore requires a high induced voltage on the

receiver coil. This in turn requires high transmitter

coil voltage and current and thus induces losses and

depreciates the efficiency of the inductive link. In

order to cancel the leakage inductance, the receiver

coil can be compensated by a series or parallel

capacitor. This process induces resonance in the

receiver circuit and the link operates at the phase

resonance frequency of the receiver coil. As a result,

real power transmission can be increased while

keeping the product of voltage and current (VA)

requirements low. A parallel compensated receiver

coil as shown in Figure 3 acts as a current source

and is usually preferred as the controllability of the

design is straight forward by employing short circuit

control (Stielau and Covic 2000). A receiver coil can

also be compensated by a series capacitor.

Compensation of the transmitter coil is also

essential to compensate not only the transmitter coil

inductance but also any reflected impedance from

the receiver; this is particularly important if there is

a lot of variation in the inductive parameters of the

system due to deformation or movement of the coils.

Just like the receiver coil, the transmitter coil can

also be compensated with a series or parallel

capacitor.

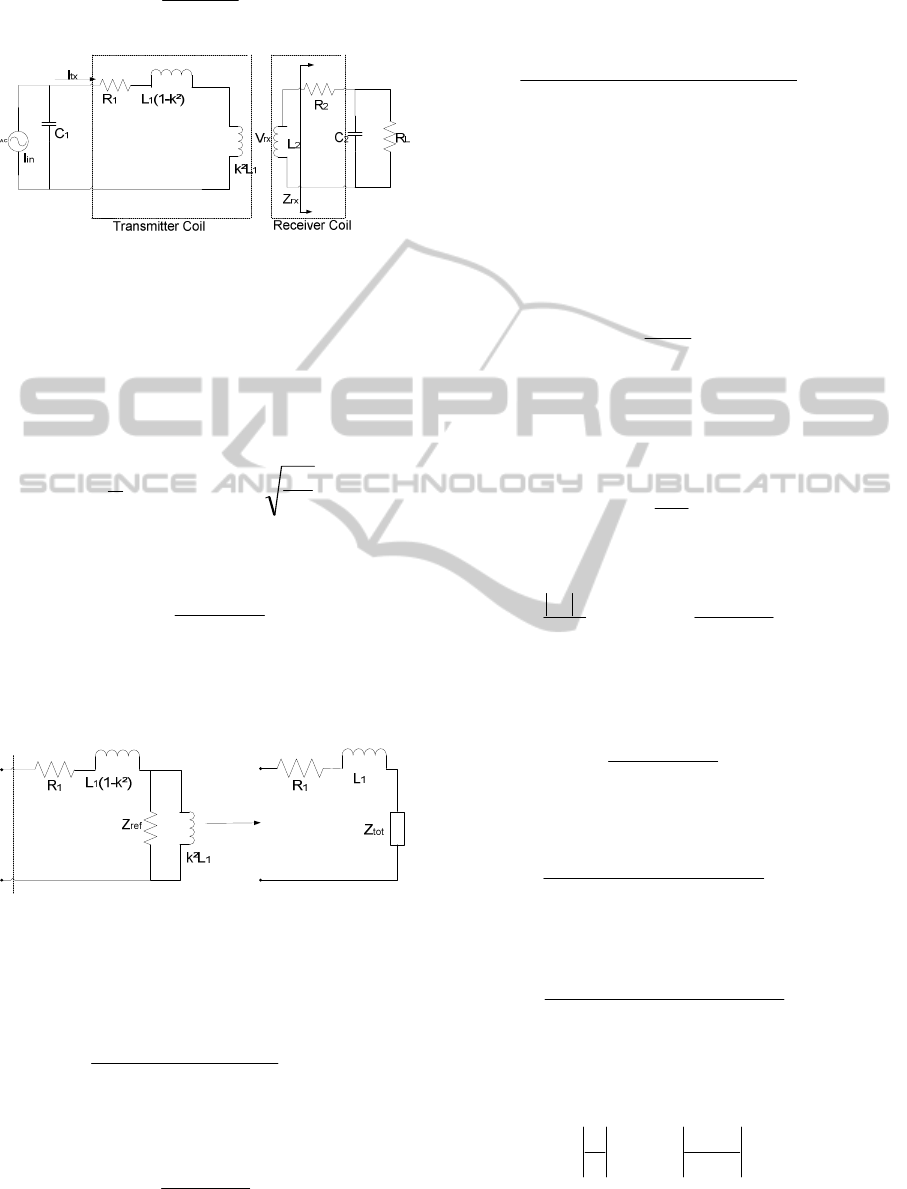

3.1 Circuit Analysis

An inductive link with both coils compensated using

parallel capacitors as in Figure 3 is analyzed to

determine an expression for maximum power

transfer in terms of the electrical parameters of the

transmitter and receiver coils The total impedance

acting against the voltage induced on the receiver

side, Z

2

, can be written as:

2

2

222

1

Cj

R

Cj

R

LjRZ

L

L

ω

ω

ω

+

++=

(6)

At the receiver resonant frequency the imaginary

component of Z

2

becomes zero, thereby defining the

resonant frequency, ω

o

, as:

2

222

0

)(

11

L

RCCL

−=

ω

(7)

Thus at resonance the total impedance of the

receiver side of the circuit is real and Z

2

can be

written as

BIODEVICES 2011 - International Conference on Biomedical Electronics and Devices

76

2

20

22

)(

L

L

RC

R

RZ

ω

+=

(8)

Figure 3: Transformer model of a parallel compensated

inductive power system.

For simplicity, the impedance presented at the

terminals of the transmitter coil in Figure 3 can be

given in terms of the impedance of the receiver

circuit referred to the transmitter side as shown in

Figure 4 (Schuylenbergh 1999), where Z

ref

is Z

rx

referred to the transmitter side:

rxref

Z

n

k

Z

2

)(=

with

2

1

L

L

n =

(9)

and Z

rx

, is the impedance of the receiver circuit other

than the coil self inductance L

2

.

L

L

rx

RCj

R

RZ

2

2

1

ω

+

+=

(10)

The transmitter circuit model can be further reduced

to an equivalent impedance Z

tot

acting in

series with

the primary coil inductance L

1

as shown in Figure 4.

Figure 4: Simplified transmitter coil circuit.

At the receiver resonant frequency, it is found

that Z

tot

is a real quantity which can be defined as

R

tot

given by:

)(

)(

2222

2

2

21

2

LRRCRC

LRCLk

R

LL

L

tot

+

−

=

(11)

Therefore, at resonance, the primary link

efficiency can be written as

1

RR

R

tot

tot

tx

+

=

η

(12)

which is given in terms of the circuit components by

substituting (11) into (12):

)())((

))((

222122

2

21

2

2

2

21

2

LRRCRRCLRCLk

LRCLk

LLL

L

tx

++−

−

=

η

(13)

Note that this expression holds true regardless of

whether or not a resonant capacitor, C

1

, is included

on the transmitter side. In most practical systems

however, a resonant capacitor is included so that a

lower source voltage can be applied. For loosely

coupled systems, it is found that C

1

is given simply

in terms of the transmitter coil inductance and

resonant frequency:

1

2

o

1

L

1

C

ω

=

(14)

The receiver link efficiency can be defined as the

ratio of useful power dissipated in the equivalent ac

load, P

L

, to the power transmitted to the receiver

circuit, P

rx

.

rx

L

rx

P

P

=

η

(15)

In turn, load power may be given as:

L

L

L

R

V

P

2

=

, with

L

Lrx

L

ZR

ZV

V

+

=

2

(16)

V

rx

is the load voltage driving Z

rx

across the ideal

circuit model of the receiver coil, and Z

L

is the

parallel combination of R

L

and C

2

:

jRC

jR

Z

L

L

L

−

−=

2

ω

(17)

Substituting (17) into (16) the resulting

expression for load voltage is given as:

2

2

2

22

222

)()(

)(

LL

LLLrx

L

RRRRC

RRCjRRRV

V

++

+

+

=

ω

ω

(18)

and the power delivered to the load resistor can be

written as

2

2

2

22

2

)()(

LL

Lrx

L

RRRRC

RV

P

++

=

ω

(19)

Similarly, the total power delivered to the

receiver circuit can now be written in terms of V

rx

as:

2

2

L2

rx

L2

2

L

L

Lrx

R

ZR

V

PR

Z

V

PP

+

+=+=

(20)

OPTIMUM CORE-WINDING RATIO FOR A RECEIVER COIL IN A BIOMEDICAL INDUCTIVE POWER SYSTEM

77

That is:

2

2

2

22

2

2

22

2

)()(

)]()([

LL

LLrx

rx

RRRRC

RRRCRV

P

++

++

=

ω

ω

(21)

Substituting for P

L

and P

rx

into (15), the

efficiency of the receiver circuit can be determined

as follows

)()(

2

2

22 LL

L

rx

RRRCR

R

++

=

ω

η

(22)

At the resonant frequency (22) reduces to

222

2

RRCL

L

L

rx

+

=

η

(23)

And the total link efficiency is given by:

rxtxlink

ηηη

=

(24)

Power transfer to the load is the product of the link

efficiency and the total real power delivered by the

driver of the transmitter coil:

txlinkL

PP

η

=

(25)

Given that one limitation to the power level that

can be transmitted in biomedical applications is the

maximum magnetic field intensity, H, that can be

applied, it is convenient to express load power in

terms of the transmitter current, I

tx

, to which the H

field is in direct proportion. More details of the H

field limitation are given in section 4. At resonance,

the total power delivered from the driver is given in

terms of I

tx

as:

)RR(IP

tot1

2

txtx

+=

(26)

where R

1

is the equivalent resistance of the

transmitter coil. Substituting for R

tot

from (11) the

total power transfer to the load can be written as:

2

2

222

2

2

201

2

)(

))((

tx

L

L

L

I

RRCL

RCLLk

P

+

=

ω

(27)

Clearly, power transfer is proportional to the

square of the reactance of the receiver coil and of

current flowing in the transmitter coil. This

relationship is used to scale power levels according

to the maximum current that can be applied within

the field regulations for different transmitter coil

excitation options in section 4.

Finally, the rms value of the load voltage at

resonance, V

L

, can be deduced as:

2

tx

2

2L22

L2

2

201

2

L

2

L

I

)RRCL(

RC)L)(Lk(

R

V

+

ω

=

(28)

to give:

tx

L

L

L

I

RRCL

RCLkL

V

222

2

21

2

20

))(()(

+

=

ω

(29)

Analysing (28), it is found that each receiver coil

has an optimum load resistor, R

Lopt

, at a given

resonance frequency. This optimum value can be

found by differentiating P

L

with respect to R

L

, where

it is found that:

22

2

RC

L

R

Lopm

=

(30)

Substituting for C

2

from (7), R

Lopm

is defined

entirely in terms of the receiver coil impedances:

2

2

2

2

20

)(

R

RL

R

Lopm

+

=

ω

(31)

Substituting (31) into (27), the expression for

maximum power transfer to the optimum load is

found as:

2

22

2

201

2

)(4

))((

txLopm

I

RL

LLk

P

ω

=

(32)

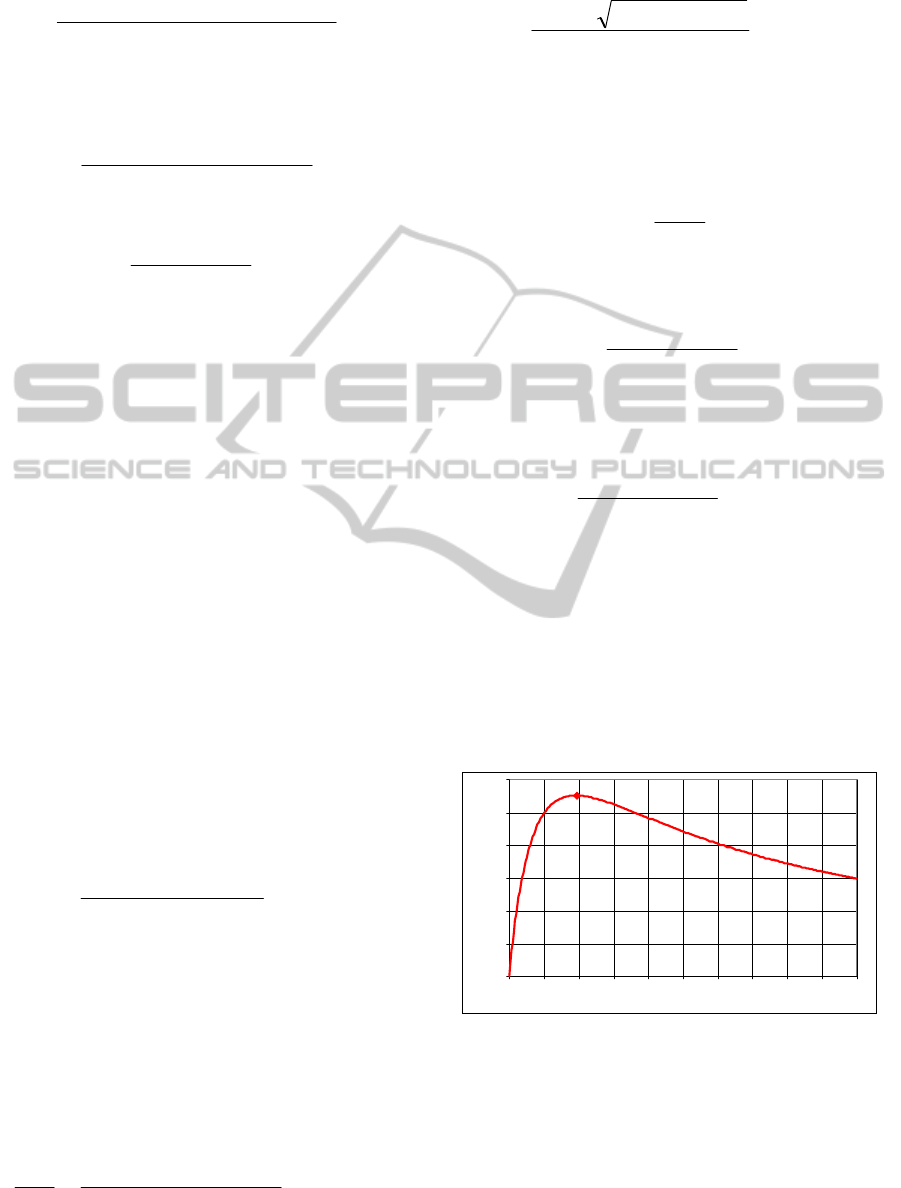

For illustration, the optimum load resistor is

verifed for coil 2 (with a 3 mm core) resonating at

320 kHz with C2 = 470 pF and R2 measured as 23.6

Ω (at 320 kHz). Using (30), the optimum load

resistor for maximum power transfer is predicted as

38.4 kΩ with measured values of L1 and L2. The

graph of PL vs. RL predicted using (27) in Figure 5

verifies the maximum power transfer at the

calculated load.

0

0.1

0.2

0.3

0.4

0.5

0.6

0 20 40 60 80 100 120 140 160 180 200

Load Resistor R

L

(k

Ω

)

Power (mW)

Figure 5: Maximum power transfer at optimum load.

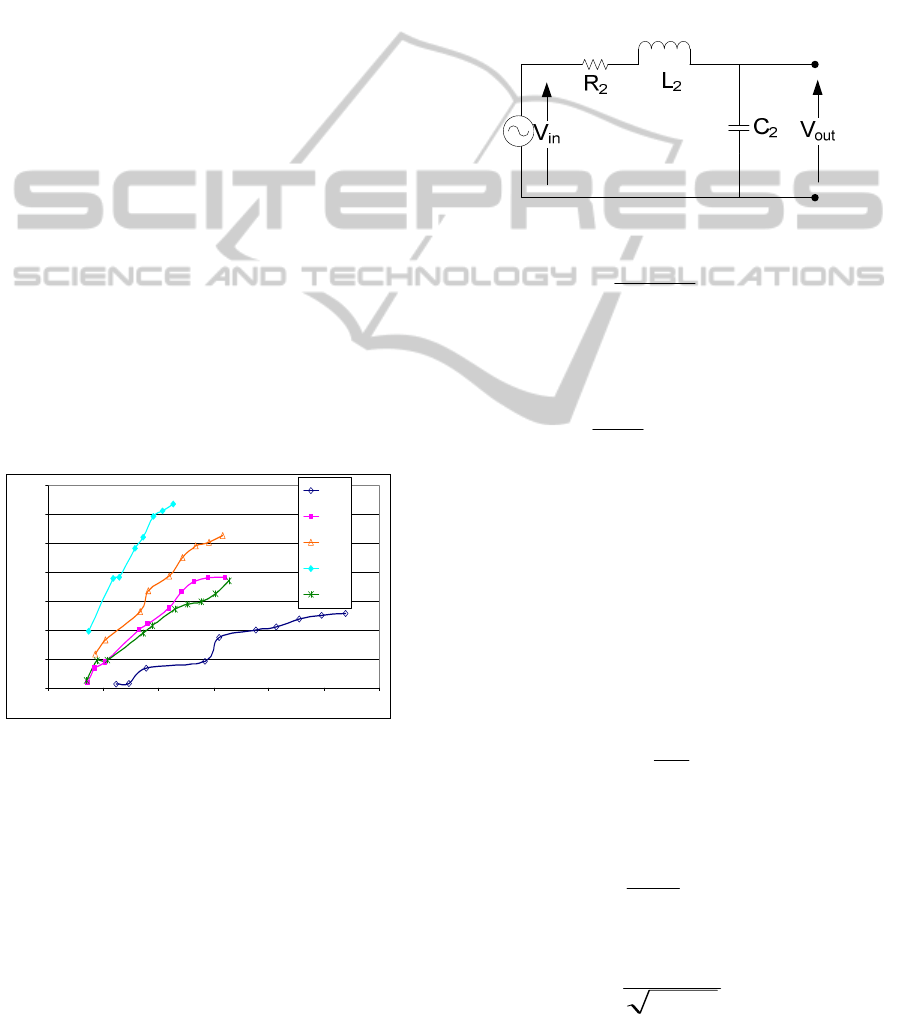

3.2 Circuit Design for Given

Transmitter and Receiver Coils

In order to enable a comparison of the different

receiver coils under investigation, the circuit of

Figure 3 was designed over a range of frequencies

BIODEVICES 2011 - International Conference on Biomedical Electronics and Devices

78

(100 – 600 kHz) for each of the five test coils

described in section 2. The main aim of circuit

design is to determine the maximum power that can

be transmitted to each coil for a given transmitter

current, and the frequency at which this transfer

occurs.

For each coil, the first step in design is to

determine the resonant capacitance value, C

2

,

required for a given operating frequency, ω

0

, using

(7), with the optimum value of R

L

determined from

(31). For this purpose, values of R

2

and L

2

vs.

frequency were measured using an impedance

analyser so that their variation with frequency was

accounted for. It was found that while inductance

values remain practically constant with frequency,

resistance values increase by up to one order of

magnitude. This is explained by the combination of

skin and proximity effects in the windings and the

contribution of core losses from the ferrite rods, both

of which are difficult to predict. Corresponding

predicted results of R

Lopm

are plotted vs. frequency

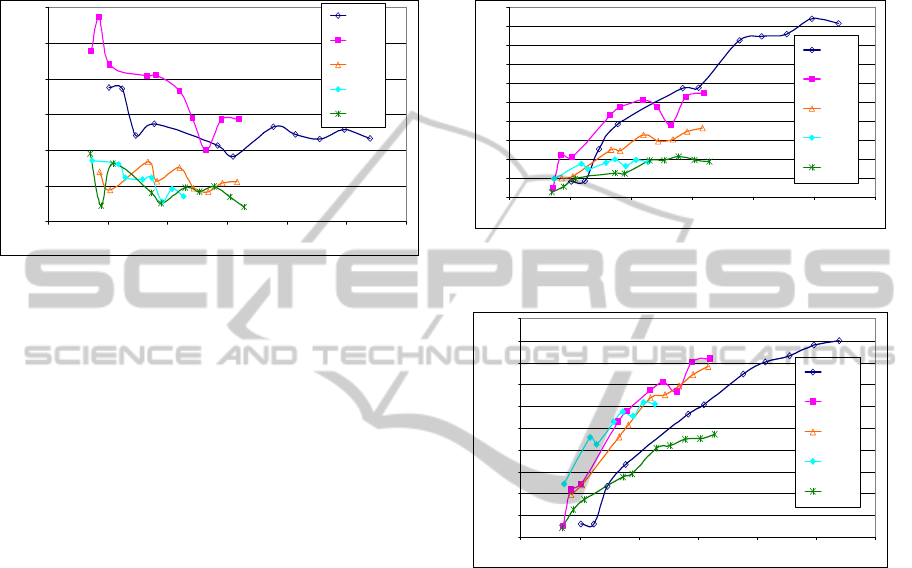

for each of the 5 test coils in Figure 6.

The first thing to note is that R

Lopm

increases with

frequency for all coils. This is explained largely by

increasing inductive impedance with frequency, and

may be applied to tune a given system for maximum

output power at a particular load resistance. The

same effect applies in relation to the trends in R

Lopm

predicted for different coils, where coil 4 has the

largest inductance and coil 1 has the smallest.

0

10

20

30

40

50

60

70

0 100 200 300 400 500 600

Frequency (kHz)

R

Lopm

( k

Ω

)

Coil 1

Coil 2

Coil 3

Coil 4

Coil 5

Figure 6: R

Lopm

vs. frequency for the test receiver coils.

At this stage, the receiver circuit design is

complete, and the only remaining parameter needed

to complete circuit analysis is the coil coupling

factor, k. This can be deduced from FEA models of

the transmitter and coil structures. However, due to

the large distance between the coils and the

differences in their sizes in this case, it was found

that the accuracy of FEA models is limited. As a

second method, coupling factor was deduced from

measurements of the voltage induced on the receiver

coil. Due to the low level of these voltages,

measurements needed to be performed under

resonant conditions and this first required that the Q-

factor of each coil be determined.

For a given receiver coil, the input voltage, V

in

,

applied to the series combination of the coil and its

resonant capacitor, C

2

, as shown in Figure 7 can be

related to a larger valued output resonant voltage,

V

out

, to give the coil Q-factor. In this case, the

resonant capacitor is given simply in terms of the

resonant frequency, f

res

, as:

Figure 7: Setup for the measurement of Q

2.

2

2

2

)2(

1

Lf

C

res

π

=

(33)

V

out

and V

in

are then found to be related in terms

of the Q-factor of the receiver coil, Q

2

= ω

ο

L

2

/R

2

=

1/ω

o

C

2

R

2

:

ininout

VjQ

RC

VjV

2

22

1

−=−=

ω

(34)

Using the function generator as a supply voltage,

values of Q

2

were calculated using (34) for each of

the test coils over a range of frequencies from 100 –

600 kHz. Values of coupling factor were then

deduced from measurements of the voltage produced

across the same resonant capacitor, V

C2

, with the

transmitter and receiver coils separated axially by

5.5 cm, and a given current, I

tx

, supplied to the

transmitter coil, as in the circuit of Figure 18. The

voltage induced on the receiver coil V

ind

was then

calculated as:

2

2

Q

V

V

C

ind

=

(35)

and the value of mutual inductance, M, between

transmitter and receiver coils was found as:

tx

ind

Ij

V

M

ω

=

(36)

Finally, the coupling factor k was calculated as:

21

LL

M

k

=

(37)

OPTIMUM CORE-WINDING RATIO FOR A RECEIVER COIL IN A BIOMEDICAL INDUCTIVE POWER SYSTEM

79

using measured values of L

1

and L

2

. The measured

coupling factor for the five test coils is shown in

Figure 8. Ideally, the coupling factors should not

vary with frequency however; the measured values

show a little variation because of the non ideal

measurement conditions.

0.003

0.004

0.005

0.006

0.007

0.008

0.009

0 100 200 300 400 500 600

Frequency (kHz)

Coupling factor "k"

Coil1

Coil2

Coil3

Coil4

Coil5

Figure 8: Measured coupling factors of test coils.

Coils 3, 4 and 5 have similar levels of coupling,

all of which are lower than 0.005. The core area is

smallest in these cases. It is interesting to note that

when compared with FEA simulation, the maximum

value of k is found with coil 2 rather than with coil 1

which has the largest core area. On further

investigation, it is found that the core and winding

cross sectional areas are approximately equal in coil

2, and this seems to confirm the optimum receiver

structure identified in section 2, in which the

reduction in core area is traded against an increasing

number of turns. Work is ongoing to explain the

difference in values of k deduced from FEA models

and measurements.

3.3 Predicted Performance of Test

Coils

Using (32), results of P

Lopm

are predicted and plotted

vs. frequency for each of the receiver coils at a

transmitter coil current, I

tx

, of 1 A in Figure 9.

Corresponding values of V

Lopm

are plotted in Figure

10. Note that these values correspond to the

measured values of R

Lopm

plotted in Figure 6. It is

seen that as given by (32) and (31), both P

Lopm

and

V

Lopm

increase with frequency, respectively. The

factor of increase is lower than given by ω

o

2

and ω

0

respectively,

due to the reduction in inductance and

increase in resistance values with frequency.

Comparing P

Lopm

for the different test coils, it is

clear that coil 2 produces the highest power levels

for most of the frequencies tested. This relates to

coil 2 having the highest coupling factor as

confirmed above and it supports the relationship to

the core: winding ratio identified in section 2; i.e. the

cross sectional areas of the core and winding are

closest for coil 2. Coil 5 has the lowest power over

all frequencies, and is most likely explained by its

highest coil resistance due to the largest number of

coil turns.

0

1

2

3

4

5

6

7

8

9

10

0 100 200 300 400 500 600

Frequency (kHz)

P

Lopm

at I

tx

= 1 A ( mW )

Coil1

Coil2

Coil3

Coil4

Coil5

Figure 9: P

Lmax

vs. frequency for the test receiver coils (I

tx

= 1 A).

0

5

10

15

20

25

30

35

40

45

50

0 100 200 300 400 500 600

Frequency (kHz)

pk-pk V

Lopm

for I

tx

= 1 A (V)

Coil1

Coil 2

Coil 3

Coil 4

Coil5

Figure 10: V

Lopm

vs. frequency for the test receiver coils

(I

tx

= 1 A).

In relation to load voltages, coils 2, 3, and 4

produce similar levels, with the two extreme coil

designs (having largest and smallest core areas)

having the lowest levels. In this case the trend is

explained approximately by the ratio of k/Q

2

, so that

the voltage of coil 1 is limited by high Q-factor and

that of coil 5 is limited by low k.

These results are translated into power levels

corresponding to the maximum transmitter current

levels allowed according to the field regulations in

section 4, and they are then verified by measurement

in section 5.

4 IMPACT OF

ELECTROMAGNETIC FIELD

REGULATIONS

In biomedical applications there are restrictions

BIODEVICES 2011 - International Conference on Biomedical Electronics and Devices

80

imposed by the ICNIRP for safe levels of

electromagnetic fields for human exposure

(IEEEStandard 1999). For a given set of inductive

coils, this translates to a maximum transmitter coil

current that must not be exceeded. Using this value

of current, the question of how much power can be

transmitted to a load connected on the receiver side

without exceeding the electromagnetic field

limitation is analyzed, to compare the performance

of the different receiver coils under investigation.

Results of voltage and power levels predicted in

section 3 are scaled in terms of I

tx

for this purpose.

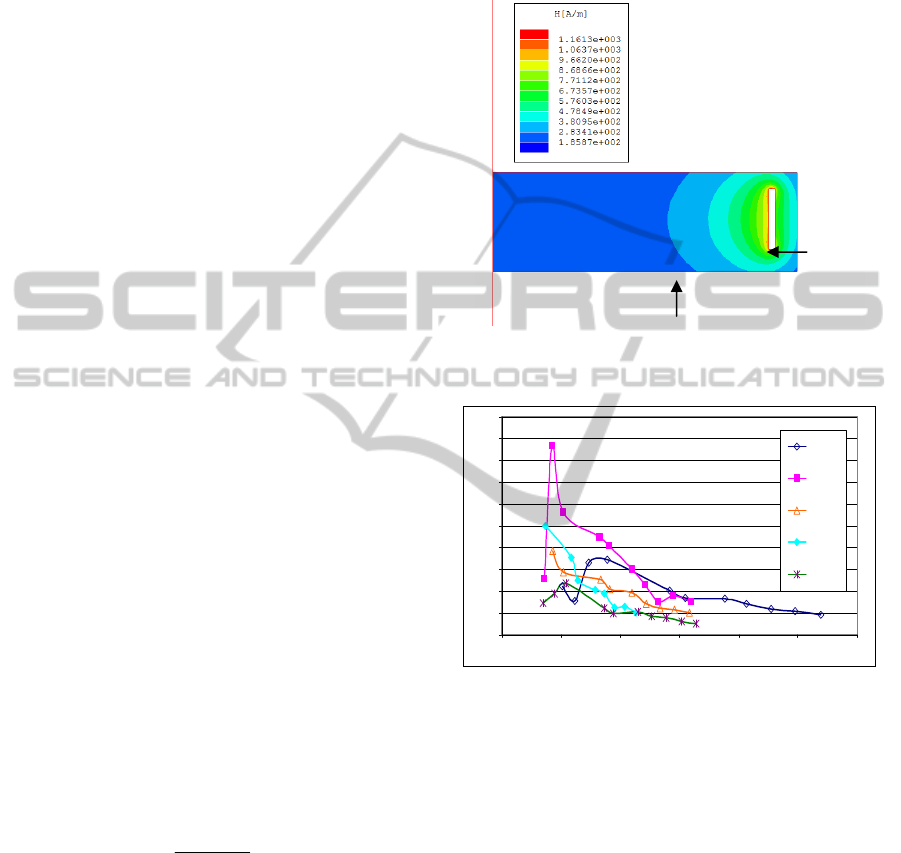

Magnetic field intensity, H, at a distance of 2

mm from the transmitter coil is considered as a

measure of the safe level of electromagnetic fields

for human exposure. As shown in Figure 11, the 2

mm distance represents a box containing the

transmitter coil and relevant circuitry, and so this is

the H field that will be exposed to the body tissues.

The allowed limit for occupational exposure to

magnetic field intensity for frequencies between

.065 - 1 MHz is 1.6/f (f in MHz); i.e. the maximum

allowed field intensity decreases with increasing

frequency. Therefore, for an operating frequency of

260 kHz for example, the rms H field is limited to

only 6.15 A/m. This H-field limit holds true for

continuous sinusoidal current, or for any other

waveform that produces the same rms current over a

6 minute interval (IEEEStandard 1999).

4.1 Continuous Powering

From FEA, it is deduced that a sinusoidal rms

current of 1 A in the test ten turn transmitter coil

corresponds a maximum rms H field, H

max(1A)

, of

420 A/m at an axial distance of 2 mm from the coil.

As magnetic field intensity is proportional to current

in the transmitter coil, it is calculated for example

that the maximum allowed rms transmitter current,

I

tx(reg)

, corresponding to a H-field limit, H

reg

, of 6.15

A/m at 260 kHz is 15 mA using:

)1max(

)(

A

reg

regtx

H

H

I =

(38)

The corresponding maximum continuous power

that can be transmitted to the load is then given by

(32) with I

tx

= I

tx(reg)

.

For the given 10 turn transmitter coil, results of

I

tx(reg)

are calculated using (38) for frequencies

ranging from 100 – 600 kHz, with H

reg

calculated as

1.6/f (f in MHz). Clearly, I

tx(reg)

decreases with

frequency in the same way as H

reg

. Equation (32) is

then applied to predict the corresponding maximum

power levels possible, as given in Figure 12, where

the system is designed according to the procedure

described in section 3.3. In effect, the results of

Figure 12 are scaled versions of those given in

Figure 9 according to I

tx(reg)

2

. Corresponding values

of pk-pk voltage are presented in Figure 13.

Figure 11: Magnetic field intensity around the transmitter

coil for a current of 1 A rms.

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

0 100 200 300 400 500 600

Frequency (kHz)

regulated P

Lopm

(

μ

W )

Coil 1

Coil 2

Coil 3

Coil 4

Coil 5

Figure 12: Predicted maximum continuous power within

field limitations.

In the same way as in Figure 9, coil 2 provides the

highest output power when Itx is limited according

to electromagnetic regulations. A mximum power

level of 4.3 µW is predicted at 100 kHz. Due to the

allowance for higher currents at lower frequencies, it

is seen that the relative performance of coil 2 is

enhanced over all other coils, and it provides the

maximum power over all frequencies considered.

Trends in pk-pk voltage levels in Figure 13 are

similar to those presented in Figure 10 , with a pk-pk

voltage of 0.5 V achieved for the maximum power

point of coil 2.

2mm outer box

TX coil

OPTIMUM CORE-WINDING RATIO FOR A RECEIVER COIL IN A BIOMEDICAL INDUCTIVE POWER SYSTEM

81

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0 100 200 300 400 500 600

Frequency (KHz)

pk-pk regulated V

Lopm

(V )

Coil 1

Coil 2

Coil 3

Coil 4

Coil 5

Figure 13: Predicted pk-pk load voltage within field

limitations.

4.2 Pulse Powering

In biomedical applications, power is often required

in short bursts of time over a longer repetitive

period. Therefore, it is possible to provide power

through an inductive link by driving high current in

the transmitter coil for short intervals of time. The

maximum value of allowed current in the transmitter

coil is a function of the repetition frequency, f = 1/T,

and the width of the pulse, PW, used. The maximum

allowed sinusoidal H field amplitude, H

pk(reg)

,

applied during the pulse time, PW, can be calculated

in terms of its rms value as:

reg

pk

H

T

PWH

=

2

.

2

(39)

The maximum instantaneous transmitter peak

current, I

pk(reg)

, is proportional to H

pk(reg)

as before.

For an rms current of 1 A the simulated rms H field

is 425 A/m as described earlier; thus the allowed

peak current amplitude can be scaled as:

425

)(

)(

regpk

regpk

H

I =

(40)

The corresponding peak instantaneous power

that can be transmitted during pulsed operation can

then be calculated using (32) with I

tx

= I

pk(reg)

. The

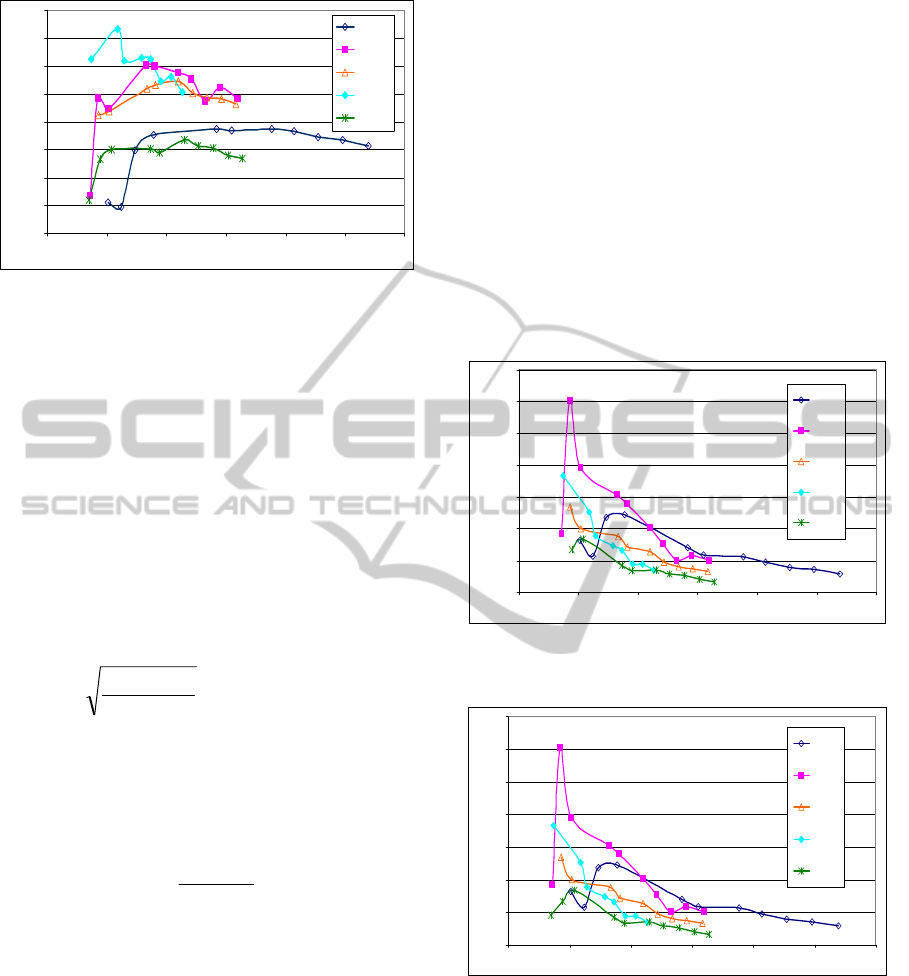

performance of the five test coils for pulse durations

of 0.5 ms and 1 ms is shown in Figures 14, 15, 16

and 17 in terms of the maximum instantaneous

power levels and the maximum pk-pk load voltages.

The time period used for pulse powering is 0.833

seconds in all cases.

As in the case of continuous powering, there is

an optimum frequency at which the maximum

instantaneous power occurs for every test coil.

Obviously, instantaneous pulse power and voltage

levels are significantly higher than corresponding

average values (shown in Figure 12 and 13), and the

levels of power and load voltage increase with

decreasing pulse time.

These power and voltage levels are sufficient for

performing periodic sensing and communication

functions in a range of biomedical applications. It

should be noted that the average power requirement

for some applications can be minimised by varying

the pulse width. For example, in cardiac pacing, it

has been found that lower power is required for

pulses of long duration with relatively low output

voltage, rather than for pulses with shorter durations

and commensurately higher output voltages (W E

Hill 1988). Work is ongoing to demonstrate the coil

performance in such applications.

0

2

4

6

8

10

12

14

0 100 200 300 400 500 600

Frequency (kHz)

Instantaeous P

Lopm

for 0.5 ms

Pulse

(

mW

)

Coil 1

Coil 2

Coil 3

Coil 4

Coil 5

Figure 14: Maximum instantaneous power possible with in

regulations for test coils for 0.50 ms pulse powering.

0

1

2

3

4

5

6

7

0 100 200 300 400 500 600

Frequency (kHz)

Instantaneous P

Lopm

fo r 1 m s

Pulse

(

mW

)

Coil 1

Coil 2

Coil 3

Coil 4

Coil 5

Figure 15: Maximum instantaneous power possible with in

regulations for test coils for 1 ms pulse powering.

BIODEVICES 2011 - International Conference on Biomedical Electronics and Devices

82

0

10

20

30

40

50

60

70

80

90

0 100 200 300 400 500 600

Frequency (kHz)

pk-pk Regulated V

Lopm

fo r

0.5 ms Pulse (V)

Coil 1

Coil2

Coil 3

Coil 4

Coil 5

Figure 16: Peak-peak Load voltage possible for 0.5ms

pulse powering.

0

10

20

30

40

50

60

70

0 100 200 300 400 500 600

Frequency (kHz)

pk-pk regulated V

Lopm

for

1 ms Pulse (V)

Coil 1

Coil2

Coil 3

Coil 4

Coil 5

Figure 17: Peak-peak Load voltage possible for 1 ms pulse

powering.

5 MEASUREMENTS

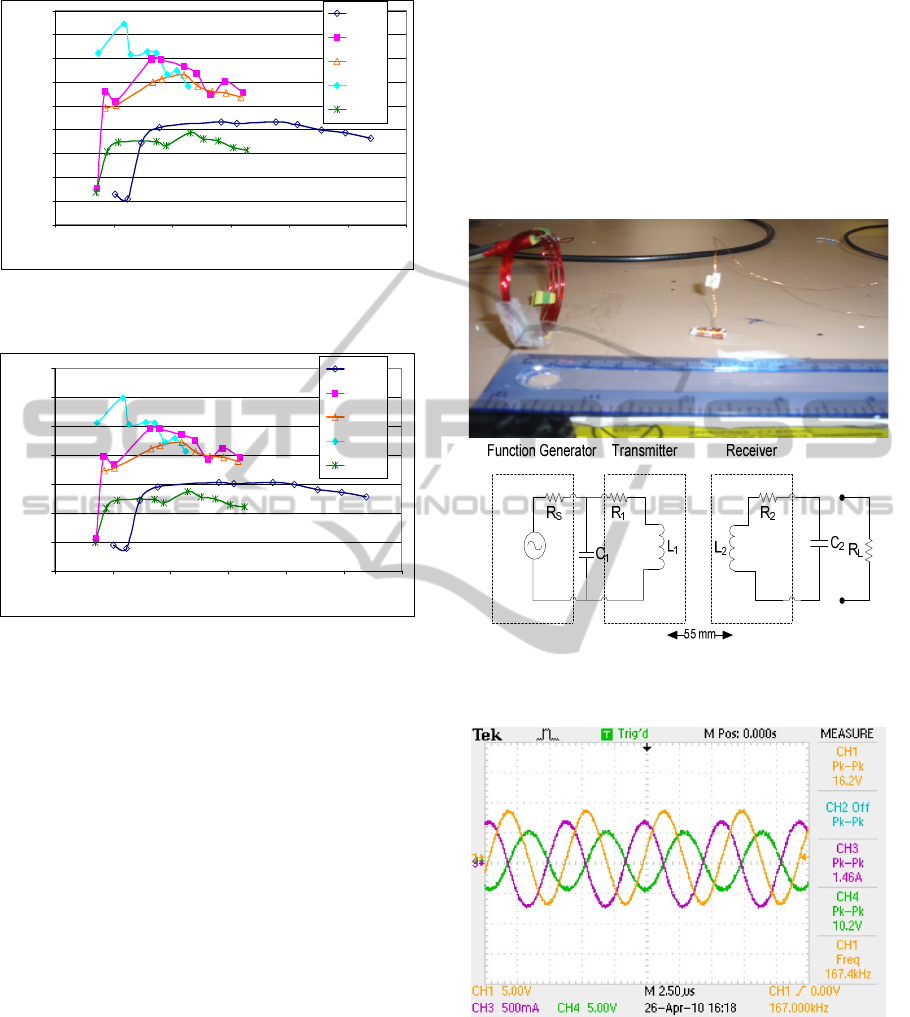

The five receiver coils were tested in the laboratory

using a set-up as described by the circuit diagram in

Figure 18. Each coil was measured for power

transmission to a matched load for a range of

frequencies. With the transmitter in a fixed position,

the position of the receiver was set equal to 5.5 cm

to make it comparable to a typical loosely coupled

inductive implant. The function generator acts as a

power supply feeding the transmitter coil through a

parallel resonant tank, and a second resonant

capacitor is connected across the receiver coil in

parallel with a load resistor. A photograph of the test

setup is shown in Figure 18a while its circuit

diagram is shown in Figure 18b.

For each coil, the design procedure described in

section 3.2 was used to determine values of the

resonant capacitor and optimum load resistance for

each test point. With the specified circuit values

connected, a voltage of 20V pk-pk was applied from

the function generator, and waveforms of pk-pk

voltages across transmitter coil (CH 1) and matched

load resistor (CH 4) were recorded. Note that a

resonant capacitor was also applied on the

transmitter side to compensate the high leakage

inductance of the transmitter coil, thereby providing

an enhanced transmitter coil current (Q

1

I

in

), I

tx

(CH

3). For example, results of transmitter coil and load

resistance pk-pk voltages along with transmitter coil

current are given for coil 3 at 167 kHz in Figure 19.

Figure 18: (a) Photograph (b) Circuit diagram of the

inductive power system test set-up.

Figure 19: Measured transmitter coil and load voltage for

coil 3 at 167 kHz.

To illustrate the low level of voltages induced on

the receiver coils with no resonant capacitor

included, measured values of open circuit pk-pk

voltage induced on the receiver coils over the test

frequency range according to the test setup in Figure

20 are shown in Figure 21.

OPTIMUM CORE-WINDING RATIO FOR A RECEIVER COIL IN A BIOMEDICAL INDUCTIVE POWER SYSTEM

83

Figure 20: Measurement of open circuit induced voltage.

0.2

0.25

0.3

0.35

0.4

0.45

0.5

0.55

0.6

0.65

0 100 200 300 400 500 600

Frequency (kHz)

pk-pk open circuit Induced Voltage (V)

Coil1

Coil 2

Coil 3

Coil 4

Coil5

Figure 21: Measured pk-pk open circuit induced Voltages.

For comparison, theoretical (predicted according

to (29)) and measured load voltages with a resonant

capacitor included (according to test setup in Figure

18) are presented in Figure 22 for the five test coils

over the frequency range from 100 – 600 kHz. In

this case, the voltage source was set at 20 V pk-pk

and the primary resonant capacitor was tuned so that

the maximum current available was drawn from the

supply for all measurement points.

1

3

5

7

9

11

13

15

0 100 200 300 400 500 600

Frequency (kHz)

pk-pk V

Lopm

(V)

Coil1

Coil 2

Coil 3

Coil 4

Coil5

Figure 22: Theoretical (dashed) Vs Measured Load

Voltages.

To validate the theoretical expression of maximum

power transfer for the optimum load resistance, the

results of load voltage were applied to predict

corresponding values of load power in Figure 23.

0.1

0.3

0.5

0.7

0.9

1.1

1.3

0 100 200 300 400 500 600

Frequency (kHz)

P

Lopm

(mW)

Coil1

Coil2

Coil3

Coil4

Coil5

Figure 23: Predicted (dashed) vs. Measured continuous

Power transfer to matched load.

The predicted and measured values of voltage

and power match each other closely. However, there

are deviations due to the unknown parasitic elements

involved that have not been accounted for in the

theoretical analysis. Moreover, it is impossible to

compensate the transmitter and receiver coils fully

because of the accuracy limitations of impedance

measurements. The tolerances of capacitors, the self

capacitance of the coils and the approximate values

of the coil resistances at different frequencies cause

deviations in the measured results. Nonetheless, the

measurements confirm the trends in voltage and

power levels predicted, and the same optimum

receiver coil design is identified. Measurements of

the continuous power scaled according to maximum

field regulated current are shown in Figure 24,

where again coil 2 is confirmed as the optimum

design.

0

0.5

1

1.5

2

2.5

3

3.5

4

0 100 200 300 400 500 600

Frequency (kHz)

regulated measured P

Lopm

(

μ

W )

Coil 1

Coil 2

Coil 3

Coil 4

Coil 5

Figure 24: Measured continuous Power scaled according

to field regulated transmitter current.

6 ANALYSIS & CONCLUSIONS

The design of an optimized receiver coil for

providing sufficient power to a remote biomedical

BIODEVICES 2011 - International Conference on Biomedical Electronics and Devices

84

implant within field regulations is the ultimate goal

of this work. In order to determine this, five different

coils were wound with different winding-core ratios

and their behaviour was investigated at different

frequencies. The performance of the system was

determined through circuit design, analysis and

experimentation. Practically, the transmitter coil was

supplied with current from a function generator,

where current levels were limited so that their

associated magnetic fields were lower than specified

by regulatory bodies. The receiver coil was placed at

a distance (55 mm) from the transmitter coil, and

voltage levels were measured under different

operating frequencies.

The results of this work indicate that an optimum

coil-core ratio for a certain receiver coil size is one

in which the cross sectional area of the winding is

approximately equal to that of the core. Average

power levels of up to 4.3 μW are demonstrated

within electromagnetic field regulations for a 5 mm

diameter / 10 mm long receiver coil when located 55

mm from a transmitter coil. Pulsed power levels of

up to 12 mW are illustrated.

Conditions for maximum power transfer are

analyzed on the basis of matching the load with the

receiver circuit impedance. It was found that there is

significant variation in coil resistance with

frequency and that this impacts on the maximum

power that can be transmitted. The power transfer

capability of each coil is illustrated in terms of the

maximum power it can transmit to matched loads at

different frequencies. Work is ongoing to customise

the receiver and transmitter coil designs for specified

load impedance values, which are typical of those

encountered in biomedical applications. The impact

of different core materials and wire dimensions will

also be investigated both for the transmitter and

receiver coils.

ACKNOWLEDGEMENTS

This work is supported by Enterprise Ireland and

Brivant Ltd. under the Innovation Partnership

Programme, Grant no. IP/2007/0447.

REFERENCES

Ahmadian, M., B. W. Flynn, et al. (2005). "Data

transmission for implantable microsystems using

magnetic coupling." communications, IEEE

proceedings- 152(2): 247-250.

Ali, H., T. J. Ahmad, et al. (2009). Inductive link design

for medical implants. Industrial electronics &

applications, 2009. ISIEA 2009. IEEE symposium.

Atluri, S. And M. Ghovanloo (2005). Design of a

wideband power-efficient inductive wireless link for

implantable biomedical devices using multiple

carriers. Neural engineering, 2005. Conference

proceedings. 2nd international IEEE EMBS

conference.

Clements, M., K. Vichienchom, et al. (1999). An

implantable power and data receiver and neuro-

stimulus chip for a retinal prosthesis system. Circuits

and systems, 1999. ISCAS '99. Proceedings of the

1999 IEEE international symposium.

Djordje Popovic, l. L. B., and Gerald E. Loeb, senior

member, IEEE (2007). "recruitment and comfort of

Bion implanted electrical stimulation: implications for

FES applications." IEEE transactions on neural

systems and rehabilitation engineering 15(4).

Fair-rite. "fair-rite products corp. PO box J,One

commercial row, Wallkill, NY 12589-0288", 2010,

from www.fair-rite.com.

Flynn, K. F. A. B. W. Wireless powering of implanted

sensors using RF inductive coupling.

Fotopoulou, K. And B. W. Flynn (2006). Wireless

powering of implanted sensors using RF inductive

coupling. Sensors, 2006. 5th IEEE conference.

Furse, C. M., R. Harrison, et al. (2007). Recent advances

in biomedical telemetry. Electromagnetics in advanced

applications, 2007. ICEAA 2007. International

conference.

Harrison, R., P. Watkins, et al. (2006). A low-power

integrated circuit for a wireless 100-electrode neural

recording system. Solid-state circuits conference,

2006. ISSCC 2006. Digest of technical papers. IEEE

international.

Hmida, G. B., M. Dhieb, et al. (2006). Transcutaneous

power and high data rate transmission for biomedical

implants. Design and test of integrated systems in

nanoscale technology, 2006. DTIS 2006. International

conference.

IEEE standard. (1999). "IEEE standard for safety levels

with respect to human exposure to radio frequency

electromagnetic fields, 3 kHz to 300 GHz, 1999."

J. H. Schulman, J. P. M., J. Wolfe, E. Regev, C. Y. Perron,

R. Ananth, E. Matei, A. Glukhovsky, R. Davis (2004).

Battery powered Bion FES network. 26th annual

international conference of the IEEE EMBS San

Francisco, CA, USA.

Kihyun Jung, Y.-H. K., Euy Jung Choi, Hyun Jun Kim,

and Yong-Jun Kim (2008). Wireless power

transmission for implantable devices using inductive

component of closed-magnetic circuit structure. IEEE

international conference on multisensor fusion and

integration for intelligent systems. Seoul, Korea.

Maxwell2d. "ansoft maxwell 2d." from www.ansoft.com.

Mounaim, F., M. Sawan, et al. (2009). Integrated

inductive power and data recovery front-end dedicated

to implantable devices. Biomedical circuits and

systems conference, 2009. BIOCAS 2009. IEEE.

OPTIMUM CORE-WINDING RATIO FOR A RECEIVER COIL IN A BIOMEDICAL INDUCTIVE POWER SYSTEM

85

Noor, F. And M. Duffy (2009). Effect of a magnetic core

in the receiver coil of a biomedical inductive power

system. Engineering in medicine and biology society,

2009. EMBC 2009. Annual international conference of

the IEEE.

Schuylenbergh, K., Puers, Robert (1999). Inductive

powering , basic theory and application to biomedical

systems.

Stielau, O. H. And G. A. Covic (2000). Design of loosely

coupled inductive power transfer systems. Power

system technology, 2000. Proceedings. POWERCON

2000. International conference.

W E Hill, A. M., J P Bourke, l Howell and R G Gold

(1988). "Minimum energy for cardiac pacing." clinical

physics and physiological measurement.

BIODEVICES 2011 - International Conference on Biomedical Electronics and Devices

86