INTEGRATION OF VARIOUS IT SYSTEMS AND SENSOR

INFORMATION FOR THE HANDLING OF RFID-ENABLED

CATERING GOODS IN THE AVIATION DOMAIN

Falk Scheiding, Kresimir Vidackovic

Fraunhofer IAO, Nobelstr. 12, 70569 Stuttgart, Germany

Felix Tönnies, Reinhard Becker

autoID systems GmbH, Heilbronner Straße 26, 74336 Brackenheim, Germany

Keywords: System integration, RFID, Middleware, Dashboard, XML, Electronic data interchange, Aviation, Airline

trolleys.

Abstract: The paper describes the main results of a research project as a use case for cross-company system

integration in the airline catering domain. Especially the connections of IT systems of different process

participants and sensor information along the catering supply chain as well as the replacement of paper-

based lists are among the achievements. Today, airline caterers suffer the lack of information and the

laborious data transfer to their corresponding IT systems. On the other side, airlines have no overview about

the quality of the catering process. Besides, they also have a lack of information concerning important facts

like the stock of trolleys or high-value catering goods. The paper shows a solution for the integration and

better analysis options by using RFID tags on the catering trolleys, middleware software and XML files for

the information flow and a monitoring dashboard to visualize up-to-date statistics for the management of

resources.

1 INTRODUCTION

In the aviation domain, the integration of

participating members and their IT systems is a huge

challenge. The logistic processes which especially

cover the handling of catering goods for the usage

on board are affected by media disruptions, delays

and opacity. Furthermore there is a variety of

participants with different IT systems and processes

involved. In order to avoid the typical problems

which arise from such a distributed system and to

make a suggestion for an integrated and transparent

information and systems chain in the aviation

domain, the German Federal Ministry of Economics

and Technology (BMWi) funded a research project

between 2007 and 2010. The project has a wide

range of objectives, such as the development of new

business models and the integration of RFID (Radio

Frequency IDentification) technology in the aviation

domain. Fraunhofer IAO and autoID systems

GmbH, two members of the project consortium,

have been responsible for the task of system

integration which was one of the most important

challenges of the project.

The foundations for achieving a seamless

integration between various IT systems is to

establish an overall data interchange format based

on XML (eXtensible Markup Language) for all the

mainly paper-based lists (e.g. assembly list, loading

list etc.) as well as transfer messages and to integrate

it into the IT environment. Furthermore, for getting

more transparency along the catering logistics

process, the catering trolleys and important high-

value goods have to be equipped with RFID

transponders.

An integration middleware is used to transport

the relevant messages and sensor data. An event-

driven and therefore real-time monitoring dashboard

is responsible to track and visualise the RFID events

along the whole logistics process and to generate

warnings in case of bottlenecks.

In section 2, we depict the importance of

integration in the aviation domain and airlines. In

section 3, we describe our proposed solution in

91

Scheiding F., Vidackovic K., Tönnies F. and Becker R..

INTEGRATION OF VARIOUS IT SYSTEMS AND SENSOR INFORMATION FOR THE HANDLING OF RFID-ENABLED CATERING GOODS IN THE

AVIATION DOMAIN.

DOI: 10.5220/0003332100910097

In Proceedings of the 7th International Conference on Web Information Systems and Technologies (WEBIST-2011), pages 91-97

ISBN: 978-989-8425-51-5

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

detail by showing how relevant events can be

tracked and organised through an RFID-based

system using a middleware for distribution and

XML structures for the standardised data

interchange. In section 4, we discuss the verification

of our solution by describing a built-up system

demonstrator and conclude with an overview of the

main results of the project.

2 MOTIVATION

The aviation domain is suitable for the introduction

of an integrated and automatic system. There are a

large number of objects to handle and millions of

passengers have to be served (cf. Schnathmann,

2009, p. 177). That is the reason why airline catering

deals with a huge amount of information. Due to the

fact that airlines learned to handle information with

the help of IT systems very early (e.g. for

reservations and ticketing processes), the basic

environment and knowledge already exists.

Nevertheless, most of the applications were

developed to solve specific problems and were

provided by different software companies or user

groups. This is the reason why most of the systems

were not and still are not integrated. Nowadays, the

urgency of system integration is identified (cf. Jones,

2004, p. 227).

Another important requirement of such a system

with a turnover of goods is their transparency and

inventory management. In practice, in supply chains

like in the airline catering domain, many errors may

happen. Items or boxes that are supposed to be in

one trolley are loaded into another one, items get

lost or trolleys are sent to the wrong clearance

position. RFID is likely the right technology with the

most impact concerning such problems. RFID tags

can be applied and provide the opportunity to track

and trace every kind of e.g. lost shipment (cf.

Garfinkel, Holtzman, 2006, p. 27-29). The whole

trolley management with its specified transport and

storage processes should be organised in a way that

it is as efficient and economic as possible.

Therefore, it is necessary to know the status of each

individual trolley. It is possible to draw conclusions

from the analysis of the whole process chain if e.g.

trolleys should be added to or withdrawn from the

process (cf. Dolenek, 2009, p. 135). Furthermore, it

is crucial that there is a distinct and well elaborated

data structure used for the integration of such a

system, so that every instance (e.g. trolley) is

identifiable and unique in the whole process (cf.

Dolenek, 2009, p. 139).

3 SOLUTION DESCRIPTION

The main idea with integrating the process cycle and

the IT environment is to enable the tracking of the

relevant events during the catering process, insert

them into the IT system, analyse them and distribute

them to the other responsible participants. The

tracking of main events e.g. the loading of trolleys

into the aircraft and the comparison with the freight

list on board will be implemented by using RFID

transponders on trolleys as well as RFID gates and

readers at several positions between the caterer

facilities and the airport and at the aircraft doors.

The main transfer messages will be available as

electronic documents and will also be inserted into

the flow of information e.g. the freight list which is

stored on board. These are XML documents which

are transferred via an integration middleware

between the different IT systems of the participating

partners. Sending documents electronically reduces

the error rate and provides the opportunity to

calculate important key performance indicators for

analysing the efficiency of the whole system. A

monitoring dashboard which displays these

indicators gives the operators the possibility to

interfere the process directly or as a long-term

strategic change (e.g. for a better planning of trolleys

and their cycle through the network).

In the following, we describe the main elements of

the developed integrated systems solution:

The process participants and the integrated IT

systems architecture

The middleware as the system integrator which

forwards all the relevant messages and RFID sensor

data to the participants

The XML files and their structure which are used

for the communication by the systems

The event-driven monitoring dashboard which

shows the location and statistics of the events and

messages

3.1 Process Participants

and IT Architecture

The process of airline catering includes several

participants.

Airport: The airport is responsible for the complete

flight schedule. The airport software creates the

schedule which has to be considered by airlines and

caterers for the catering logistics process.

Passenger: In an integrated, pull-based logistics

chain, the passenger is the one who starts the process

WEBIST 2011 - 7th International Conference on Web Information Systems and Technologies

92

flow of catering goods. Today it is possible or even

common to book flights online at home from the

private computer, so the additional ordering of

individual catering goods (e.g. special meals or duty

free concessions) and services for the flight or the

destination is imaginable as a new offer for the

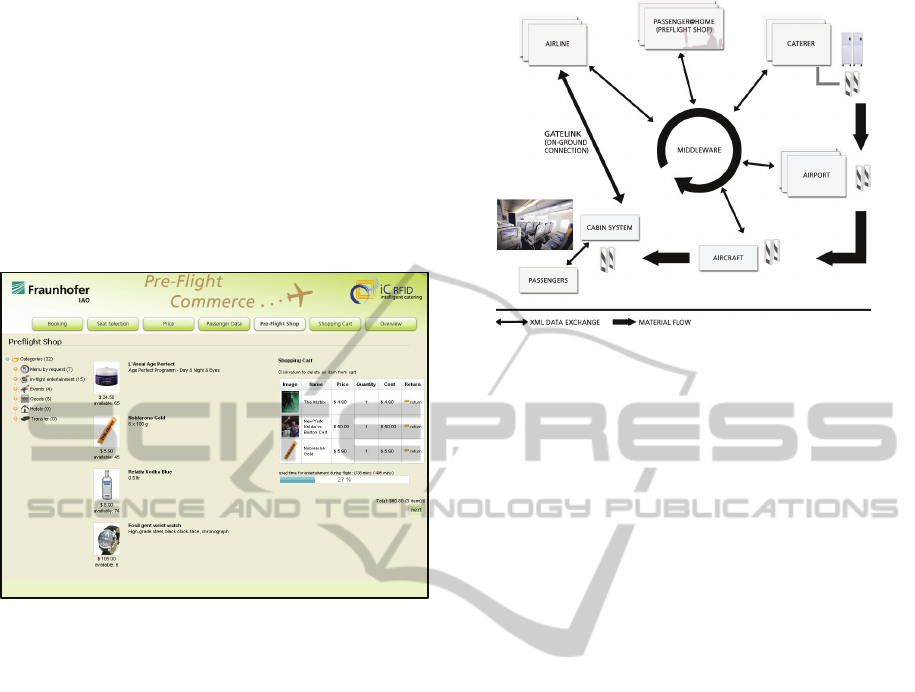

passengers. As we wanted to simulate such an online

booking scenario, we developed the prototype of a

pre-flight shop realised with up-to-date

programming frameworks (like ICEfaces) which can

be seen in figure 1.

Figure 1: The user interface of the pre-flight shop.

Airline: Subsequently in the information flow, the

airline is the next participant which is introduced.

The booking and ordering information from the

passengers will be collected by the airline and an

assembly list for the goods will be created.

Caterer: The caterer receives the assembly list

which shows what he has to load into the trolleys.

He now has to plan his flow of goods in a way that

he can load the trolleys as planned in the assembly

list. Different software systems support this by

planning the assembly lanes. At the end a freight list

with the loaded goods is generated which will

directly be communicated to the aircraft crew.

Aircraft: The aircraft and the entire crew receive the

freight list and store it in the onboard server. They

now have to take care that the incoming trolleys

match with the freight list.

All these participants are working with their own IT

systems. In order to integrate them, we developed an

XML data interchange format and a middleware

application which distributes the messages through

every participant. Figure 2 shows the arrangement of

the different participants and the information flow.

Figure 2: Participants of the information flow.

3.2 Integration Middleware

for the Distribution of Messages

and RFID Sensor Data

In order to get the full benefit of an RFID-based

system, it is necessary to incorporate RFID data into

the decision making processes. The IT systems of

the participants are the central elements for these

processes. Middleware connects the RFID hardware

with the IT systems. RFID hardware is useless

without the Middleware as integrating software (cf.

Hunt, Puglia, M., Puglia, A., 2007, p. 33).

The middleware is responsible for the

communication between all the participants involved

in the process. Concerning the research project, it

was completely developed by the project team of

autoIDsystems and was used in several other

projects and use cases before. The main idea of

using the middleware is to route data between the

RFID network and the IT systems and therefore it is

responsible for the quality and usability of the

information which is produced by RFID systems as

Hunt et al. (2007) described the main functions.

The middleware is the central data hub for the

communication of all participants. The flow of data

is organised by a messaging bus which works like a

post-office box. The messages are hold in queues

until they are collected. The queues can handle many

different data formats but the receptor has to know

the data structure. Due to this fact the data structures

of e.g. the electronic lists are predefined as XML-

files which will be introduced in section 3.3. In that

way, it is possible to provide all the information to

many partners without changing their IT systems

and media for processing the data. Even new and not

planned participants can be integrated easily if

access is granted.

INTEGRATION OF VARIOUS IT SYSTEMS AND SENSOR INFORMATION FOR THE HANDLING OF

RFID-ENABLED CATERING GOODS IN THE AVIATION DOMAIN

93

Several components from various domains have

to be integrated via the middleware. This is

accomplished by connecting them to the messaging

bus which is used as the central communication

interface. The processing of the incoming events and

documents will be done by the database and

application server. The other integrated systems can

be seen in figure 3. The integration architecture of

the project includes the following elements:

DATABASE

AND

APPLICATION

SERVER

SITE

SERVER

HANDHELD READER

(WLAN, BLUETOOTH)

INTELLIGENT

READERS

(TCP)

READER GATE (TCP)

READER AT FORKLIFT

(WLAN)

READER, DIRECT

(SERIAL, USB)

SITE

SERVER

+

ERP-

SYSTEMS

(CATERER /

AIRLINE)

ADAPTER

ERP

ADAPT

ER

ERP-

SYSTEM

CATERER

SITE

SERVER

SITE

SERVER

READER GATE (TCP)

MOBILE READER

(WLAN)

READER (USB)

READER

(SERIAL)

EXTERNAL

DATABASE

ADAPTER

MESSAGING BUS

SERIAL

USB

BLUETOOTH

TCP

GUI

ADMINISTRATION

TRANSPORT LAYER

IN / OUT Queues

DASHBOARD

MULTI-AGENT SYSTEM

A

B

C

F

E

G

H

I

J

AIRPORT

DATABASE

ADAPTER IN

MIDDLEWARE

D

MQ

Figure 3: The system architecture of the integrated

solution.

A: Intelligent readers which are directly connected

to the messaging bus

B: Site servers which provide a connection to

various readers

C: Bidirectional connection of external systems

with local adapters

D: unidirectional pulling of data from external

databases (adapter in middleware)

E: unidirectional pushing of data from external

sources (adapter in source)

F: Site servers and independent middleware system

for partners to allow autonomous and completely

integrated work

G: The messaging bus for the transport of the

information

H: The database and application server for

processing events

I: The monitoring dashboard for the visualisation

of the middleware (also see section 3.5)

J: The connection to a multi-agent system for

economic analysis

3.3 XML Data Interchange Format

In the previous section, we depicted the software

system to arrange the messages and their distribution

between the participants of the system. In the field

of airline catering, it means that for example an

order for a booked flight now can easily be

transferred from the system of the airline to the one

of the caterer. We now want to show our suggestion

for a standardised data transfer between the

participants with the help of an XML-based data

interchange format.

Electronic Data Interchange (EDI) is used as a

transfer method of business data mostly established

between business partners in both directions. EDI is

structured in standardised formats for a seamless

processing. Currently, the implementation of EDI in

the aviation domain is not really considered, because

the main data interchange is still realised with the

help of paper-based lists. Fraunhofer IAO has

developed the following XML structure for the

establishment of EDI between the participants in the

field of airline catering.

The root element contains the five main lists

which base upon original lists used at airports

nowadays in paper format:

The Flight Schedule with the exact flight data that

will be transferred to the caterer.

The Preflight Order is an element developed in the

project to order goods or services by the passenger

from his home via internet.

The Assembly and Freight Lists are used to show the

target loading of a flight and in consequence the

realistic trolley assembly when the caterer has

finished loading. It is also used for additional

delivery orders which could appear if some of the

trolleys are not loaded correctly.

The Transfer Order describes the data for the

transport of the trolleys from the ramp of the caterer

to the aircraft door using a highloader.

The Ground Delivery is a structure for pre-flight

orders which will be collected at the destination

airport by the passenger. This may be used to avoid

bulky and heavy luggage.

The different structures enable some benefits for the

process participants. The following scenarios point

WEBIST 2011 - 7th International Conference on Web Information Systems and Technologies

94

them out and show some examples how the XML

files and the newly achieved paperless transactions

affect the work in airports:

Order to Caterer: Current flight plans and orders

from the airline to the caterer are sent weekly and

via e-mail. The caterer then enters the data into his

individual software and has to assign e.g. order to

flights manually. The newly developed structures

provide the caterer with the ability to receive orders

directly and without media disruptions from the

airport and airline system into the caterer system. All

the necessary assignments can then be done

automatically.

Freight List at On-board Server: Currently, the

freight list and the trolley inventory are matched

manually and the sales volume is recorded as a

paper-based list or on a USB device. The XML

structure makes it possible that the freight list now

can be transferred to the server on board. When the

RFID-tagged trolleys are loaded into the aircraft, a

reader sends the loading information from the tag to

the server and the freight list and the real content of

the trolleys can be matched by the system.

Precise Transfer of Trolleys: The new XML

structures allow a precise transfer of trolleys

beginning at the ramp of the caterer. The operator of

the highloader receives the data in form of the

transfer order and can identify the trolleys with the

help of the RFID tags. Mistakes in the correct trolley

to flight assignment are now prevented.

3.4 RFID Tag Structure

Besides the structure of the distributed electronic

XML files as a replacement for paper-based lists, the

configuration of the content of the RFID tags is

another important challenge for standardising the

data flow in the whole catering process. The project

uses a 96-bit UHF RFID transponder for every

transport container and the high-value items (e.g.

expensive duty-free goods) which are also equipped

with an RFID tag. This allows the widest range of

possibilities for implementation (e.g. because of the

low price and high range). The following elements

are part of the RFID structure used in the project

(the complete structure is not shown due to the

limited space):

Five bits are reserved for the type of container (e.g.

trolley, item, and bag). Thirty bits contain the unique

ID of the trolley. Two bits are reserved for the code,

if the trolley has to be maintained or not. Further

elements of the structure are the last maintenance

date, the type of the trolley content, if the trolley

remains in the aircraft or not, information concer-

ning duty and additional information.

3.5 Event-driven Monitoring

Dashboard

Finally, after we have shown the way we integrated

the systems and the data between the participants,

we want to show how to visualize the whole

transaction cycle.

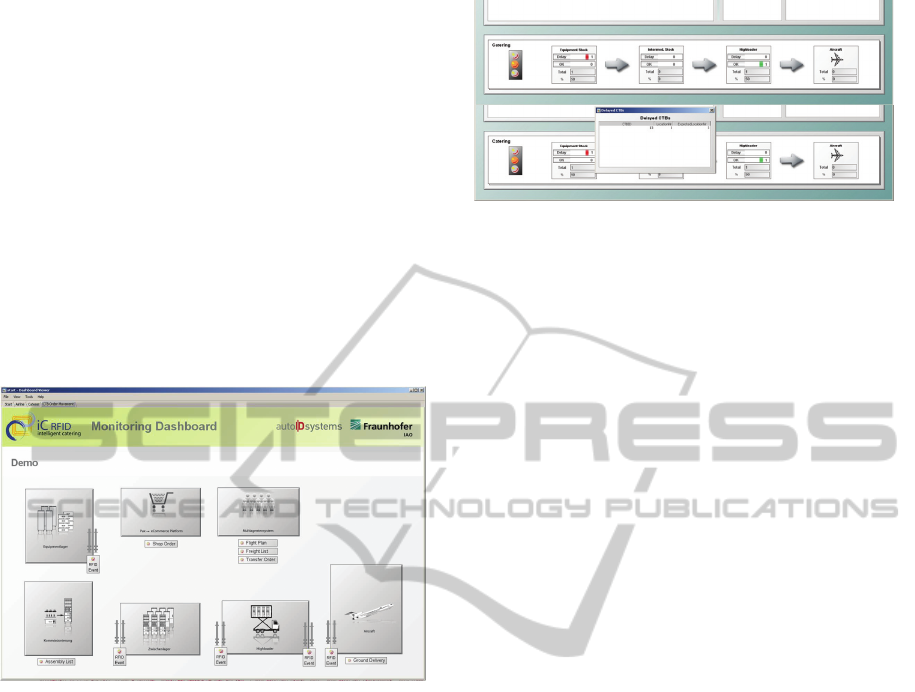

All the relevant objects identified by the central

RFID middleware need to be illustrated and

analysed in a monitoring dashboard. One of the main

requirements is the customisation to the highly

individual processes. Due to this fact, it is not

possible to develop a standard dashboard. For an

individual configuration, the knowledge about all the

relevant performance indicators of the process is

necessary. With the help of these performance

indicators, the project team developed a monitoring

dashboard for the tracking and tracing of the trolleys

covering the whole catering process. This increases

transparency, and several potentials for optimisation

can now be discovered. If there are any bottlenecks

or high deviations of the performance indicators

from the expected values, warnings are displayed

immediately in order to improve the reaction time

along the process.

The target users for such a monitoring dashboard

are airlines interested in a transparent catering

process as well as caterers focussing on a

visualisation of their own processes. For both

parties, different dashboard views are available.

For the development of such a monitoring

dashboard application, we used the commercial

software Progress Apama (cf.

http://web.progress.com/de-de/apama/index.html)

which is based on a complex event processing (CEP)

engine and additionally includes modelling and

execution of an event-driven dashboard. This CEP

platform is specialised for the analysis of a multitude

of events with very low latency. It can react to these

events immediately by using specified event

processing rules and can visualise relevant metrics in

a web-based dashboard. An event in the context of

the project for example is the transit of a trolley

through a gate or an alert which is generated by the

system and shall be visualised in the dashboard. In

contrast to traditional software architectures, an

event-driven architecture is used because of the

capability to react in real-time and a high

performance in processing multiple events.

In the scope of the project Fraunhofer IAO has

published a market overview with different CEP-

tools (cf. Vidackovic, Renner, Rex, 2010). CEP is

INTEGRATION OF VARIOUS IT SYSTEMS AND SENSOR INFORMATION FOR THE HANDLING OF

RFID-ENABLED CATERING GOODS IN THE AVIATION DOMAIN

95

used to combine simple platform events into more

useful, higher-level business events. In contrast to

time-driven processing, generated reports and

reactions are related to received events and not time

frames (cf. Chandy, Schulte, 2010, p. 43, 47). A

simple example in the aviation context is a generated

warning as soon as the trolley stock falls below a

pre-defined threshold. The Apama CEP engine uses

a specific event processing language (EPL) to

describe event patterns which should be identified

from a multitude of received events and to execute

necessary reactions. The dashboard communicates

with the CEP engine for displaying relevant business

events in real-time. Figure 4 shows the developed

monitoring dashboard with the display of RFID

events and the interchange of XML files.

Figure 4: The monitoring dashboard shows the process

cycle.

Figure 5 shows an example of the tracking and

tracing of trolleys with the monitoring dashboard:

the screen shows trolleys which are delayed

including their last known position.

The developed dashboard solution supports the

caterer for example by the following key

performance indicators:

Average cycle time of process steps

Portion of wrong deliveries

Lack of goods and bottlenecks

The airline gets support by the following example

key performance indicators:

Delivery reliability of the caterer

Number of trolleys in flow, maintenance or store

Flight delays and resulting lack of trolleys

For the scientific staff of Fraunhofer IAO, the

development of the dashboard was the basic work

for the research concerning a new monitoring

concept for the introduction in business networks

with several participants.

Figure 5: The monitoring dashboard shows tracking and

tracing of trolleys.

4 DISCUSSION

AND CONCLUSIONS

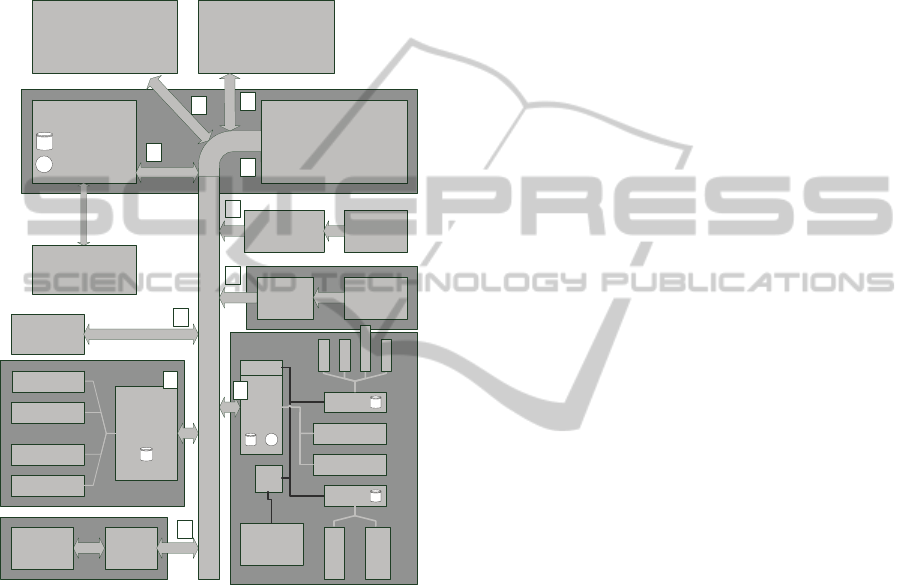

All the presented results and ideas were completely

assembled for testing in a presentation hall at the

aircraft constructor Airbus in Hamburg. The main

goals of the tests were the proof of the system

integration in a running environment. For this

special scenario, the XML files and structures were

slightly modified so that the project specific systems

could be integrated as well. The concrete test of the

whole system with a general system run has been

operated in June 2010 including evaluators from the

German Federal Ministry of Economics and

Technology (BMWi). The positive result of the test

performance will now be transferred to the interested

public especially by the research partners. The

developed prototypes will be developed into

products and included within the portfolio of the

business partners.

Furthermore, the concepts and solutions that are

presented here could be transferred to other sectors

than the aviation domain. The RFID solution can

support every domain which has to deal with

tracking and tracing of objects and its

documentation. An obvious application area which

also deals with the handling of trolleys is the

catering in hospitals. The following solutions would

be possible:

Temperature control with RFID and sensors

Assignment of medicine to patients

The logistic process for important materials (for

inspection, quality control and security)

Implementation in lunchrooms of hospitals

Anti-theft protection

Another sector for the implementation of the

solution is the railway transport sector including the

catering processes.

The paper showed a use case of an integration of

WEBIST 2011 - 7th International Conference on Web Information Systems and Technologies

96

various IT systems with different participants in a

service network with a high demand of security and

precision in the aviation domain. The complete

system was assembled in a demonstrator this year

and successfully tested. The final results will now be

exploited in further scientific work.

REFERENCES

Chandy, K. M., Schulte, W. R., 2010. Event Processing:

Designing IT Systems for Agile Companies, McGraw

Hill, New York et al.

Dolenek, J., 2009. Container and Asset Management. In

Bartnek, N., Klaas, V., Schoenherr, H., Weinlaender

M. (ed.), 2009. Optimizig Processes with RFID and

Auto ID, Publicis Publishing, Erlangen.

Garfinkel, S., Holtzman, H., 2006. Understanding RFID

Technology. In Garfinkel, S., Rosenberg, B. (ed.),

2006. RFID: Applications, Security, and Privacy,

Pearson Education, Inc., Upper Saddle River, NJ.

Hunt, V. D., Puglia, A., Puglia M., 2007. RFID – A Guide

to Radio Frequency Identification, John Wiley &

Sons, Inc., Hoboken, New Jersey.

Jones, P., 2004. Flight Catering, Elsevier Ltd. Amsterdam,

Boston et al., 2

nd

edition.

Schnathmann, R., 2009, RFID at the airport. In Bartnek,

N., Klaas, V., Schoenherr, H., Weinlaender M. (ed.),

2009. Optimizig Processes with RFID and Auto ID,

Publicis Publishing, Erlangen.

Vidackovic, K., Renner, T., Rex, S., 2010. Marktübersicht

Real-Time Monitoring Software: Event Processing

Tools im Überblick, Fraunhofer Verlag, Stuttgart.

INTEGRATION OF VARIOUS IT SYSTEMS AND SENSOR INFORMATION FOR THE HANDLING OF

RFID-ENABLED CATERING GOODS IN THE AVIATION DOMAIN

97