SURFACE RECONSTRUCTION FOR GENERATING DIGITAL

MODELS OF PROSTHESIS

Luiz C. M. de Aquino, Diego A. T. Q. Leite, Gilson A. Giraldi

National Laboratory for Scientific Computing, Petr

´

opolis, Brazil

Jaime S. Cardoso

INESC Porto, Faculty of Engineering, University of Porto, Porto, Portugal

Paulo Sergio S. Rodrigues

1

, Luiz A. P. Neves

2

1

FEI, S

˜

ao Bernardo do Campo, Brazil

2

Federal University of Paran

´

a, Curitiba, Brazil

Keywords:

Digital prosthesis design, Segmentation, Deformable model, Shape recovery.

Abstract:

The restoration and recovery of a defective skull can be performed through operative techniques to implant

a customized prosthesis. Recently, image processing and surface reconstruction methods have been used for

digital prosthesis design. In this paper we present a framework for prosthesis modeling. Firstly, we take the

computed tomography (CT) of the skull and perform bone segmentation by thresholding. The obtained binary

volume is processed by morphological operators, frame-by-frame, to get the inner and outer boundaries of the

bone. These curves are used to initialize a 2D deformable model that generates the prosthesis boundary in each

CT frame. In this way, we can fill the prosthesis volume which is the input for a marching cubes technique that

computes the digital model of the target geometry. In the experimental results we demonstrate the potential of

our technique and compare it with a related one.

1 INTRODUCTION

The repairing of a defective skull is needed not only

for aesthetic factors but also because large defects in

the skull may expose a significant area of the brain.

In this case cranioplasty (the procedure of repairing

holes in the skull with cranial implants) becomes nec-

essary (Sanan and Haines, 1997). In traditional sur-

gical procedures, cranioplastic implants were manu-

factured directly in the operating-theater where the

surgeon modeled by hand the material, namely poly-

methylmethacrylate (PMMA), to make the prosthe-

sis. However, the success of such procedure depends

strongly on the manual skill of the surgeon, with a

high risk of infection and a certain percentage of fail-

ure due to rejection (Solaro et al., 2008).

Nowadays cranioplasty continues to be a chal-

lenge to craniofacial surgeons which motivates the

development of computational tools for surgical plan-

ning and implants design (Chen et al., 2006; Lee et al.,

2009; Solaro et al., 2008).

In early 1980s, the introduction of 3-D CT scans

and surface reconstruction methods provided a new

effective tool for surgical planning. The generated

digital models and stereolithography rapid prototyp-

ing technologies (RP) made skull prostheses manu-

facture more accurate and customized for each case

(Lee et al., 2002).

The application of medical image processing,

computer graphics and rapid prototyping (RP) tech-

nology allows the customization of cranioplasty pro-

cedures to relieve the injury of patients in opera-

tions (Kai et al., 2009). The pipeline for the prosthe-

sis generation begins with the acquisition of the com-

puted tomography (CT) image of the skull. Then, im-

age processing methods are applied for bone segmen-

tation. Next, some surface reconstruction method is

applied to get a three-dimensional model of the pros-

thesis. Such model is the input for the next step where

the prosthesis of defective skull is manufactured us-

137

C. M. de Aquino L., A. T. Q. Leite D., A. Giraldi G., S. Cardoso J., Sergio S. Rodrigues P. and A. P. Neves L..

SURFACE RECONSTRUCTION FOR GENERATING DIGITAL MODELS OF PROSTHESIS.

DOI: 10.5220/0003356601370142

In Proceedings of the International Conference on Computer Vision Theory and Applications (VISAPP-2011), pages 137-142

ISBN: 978-989-8425-47-8

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

ing RP technology. Lastly, the prosthesis is implanted

into the defective position.

From the viewpoint of image processing and geo-

metric modeling the approaches in this area fall into

two main categories. In the first one surface recon-

struction is usually applied to get a representation of

the defective skull which is then used to reconstruct

the digital model of the lost part. In (You et al., 2009)

we find one of such method, which divides each voxel

into tetrahedra and applies a marching technique to

get a polygonal representation of the defective skull.

Then, the method uses user-defined guiding points

and computational geometry algorithms to generate

the digital version of the prosthesis taking into ac-

count only the polygonal mesh.

The second class of techniques includes methods

that first reconstruct the skull in the image space.

Then, they apply Boolean operations and Marching

Cubes methods to get the digital model of the pros-

thesis. Reflection techniques, based on the assump-

tion of skull symmetry, belong to this class. In this

case, we can compute the axis of symmetry and re-

flect the segmented image (bone) respect to this axis.

However, this method can be used only if the lesion

do not cross that axis.

In this paper, we propose a new methodology for

digital prosthesis generation, which falls into the sec-

ond category. Our proposal is roughly divided into

5 stages: 1) Slice-by-Slice Segmentation: Extract the

bone from the other tissues; 2) Feature Extraction: get

geometric information about the frontier of the lesion

(terminal points and their tangents); 3) Deformable

Model: With the information from step 2, compute

the inner and outer boundaries of the prosthesis, using

a deformable 2D model of type balloon; 4) Prosthe-

sis Volume: Fill each patch obtained in the step above

to complete the prosthesis volume; 5) Surface Recon-

struction: Marching cubes is applied to generate the

digital version of the prosthesis geometry.

To accomplish the first step, we take each frame of

the volume and we apply a simple thresholding tech-

nique based on image inspection. Then, we perform

the feature extraction. Firstly, we use an edge detec-

tor to extract the boundary B of the bone in the binary

image and a thinning process to get the skeleton of

the bone. Then, the convex hull S is computed for the

skeleton. We consider the difference B−S as the outer

boundary of the bone and the set B ∩ S as the inner

boundary of the bone. The obtained curves are used

to get the geometric information need for the next

step. We take the end points and tangents as boundary

conditions for a deformable model, a balloon-like one

(Cohen, 1991), which is used to compute the patch

of the prosthesis in each image frame. We set two

instance of the balloon model: one to get the outer

boundary of the prosthesis and another one to get the

inner boundary of the prosthesis. In the next stage,

we recover the lost part of the bone, following the bal-

loon result in each frame. Finally, the geometry of the

prosthesis is reconstructed through a marching cubes

technique. In the experimental results we demonstrate

the advantages of our technique when compared with

the one presented in (You et al., 2009).

2 PROPOSED METHOD

The standard format for CT images is DICOM (Dig-

ital Imaging and Communications in Medicine). In

the case of CT images of the head we find the bone

as well as soft tissues (brain, skin, etc.). In a DICOM

image, the data matrix has real values in the range

[−1000,1000], called CT numbers. It is known that

the CT number for bone tissues belongs to the range

[400,1000]. So, a simple binarization method can be

performed in order to highlight just the structure of

interest. Besides, we also apply a hole filling method

to correct bone topology and a simple search process

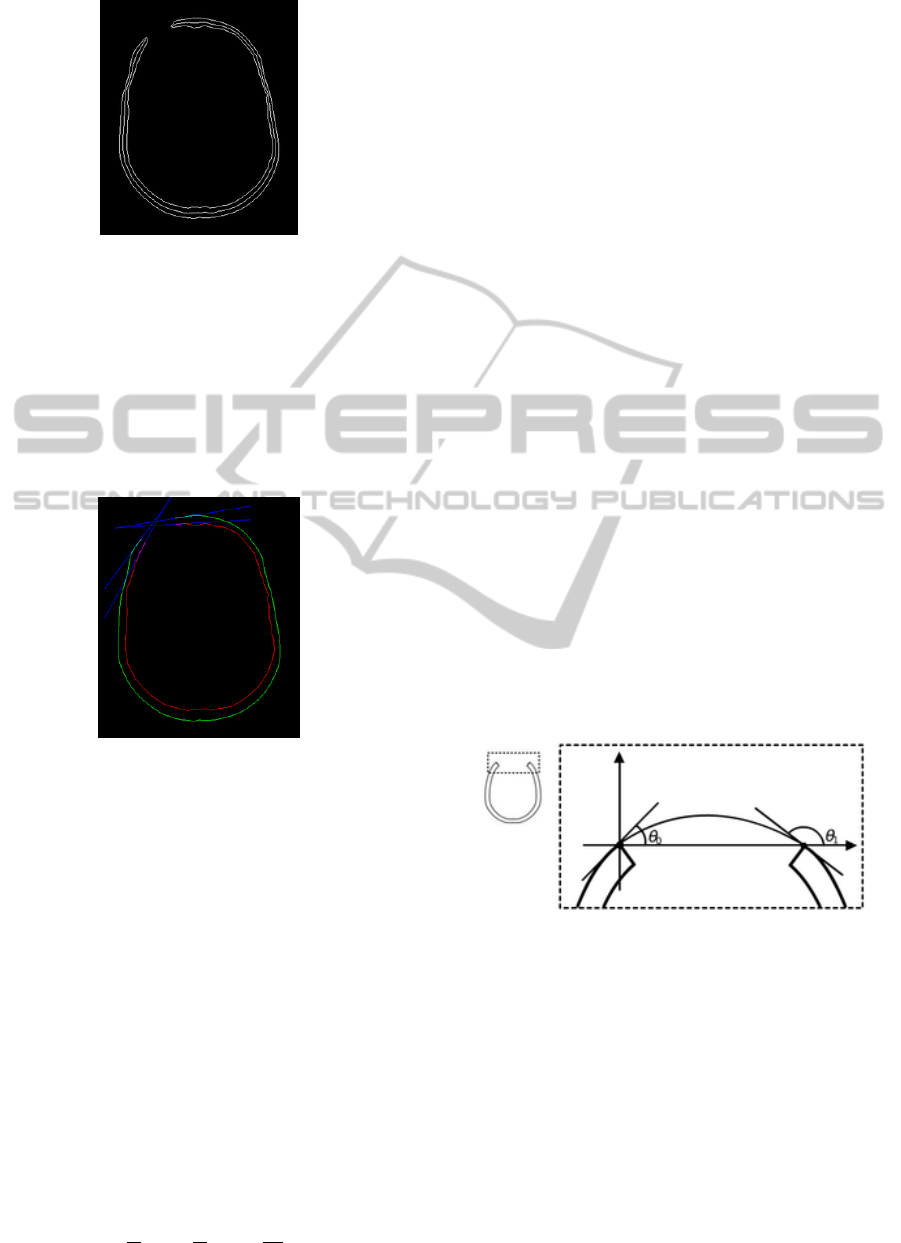

to discard acquisition artifacts. The Figures 1.(a)-(b)

shows the original image and the segmentation result,

respectively.

(a) (b)

Figure 1: (a) Slice of the defective skull. (b) Bone segmen-

tation.

Now, once the bone is segmented, we take each

frame and get the end points of the lesion and their

tangents. In order to perform this task, we apply an

edge detector to extract the boundary B of the bone

in the binary image and a thinning process to get the

skeleton of the bone. The obtained results are pictured

on Figure 2.

Then, a convex hull S is computed for the skele-

ton. We consider the difference B − S as the outer

boundary of the bone and the set B ∩ S as the in-

ner boundary of the bone. The obtained curves are

used to get the geometric information need for the fur-

ther step. Firstly we discard a set of boundary points

VISAPP 2011 - International Conference on Computer Vision Theory and Applications

138

Figure 2: Bone boundary and skeleton.

nearby the lost part of the bone, typically 10 points

nearby the end points of the skeleton. Then, for each

boundary, we take the boundary points inside a neigh-

borhood of each end point to fit a line which direction

will be used to get the tangent necessary for the bal-

loon model setup. This process is applied for both, the

inner and outer curves, generating the results pictured

on Figure 3.

Figure 3: (a) Inner (red) and outer (green) boundaries of the

bone plus the tangent lines.

Next, we apply a deformable model, a balloon-

like model (Cohen, 1991), to compute the patch of

the prosthesis in each image frame. We take the end

points and tangents already obtained as boundary con-

ditions for a deformable model. We set two instance

of the balloon model: one to get the outer boundary of

the prosthesis and another one to get the inner bound-

ary.

Geometrically, the balloon model (Cohen, 1991)

is described by a parametric contour c : [0,1] → D ⊂

ℜ

2

. From the dynamic viewpoint, we have a de-

formable contour which is viewed as a time-varying

curve c (s,t) = (x (s,t),y(s,t)). In this formulation,

the Lagrange equations of motion (balloon model

equation) can be expressed as:

˙c − (ω

1

c

0

)

0

+ (ω

2

c

00

)

00

=

~

F

ext

+ k~n(c), (1)

subject to c(0,t), c(1,t), c

0

(0,t), c

0

(1,t). In (1) we use

the notations ˙c ≡

∂c

∂t

, c

0

≡

∂c

∂s

, c

00

≡

∂

2

c

∂s

2

,~n(c) is the unit

normal over the curve and k is a scale factor. The field

~

F

ext

means an external force, which depends on image

elements or constraints.

In our case,

~

F

ext

= 0, each curve is an open one,

fixed in the end points of the lesion following the tan-

gents at that points. Besides these boundary condi-

tions, we must set the initial curve to complete the

initialization of each instance of the balloon.

To solve (1) we use finite differences as described

in (Cohen, 1991). In order to include the initial

curve in the numerical method, we must give an ini-

tial sequence of points C

0

= c(i∆s,0) = c

0

i

, with i =

0, ..., N, which is the discrete version of the initial

curve. Such curve must satisfies the boundary con-

ditions also. In the case of the outer curve, we can

simplify the equations by using the reference system

pictured on Figure 4, which has both the end points

on the horizontal axis (one in the origin and the other

one at x = L), to write the constraints as:

C(0) = C(L) = 0, (2)

C0(0) = tan θ

0

,

C0(L) = tan θ

1

.

Besides, the initial shape should be as closer as

possible to the target to reduce time computation. We

observe that a cubic curve, represented by

c(s) = (Ls, L(tanθ

0

+ tanθ

1

)s

3

−

L(2tan θ

0

+ tanθ

1

)s

2

+ L tan θ

0

s), (3)

where s ∈ [0, 1], fits all of these requirements.

Figure 4: Coordinate system used to setup the outer balloon.

An analogous construction can be made for the in-

ner balloon. The Figure 5.(a) shows a typical result

obtained through the deformable model. From this

result, we can complete the patch of the prosthesis in

the corresponding slice. It is just a matter of filling

the region between the obtained curves and take the

difference between this region and the bone (Figure

5.(b)). So, by executing this procedure in each slice

we can complete the prosthesis volume.

Besides, there are cases in which we observe lost

of bone without changing the topology of the corre-

sponding region. The Figure 6.(a) shows such a case.

SURFACE RECONSTRUCTION FOR GENERATING DIGITAL MODELS OF PROSTHESIS

139

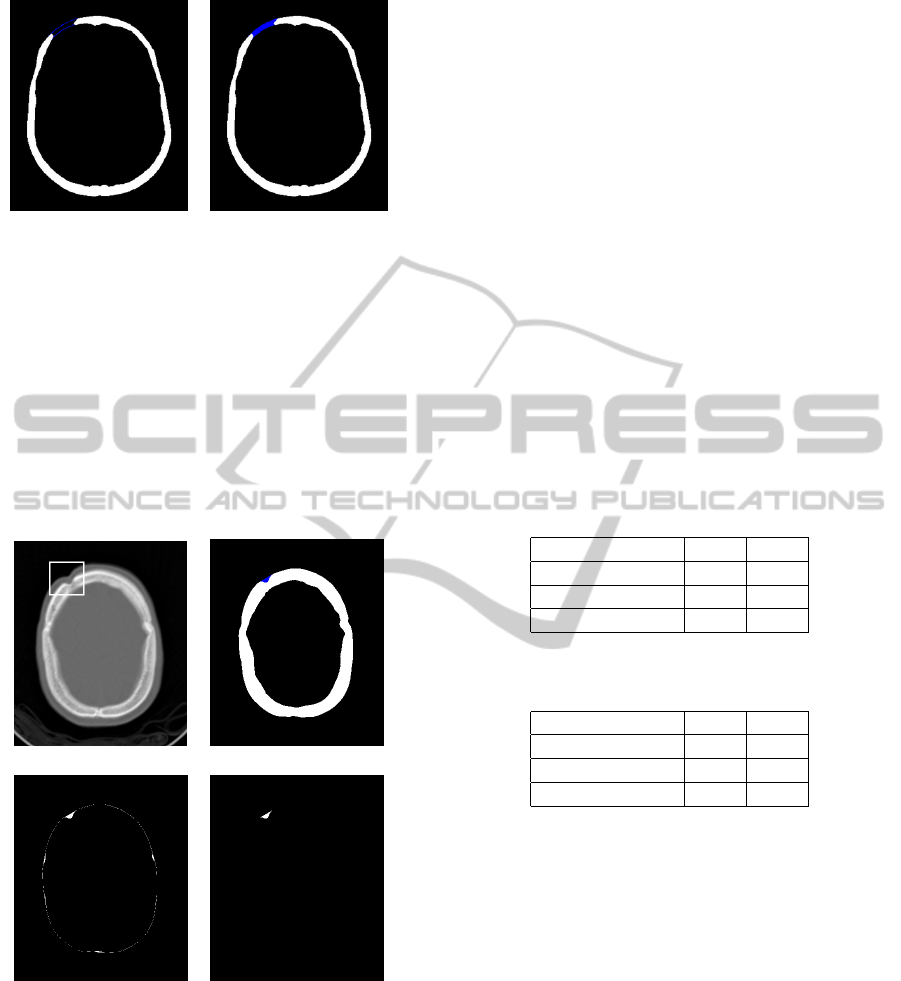

(a) (b)

Figure 5: (a) Balloon results. (b) Prosthesis patch (in blue).

The bone region, pictured in white on Figure 6.(b),

has a skeleton given by a closed curve which automat-

ically indicates this problem. In this case, we can as-

sume that the lost region is small. Therefore, we just

take the difference between the segmented bone and

its convex hull (Figure 6.(c)). Then we discard small

islands and the biggest region to isolate the prosthe-

sis patch, pictured on Figure 6.(d). In the final stages,

we recover the geometry of the prosthesis through a

marching cubes technique.

(a) (b)

(c) (d)

Figure 6: (a) Original slice with defective region high-

lighted. (b) Segmented bone. (c) Difference between the

convex hull and the bone region. (d) Prosthesis patch.

3 EXPERIMENTAL RESULTS

The proposed model is applied to generate the pros-

thesis for repairing the defective skull pictured on Fig-

ure 8.(a). In this case, we can also use a reflection

technique, based on the assumption of skull symme-

try, to reconstruct the skull. We will use this solution

to measure the quality of the result. The defective re-

gion intersects 23 slices of the whole image volume

(68 slices). Three of them are processed using the

convex hull, like in Figure 6 and the other ones are

processed through the balloon model.

In the experiments of this section we set null the

external force in expression (1). Following (Cohen,

1991), the parameters ω

0

and ω

1

are set to (∆s)

2

and (∆s)

4

, for both the balloon instances where ∆s

is the discretization step applied to get the numeri-

cal solution of equation (1). The value of the normal

force scale parameter is k = −0.062. The stopping

criterium for the iterative method used to solve (1)

is based on expression

C

t+∆t

−C

t

≤ 10

−3

, where

C

t+∆t

and C

t

are the curves at time t + ∆t and t. The

Tables 1 and 2 report some statistics about the initial-

ization (expression (3)) and evolution of the balloon

instances.

Table 1: Outer balloon: Statistics for parameters (θ

0

, θ

1

)

and number of interactions of balloon.

Parameter Min Max

θ

0

4

◦

22

◦

θ

1

156

◦

169

◦

No. Interactions 48 135

Table 2: Inner balloon: Statistics for parameters (θ

0

, θ

1

)

and number of interactions of balloon.

Parameter Min Max

θ

0

12

◦

29

◦

θ

1

143

◦

156

◦

No. Interactions 31 147

Considering that the mean number of interactions

of the numerical scheme is 135 for the outer balloon

and 147 for the inner one and we have a mean num-

ber of 21 snaxels for the balloon model instance, we

can say that the computational cost is not expensive.

The Figures 7.(a)-(c) show three slices and the cor-

responding prosthesis patches. In the first two cases,

the result is visually acceptable. However, the Fig-

ure 7.(c) shows that the thickness of the prosthesis

patch is not suitable in this case, as we can observe

with a zoom in the defective region, pictured on Fig-

ure 7.(d). This problem happens because we did not

get the suitable boundary conditions. We will address

this problem in further works.

Figures 8.(b)-(d) show three viewpoints of the re-

paired skull. A visual inspection indicates that the

prosthesis geometry suitably reconstructs the defec-

tive region. However, the method is sensitive to the

parameters choice. So, we must be careful about this

VISAPP 2011 - International Conference on Computer Vision Theory and Applications

140

(a) (b)

(c) (d)

Figure 7: (a)-(c) Prosthesis patches obtained with our

method. (d) Zoom in the patch of last figure.

(a) (b)

(c) (d)

Figure 8: (a) Original defective skull. (b)-(d) Skull surface

reconstructed.

point during the setup of the balloon technique.

In order to measure the quality of the obtained

result we compute a similarity measure, based on

the distance from the top and inner surfaces of the

prosthesis and the prosthesis generated by reflection,

taken as a ground truth. Specifically, for each node of

the top (inner) surface we calculate the distance from

the corresponding surface obtained by reflection. The

Table 3 reports a statistics for the distance field ob-

tained. For the top surface the reported minimum dis-

tance is 0.0 and the maximum one is 2.89.

Therefore, the distance field lies in the range

[0,2.89], which is acceptable if we consider that the

Table 3: Statistics for the distance field (in voxel units) be-

tween the prosthesis surfaces and the ground through (re-

flection).

Distance Top Inner You et al.

Min. 0.0 0.0 0.06

Max. 2.89 3.16 6.06

Mean 1.10 0.72 3.09

StD. 0.52 0.48 1.34

resolution of the skull volume is 512 × 512 × 68 vox-

els. The inner surface precision is smaller; between

[0,3.16]. However, the Figure 9 shows that the maxi-

mum distance happens in small places over the pros-

thesis surface. This figure shows a color map that pic-

tures the intensity of distance field. This fact is also

confirmed through the standard deviation (named StD

in Table 3), which is too smaller then the maximum

distance.

(a) (b)

(c)

Figure 9: (a) Distance map plotted over the top surface ob-

tained by our method. (b) Artificial inner surface and col-

ored distance map. (c) Top surface and distance map for

You et al. technique.

It is worthwhile to compare our method with the

one proposed by You et al. in the reference (You et al.,

2009). The Figure 10 pictures the solution obtained

with that method. It does not take into account the

tangent directions at the boundary of the hole. There-

fore, the obtained prosthesis may not fit the curvature

of the skull. In fact, the method has a bias towards

planar shapes due to the fact that there is no any con-

straint related to local curvature. We can check this

problem in the result pictured on Figure 10 as well

as through comparisons with the reflection result pre-

SURFACE RECONSTRUCTION FOR GENERATING DIGITAL MODELS OF PROSTHESIS

141

sented on the third column of Table 3, for the top sur-

face. All the reported distances are higher than the

ones reported by our technique which indicates that

we can better recover the curvature of the region. This

fact is also confirmed by the distance field pictured on

Figure 9.(c).

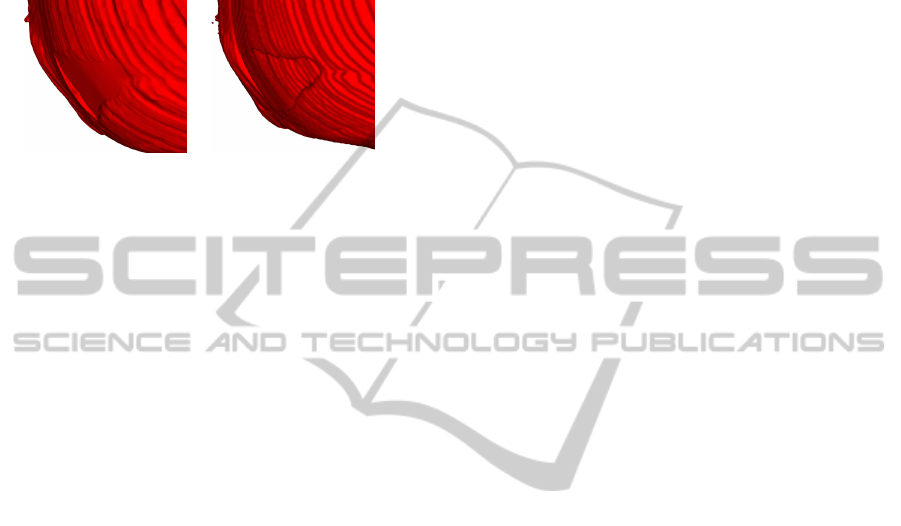

(a) (b)

Figure 10: (a) Viewpoints of the solution obtained by the

method described in (You et al., 2009). (b) A viewpoint of

the prosthesis generated by our technique.

4 CONCLUSIONS AND FUTURE

WORKS

Based on a deformable model, a method is proposed

to reconstruct the defective position of a skull. The

goal is to construct the prosthesis model for the defec-

tive region. We show a promising result and compare

our technique with a state-of-the-art one, showing that

our method can generate a more suitable prosthesis

geometry.

Future directions for our work are to improve the

method that obtain the boundary conditions (avoid-

ing the problem pictured on Figure 7). We also plan

to test and compare the approach with other available

techniques (Hu et al., 2007; Lin et al., 2008). Besides,

we intend to apply a 3D deformable model, using D-

NURBS (Qin and Terzopoulos, 1996), to get the pros-

thesis geometry. It could address the staircase defect

generated by the slice-by-slice strategy and generate

more smooth patches.

ACKNOWLEDGEMENTS

Authors would like to thank the support provided by

CNPq, CAPES (grant 094/2007) and FAPERJ (grant

E-26/170.030/2008).

REFERENCES

Chen, J.-J., Liu, W., Li, M.-Z., and Wang, C.-T. (2006).

Digital manufacture of titanium prosthesis for cranio-

plasty. The International Journal of Advanced Manu-

facturing Technology, 27(11-12):1148–1152.

Cohen, L. D. (1991). On active contour models and bal-

loons. CVGIP:Image Understanding, 53(2):211–218.

Hu, Q., Yang, H., and Yao, Y. (2007). A software method to

model and fabricate the defective bone repair bioscaf-

fold using in tissue engineering. In Li, K., Li, X.,

Irwin, G., and He, G., editors, Life System Model-

ing and Simulation, volume 4689 of Lecture Notes in

Computer Science, pages 445–452. Springer Berlin /

Heidelberg.

Kai, C. C., Meng, C. S., Ching, L. S., Hoe, E. K., and

Fah, L. K. (2009). Cranioplasty using polymethyl

methacrylate prostheses. Journal of Clinical Neuro-

science, 16(1):56–63.

Lee, M.-Y., Chang, C.-C., Lin, C.-C., Lo, L.-J., and Chen,

Y.-R. (2002). Custom implant design for patients with

cranial defects. Engineering in Medicine and Biology

Magazine, IEEE, 21(2):38–44.

Lee, S.-C., Wu, C.-T., Lee, S.-T., and Chen, P.-J. (2009).

Cranioplasty using polymethyl methacrylate prosthe-

ses. Journal of Clinical Neuroscience, 16(1):56–63.

Lin, L., Zhang, J., and Fang, M. (2008). Modelling the bio-

scaffold for repairing symmetrical and unsymmetrical

defective skull. In Bioinformatics and Biomedical En-

gineering, 2008. ICBBE 2008. The 2nd International

Conference on, pages 905–908.

Qin, H. and Terzopoulos, D. (1996). D-nurbs: a physics-

based framework for geometric design. Visualiza-

tion and Computer Graphics, IEEE Transactions on,

2(1):85 –96.

Sanan, A. M. and Haines, S. J. M. (1997). Repairing holes

in the head: A history of cranioplasty. Neurosurgery,

40(3):588–603.

Solaro, P., Pierangeli, E., Pizzoni, C., Boffi, P., Scalese,

G., Di Lorenzo, N., and Pirillo, V. (2008). From

computerized tomography data processing to rapid

manufacturing of custom-made prostheses for cran-

ioplasty: Case report. Journal of Neurosurgical Sci-

ences, 52(4):113–116.

You, F., Hu, Q., Yao, Y., and Lu, Q. (2009). A new modeling

method on skull defect repair. Measuring Technology

and Mechatronics Automation, 2009. ICMTMA ’09.

International Conference on, 1(11-12):568–572.

VISAPP 2011 - International Conference on Computer Vision Theory and Applications

142