AUTOMATIC CONTACTLESS MOBILE FINGERPRINTING

SYSTEM

M. Baier, S. Foret, V. Oliyil Kunnil, M. Paradis, P. Bustos and S. Mil’shtein

Advanced Electronic Technology Center, Department of Electrical and Computer Engineering

University of Massachusetts Lowell, MA 01854, U.S.A.

Keywords: Fingerprinting, Electro-mechanics, Electro-optics, Mobile embedded system, Wireless.

Abstract: Increased security requirements relevant to the worldwide war against terrorism and cyber crime recently

prompted the development of biometric systems for use in identifying individuals at commercial facilities,

border crossings, airports, and government building access points. Fingerprinting is one of the oldest means

of biometric identification; however, the current methods of fingerprint capture carry inherent limitations on

image quality. The current study describes the development of a novel, mobile, and contactless

fingerprinting system. This system combines the advantages of contactless fingerprinting with the ability to

create a digital map of the blood vessels within a finger for use as a second data set for use in biometric

identification. The distinguishing feature of the system is the use of line scanning technology which allows

for the acquisition of nearly distortion-less 180

o

or “nail-to-nail” fingerprints. The study describes a fully

automatic system and assesses the technical aspects of this novel device. We describe the design of the

subsystems: adaptive lighting, optical image formation, power management methods, wireless data transfer,

and subsystem synchronization techniques. We will also discuss the system’s embedded software, which

synchronizes the operation of all subsystems and allows for fingerprint visualization on an onboard touch

screen display.

1 INTRODUCTION

Fingerprint image acquisition is considered the most

critical step of an automated fingerprint

authentication system as it determines the final

fingerprint image quality and therefore the rate of

success of fingerprint recognition. Not long ago, the

rolled-ink technique was widely used to obtain

fingerprint images (Xia, 2003). This involves

coating a finger in ink and then pressing the fingers

surface against a piece of paper. This method has

been slowly replaced by digital fingerprint readers

which can be grouped into two major families: solid-

state and optical (Xia, 2003). The basic idea behind

each capture approach is to generate an image which

will allow for the extraction of accurate fingerprint

ridge data. When capturing a fingerprint using a

solid-state reader, a finger must come in direct

contact with the sensor; however, because the skin

tissue which comprises a fingerprint is elastic, this

“contact based” method can lead to fingerprint

distortion. In (Mil’shtein, 2004) and (Parziale, 2006)

it was demonstrated using contact based methods

that under the pressure of a finger’s own weight,

fingerprint ridge spacing can be distorted by about

20% in the captured image. Forceful contact of the

finger against the scanner produces even more

distortion as can be seen in (Mil’shtein, 2004). The

pressures magnitude and direction is directly

correlated with the degree of distortion captured in

the resulting image, causing an image of the same

fingerprint to change every time it is printed.

Because of this contact distortion, contactless

techniques are the method of choice in any

fingerprinting technology.

There are a number of contactless scanners on

the market today. Most of these systems are

comprised of a standard area-scan camera that takes

a picture of a fingerprint from a known distance.

This method is capable of imaging the flat portion of

the finger without any distortion; however, close

observation of the physical finger’s edges will reveal

that they are somewhat round in shape. These edge

portions of the finger are not perpendicular to the

camera’s CCD, which causes their projection onto

the flat surface of the sensing element to be a

445

Baier M., Foret S., Oliyil Kunnil V., Paradis M., Bustos P. and Mil’shtein S..

AUTOMATIC CONTACTLESS MOBILE FINGERPRINTING SYSTEM.

DOI: 10.5220/0003362004450450

In Proceedings of the 1st International Conference on Pervasive and Embedded Computing and Communication Systems (PECCS-2011), pages

445-450

ISBN: 978-989-8425-48-5

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

distorted representation of the actual finger

(Parziale, 2006). As a result, current research has

been directed to obtain rolled fingerprint equivalents

in a contactless fashion. These fingerprints have

been shown to be fully compatible with current law

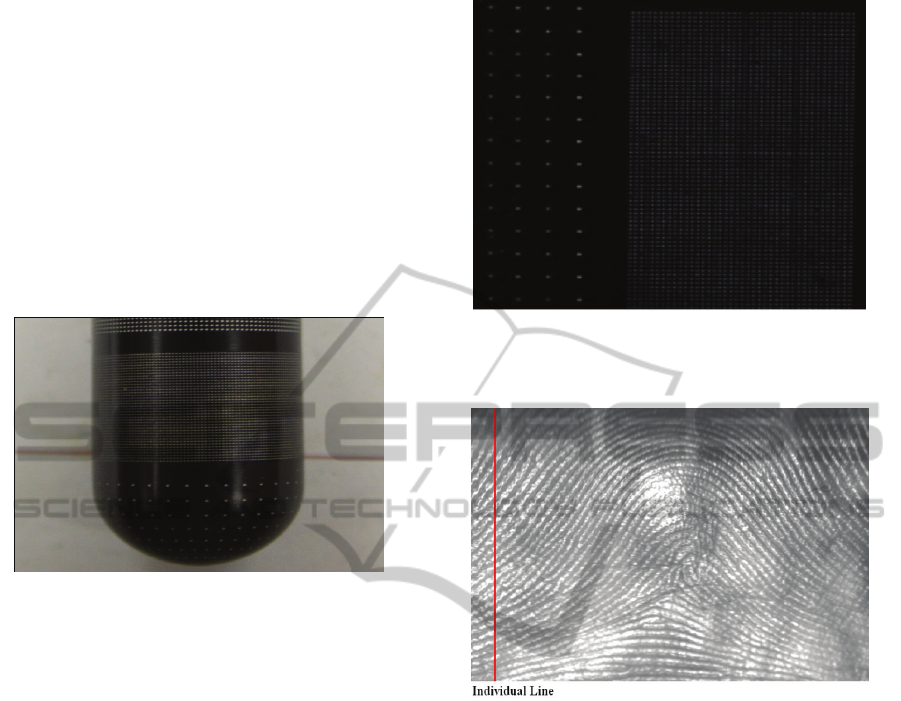

enforcement databases (Yi Chen1, 2006). Figure 1

displays an image of a test finger taken with a

traditional CCD. The test finger has a pattern of dots

arranged in a grid with regular spacing. As expected,

it can be seen that the pattern appears to be

compressed towards the edge of the image due the

fact that the edges of the test finger are “falling

away” from the CCD.

Figure 1: Image of the standard finger emulator with a

traditional CCD. Distortion in the form of compression of

the grid towards the left and right hands of the image can

be seen.

In the current study, the advantages of

contactless imaging techniques are combined with

the very attractive attributes of line-scanning

technology. A two dimensional image of a finger is

recorded in one pixel-thick lines by scanning a line-

scan camera around the finger, completing a 180

o

arc. The image captured represents an uncoiled view

of the finger equivalent to a “rolled ink” print. The

line-scanner views each portion of the finger

perpendicularly, therefore removing the projection

errors inherent in conventional aerial-scanning

techniques. Figure 2 displays an image of the same

test finger shown in figure 1 taken using the line

scanning technique. It can be seen that the

irregularities present in figure 1 are nonexistent, and

the regular spacing’s of the grid pattern have been

preserved.

In such a setup we are able to produce fingerprint

images that are greater than 1000 ppi resolution and

tests of the optical system suggest that the resulting

image is virtually distortion free. Such high

precision allows seeing fingerprint ridges and even

pores in great detail. Figure 3 shows a sample image

taken by our system.

Figure 2: Image of the standard finger emulator taken with

the rotational line scanning approach. Spacing between

the lines is 0.44 mm.

Figure 3: Fingerprint generated by line scan. The solid

line denotes a single line taken by the line scanner.

2 DESCRIPTION

OF MOBILE SYSTEM

2.1 Image Formation

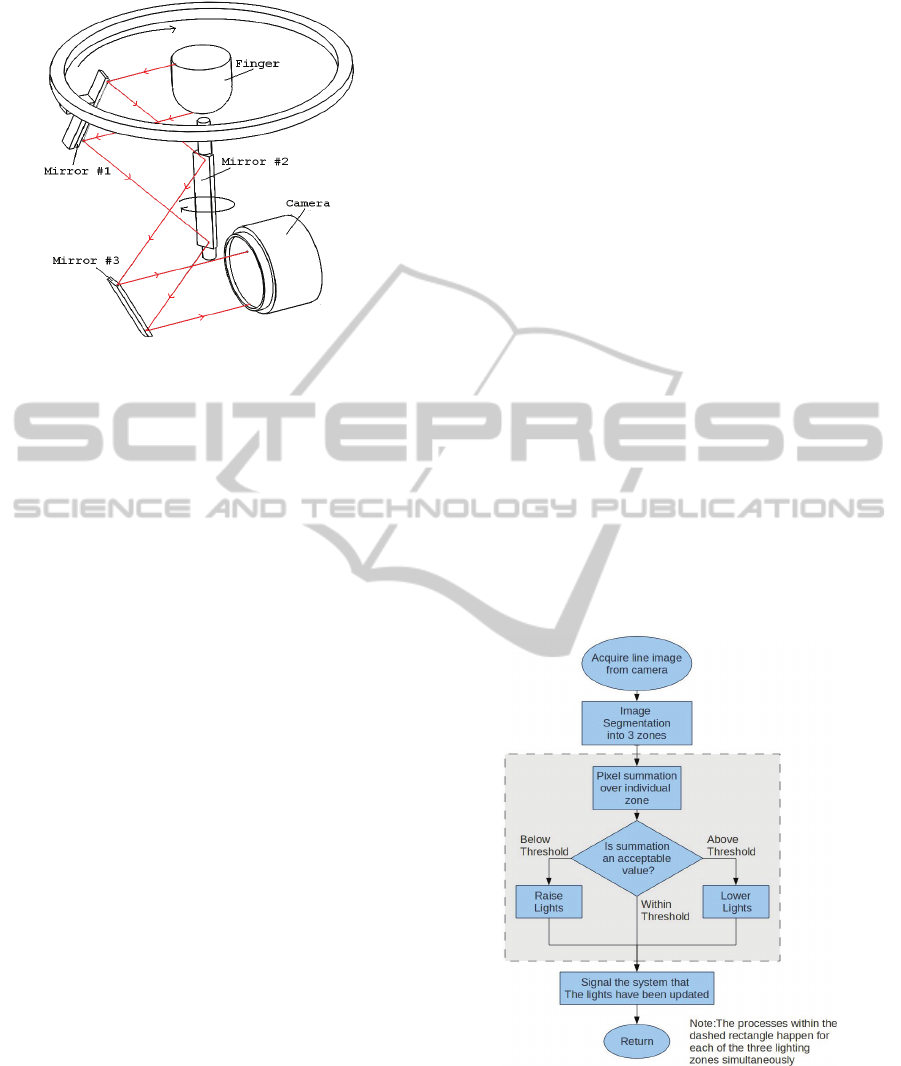

The first step in a fingerprint authentication system

is image capture. In the current study, a nail-to-nail

fingerprint image is captured using the optical setup

shown in figure 4.

The lens system used in this machine is designed

with an overall object-to-image distance of 368mm.

The working distance, which is the distance between

the surface of the finger and the objective lens of the

lens system, is established using the three first-

surface mirrors as seen in Figure 4. First-surface

mirrors are used instead of traditional secondary

surface mirrors to minimize dimming and blurring of

the image that occur as a direct result of light

passing through the glass of a traditional mirror.

PECCS 2011 - International Conference on Pervasive and Embedded Computing and Communication Systems

446

Figure 4: Optical system - arrangement of the mirrors,

camera and finger.

These mirrors direct the image onto the

stationery line-scan camera. Mirror #1 as shown in

figure 4 is mounted onto a rotating turntable. This

turntable allows the mirror to revolve 180

o

concentrically around the finger being imaged.

While rotating, this Mirror (#1) directs the light rays

which are reflected from the fingers surface onto

Mirror #2. Mirror #2 is located directly below and

on axis with the center of the finger. During a scan,

Mirror #2 rotates through a 90

o

sweep within the

same time Mirror #1 completes a 180

o

sweep,

allowing light rays reflected from the finger to

always be focused onto the stationery Mirror #3

which then directs these rays into the camera lens.

The entire scanning procedure takes approximately

¾ of a second. This mirror system greatly reduces

the overall size of the unit to 6”x7”x10” and

minimizes the number of moving parts needed.

The lens system consist of two major parts, the

first is a series of lenses with an effective focal

length of 80mm and the second is a focusing mount

which allows for fine focusing adjustments to the

lens system. This system allows high-resolution

imaging of the fingerprint at resolutions greater than

1000ppi.

The optics, mechanical drive train, and other

components within the scanner are rigidly mounted

within a 6061-T6 aluminum superstructure. The

scanner chassis has been optimized to reduce the

overall weight of the machine, as well as the size of

its construction.

2.2 Lighting Systems

In a typical fingerprint lighting system, illuminators

are aimed at the fingerprint at the start of the scan

and then shut off once a scan is complete (Palma,

2006). This method offers no feedback from the

camera on whether the lighting conditions are

optimal. This can result in washed-out or over

saturated images and the loss of useable information.

For this reason, this scanner utilizes a novel lighting

servo system.

This servo system uses real-time feedback from

the line-scan camera to adjust the lighting intensity

over three separate zones in the fingerprint: top,

middle, and bottom. Every time the scanner’s

processor receives a new line from the line-scan

camera (this happens approximately 1300 times for a

scan at 1000ppi resolution) the line is broken into

three segments: top, middle and bottom. The average

value of the light intensity within each of the three

sections is then computed (pixels in each segment

(numbering N) are summed and the resulting

number is divided by N) and the lighting zone

associated with each of the respective segments (top,

middle, and bottom) is adjusted up or down as

needed. This process is continued until all of the

lines which comprise the fingerprint image have

been taken. This method allows for 3900 different

lighting intensities to be implemented throughout

one scan of 1300 lines, and is visually described

below in figure 5.

Figure 5: Logical flow chart of the contactless

fingerprinter’s lighting servo system. This process is

repeated every time the system receives a new line from

the camera.

2.3 Blood Vessel Mapping

There are well known systems made by Mitsubishi

AUTOMATIC CONTACTLESS MOBILE FINGERPRINTING SYSTEM

447

and Hitachi that use blood vessel mapping as a

primary method of finger identification (Mitsubishi,

2006). In contrast, our system uses blood vessel

mapping as a secondary finger recognition method,

as well as to check the “liveliness” of a finger, or

whether there is blood actively being circulated

within the fingers veins.

IR LEDs are positioned directly behind the

finger and opposite the first imaging mirror. These

provide light that is transmitted through the finger

then recorded via the same line-scan camera used in

fingerprinting. This feature allows for a second basis

of comparison for an individual, and increases the

overall reliability of identification (Nixon, 2005).

Figure 6 presents an example of an unprocessed

view of blood vessels in a finger.

Figure 6: Image of blood vessels produced by IR light

transmitted through the finger. The image was recorded by

a line-scan camera.

2.4 Processor

The current system uses an OMAP35X processor

running Linux kernel version 2.6.31. This processor

is ideally suited for handheld, high level computing

applications. It has a DSP core and an ARM cortex

A8 core, which enables the device to interface with

advanced peripherals such as WiFi modules, a touch

screen, and a large image sensor. This processor

runs at 600 MHz, and is accompanied by 256MB of

DDR RAM and 256Mb of flash memory.

Stepper motor control pulses are driven by PIC

microcontroller which communicates with the

OMAP35X processor via a serial connection.

2.5 Software Architecture

Figure 7 describes the different relevant software

components running on the OMAP35X. The

software is roughly split into three components

namely, the Linux Kernel, Middleware, and

Graphical User Interface.

Figure 7: Software Architecture of the mobile unit.

The uppermost software layer consists of the

user interface applications that interact with the end

user, allowing for configuration of the machine’s

parameters, network configurations, and control.

These applications are based on a windowing API

provided by Nano-X.

The processor runs Linux kernel 2.6.31, along

with device drivers for the LCD and touch screen,

WLAN, Serial port, and camera. The middleware is

a user-mode application called Imaging Manager.

The Imaging Manager controls the camera, and

coalesces the line-scan pixel-thick images into a

single image. It is also responsible for calculating

the lighting values for the adaptive lighting system.

These values are used as feedback by the adaptive

lighting system to moderate incident ambient light

on the finger. The imaging manager also securely

transfers fingerprints to any remote image database

over a WLAN connection.

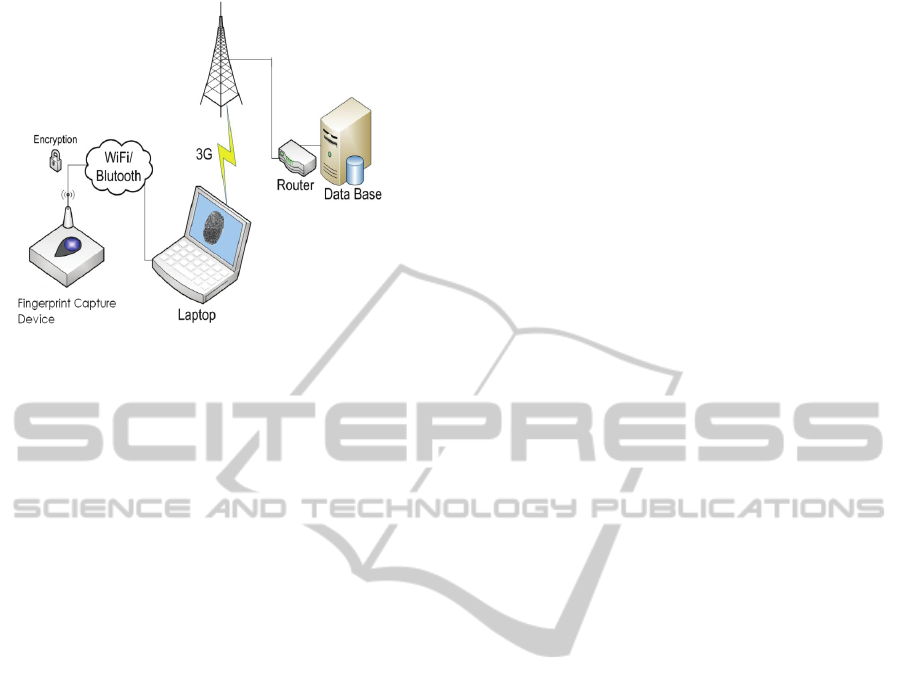

A PC-based image database application receives

the images read by the fingerprinting device. This

facilitates registration of new images to a local

database as well as comparison of fingerprint

images. This application may also be used to

connect to any larger or remote database to store the

fingerprint image or for fingerprint image via an

internet connection. This connection can be provided

by LAN, WLAN, or 3G/4G cellular networks. This

feature allows for the full system to be fully utilized

and remain in communication with existing

fingerprint databases anywhere there is available

cellular service. The flow of image data can be seen

in Figure 8.

2.6 Battery and Power Management

Systems

The unit’s power management system is designed to

supply power to all of the onboard electrical

systems. It is supplied by three Li-ion polymer cells.

PECCS 2011 - International Conference on Pervasive and Embedded Computing and Communication Systems

448

Figure 8: System diagram displaying the flow of data from

the mobile unit to a nearby supporting PC and then to a

remote database via a 3G cellular connection.

Li-ion polymer cells were chosen due to their high

energy density and low internal resistance. A robust

set of features protect and maintain these battery

cells. These include the use of high efficiency

switching regulators, selective power delivery, and

clock frequency switching on all onboard

processors. Individual battery cells are different due

to variances in manufacturing processes. In a multi-

cell battery pack each cell may have minor

differences in their discharge and charge profiles

resulting in each cell charging to slightly different

voltages. Cell balancing is used to keep the cells in

the battery system balanced and to maximize battery

longevity and capacity. This is done in the current

system in real-time and is controlled through

software on the PIC microcontroller. This system

also features low voltage, over voltage, over

discharge, and over charge protection. Idle power

consumption has been minimized to obtain longer

battery life. When in idol mode, both of the systems

processors clock frequencies are reduced in an effort

to minimize unnecessary power consumption.

Selective power management techniques, which

intelligently deliver power to each module in the

system as needed, are also utilized. In the current

design, each subsystem is severed from its power

source programmatically when it is not needed. For

instance, when the unit is idle, all of the circuitry

controlling the adaptive lighting, the motor, and the

camera systems are disconnected from system

power. This eliminates most of the idle power

consumed by devices while not in use. Through the

use of selective power delivery, the current system is

able to achieve over 150 hours of standby operation,

or over 1000 scans per charge.

3 CONCLUSIONS

The line-scan contactless fingerprinting system

described is compatible with AFIS and APIS. This

novel fingerprinting technology meets the

requirements of federal law enforcement regulations.

Our study has shown that a line-scan technique is a

suitable and high-resolution technique for

contactless and low-distortion acquisition of

fingerprints. In contrast to the contactless system

that uses six separate area cameras as described in

(Parziale, 2006), line-scanning allows for the

creation of high-resolution fingerprint capture

systems that are cheap, small, and portable

(Mil’shtein, 2008). The system described is expected

to be used in police patrol cars, border patrols,

access control environments, and in fingerprint data

processing centers. For mobile applications, the

system is equipped with a battery system that allows

for over 150 hours of standby operation, or over

1000 scans per charge. The system also contains a

WIFI module to facilitate wireless connectivity and

fingerprint transfers between the fingerprint reader

and a host computer. This system also acquires a

blood vessel map for use as a second method for

biometric identification. The automatic operation of

our fingerprint capture system is supported by

embedded software released under GPL, which will

allow any potential customer to purchase the system

without a need to license any external software

package. In the near future, we will be testing the

novel system with the police departments and the

police officers.

REFERENCES

Xia X., O’Gorman L., 2003. “Innovations in Fingerprint

Capture Devices” Pattern Recognition, 36, 2, pp: 361-

369.

Mil’shtein S., Doshi U., 2004. “Scanning of the pressure-

induced distortion of fingerprints” Scanning, 26, 4, pp:

323-327.

Palma J., Liessner C., and Mil’shtein S., 2006.

“Contactless Optical Scanning of Fingerprints with

180º View”, Scanning, 28, 2, 90.

Parziale G. and Diaz-Santana E., 2006. “The Surround

Imager: A Multi-Camera Touchless Device to Acquire

3D Rolled-Equivalent Fingerprints,” Prec. of Conf.

Int’l Conf. Biometrics, pp. 244-250.

S. Mil’shtein, J. Palma, C. Liessner, M. Baier, A. Pillai,

and A.Shendye, 2008. "Line Scanner for Biometric

Applications" IEEE Intern. Conf. on Technologies for

Homeland Security, ISBN 978-1-4244-1978-4 P 205-

208.

AUTOMATIC CONTACTLESS MOBILE FINGERPRINTING SYSTEM

449

S. Mil’shtein, M. Baier, C. Granz and P.Bustos, 2009.

"Mobile System for Fingerprinting and Mapping of

Blood -Vessels across a Finger", ISBN 978-1-4244-

4179-2, p.30-34.

Parziale G., Diaz-Santana E., 2006 “3D Touchless

Fingerprints: Compatibility with Legacy Rolled

Images” Proc. Int’l Conf. Biometrics, pp: 244-250.

Yi Chen, Geppy Parziale, Eva Diaz-Santana, and Anil K.

Jain, 2006. ‘3D Touchless Fingerprints: Compatibility

with Legacy Rolled Images’ 1 Michigan State

University, Department of Computer Science and

Engineering, East Lansing, Michigan, 48824, 2 TBS

Holding AG, Schindellegistrasse 19 CH-8808,

Pfaeffikon, Switzerland

Nixon K. A., Rowe R. K., 2005. “Multispectral

Fingerprint Imaging for Spoof Detection,” Proc. SPIE

Conf. Biometric Technology for Human Identification,

pp: 214-225.

Mitsubishi, 2006. “Mitsubishi Touchless Fingerprint

Sensor,” http://global.mitsubishielectric.com.

PECCS 2011 - International Conference on Pervasive and Embedded Computing and Communication Systems

450