TESTING A SOFTWARE-BASED PID CONTROLLER USING

METAMORPHIC TESTING

T. Y. Chen, F.-C Kuo, W. K. Tam

Centre for Software Analysis and Testing, Swinburne University of Technology, Melbourne, Australia

R. Merkel

Faculty of Information Technology, Monash University, Melbourne, Australia

Keywords: Software testing, Metamorphic testing, PID controller, Control engineering, Embedded system, Embedded

software.

Abstract: The Proportional-Integral-Derivative (PID) controller is ubiquitous in industrial and military systems.

Almost all PID controllers are now implemented as software in a microcontroller. Control systems are

required to have very high reliability, particularly as they are regularly used in safety-critical systems. An

effective testing technique is essential to achieve reliable PID controller software. Unlike simple control

algorithms, PID controllers are capable of manipulating the process inputs based on the history and rate of

change of the signal. It is very difficult to know whether the computation of the software is correct from the

computed outputs. Previous research in other areas has shown that metamorphic testing is an effective

technique for this kind of problem. In this paper, we examine metamorphic testing in the context of testing

an embedded software PID controller based on the free sample code from ATMEL Corporation. We show

that metamorphic testing killed all mutants inserted into the controller software, demonstrating the utility of

the technique in testing control systems.

1 INTRODUCTION

Control engineering, the application of control theory

to engineering, is widely applied in many industrial

and military systems. The main purpose of control is

to aid the product or process to do its job efficiently

to a required specification. A controller is a device

which receives monitoring signals and outputs

control signals that affect the operational conditions

of a given dynamical system. The operational

conditions are the output variables of the system

which can be affected by adjusting certain input

variables.

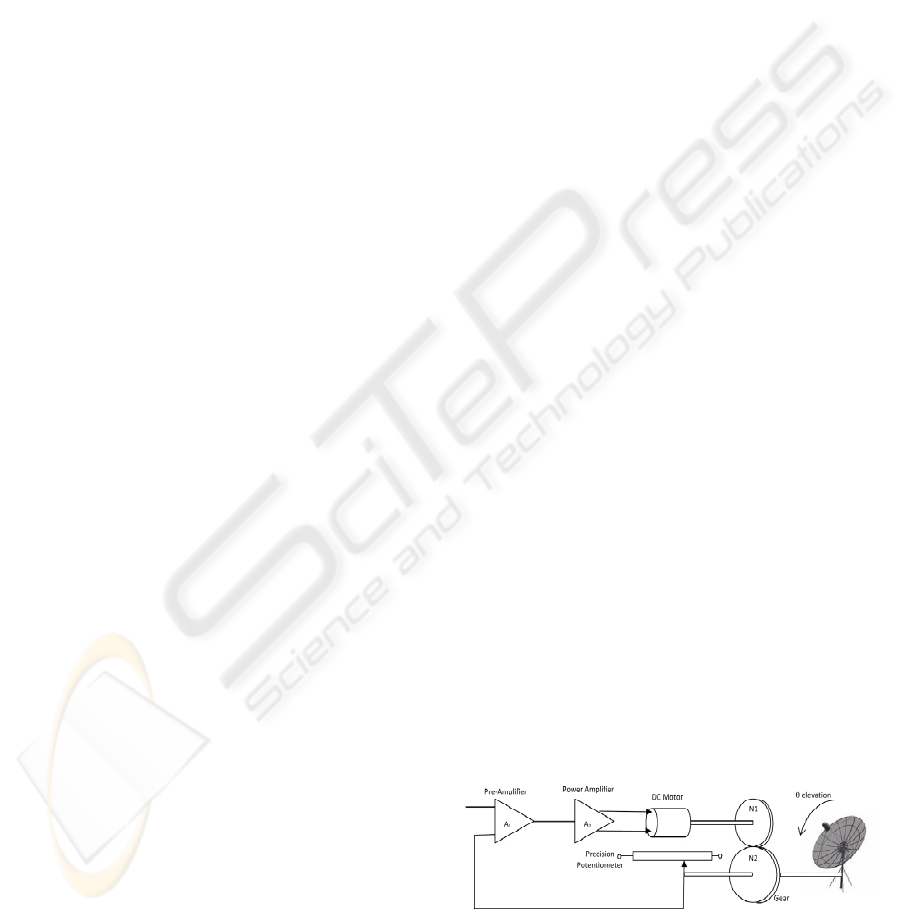

For example, consider a radar tracking antenna

(as described in Nise (2008)), in which the antenna

dish is driven through a step down gearbox by an

armature controlled D.C. motor as shown in Fig. 1.

The antenna azimuth position is monitored by a

precision potentiometer, the output of which is then

compared with demand signal provided by the radar

system. The error signal – the difference between the

desired position and the measured antenna azimuth

position - is amplified to drive the motor so that the

antenna follows the target motion. In this example,

the amplifiers act as the controller, directing the

activities of the D.C. motor. The D.C. motor is the

processor that affects the antenna position to follow

the target position (also known as the set point). The

antenna azimuth position information from the

potentiometer is the feedback. The antenna position

is the operational condition.

Control systems are ubiquitous, and many control

systems are applied in safety-critical systems and

thus face very high reliability requirements. Control

systems are broadly classified as open-loop and

Figure 1: Radar tracking antenna.

closed-loop control system. An open-loop control

system is controlled directly, and only, by an input

387

Y. Chen T., Kuo F., K. Tam W. and Merkel R. (2011).

TESTING A SOFTWARE-BASED PID CONTROLLER USING METAMORPHIC TESTING.

In Proceedings of the 1st International Conference on Pervasive and Embedded Computing and Communication Systems, pages 387-396

DOI: 10.5220/0003365003870396

Copyright

c

SciTePress

signal, without any feedback from outputs. The

systems that utilize feedback are called closed-loop

control systems. The feedback is used to make

decision about changes to the control signal that

drives the plant (in the case of our example, the

antenna). It is well known that the deliberate use of

feedback can be used to stabilize an otherwise

unstable system, to reduce errors due to input

disturbance and to reduce the sensitivity of the

system performance to changes in parameter values

caused by temperature, aging of hardware, etc. Hence,

most control systems are of the closed-loop type.

Many different control algorithms have historically

been used in control systems, but Proportional-

Integral-Derivative (PID) control (Kuo, 1982) is the

most common control algorithm used in industry and

has been universally accepted in industrial control.

The popularity of PID controllers can be attributed

partly to their robust performance in a wide range of

operating conditions and partly to their functional

simplicity, which allows engineers to configure them

in a simple, straightforward manner. With the

ubiquity of microcontroller technology, PID

controllers are typically implemented by the

embedded software in a microcontroller.

As PID controllers are used in most control

systems, it is important to ensure the reliability of

PID software. Software testing is the primary way in

which the reliability of software is assessed and

improved, and, therefore, effective testing of PID

software is the critical step for a reliable control

system. Testing PID software is a challenging task.

Unlike simple control algorithms, the PID controller

is capable of manipulating the process inputs based

on the history and rate of change of the error signal.

This gives a more accurate and stable control method

but complicates the testing process. As the output can

vary because of the history and the rate of change of

the error signal, it is very difficult to check the

correctness of PID implementation from its outputs.

This is known as the oracle problem in software

testing. Recently, the technique of metamorphic

testing has been proposed for testing software

without the need of an oracle (Chan, Chen, Lu, Tse &

Yao (2006); Chen, Cheung & Yu (1998); Chen, Tse

& Zhou (2002); Zhou, Huang, Tse, Yang, Huang &

Chen (2004)). This technique identifies some

necessary properties of the application domain as

metamorphic relations (MRs), that (as discussed in

Section 2) express relationships between multiple

executions, with different inputs, of the software

under test. In metamorphic testing, testers check the

MRs among multiple executions of the program

being tested – if the MRs do not hold, this indicates a

software fault.

In this paper, we study the application of

metamorphic testing to alleviate the oracle problem

of testing PID controller software. We present a case

study on the testing of the PID controller software

embedded in an ATMEL ATmega128

microcontroller. The PID controller software was

implemented in C based on the free sample code

provided by ATMEL Corporation (Atmel

Corporation, 2006). To verify the effectiveness of

using metamorphic testing in the embedded software

for control engineering, we conducted our

experiments in the control of antenna azimuth

position. Instead of building the actual antenna

azimuth position control system, we simulated the

system in the embedded platform using Z-transform.

This approach eliminates the measurement error in

the mechanical position measurement and avoids

hardware faults interfering with the testing of the PID

controller software.

The rest of the paper is organized as follows. In

Section 2 we briefly present the technique of

metamorphic testing. Section 3 presents the basic

design of the PID controller. In Section 4, we identify

four MRs for PID controllers. We then apply the

technique of metamorphic testing to test the software

of a PID controller. Section 5 briefly analyzes

threats to validity. Section 6 concludes our paper by

considering the implications of the work and

identifying opportunities for future research.

Detailed justification of the MRs are provided in the

Appendix.

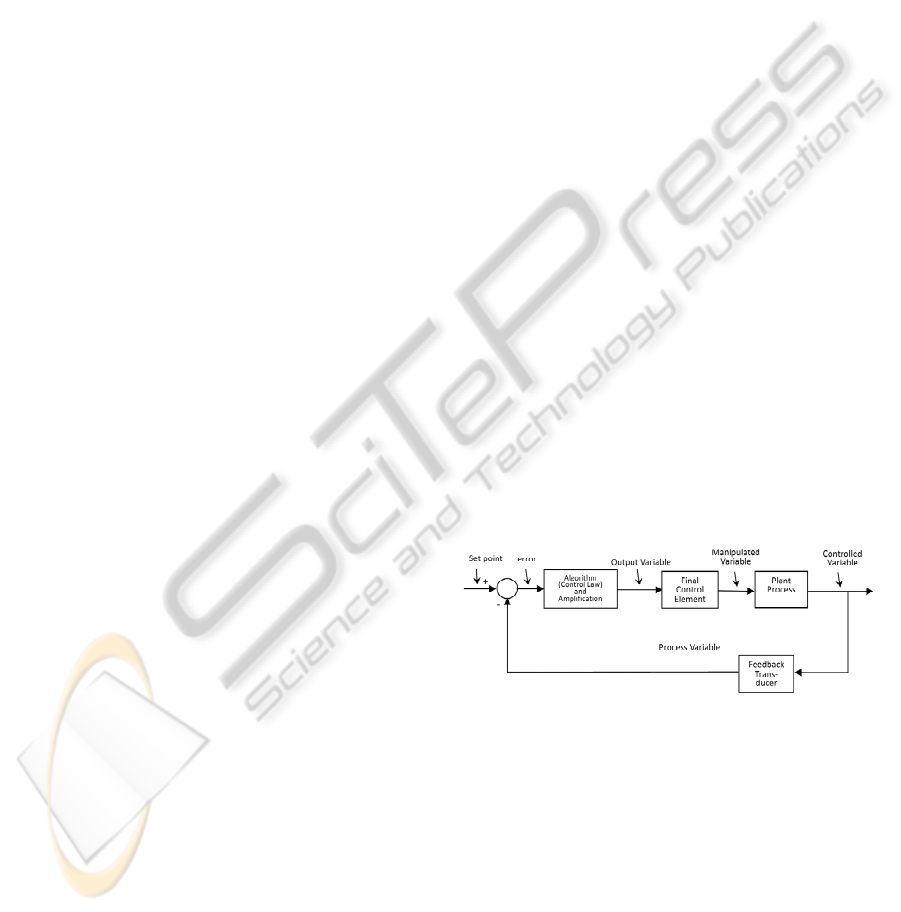

Figure 2: Feedback control system.

2 METAMORPHIC TESTING

Metamorphic testing (Chen, Cheung & Yiu, 1998) is

a property-based approach to software testing. It does

not check the correctness of individual outputs.

Instead, it checks metamorphic relations among

multiple executions of the target program. A

metamorphic relation (MR) is an expected relation,

which is identified from the necessary properties of

application domain, over a set of distinct input data

PECCS 2011 - International Conference on Pervasive and Embedded Computing and Communication Systems

388

and their corresponding output values for multiple

executions of the target program. In theory, a

program should satisfy all the necessary properties if

implemented correctly. Any program which violates

the MRs contains faults.

Let us consider a function f. Suppose R

f

denotes

some properties of f that can be expressed as a

relation among a series of the function’s inputs x

1

,

x

2

, …, x

n

, where n > 1, and their corresponding

values f(x

1

), f(x

2

), …, f(x

n

). The relation R

f

is called a

metamorphic relation. For instance, consider the sine

function. For any two inputs x

1

and x

2

such that x

1

+

x

2

=

π

, we must have sin(x

1

) = sin(x

2

). This property

can be a metamorphic relation for testing the

correctness of the sine function. It can be written as

R

sin

: If x

1

+ x

2

= π, then sin(x

1

) = sin(x

2

)

To verify this relation, two executions are needed.

The first input to sine function is a real number x

1

,

followed by a second input x

2

=

π

- x

1

.

In summary, even if a testing oracle does not

exist, metamorphic testing can still be applied as it

checks the relations among the inputs and outputs of

more than one execution of the program.

3 PID CONTROLLER

As discussed in Section 1, a control system is a

device that monitors and affects the operational

conditions of a given dynamical system.

A generalized block diagram for a feedback

control loop is shown in Fig. 2. The plant process is

the process or device that acts on the system; in the

context of the radar antenna it is the DC control

motor. The feedback transducer, in turn, measures

the current state of the system under control – for the

antenna system, the potentiometer position sensor.

The role of the controller is therefore to: (a) enable

the desired value of output to be set, (b) accept the

measured output value from the feedback transducer,

(c) generate the error (deviation between desired and

present output) signal, (d) amplify and process the

error signal to provide a suitable input to the final

control element.

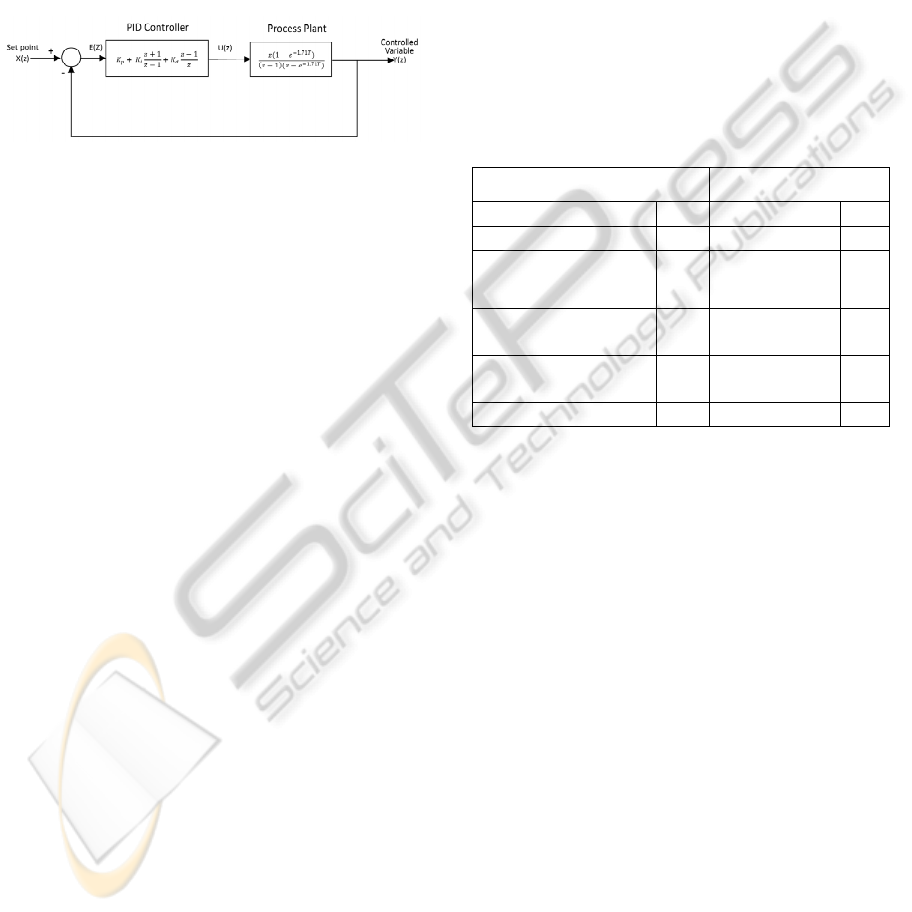

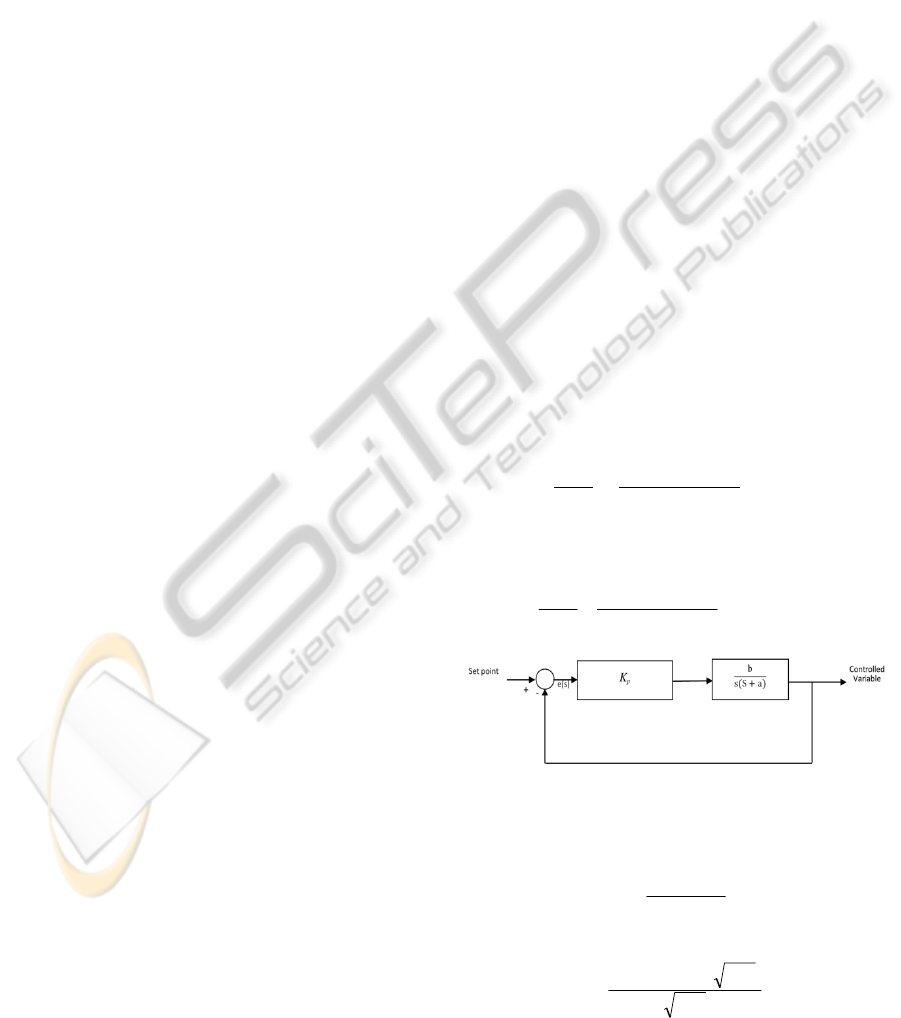

Figure 3: Block diagram of general PID control system.

The PID controller is the most common solution

because of its simplicity of implementation and good

performance. Fig. 3 shows the block diagram of a

general PID control system. As can be seen, the

output value at time t, u (t) of a PID controller is

governed by the following equation (Atmel

Corporation, 2006):

() () ()

()

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

++=

∫

dt

tde

Tde

T

teKtu

d

t

i

p

0

1

σσ

(1)

This can be easily considered as the sum of three

terms, governed by three key parameters: the

proportional parameter K

p,

the integral parameter K

i

,

and the derivative parameter K

d

. The integral and

derivative terms can also be equivalently expressed

as “action times” T

i

and T

d

respectively. The three

terms are as follows:

Proportional term:

()

teK

p

×

Integral term:

() ()

∫∫

×=×

σσσσ

deKde

T

K

i

i

p

Derivative term:

() ()

te

dt

d

Kte

dt

d

TK

ddp

×=××

In control theory, a continuous control system is

usually represented by a Laplace transformed s-

transfer function. The s-transfer function of PID

controller can be expressed as follows:

() ()

sEsT

sT

Ksu

d

i

p

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

++=

1

1

where u(s) is the Laplace transform of the controller

output u(t) and E(s) is the Laplace transform of error

signal e(t).

Not all controllers necessarily make use of all

three terms in the PID control formula. While all

controllers use some level of proportional control

(and thus have a non-zero K

p

), in different

applications the integral and derivative terms may or

may not be used.

P control, on its own, is the simplest form of

control. If the parameter K

p

is increased, it reduces

the errors inherent in the system. The maximum

value of K

p

is limited due to the onset of instability

(that is, the controller failing to reach a steady state).

PI control, involving both the proportional and

integral terms, can reduce the steady-state error (the

difference between the actual final state and the

desired final state). PD control, involving both

proportional and derivative terms is used to improve

the dynamic performance of the loop, to improve

TESTING A SOFTWARE-BASED PID CONTROLLER USING METAMORPHIC TESTING

389

stability and speed up the time response. PID control

combines all three forms of control. It can eliminate

the steady-state error and improve the dynamic

performance.

Digital controllers are widely available at low

cost and are consequently in widespread use. These

range from small inexpensive single board

controllers having a limited amount of input/output

facilities and memory, and a small high level

language instruction set, to powerful microcomputers

or programmable logic controller (PLC) capable of

controlling many control loops. There are many

advantages in using digital controllers, including:

• The possibility of a wide range of control

algorithms.

• The ability to change algorithm parameter

values easily by software without modifying

any hardware.

• The ability to make the system adaptive.

• The ability to compensate for process non-

linearity by non-linear control algorithms.

• The ease of implementing arithmetic

operations.

Unlike analogue controllers, digital controllers

use discrete, periodic sampling from the feedback

transducer. It is important for the intervals between

sampling to be small enough – or, in other words, the

sample frequency to be high enough - so that the

sampled points represent the continuous signal

accurately enough. If the maximum frequency

presents in the signal is

ω

, the theoretical minimum

sampling frequency should be 2

ω

(Nyquist, 1928).

Consider a control system as shown in Fig. 3, the

PID controller is a digital controller implemented by

the embedded software in a microcontroller. At time t,

the digital PID controller will read the error e(t),

calculate and output the control input u(t) to the

system. The process repeats at intervals defined by

the sample period T. At time t, n = t/T such cycles

have occurred; in other words, t=nT.

When implementing a software-based digital PID

controller, the continuous integrals are approximated

using summations. The integral term is approximated

as follows:

() ()

∑

∫

=

≈

n

k

t

keTde

0

0

σσ

The derivative term is approximated by the

following equation:

() () ( )

T

nene

dt

tde 1−−

≈

This gives the controller:

(2)

where

i

p

T

K

i

K = and

dpd

TKK =

.

Figure 4: Block diagram of antenna azimuth position

system with PID control.

Most software PID controllers are implemented

based on formula (2).

4 TESTING PID SOFTWARE

USING METAMORPHIC

TESTING

4.1 Experimental Subject

The PID controller software being tested is based on

the sample code revision 456 dated 16 Feb. 2006

provided by ATMEL Corporation (Atmel

Corporation, 2006). The code comprised 478 lines of

C code, and was compiled using the IAR EWAAVR

4.11A compiler for the ATMEL AVR

microcontrollers. In our experiment, we chose the

AVR ATMega128 microcontroller to run the PID

software.

4.2 Experimental Setup

We used an antenna azimuth position system, as

shown in Fig. 4, in our experiment. The process plant

in the block diagram is a mechanical system with

D.C. motor, gear and potentiometer.

Instead of using a real antenna azimuth position

system, we simulated the antenna azimuth position

system in the embedded platform. The behavior of

the system is described using z-transfer functions

(Kuo (2006), p51). The block diagram of the

experimental system is shown in Fig. 5. Aside from

the obvious convenience of not requiring an actual

radar antenna system for our experiments, there are

many advantages of using a simulation platform to

replace the actual system:

()

)1()()()()(

0

−−++=

∑

=

neneKkeKneKnu

d

n

k

ip

PECCS 2011 - International Conference on Pervasive and Embedded Computing and Communication Systems

390

• Hardware problems in antenna azimuth

position system are eliminated when testing

the PID controller software.

• The system outputs are monitored easily to

verify the performance of the PID controller

without using expensive testing equipment.

• The system parameters can be varied easily.

• A wide range of test cases can be selected in

the simulation platform without the need to

consider hardware limitations.

Figure 5: Block diagram of antenna azimuth position

system with PID control in z-transfer functions.

We conducted the experiments by loading the

PID controller application and the antenna azimuth

position system simulation to an ATmega128

microcontroller on a STK501 development board.

We used the AVR studio and JTAGICE Mk II

development tools supplied by Atmel Corporation.

The output of the PID controller is sent to the input

of the simulated antenna azimuth position system on

the STK501 development board. The STK501 was

connected through an RS232 serial interface to a PC,

which runs terminal emulation software to capture

the system output and store the data in a text file.

4.3 Input and Output Parameters of

PID Control System

The inputs and outputs to the system that were used

to control and evaluate the system are summarized in

Table 1.

4.3.1 Inputs

• The set point x is the reference input of the

system.

• The system status y is the (simulated) output

of the system position sensor, which acts as

feedback to compare with the set point in the

control system.

• The proportional parameter K

p

, also known

as the gain, controls the proportional

response by the control system to the error

signal as described in Section 3.

• The integral parameter K

i

is sometimes

called integral gain, controls the contribution

of the integral term to the overall control

response, as described in Section 3.

• The derivative parameter K

d

is sometimes

called derivative gain which determines the

magnitude of contribution of the derivative

term to the overall control action.

• The sampling period T is the time period the

digital system samples the analog signal

input.

4.3.2 Outputs

• The settling time ts is the time for the

transient’s damped oscillations to reach ±2%

of the steady-state value.

Table 1: Input and outputs of PID control system.

Inputs Outputs

Set point x Settling time ts

System status y Peak time tp

Proportional

parameter

K

p

Rise time tr

Integral parameter K

i

Percentage

overshoo

t

os

Derivative

parameter

K

d

Steady state

error

ess

Sampling period T

• The peak time tp is the time required to reach

the first or maximum peak.

• The rise time tr is the time required for the

waveform to go from 0.1 of the final value to

0.9 of the final value.

• The percentage overshoot os is the amount

that the waveform overshoots the steady-

state, or final value, at the peak time,

expressed as percentage of the The steady

state error ess is the system output error

when the system is in steady state. It is used

to measure the accuracy of the control

system.

4.4 Metamorphic Relations

for Testing of PID Controllers

We have identified four MRs for testing the PID

controller from the properties of the PID control

stated in Section 3.

In this section, we present an explanation of our

metamorphic relations. In some cases, the full

mathematical justifications for our metamorphic

relations are quite complex, and are thus presented in

the Appendix.

TESTING A SOFTWARE-BASED PID CONTROLLER USING METAMORPHIC TESTING

391

In the following, subscripted variables indicate

whether the parameter refers to the source test case or

follow up test case. For instance, tr

1

refers to the rise

time output for the source test case, and tr

2

refers to

the rise time for the follow-up test case.

Metamorphic Relation 1

It is obvious that the larger the difference between set

point and system status the longer the settling time is

needed. Based on this property, we can identify a

metamorphic relation denoted MR1 as follows:

MR1:

If (x

1

– y

1

)< (x

2

– y

2

) then

ts

1

< ts

2

,

Metamorphic Relation 2

For a pure P controller — that is, one where K

i

=0

and K

d

=0 — if the proportional coefficient K

p

increases, the rise time tr will decrease. Furthermore,

the maximum overshoot will increase, and the

steady-state error will decrease (see the Appendix for

a full mathematical analysis of these propositions).

Hence, we define MR2 as follows:

MR2:

If (K

p1

< K

p2

)∧(K

i1

= K

i2

=0)∧(K

d1

= K

d2

=0) then

(tr

1

≥ tr

2

) ∧ (os

1

< os

2

) ∧ (ess

1

≥ ess

2

)

Metamorphic Relation 3

Increasing the integral term has the effect of reducing

the steady-state error (see the Appendix for a full

explanation). However, it can also cause the present

value to overshoot the set point value and slow the

settling time, since the integral term responds to the

accumulated error from the past. MR3 is therefore

defined as follows:

MR3:

If K

i1

< K

i2

then

(os

1

< os

2

) ∧ (ess

1

≥ ess

2

) ∧ (ts

1

≤ ts

2

)

Table 2: Input Parameter Ranges for PID Controller.

Input Parameters

Range for

Original Test

Cases

Range for

Follow-up

Test Cases

Set point, X(z) [1, 8] [2,10]

Proportional gain, K

p

[1, 8] [2, 10]

Integral constant, K

i

[0.001, 0.006] [0.002, 0.01]

Derivative constant,

K

d

[0, 8] [0.5, 10]

Metamorphic Relation 4

Since

()

te

dt

d

represents the slope of e(t), the

derivative control is essentially an anticipatory type

of control. Normally, in a linear system, if the slope

of e(t) due to a step input is large, a high overshoot

will subsequently occur. The derivative control

measures the instantaneous slope of e(t), predicts the

overshoot ahead of time, and makes a proper

correcting effort before the overshoot actually occurs.

As a result, the increase of K

d

will reduce the

overshoot. It is apparent that the derivative control

will affect the steady-state error of a system only if

the steady state error varies with time. If the steady-

state error of a system is constant with respect to time,

the time derivative of this error is zero, and the

derivative control has no effect on the steady-state

error. If K

d

is increased, the steady state error will

decrease or remain the same. As the increase of K

d

will decrease the overshoot, the settling time will be

decreased with the increase of K

d

. We can therefore

define MR4 as follows:

MR4:

If K

d1

< K

d2

then

(ts

1

≥ ts

2

) ∧ (os

1

≥ os

2

) ∧ (ess

1

≥ ess

2

)

4.5 Testing Procedures

We tested the embedded software of PID controller

using a typical position control application for

antenna. As mentioned in Section 4.2, we used a

simulated antenna azimuth position system instead of

a real antenna system. We then modeled the transfer

function of the real antenna system as indicated in

Fig. 4 with the z-transfer function as indicated in Fig.

5 and then implemented it using a difference

equation in C on the embedded platform. The

difference equation of the antenna azimuth position

system is

y(n) = 0.0006612x(n) + 1.9983y(n-1) – 0.9983y(n-2)

where n is the discrete step at time t with a sampling

period of T.

We then used the AVR studio and JTAGICE Mk

II to load the PID controller application and the

antenna azimuth position system simulation into the

flash memory of ATMega128 microcontroller on a

STK501 development board. The output of the PID

controller is sent as the input of the simulated

antenna azimuth position system in the STK501

development board. The output of the antenna system

is captured by a terminal application running on a PC

connected to the STK501 board through the serial

PECCS 2011 - International Conference on Pervasive and Embedded Computing and Communication Systems

392

Table 3: Mutants of PID Controller.

Mutant Modified line # Fault description

Mu1 103 Replacement of + by – in pid.c

Mu2 95 Replacement of pid_st->sumError by error in pid.c

Mu3 80 Replacement of * by + in pid.c

Mu4 103 Replacement of + by * in pid.c

Mu5 99 Replacement of - by / in pid.c

Mu6 94 Replacement of + by * in pid.c

Mu7 103 Replacement of i_term by p_term

Mu8 103 Replacement of p_term by i_term

Table 4: Proportion of Test Cases That Killed Mutants Using Metamorphic Relations.

MR1 MR2 MR3 MR4

Original

0% 0% 0% 0%

Mutant 1

0% 0% 1% 100%

Mutant 2

0% 0% 37% 0%

Mutant 3

99% 0% 40% 42%

Mutant 4

98% 0% 100% 0%

Mutant 5

95% 0% 1% 100%

Mutant 6

0% 0% 100% 0%

Mutant 7

0% 0% 100% 0%

Mutant 8

17% 100% 100% 0%

interface.

As mentioned in Section 3, the selection of the

ranges of set point x, K

p

, K

i

and K

d

were chosen to

ensure that the resulting system is stable. We

performed a number of simulations of the control

system as shown in Fig. 5 to define the range of input

parameters as listed in Table 2 for stable operation.

These ranges were used to determine bounds for the

generation of input parameters. As the sampling

interval T is not present in our metamorphic relations,

and its effects on computation can also be achieved

by varying the gain constants, it was set as a constant

at 10 milliseconds for all test cases. Similarly, as the

behavior of the PID controller depends on the

difference between the Set point and the initial

system status (y), for simplicity y was set at 0 for all

test cases.

100 source test cases were generated by uniform

random sampling within the input ranges as specified

in Table 2. For each source test case, four follow-up

test cases were generated, one for each of the MRs.

To generate a follow-up test case, a random sample

for the varying parameter (for instance, for MR1, the

initial set point X(z)) was generated from the ranges

for the follow-up test cases defined in Table 2. If the

resulting test case met the MR condition (for instance,

that X(z) was increased), the follow-up test case

input was accepted, otherwise the process was

repeated until an eligible follow-up test case was

located.

We initially ran the test cases on the unmodified

source code to determine if there were any pre-

existing faults in it – while this was considered

unlikely, it avoided the possibility of such pre-

existing faults interfering with measurement of the

effectiveness in mutant detection. As no fault was

detected in the original software, we went on to

generate 8 mutant versions of the software to

evaluate the failure-detection performance of

metamorphic testing.

4.6 Mutants

Mutants were generated by transforming the original

code to a mutated code using randomly selected

mutation operator. The program line to mutate is

randomly selected using random number generator.

If the mutation operator cannot be applied for the

selected line, we will search the program lines closest

to it. Table 3 shows the mutant versions of the PID

controller.

4.7 Results

Table 4 shows the proportion of source/follow-up test

case pairs which revealed a violation of the

metamorphic relation (and thus revealed a bug and

“killed the mutant”) for the unmodified source code,

and the eight mutants.

All the mutant versions of the PID controller

were killed by at least one of the MRs with the test

TESTING A SOFTWARE-BASED PID CONTROLLER USING METAMORPHIC TESTING

393

cases available. Mutant 1 violates MR3 and MR4

when tested with 1% and 100% of the test case pairs,

respectively. It is reasonable because the fault of

Mutant 1 is in the sign of derivative term. It therefore

causes a violation of MR4 with 100% of the

generated test cases. Mutant 2’s fault is due to a

single error value instead of the sum of errors in the

integral term. This fault effectively results in the PID

controller acting as a PD controller, causing a 37%

failure rate in the testing associated with MR3. The

proportional gain is added to the error instead of

multiplied by the error in Mutant 3. It does not affect

the direction of effect of proportional parameter, as

the proportional term still increases if the

proportional parameter is increased, and as such

MR2 does not detect the error. Since this mistake

turns the PID controller to another unknown type of

controller, it does not satisfy the relations of MR1,

MR3 and MR4 which hence reveal the error. Mutant

4 has the integral term and derivative term to be

incorrectly multiplied together, instead of added.

Mutant 4 is therefore no longer a PID controller, and

so MR1 and MR4 are violated with most test case

pairs. As MR2 relates to the change of K

p

which is

unaffected by this seeded fault, and the integral term

of dominates the effect of derivative term, MR2 and

MR4 cannot detect the fault. Mutant 5 relates to a

fault in the derivative term, so it is understandable

that there is a violation of MR4 in 100% of test case

pairs. Since MR1 relates to all the parameters, it is

also affected. MR3 is a summation of all sampled

errors, so it is violated in some test cases. Mutant 6

and Mutant 7 change the integral term calculation, so

MR3 is violated in 100% of cases. The fault in

Mutant 8 is the replacement of the proportional gain

by the integral parameter. It is therefore

understandable that MR2 and MR3 are violated in

100% of the test case pairs.

5 THREATS TO VALIDITY

5.1 Internal Validity

The only major threats to the internal validity of this

study are incorrect implementation of the code

simulating the antenna motor and sensor, and the

various pieces of experimental scaffolding used to

generate test cases and collect results. The motor

simulation required very few lines of code, and was

tested to ensure that it reflected the expected

behavior. The experimental scaffolds are also very

simple. The PID controller itself was, as noted,

sample code and not implemented by the authors.

5.2 External Validity

The “bugs” detected by the metamorphic relations

were mutations deliberately seeded into the controller

code. While at least one study suggests a connection

between the failure behavior of mutants and “real”

bugs (Daran & Th’evenod-Fosse (1996)) we cannot

be certain such a connection generalizes to controller

software.

While the metamorphic relations demonstrated

here should be applicable to most applications in

which a PID controller is used, it is uncertain how

they will perform in revealing actual bugs in real

systems. It is also uncertain whether effective

metamorphic testing can be achieved on other types

of controllers. While the extensive mathematics

underpinning control theory should make it relatively

straightforward to derive metamorphic relations for

other types of controllers, further studies will be

required to demonstrate efficacy.

6 CONCLUSIONS

Software-based control systems in general, and PID

controllers in particular, are widely deployed

technologies. It is therefore crucial that they are

demonstrated to be reliable before deployment.

However, they can be difficult to test effectively as

verifying the outputs is subject to the oracle problem.

We have demonstrated the ability to effectively kill

mutants in a PID controller using metamorphic

testing; all eight mutants tested were killed by at least

one metamorphic relation.

A key question for the industrial application of

metamorphic testing is the ease with which effective

MRs can be found. In the case of the PID controller,

control theory made it relatively straightforward for a

domain expert to find suitable MRs. This is

consistent with studies in other problem domains,

where suitable MRs have been reasonably readily

identified.

However, it is worth considering the relative

effectiveness of the four metamorphic relations. The

most effective was MR3, which relates to the integral

term. It was able to kill all eight mutants. As the

integral term consists of the summation of the entire

error signal (and thus the behavior of the controller

over the entire time scale), it makes sense that it

revealed more mutants than other MRs. By contrast,

MR2, which relates to the proportional term and thus

depends only on the instantaneous error, revealed

only one mutant. To maximize the effectiveness of

metamorphic testing, it would obviously be desirable

PECCS 2011 - International Conference on Pervasive and Embedded Computing and Communication Systems

394

to have some way to identify MRs that are more

likely to find faults.

Our study concentrated entirely on the testing of

the controller software, and simulated “perfect”

hardware. In practice, hardware may of course have

faults. Metamorphic testing could be used to test the

complete system, including hardware. However, it is

not clear whether the metamorphic relations used

here are useful in detecting hardware faults – and, if

the present MRs are unsuitable, whether there are

others that can provide useful fault-finding

capabilities beyond existing techniques. This is

clearly an area worthy of future study.

We believe that our study provides good evidence

of the promise of metamorphic testing in control

applications. However, there are more advanced

control systems that control higher order attributes

(for instance, in a mechanical system, speed and

acceleration). We propose to conduct further studies

to demonstrate that these, too, can be effectively

tested without an oracle using metamorphic testing

techniques.

ACKNOWLEDGEMENTS

This project was supported by an ARC Discovery

Project (ARC DP 0984760).

REFERENCES

Application Note AVR221, “Discrete PID controller”,

Atmel Corporation, 2006. Retrieved from: http://www.

atmel.com/dyn/products/app_notes.asp?family_id=607

W. K. Chan, T. Y. Chen, H. Lu, T. H. Tse and S. S. Yau,

“Integration testing of context-sensitive middleware-

based applications: a metamorphic approach”,

International Journal of Software Engineering and

Knowledge Engineering. Vol. 16(5), 2006, pp. 677-

703.

T. Y. Chen, S. C. Cheung and S. M. Yiu, “Metamorphic

testing: a new approach for generating next test cases”

Technical Report HKUST-CS98-01, Department of

Computer Science, Hong Kong University of Science

and Technology, Hong Kong, 1998.

T. Y. Chen, T. H. Tse and Z. Q. Zhou, “Semi-proving an

integrated method based on global symbolic

evaluation and metamorphic testing”, in Proc. ACM

SIGSOFT International Symposium on Software

Testing and Analysis (ISSTA 2002) (ACM Press,

2002), pp. 191-195.

M. Daran and P. Thévenod-Fosse, “Software Error

Analysis: A Real Case Study Involving Real Faults

and Mutations,” ACM SIGSOFT Software

Engineering Notes, vol. 21, no. 3, pp. 158–177, May

1996

B. C. Kuo, Automatic Control Systems, 4th edition, 1982,

Prentice-Hall, inc., Eaglewood Cliffs, N. J., U.S.A.

Chapter 8.2, pp. 471-483.

N. S. Nise, Control Systems Engineering, Fifth Edition,

2008, Wiley.

H. Nyquist, "Certain Topics in Telegraph Transmission

Theory", AIEE Trans., vol. 47, pp. 617-644, 1928.

Z. Q. Zhou, D. H. Huang, T. H. Tse, Z. Yang, H. Huang

and T.Y. Chen, “Metamorphic testing and its

applications”, in Proc. of the 8

th

International

Symposium on Future Software Technology

(ISFST2004), Software Engineers Association, Japan

2004.

APPENDIX: DERIVATION

OF SOME METAMORPHIC

RELATIONS

In this appendix, we follow the notation used in

Table 1.

Metamorphic Relation 1

Consider a P controller (that is, a PID controller

where the integral and derivative parameters are 0)

controlling a second order plant as shown in Fig. 6,

the closed loop transfer function will be

()

()

=

++

(3)

For any second order control system with the general

closed loop transfer function of

()

()

2

2

2

2

n

n

ss

sX

sY

ωξω

ω

++

=

(4)

Figure 6: General P control system.

The rise time tr can be obtained by the following

approximation:

η

ω

ξ

5.28.0 +

≅tr

From equations (3) and (4), we have

(

)

bK

bKa

tr

p

p

2/5.28.0 ×+

≅

TESTING A SOFTWARE-BASED PID CONTROLLER USING METAMORPHIC TESTING

395

Increasing K

p

will decrease the rise time tr.

For any second order control system, the maximum

overshoot can be obtained as:

2

1

100max

ξ

ξ

−

−

×=

n

eos

From equations (3) and (4), we obtain

2

/

2

100 maximum

abK

bK

na

p

p

eos

−

−

×=

When K

p

increases, maximum overshoot increases.

From Fig. 6, for step input with the error

(

)

=

,

the steady state error can be obtained as follows:

()

pp

s

KaK

as

e

1

lim

0

=

+

=∞

→

When K

p

increases, the steady state error decreases.

Therefore, we have:

MR2:

If (K

p1

< K

p2

) ∧ (K

i1

=K

i2

=0) ∧ (K

d1

=K

d2

=0)

then (tr

1

≥ tr

2

) ∧ (os

1

< os

2

) ∧ (ess

1

≥ ess

2

)

Metamorphic Relation 2

The integral term added to the proportional term is

equivalent to adding a zero at s = -K

i

/K

p

and a pole at

s = 0 to the open loop transfer function.

The transfer function will be

()

()

()

sX

K

K

sbass

K

K

sb

sY

i

p

i

p

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

+++

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

+

=

2

Then

()

()

()

()

sX

K

K

sbass

ass

sE

i

p

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

+++

+

=

2

2

For a step input with magnitude X, the steady state

error is:

()

()

()

bK

XK

X

K

K

sbass

ass

e

p

i

i

p

⋅

⋅

=

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

+++

+

=∞

→

2

2

0s

lim

Since K

I

< 1, it will then reduce the steady state error.

Since the integral term is responding to accumulated

errors from the past, it can cause the present value to

overshoot the set point value and slow the settling

time. MR3 is therefore defined as follows:

MR3:

If K

i1

< K

i2

then

(os

1

< os

2

) ∧ (ess

1

≥ ess

2

) ∧ (ts

1

≤ ts

2

)

Metamorphic Relation 3

Since de(t)/dt represents the slope of e(t), the

derivative control is essentially an anticipatory type

of control. Normally, in a linear system, if the slope

of e(t) is large due to a step input, a high overshoot

will subsequently occur. The derivative control

measures the instantaneous slope of e(t), predicts the

large overshoot ahead of time, and makes a proper

correcting effort before the overshoot actually

occurs. As a result, the increase of K

d

will reduce the

overshoot. It is apparent that the derivative control

will affect the steady-state error of a system only if

the steady state error varies with time. If the steady-

state error of a system is constant with respect to

time, the time derivative of this error is zero, and the

derivative control has no effect on the steady-state

error. The increase of K

d

will not increase the steady

state error. As the increase of K

d

will decrease the

overshoot, the settling time will be decreased with

the increase of K

d

. We can therefore define MR4 as

follows:

MR4:

If K

d1

< K

d2

then

(ts

1

≥ ts

2

) ∧ (os

1

≥ os

2

) ∧ (ess

1

≥

ess

2

)

PECCS 2011 - International Conference on Pervasive and Embedded Computing and Communication Systems

396