REAL-TIME IMAGE BASED VISUAL SERVOING ARCHITECTURE

FOR MANIPULATOR ROBOTS

Adrian Burlacu, Copot Cosmin, Andrei Panainte, Carlos Pascal and Corneliu Lazar

Department of Automatic Control and Applied Informatics, ”Gheorghe Asachi” Technical University of Iasi, Iasi, Romania

Keywords:

Visual servoing, Real-time implementation, Feature points, Manipulator robot.

Abstract:

The necessity of designing flexible and versatile systems is one of the most current trends in robotic research.

Including visual servoing techniques in an existing robotic system is a very challenging task. In this paper a

solution for extending the capabilities of a 6 d.o.f manipulator robot, for visual servoing system development,

is presented. An image-based control architecture is designed and a real-time implementation on an ABB

robot is developed. The image acquisition and processing, toghether with the computing of the image-based

control law were implemented in Matlab. A new type of robot driving interface that links the robots’ controller

with Matlab environment is proposed. The robustness and stability of the feature point based control laws are

tested in multiple experiments. Experimental results revealed very good performances for the real-time visual

servoing system.

1 INTRODUCTION

Visual servoing has been studied in various forms for

more than three decades starting from simple pick

and place tasks to todays real-time, advanced ma-

nipulation of objects. In terms of manipulation, one

of the main motivations for incorporating vision in

the control loop was the demand for increased flex-

ibility of robotic systems. The main aim of the

image based visual servoing is to control the end-

effector of a robot arm such as a set of image features

to reach a desired configuration (Hutchinson et al.,

1996; Chaumette and Hutchinson, 2007). Even if

new visual features were proposed (Marchand and

Chaumette, 2005; Chaumette and Hutchinson, 2006),

point features still remain the most used image mea-

surements in designing real-time visual servo control

laws. Usually they are coordinates of the centroids or

corners that describe an object.

The main problem for visual servoing systems is

that in order to have a robust and stable control law

the image based controller must be designed taking

into account the dynamic constraints of the manipula-

tor robot and also the workspace configuration. A di-

rect implementation of the visual feedback scheme is

very difficult to obtain, mainly due to the access im-

possibility over the low level components (ex: joint

motors) that are part of the robot. Due to this imped-

iment, a method for extending the capabilities of the

robots’ controller is needed. This extension must be

designed in a matter that all the existing time periods

(due to communication, to image processing and con-

trol computation) are included and the system works

in real-time.

Many simulators that implement image based vi-

sual servoing architectures were proposed in the last

decade (Corke, 2005; Cervera, 2003; Lazar and

Burlacu, 2008). Also, real time applications of visual

servoing systems are presented in different research

areas. A real-time 3D visual tracking and control al-

gorithm for a 5 degrees of freedom microassembly

workcell is presented in (Tamadazte et al., 2009). The

solution proposed uses a model-based tracking algo-

rithm in real-time in order to obtain the 3D pose of

the Micro Electro Mechanical Systems. A classical

Reinforcement Learning (RL) architecture that use an

actor-critic design was proposed for a real-time visual

tracking task of a 6 d.o.f. robot (Perez-Cisneros and

Mora-Galvez, 2005). Knowing, the potential of ul-

trasound imaging for guiding a surgical instruments,

Stoll (Stoll et al., 2006) proposed a real-time 3D ultra-

sound image-guide robotic system. This system was

designed in order to autonomously navigate a mini-

mally invasive surgical instrument in 6 d.o.f. using

only passive tracking.

In the present paper a real time image based vi-

sual servoing architecture for a 6 d.o.f. manipulator is

proposed. The architecture is structured in three mod-

502

Burlacu A., Cosmin C., Panainte A., Pascal C. and Lazar C..

REAL-TIME IMAGE BASED VISUAL SERVOING ARCHITECTURE FOR MANIPULATOR ROBOTS.

DOI: 10.5220/0003367005020510

In Proceedings of the International Conference on Computer Vision Theory and Applications (VISAPP-2011), pages 502-510

ISBN: 978-989-8425-47-8

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

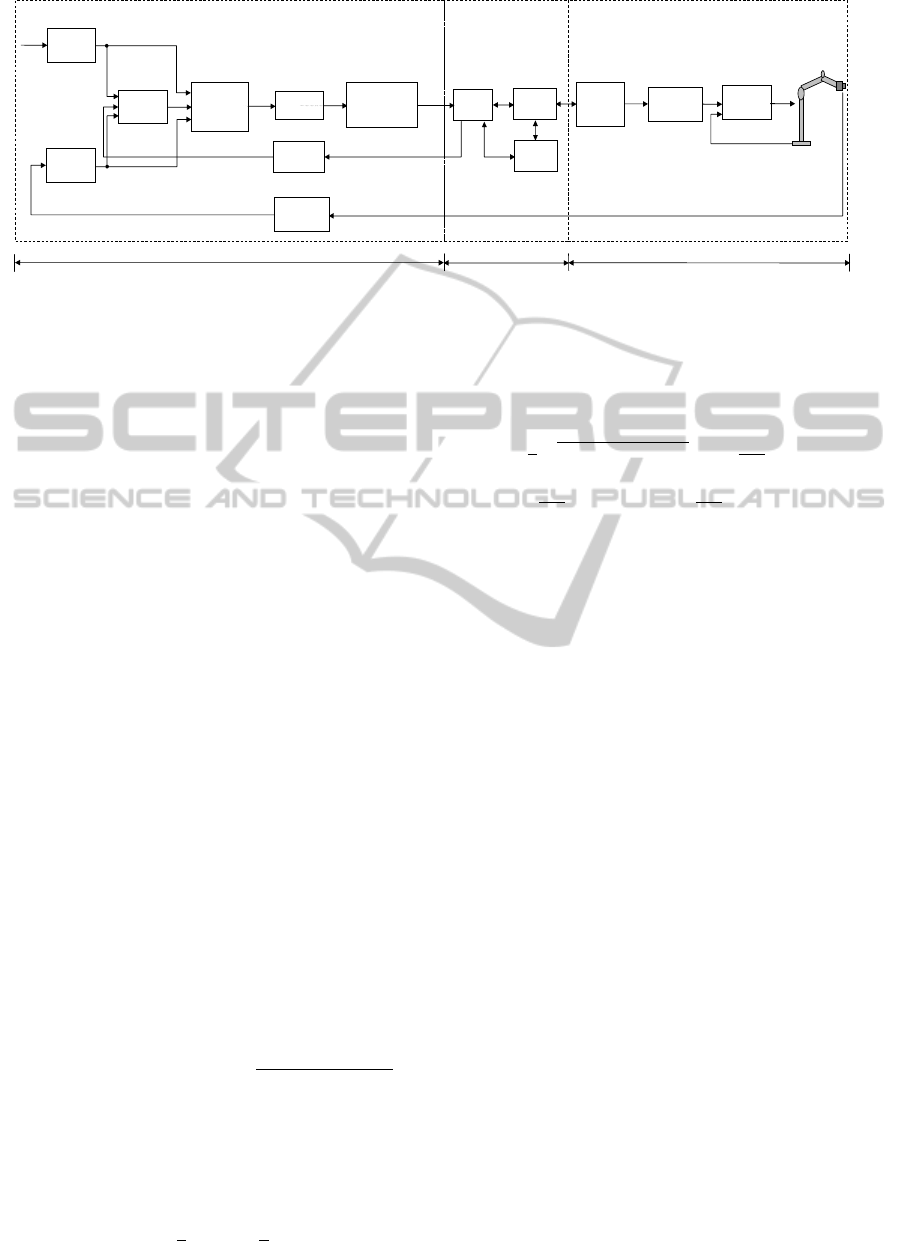

ules (Image Based Control, Robot Driver Interface,

Robot Controller), each one having a different objec-

tive, but in the same time is connected with the other

ones. The configuration of the manipulator robot is

an eye-in-hand type. Images are acquired and pro-

cessed in real time, thus point features are extracted.

The visual feedback control law will be designed in

order to minimize the error between the current and

the desired point features. A 6 d.o.f. ABB IRB-

2400 manipulator robot was chosen in order to imple-

ment the designed visual servoing architecture. On

the robots’ gripper a video camera was mounted. A

commonly cited problem in real-time applications is

the bounded bandwidth communication between the

visual sensor and the robot which induce a latency in

the closed-loop system. In order to obtain a sufficient

sampling bandwidth an extension of the robots’ con-

troller (named ABB S4CPlus) is usually a solution.

In (Blomdell et al., 2005) such an extension was de-

veloped, but the visual servoing applications were not

considered. A new extension of the capabilities of

the ABB S4CPlus controller is proposed in this pa-

per. Using a robot driver interface, low-level real time

interaction between the robot controller and a mas-

ter PC are possible. The visual control algorithm was

implemented in Matlab using a classical proportional

approach based on point features.

The present paper is organized as follows: Section

II presents the structure of a visual servoing system

for a real-time application. Section III is dedicated

to the image based control algorithm. In Section IV

experimental results are presented, while the conclu-

sions are detailed in Section V.

2 VISUAL SERVOING

ARCHITECTURE

In order to develop a real-time image based control al-

gorithm for an ABB manipulator robot with 6 d.o.f.,

using point features, the visual servoing control ar-

chitecture from Figure1 was designed. The proposed

structure has as input the desired configuration f

∗

of

the point features extracted from the desired image.

Starting from an initial pose of the gripper, an im-

age is acquired using a Sony XCD-V60CR camera

mounted on the gripper and point features f were ex-

tracted based on the Harris detector presented in the

next Section. The image based controller minimizes

the error between the desired f

∗

and the current point

features f (t), and has as output the reference cam-

era velocity v

∗

c

. Integrating this reference camera ve-

locity a new gripper pose denoted x

∗

c

is obtained and

transformed into a quaternion based pose representa-

tion (x

∗

c

q

) which represents the input for the robot con-

troller via the Robot Driver Interface (RDI).

This architecture is composed from three different

modules: Image Based Control, RDI and Robot Con-

troller, each one having a different execution time.

The following notions are considered: T

ap

the exe-

cution time for the Image Based Control module, T

c

the RDI module execution time and T the execution

time for Robot Controller module. The sample period

(T

s

) of the entire architecture is obtained from:

T

s

= T

ap

+ T

c

+ T. (1)

The Image Based Control module implements an im-

age based control algorithm and contains the follow-

ing blocks: Features Extraction, Interaction Matrix,

Proportional Controller, Integrator, Quaternion based

Pose Representation, Depth Extraction and Image

Acquisition. Features Extraction, Interaction Matrix

and Proportional Controller blocks will be presented

in the next Section, while Image Acquisition block

is detailed in the Experimental Results section. The

RDI module has three blocks: I/O, Robot Interface

and User Interface. Robot Controller (ABB S4CPlus)

is a module composed from all the entities that en-

sure the correct motion of the robot. ABB S4CPlus

controller uses instructions from the RAPID program

in order to generate trajectories for the internal arm-

level. Next, the motor controllers are responsible for

the low-level motion control of each joint. In this Sec-

tion the Rapid Program block of the Robot Controller

module and the RDI module are detailed.

2.1 Rapid Program

ABB IRB 2400 is a 6-axis manipulator robot, de-

signed specifically for manufacturing industries that

use flexible robot-based automation. The robot is

equipped with an operating system called BaseWare

OS that constitutes the kernel of the RobotWare fam-

ily.

BaseWare OS controls every aspect of the robot,

like motion control, development and execution of ap-

plication programs communication, etc. The proper-

ties of BaseWare OS can be split up in five main ar-

eas: The RAPID Language and Environment; Excep-

tion handling; Motion Control; Safety; the I/O Sys-

tem. RAPID is a textual programming language for

industrial ABB robots, thus the RAPID program can

be written using the console (teach pendant) and also,

it can be written on any other computer following the

RAPID syntax.

The motion of the robot represents the pose mod-

ification of a frame attached to the gripper. The ori-

gin of the gripper’s reference frame is known as Tool

REAL-TIME IMAGE BASED VISUAL SERVOING ARCHITECTURE FOR MANIPULATOR ROBOTS

503

User

Interface

( )

f t

f

∗

Trajectory

Generation

Features

Extraction

Image

Acquisition

Features

Extraction

( )

t

∗

c

v

( )

t

∗

c

x

Motor

Controller

f

L

Proportional

Controller

Integrator

I/O

Robot

Interface

Depth

Extraction

Rapid

Program

( )

z t

Desired

Image

Interaction

Matrix

( )

t

∗

q

c

x

ROBOT DRIVER

INTERFACE

ROBOT CONTROLLER

Quaternion

based Pose

Representation

IMAGE BASED CONTROL

ap

T

c

T

T

Figure 1: Visual servoing structure.

Center Point (TCP). The structure of any variable that

stores a pose of the TCP is:

pPosDest = [[x

1

,x

2

,x

3

],[q

0

,q

1

,q

2

,q

3

],...], (2)

where [x

1

,x

2

,x

3

] represent the new position of the

TCP and [q

0

,q

1

,q

2

,q

3

] are the TCP orientation given

in quaternion.

Integrating the reference camera velocity v

∗

c

=

[v

∗

x

,v

∗

y

,v

∗

z

,ω

∗

x

,ω

∗

y

,ω

∗

z

]

T

, the new TCP pose x

∗

c

=

[x

1

,x

2

,x

3

,α,β,γ]

T

is obtained. The new orientation

is stored in a roll-pitch-yaw (RPY) matrix:

R =

"

c(α)c(β) c(α)s(β)s(γ)−s(α)c(γ) c(α)s(β)c(γ)+s(α)s(γ)

s(α)c(β) s(α)s(β)s(γ)+c(α)c(γ) s(α)s(β)c(γ)−c(α)s(γ)

−s(β) c(β)s(γ) c(β)c(γ)

#

, (3)

where c() and s() denotes the cos and sin functions.

In case of ABB IRB-2400 robots, as for many

manipulator robots, the orientation is represented by

quaternions (Siciliano et al., 2009). In the same way

as complex numbers, the quaternions can be defined

by introducing abstract symbols i, j,k which satisfy

the rules i

2

= j

2

= k

2

= i jk = −1 and the usual al-

gebraic rules except the commutative law of multipli-

cation. When quaternions are used in geometry, it is

more convenient to define them as:

ˆq = q

0

+~q = q

0

+ q

1

i + q

2

j + q

3

k, (4)

where the imaginary part q

1

i + q

2

j + q

3

k behaves like

a vector ~q = (q

1

,q

2

,q

3

) in V

3

, and the real part q

0

behaves like a scalar in R. The conjugate of a quater-

nion is denoted ˆq

∗

= q

0

−~q. Let Q

u

be the ensemble of

quaternions having unit length (

q

q

2

0

+ q

2

1

+ q

2

2

+ q

2

3

=

1). If ˆq ∈ Q

u

then rotating a vector

−→

r around an

−→

η

direction axis with an angle α can be express by:

ˆ

ρ = ˆq ˆr ˆq

∗

, (5)

where is the quaternion multiplication, ˆr = 0 +

−→

r ,

ˆ

ρ = 0 +

−→

ρ and ˆq = cos

α

2

+

−→

η sin

α

2

.

The transformation that links the orientation ex-

pressed by a rotation matrix with the orientation ex-

pressed by quaternions is:

q

0

= ±

1

2

p

1 + r

11

− r

22

− r

33

; q

1

=

1

4q

0

(r

12

+ r

21

)

q

2

=

1

4q

0

(r

13

+ r

31

); q

3

=

1

4q

0

(r

32

− r

23

),

(6)

where r

i j

are the components of the rotation matrix

from (3). Equation (6) will be used to convert the

RPY matrix in quaternion that is necessary to control

the gripper of the ABB IRB-2400 manipulator robot.

The pPosDest variable which store the TCP pose

is called RobTarget and represent the input signal for

the ABB S4CPlus controller. Moving to a RobTarget

data involves using one of the following instruction:

MoveAbsJ, MoveC, MoveJ, MoveL, MoveCDO,

MoveJDO, MoveLDO, MoveCSync, MoveJSync. In

order, to control the griper movements of an ABB

IRB-2400 manipulator robot a MoveJ instruction is

used and has the following syntax:

MoveJ ToPoint Speed[\V ][\T ] Zone[\Z] Tool[\Wob j]

with ToPoint - the desired point, Speed - the TCP

speed, Zone - the TCP position related to desired

point and Tool - the effector used. The optimal pa-

rameter [\V ] represent the TCP velocity in mm/s and

replace the Speed argument, [\T ] is the execution

time for a motion from the current to the new TCP

pose, [\Z] specified the distance of the effector ap-

proaches the target position and [\Wob j] represent the

working object.

The new reference pose of the robots’ TCP, rep-

resenting the output of the image based visual con-

trol algorithm after integration, is saved in a file and

transmitted to the robots’ controller. The first row of

the file contains the position given in Cartesian coor-

dinates and the second line from the file contains the

VISAPP 2011 - International Conference on Computer Vision Theory and Applications

504

orientation as quaternion form. Workflow begins with

a first step by copying the RAPID program from the

disk and loading it on the S4CPlus controller. This

simple program is designed using a single persistence

variable pPosDest. The RAPID program is formed by

lines of code that have as effect the movement of the

griper to the pose defined by the position and orien-

tation contained in variable pPosDest. The procedure

that performs this operation is decribed below:

PROCMoveTo()

checkPoint := 0;

Con f J \ O f f ;

Con f lict \ O f f ;

MoveJ pPosDest, T 0.5, fine, toolGRIP;

Con f J \ On;

Con f lict \ On;

checkPoint := −1;

ENDPROC

This procedure is loaded in the Robot Controller

and executed when the persistent variable pPosDest

is changed by the image-based control algorithm.

2.2 Robot Driver Interface

In order to have a direct communication between the

Matlab environment and the robots’ controller a new

type of Robot Driver Interface (RDI) is proposed. The

RDI is the link between the MATLAB application

which implements the Image Based Control module

and the Rapid Program (RP). The role of RDI is to

analyze the MATLAB output and transfer the proper

data to the RP by running a specific procedure of the

RP, and to return the new pose of the TCP to the MAT-

LAB program. The RDI incorporates the Robot In-

terface module, the I/O module, and a User Interface

module.

The Robot Interface module manages the commu-

nication between the RDI and the S4Plus Controller,

which is the robots controller. This one allows exter-

nal interaction through the TCP/IP via two serial con-

nections (RS232 and RS422 Full duplex) or an Ether-

net network. The effective communication is carried

out by the ABB Interlink service, which sends com-

mands to the robots controller, collects data from it

through the Interlink Monitor module of the service

by means of a polling mechanism and modifies the

RP at the persistent variables level. It is important

to note that the minimum polling interval that can be

set is 200 ms, and this interval is also maintained be-

tween two successive commands. For a given list of

persistent variables, the Interlink Monitor maintains

their state and notifies each time when a value was

changed. A programmable way to interact with the

Interlink service and Monitor is allowed through a

specific ActiveX component, namely the Helper Con-

trol, part of WebWare SDK (Cederberg et al., 2002).

The Robot Interface module wraps the components

and offers further means to the other modules.

1

2

3

4

5

6

7

8

9

10

Figure 2: User Interface.

The role of the I/O module is to acquire the MAT-

LAB output, to read the new pose of the TCP and

to send it towards the MATLAB input. When the

file is changed, it interprets this as a command and

reads the file information, modifies the persistent vari-

ables in the RP (in this case the pPosDest variable see

the previous section) and runs the proper procedure

(MoveTo) using the robot interface module. The end

of the procedure is notified by the monitored variable

checkPoint and its value is changed to -1. After this,

the I/O module gets the current pose of the gripper

and puts the information at the MATLAB input.

The User Interface of the RDI (Figure 2) was de-

signed, tested and implemented in C# and has the fol-

lowing capabilities: connects the RDI to a robot con-

troller (label 1), interacts with the selected controller

by copying, running, stopping Rapid programs (label

4), open/close the robots motors (label 3), and change

its grippers position/orientation (label 10). Addi-

tionally, it maintains and shows relevant information

about the controller and robots states (labels 2 and 7),

the program variables (6), significant events (8), and

also the data from the MATLAB output (9).

Using these modules, the RDI offers a solution to

link the MATLAB algorithm to the physical compo-

nent. From the safety point of view, the solution mod-

ifies safely some persistent variables and guides the

work-flow of the Rapid program. As performance,

our measurement showed that the time between a

command from visual control algorithm and the effec-

tive execution by the robot controller is in the polling

interval set at 200 ms. Through RDI module, the cur-

REAL-TIME IMAGE BASED VISUAL SERVOING ARCHITECTURE FOR MANIPULATOR ROBOTS

505

rent gripper pose are used as feedback in order to ob-

tain a better approximation of the depth related to the

camera frame, depth that are used in visual control

algorithm to compute the interaction matrix.

3 IMAGE BASED VISUAL

CONTROL

In this Section the image based control algorithm is

presented. As visual information input point fea-

tures are considered. Next an algorithm for point

features extraction from monocrome images is pre-

sented. Also the design of the visual proportional con-

troller is revealed. The proposed controller minimizes

the error between current and desired point features

configuration, while taking into account the visibility

constraints, and generates the reference velocity vec-

tor of the camera.

3.1 Point Features

A variety of operators have been proposed to detect

point features. For our real-time visual servoing struc-

ture the Harris detector (Ma et al., 2003) was chosen.

For the Harris algorithm, the definition of a point fea-

ture is typically taken to be a location in the image

where the local autocorrelation function has a distinct

peak.

Given an image I(u,v), the autocorrelation matrix

is computed from:

A =

∑

u

∑

v

g(u,v)

I

2

u

I

u

I

v

I

u

I

v

I

2

v

=

< I

2

u

> < I

u

I

v

>

< I

u

I

v

> < I

2

v

>

, (7)

where g is the gaussian kernel and I

u

,I

v

are the gradi-

ents on the u and v directions:

I

u

=

∂I

∂u

= I ∗ [−1 0 1]

I

v

=

∂I

∂v

= I ∗ [−1 0 1]

T

. (8)

The main idea for detecting point features is to

analyze the function:

C(A) = det(A) − δtrace

2

(A), (9)

where δ ∈ R is a tunable sensitivity parameter. In or-

der to establish the influence of δ let the two eigenval-

ues (which in this particular case are also the singular

values) of A be σ

1

, σ

2

. Then:

C(A) = σ

1

σ

2

− δ(σ

1

+ σ

2

)

2

, (10)

and for δ being small, both eigenvalues need to be big

enough to make C(A) pass a threshold thus only point

features are detected.

The algorithm has proved robust due to its high re-

liability in finding L-junctions and its good temporal

stability making it an attractive point feature detec-

tor for tracking. Also the computational time is lower

than 0.15 ms thus being suitable for real time imple-

mentation.

3.2 Visual Proportional Controller

The main goal of any image based control architecture

(IBVS) is to drive a robot system using information

acquired by a visual sensor (Chaumette and Hutchin-

son, 2006). If the considered robot system is a manip-

ulator robot that has a video camera mounted on the

gripper then a visual servoing structure with an eye-

in-hand configuration is created. In order to achieve

the main goal, a trajectory for the video camera must

be designed. The trajectory is given by the integra-

tion of the camera velocity obtained from the IBVS

architecture by minimizing the error between the cur-

rent point features configuration and the desiring one.

The error between point features in the image plane is

defined as follows:

e(t) = f (t) − f

∗

, (11)

where f (t) represents the point features position at

time t and f

∗

the desired configuration. Equation (11)

is the general representation of the input signal for

the image based controller. The outputs of the im-

age based controller is the reference velocity v

∗

c

of the

camera. If the task of extracting point features and

finding the correspondences in the desired configu-

ration is completed then a relationship between time

variation of f (t) and camera velocity can be gener-

ated. Let v

∗

c

be a vector composed from linear veloci-

ties of the camera frame and the instantaneous angular

velocities of the camera frame.

The link between the motion of point features and

camera velocity is given by (Chaumette and Hutchin-

son, 2006):

˙

f = Lv

∗

c

, (12)

where by L ∈ R

2n×6

is denoted the image Jacobian of

n point features that compose the vector f . From (11)

and (12) it is obvious that:

˙e = Lv

∗

c

. (13)

In order to increase the robustness of the visual

based control algorithm a different error function can

be used:

e

D

= De, (14)

VISAPP 2011 - International Conference on Computer Vision Theory and Applications

506

where D = Diag{d

1

,...,d

n

} is a weighting matrix

used to remove the outliers from the point features

set. The weights d

i

vary from 1 when the robust es-

timation gives full confidence and 0 when the feature

is doubstlessly an outlier. For exemple an weighting

algorithm for establishing the values for {d

1

,...,d

n

}

can be generated using the distance of each feature to-

wards the center of the image. If the i-th point feature

is positioned near the image center, the d

i

will have a

value close to 1, else if the point feature is near one

the edges of the image the value of d

i

will be close to

0. Taking into acount that D can be considered to vary

slowly and thus

˙e

D

= D ˙e. (15)

A classical proportional controller is defined by

(Chaumette and Hutchinson, 2006):

v

c

∗

= −λ

c

L

+

e

D

, (16)

but using (13), (14), (15) a more robust expression can

be obtained:

v

c

∗

= −λ

\

(DL)

+

De. (17)

Let

L

f

= DL, (18)

be the interaction matrix of the detected point features

and thus (17) can be expressed:

v

c

∗

= −λL

+

f

De. (19)

In (19) L

+

f

∈ R

6×2n

is the Moore-Penrose pseu-

doinverse of L

f

, that is L

+

f

= (L

T

f

L

f

)

−1

L

T

f

. Consider-

ing that the structure of a point feature is f = (u, v) =

K · [x,y,1]

T

, where K is the intrinsic parameters ma-

trix (Ma et al., 2003),(u,v) are the image plane coor-

dinates expressed in pixels, (x,y) the point features’

coordinate in the virtual projection plane, then the in-

teraction matrix for a point feature can be computed

using (Mansard et al., 2009):

L

1

f

=

h

d

1

0

0 d

2

i

·

−

1

z

0

x

z

xy −(1+y

2

) y

0

1

z

y

z

1+y

2

−x·y −x

, (20)

where z is the depth of the corresponding projection

point in the Cartesian space related to the camera

frame. The initial depths of the point features are re-

covered using an epipolar geometry method (Hartley

and Zisserman, 2004), were the two views are the ini-

tial image and the desired one.

The correspondence between the point features

detecting in consecutive frames is a computational

consuming operation. In order to have a real time im-

plementation this operation must be optimized. Our

approach was to use a local model predictor of the fu-

ture position of the point feature in order to narrow

the correspondence search area. If f (t) is the current

position of the point feature then the correspondent

f (t + T

s

) from the next frame will be search in the

proximity of the predicted position computed by the

discretization of (12) using Euler’s method (Lazar and

Burlacu, 2009):

˜

f (t + T

s

) = f (t) + T

s

L

f

v

∗

c

(t). (21)

Due to the composition of T

s

from (1) the velocity

vector v

∗

c

is equal to 0 during the period T

ap

+ T

c

. An

area of 11×11 pixels centered in

˜

f (t +T

s

) is extracted

from the image and the point feature detector is em-

ployed, thus resulting the correspondent f (t + T

s

).

4 EXPERIMENTAL RESULTS

The visual servoing architecture proposed in the

present paper was implemented, tested and validated,

and the results of the conducted experiments are re-

vealed. A visual servoing system (Figure 3) was de-

veloped and it is composed from: a master PC (la-

bel 1), the S4CPlus ABB controller (label 2), an IRB

2400 ABB 6 d.o.f. manipulator robot (label 3), a vi-

sual sensor mounted on the gripper (label 4) and the

work table (label 5). The link between the visual sen-

sor (label 4) and the master PC (label 1) is realized by

an IEEE-1394b serial bus interface. The robots’ con-

troller (label 2) communication with the mater PC is

realized using an Ethernet network.

1

4

2

3

5

Figure 3: Servoing system.

Images were acquired using a Sony XCD-V60CR

visual sensor. This type of industrial camera is

based on a serial communication interface IEEE-

1394b (FireWire). The IEEE-1394b interface allows a

transfer rate of 800 Mbit/s and use a 9-pin connector.

The intrinsic camera parameters used are : the unit

cell size 7.4µm × 7.4µm, the depth resolution was set

to RAW16: 10bits/pixel and the focal length was set

REAL-TIME IMAGE BASED VISUAL SERVOING ARCHITECTURE FOR MANIPULATOR ROBOTS

507

to 4.5mm. Since an eye-in-hand camera configuration

it is used, the extrinsic camera parameters are related

to the robot effector frame. The visual sensor is able

to acquire 90 fps with 640 × 480 image resolution. In

order to optimize the computational time for the point

features extraction, images with 320 × 240 resolution

were considered.

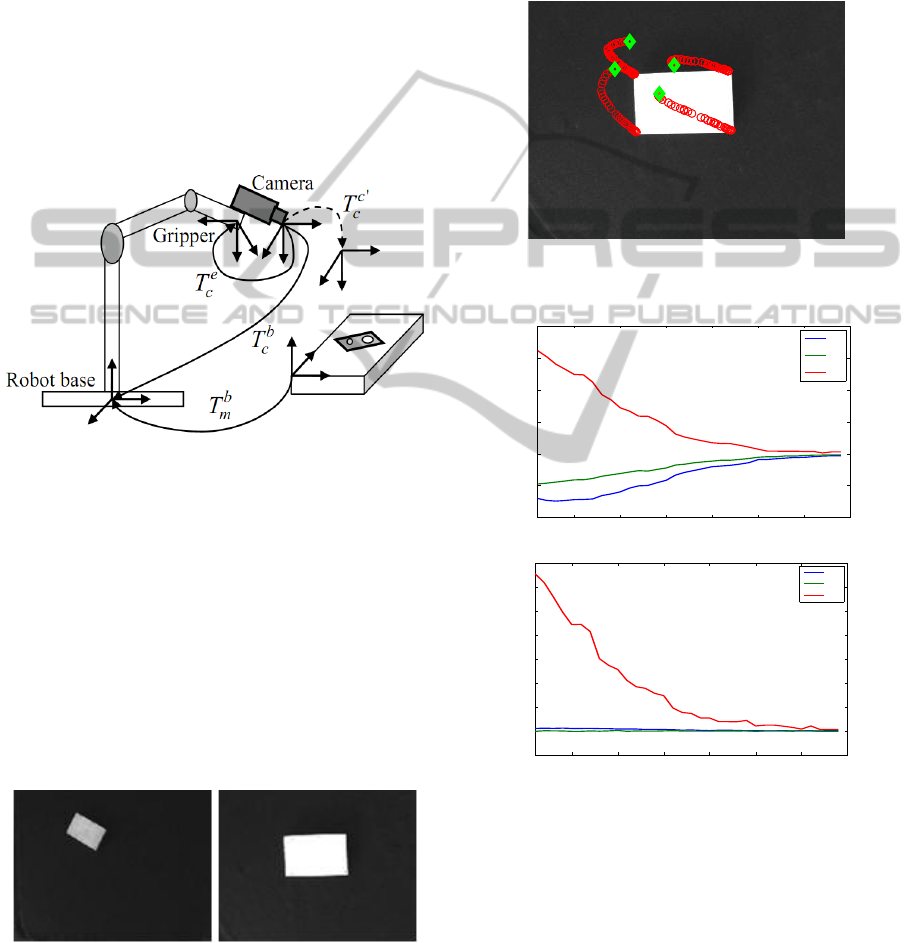

Considering the frames attached to the robot base

R

b

, to the camera R

c

, to the gripper R

e

and the work

table R

m

, the homogeneous matrix T

b

m

between the

frames R

m

and R

b

is given (Figure 4). Having an eye-

in-hand camera configuration and knowing the trans-

formation T

e

c

between R

c

and R

e

frames, thus, the

homogeneus transformation T

b

c

between the frames

R

c

and R

b

is obtained. Let T

c

0

c

be the homogeneus

Work table

Figure 4: Robot frames.

transformation between R

c

frame and the new cam-

era pose. The following work scene information were

apriori known: the pose of the robot frame, the pose

of the object frame, the transformation between cam-

era and TCP.

Considering an initial and desired image (Figure

5), point features were extracted using the Harris de-

tector. First step was to establish the correspondence

between the initial and the desired point features. This

step is done, for now, manually by the user. After the

starting correspondence will be generated automati-

cally using the motion prediction model (21).

Figure 5: Initial and desired images.

Having established the correspondence for each

iteration, the image based control law (19) was im-

plemented in order to ensure an exponential decrease

of the error from the image plane. The proportional

controller was tuning manually and the parameter λ

was set to 0.01. For this visual feedback control law

and with an execution time for motion T = 0.5, the

following results are obtained: the point features tra-

jectory in image plane (Figure 6), the camera velocity

vector (Figure 7) and the camera trajectory in Carte-

sian space (Figure 8).

Figure 6: Image plane point features trajectory for λ = 0.01

and T = 0.5.

1 5 10 15 20 25 30 35

−100

−50

0

50

100

150

200

Samples

Linear velocities (mm/s)

v

∗

x

v

∗

y

v

∗

z

1 5 10 15 20 25 30 35

−0.1

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

Samples

Angular velocities (rad/s)

ω

∗

x

ω

∗

y

ω

∗

z

Figure 7: Linear an angular camera velocities evolution.

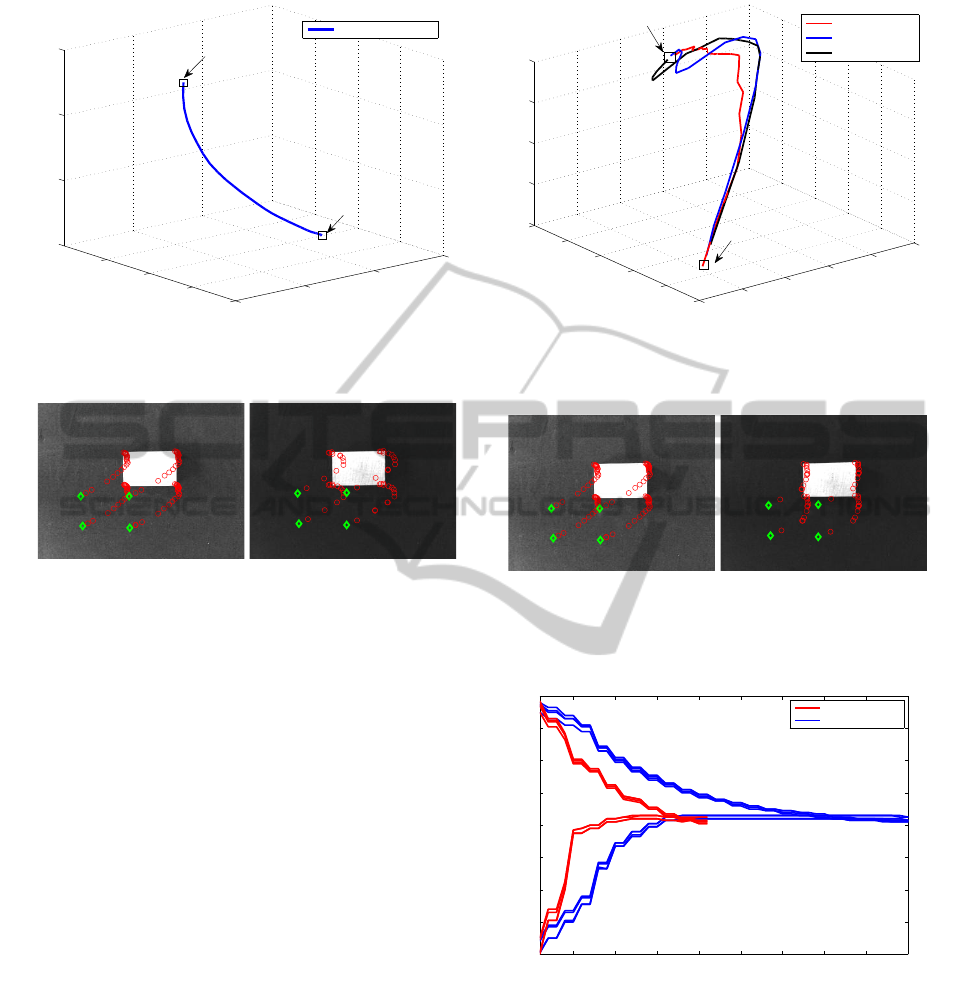

The visual servoing system performances depends

on the gain factor λ and on the execution time for the

motion parameter T . Considering a new starting con-

figuration (the green diamond from Figure 9), a gain

factor λ = 0.01 and an execution time raging from

0.5 to 0.9, the following point features trajectory is

obtained, Figure 9. As it can be observed, if the exe-

cution time is increased, the error will decrease faster

but with a more complicated gripper trajectory (Fig-

ure 10) and a greater effort for controlling the robot

VISAPP 2011 - International Conference on Computer Vision Theory and Applications

508

650

700

750

800

−1180

−1160

−1140

−1120

900

950

1000

1050

X (cm)

Y (cm)

Z (cm)

3D camera trajectory

Initial position

Final position

Figure 8: 3D Camera trajectory for λ = 0.01 and T = 0.5.

(a) (b)

Figure 9: Point features trajectory for: (a) λ = 0.01 and

T = 0.5; (b) λ = 0.01 and T = 0.9.

joints.

Considering the same initial configuration, a new

experiment was conducted in order to analyze the

visual servoing system performances related to gain

factor changes. Thus, for a constant execution time

T = 0.5, different values for the gain factor was con-

sidered: λ = 0.01 and λ = 0.02. In Figure 11, the

image plane trajectory of the point features are il-

lustrated. Analyzing the error evolution (Figure 12)

it can be observed that, increasing the gain factor

will leads to a faster decrease of the error and con-

sequently a decrease of the transient response. The

downward when increasing the gain factor is the in-

crease of the control effort, undesirable action in a

control structure. Therefore, it is necessary to estab-

lish a compromise value for the gain factor in order to

obtain optimal performances without great effort.

5 CONCLUSIONS

In the present paper, a real-time image based visual

servoing architecture for an ABB manipulator robot

with 6 d.o.f. and an eye-in-hand configuration was de-

veloped. The proposed architecture is composed from

640

650

660

670

680

690

−1260

−1240

−1220

−1200

−1180

−1160

934

936

938

940

942

X (cm)

Y (cm)

Z (cm)

λ=0.01 and T=0.5

λ=0.01 and T=0.7

λ=0.01 and T=0.9

Initial position

Final position

Figure 10: 3D Camera trajectory for different execution

motion time and λ = 0.01.

(a) (b)

Figure 11: Image plane point features trajectory for: (a)

T = 0.5 and λ = 0.01; (b)T = 0.5 and λ = 0.02.

1 5 10 15 20 25 30 35 40 45

−80

−60

−40

−20

0

20

40

60

80

Samples

Error (pixels)

λ=0.02 and T=0.5

λ=0.01 and T=0.5

Figure 12: Point features error evolution for different gain

parameter.

three modules (Image Based Control, Robot Driver

Interface and Robot Controller) connected between

them, but each one has a different objective.

The communication between the robots’ con-

troller and the Matlab environment which implements

the Image Based Control module is realized using a

new extension of the robot controller based on RDI.

In order to implement the designed visual servoing ar-

REAL-TIME IMAGE BASED VISUAL SERVOING ARCHITECTURE FOR MANIPULATOR ROBOTS

509

chitecture, a classical proportional control law based

on point features was considered. For a better sta-

bility of the control law, the RDI provide a feedback

(the current gripper pose) that are used to estimate the

depths of the point features, thus generated the inter-

action matrix. The experimental results revealed good

robustness and stability for the real-time image based

servoing architecture designed.

ACKNOWLEDGEMENTS

This paper was supported by the project PERFORM-

ERA ”Postdoctoral Performance for Integration in the

European Research Area” (ID-57649), financed by

the European Social Fund and the Romanian Govern-

ment.

REFERENCES

Blomdell, A., Bolmsj, G., Brogrdh, T., Cederberg, P., Isaks-

son, M., Johansson, R., Haage, M., Nilsson, K., Ols-

son, M., Olsson, T., Robertsson, A., and Wang, J.

(2005). Extending an industrial robot controllerim-

plementation and applications of a fast open sensor

interface. IEEE Robotics and Automation Magazine,

12(3):85–94.

Cederberg, P., Olsson, M., and Bolmsj, G. (2002). Remote

control of a standard abb robot system in real time

using the robot application protocol (rap). In Pro-

ceedings of the International Symposium on Robotics,

ISR2002, Stockholm.

Cervera, E. (2003). Visual servoing toolbox.

http://vstoolbox.sourceforge.net/. Jaume I Uni-

versity.

Chaumette, F. and Hutchinson, S. (2006). Visual servo con-

trol, part i: Basic approaches. IEEE Robotics and Au-

tomation Magazine, 13(4):82–90.

Chaumette, F. and Hutchinson, S. (2007). Visual servo con-

trol, part ii: Advanced approaches. IEEE Robotics and

Automation Magazine, 14(1):109–118.

Corke, P. (2005). Machine vision toolbox. IEEE Robotics

and Automation Magazine, 12(4):16–25.

Hartley, R. and Zisserman, A. (2004). Multiple View Geom-

etry in Computer Vision. Cambridge University Press,

2 edition.

Hutchinson, S., Hagerand, C., and Corke, P. (1996). A tuto-

rial on visual servo control. IEEE Trans. On Robotics

and Automation, 12(5):651–670.

Lazar, C. and Burlacu, A. (2008). Dynamic simulation

model for image based visual servo control systems.

In 11th Int. Conf. on Optimization of Electrical and

Electronic Equipment. OPTIM 2008., pages 185–190,

Brasov, Romania.

Lazar, C. and Burlacu, A. (2009). Visual servoing of robot

manipulators using model-based predictive control.

In 7th IEEE International Conference on Industrial

Informatics. INDIN 2009., pages 690–695, Cardiff,

Wales.

Ma, Y., Soatto, S., Kosecka, J., and Sastry, S. (2003). An

Invitation to 3-D Vision. Springer.

Mansard, N., Remazeilles, A., and Chaumette, F. (2009).

Continuity of varying-feature-set control laws. IEEE

Trans. on Automatic Control, 54(11):2493–2505.

Marchand, E. and Chaumette, F. (2005). Feature track-

ing for visual servoing purposes. Robotics and Au-

tonomous Systems, 52(1):53–70.

Perez-Cisneros, M. and Mora-Galvez, A. (2005). Real-time

robotic visual servoing using reinforcement learning

agents. In Proceedings of the IEEE International Con-

ference on Information and Automation, pages 215–

220.

Siciliano, B., Sciavicco, L., Villani, L., and Oriolo, G.

(2009). Robotics’ Modelling, Planning and Control.

Springer, London.

Stoll, J., Novotny, P., Howe, R., and Dupont, P. (2006).

Real-time 3d ultrasound-based servoing of a surgical

instrument. In Proceedings of the 2006 IEEE Interna-

tional Conference on Robotics and Automation, pages

613–618, Orlando, Florida.

Tamadazte, B., Arnould, T., Dembele, S., Lefort-Piat, N.,

and Marchand, E. (2009). Real-time vision-based mi-

croassembly of 3d memss. In IEEE/ASME Int. Conf.

on Advanced Intelligent Mechatronics, AIM 2009,

pages 88–93, Singapore.

VISAPP 2011 - International Conference on Computer Vision Theory and Applications

510