GENERATING MULTIDIMENSIONAL RESPONSE SURFACES

FROM PROCESS DATA

Finding Optimal Set Points for Machine Control

Wolfgang Mergenthaler, Jens Feller, Bernhard Mauersberg

FCE Frankfurt Consulting Engineers GmbH, Altmünsterstrasse 2D, D-65439 Flörsheim, Germany

Roger Chevalier

Electricité de France, R&D, 6, Quai Watier, F-78401 Chatou Cedex, France

Keywords: Multidimensional Response Surfaces, Nonlinear Optimization, Dynamic Programming, Gaussian Shapes,

Adaptive Control, Statistical Learning.

Abstract: Technical processes, notably in the power transforming industries, generate a wealth of process data,

commonly organized in a file with M records and 1 + n + m fields, i.e. a time stamp, followed by n

independent and m dependent variables, summarized in the vectors x and y, respectively. Regardless of the

availability of physical models it is interesting and often necessary to generate functional relationships

between x and y from process data. The most prominent purpose is the optimization of certain performance

indices under given constraints. This paper describes response surface estimation using Gaussian shapes

along with finding optimal points on the surfaces to be used in machine control. The practical impact lies in

the usability of this technique to increase machine efficiency on a broad industrial scale with its applications

towards energy efficiency and climate protection.

1 INTRODUCTION

Technical processes, notably in the power

transforming domain, continuously produce a large

series of data at a given sampling rate determined by

a time interval

0>Δt

. At any particular time

assume there are M records given, organized into a

time stamp, n independent (or state) variables and m

dependent (or response) variables. These fields are

summarized in the n- and m-dimensional vectors x

and y. For instance, when monitoring power

generating systems such gas turbines, there are up to

1200 signals monitored simultaneously, comprising

ambient conditions, pressures, temperatures, mass

flows, guide vane angles, vibration amplitudes in

various channels etc. Not all of those, of course, find

their place in physical models, which are usually

dominated by thermodynamics, but reveal a lot of

information about the system, worthwhile to be

exploited.

Therefore, whether or not there is a physical

model expressing y – or, rather, its expected value –

in terms of x, it is always useful and sometimes

necessary to estimate the functional dependence,

using process data only.

With such a functional dependence established, a

multitude of applications in system control, process

optimization and experimental design come into

view.

It is the goal of this paper to show that there is a

class of functions, called linear combinations of

Gaussian shapes below, which allow to approximate

an arbitrary cloud of points precisely and can be

differentiated continuously infinitely often. This

property is conducive to many tasks in mathematical

optimization and machine control, as shown below.

2 MODEL

Let this functional relationship be described by a

function y, where

ε

+

=

)(xfy

(1)

mn

RRf →:

(2)

and

ε

, for the sake of simplicity, is assumed to be a

397

Mergenthaler W., Feller J., Mauersberg B. and Chevalier R..

GENERATING MULTIDIMENSIONAL RESPONSE SURFACES FROM PROCESS DATA - Finding Optimal Set Points for Machine Control.

DOI: 10.5220/0003408703970404

In Proceedings of the 8th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2011), pages 397-404

ISBN: 978-989-8425-74-4

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

random vector with

nxn

ICovE == ][ ,0][

ε

ε

(3)

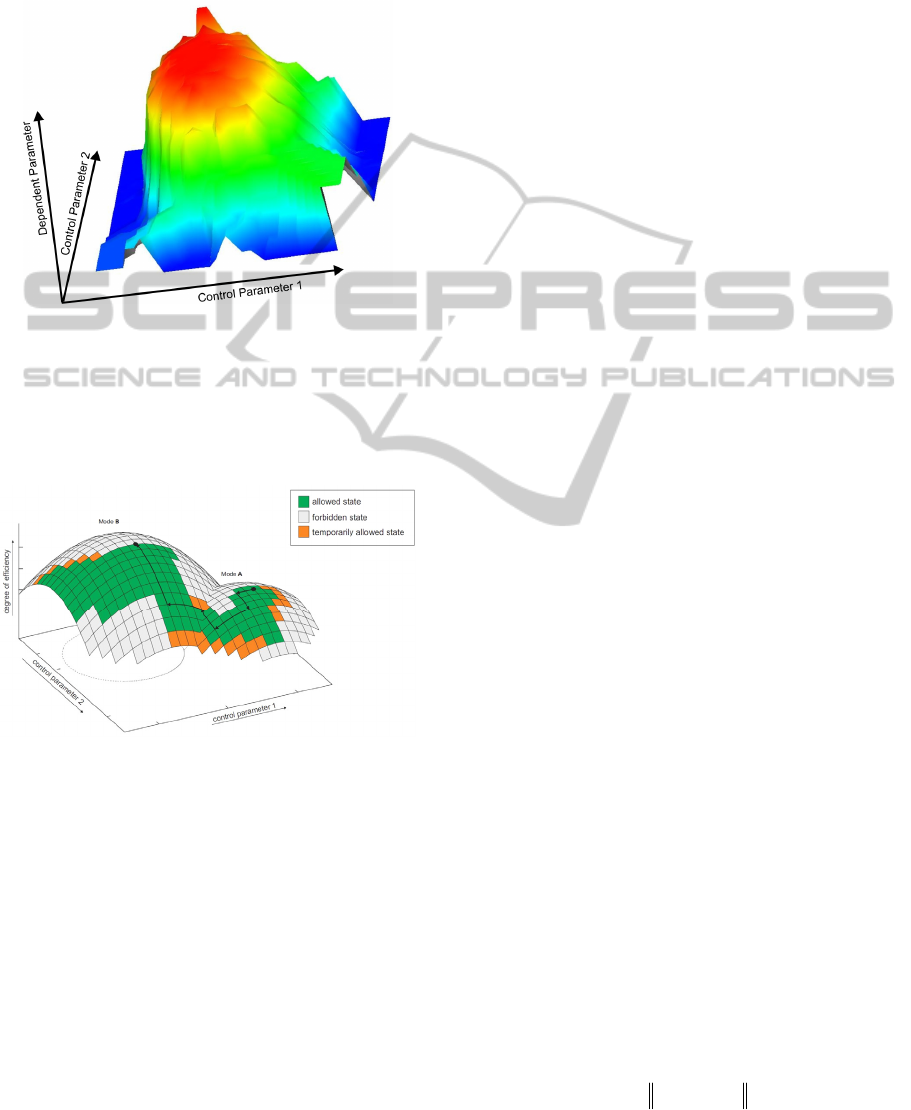

Figure 1 shows, in the special case of n=2 and m=1,

a practical example of a response surface:

Figure 1: Empirical Response Surface.

Please note that the data underlying this figure as

well as the following figure are arbitrarily selected

from among the authors' pool of data and only serve

the purpose to explain principles.

Figure 2 shows a schematic idealization:

Figure 2: Schematic Idealization.

There is one – particularly important – example for

the use of response surfaces in controlling industrial

processes. Assume that in a fossil power plant such

as a gas turbine, two of the response variables are

given by the power output and the NO

x

emissions,

while one particularly important independent

variable is the gas inflow. It may then be of interest

to find that particular input variable

n

Rx ∈*

which

maximizes power output given gas inflow and an

upper limit on the NO

x

emissions or minimizes gas

inflow for given power output and - again - an upper

limit on the NO

x

emissions etc. In other words, one

is interested in maximizing efficiency for given

power output under additional conditions.

This optimal value can be found in a twofold

procedure, whereby the first step consists in finding

the m response surfaces corresponding to the m

response variables given by formula (1) and the

second step is expressed as

)(

1

xfMax

n

Rx∈

(4)

such that

g(x)f

<

=

2

(5)

and

03

f(x)f

≤

(6)

where f

1

(x), f

2

(x), f

3

(x), p and f

0

are power output,

gas inflow, emissions, gas available and emission

limit, respectively.

In a third step, whenever a process is in a state

n

Rx ∈ a sequence of “control variables” must be

found, which drives the process towards the optimal

state

n

Rx ∈* .

In this paper it is shown how to find the

functional relationship f, how to use this in order to

find an optimal operating point under given

constraints and how to use the optimal operating

point in an adaptive control policy. An example

concludes this research.

It is to be noted that the time dependency

between signal records plays no role in this paper,

because, in finding optimal operating points, as well

as regression with given input variables as

arguments, time is not used as a regressor. Therefore

time series analysis as expressed in ARMA or

ARMAX techniques (Bhattacharya, 2009) remains

in the background.

3 FINDING THE RESPONSE

SURFACE

This step asks for the solution of a certain type of

multidimensional approximation problem, wherein -

simultaneously - m real functions of n real variables

are to be approximated.

3.1 The Least Squares Principle

The method suggested in this paper uses the least

squares principle where the objective function is to

be minimized by an appropriate selection of the

function f. While classical response surface

∑

=

−=

M

i

ii

xfyfZ

1

2

)(:)(

(7)

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

398

methodology mostly works with quadratic forms of

the response variable with respect to the input

variables, see for instance (Myers, 2009) and

(Oezer, 2004), in this paper f is to be selected from

among the more general set of twice continuously

differentiable functions mapping

n

R

onto

m

R

.

From the practical point of view this requires an

idea about the functional dependence of f(x) on

n

Rx ∈ . Once this functional relationship is

established and expressed in a formula with

appropriate parameters, minimization over the

function space is reduced to minimization over the

appropriate parameter space.

3.2 Linear Combinations of Gaussian

Shapes

A possible choice for the functional relationship is

an element-wise linear combination of Gaussian

shapes such that

)()(

1

)(

1

1

)()()(

)(

:

:)(:),,;(:)(

j

k

j

k

T

j

k

j

xAx

N

k

j

k

m

j

j

j

m

j

j

ece

xfeAcxfxf

μμ

μ

−−−

==

=

∑∑

∑

=

===

(8)

In (8) e

j

is the unit vector in j-direction, N

(j)

is the

number of Gaussian shapes used in approximating

f

j

(x), c

k

(j)

,

},...,1{

)( j

Nk ∈

is the height of the k-th

shape for the corresponding element,

μ

k

(j)

is the

corresponding location vector and A

k

(j)

the

corresponding shape matrix. The symbols c,

μ

and A

are abbreviations as explained in the appendix. An

additional stipulation is that the matrices A

k

(j)

are

required to be positively definite. Moreover, with

this choice of functional representation, one works

with functions that are infinitely often - not just

twice - continuously differentiable. Also these

functions tend towards zero with either of its

arguments going to infinity, having no poles or wild

erratic oscillations and therefore, being less prone to

overfitting the data.

Expanding the Euclidean norm in (7) it can be

seen that

},...,1{

)²,(

))²((:)(

with)()(

)()(

1

)(

1

)(

1

)(

1

)()()(

)(

mj

ecy

xfyfZ

fZfZ

j

k

i

j

k

Tj

k

i

j

xAx

N

k

j

k

M

i

j

i

ij

M

i

j

ijj

j

m

j

j

∈

−

=−=

=

−−−

==

=

=

∑∑

∑

∑

μμ

(9)

The minimization method for the objective function

amounts to solving separately m individual

minimization problems with the objective functions

Z

j

(f

j

). Each of these minimization problems requires

finding values for the decision variables

()

()

() ()

() ²

{1,..., }

{1,..., }

{1, . . . , }

j

j

k

jn j

k

jn

k

NM

cR

jm

Rk N

AR

μ

⎫

∈

⎪

⎫

∈

⎪

∈

⎪

⎬

∈∈

⎬

⎪

⎪

⎪

∈

⎭

⎭

(10)

Since N

(j)

is a discrete parameter and all other

parameters are real, the minimization problems are

mixed integer real. Therefore, if derivative based,

non-linear minimization techniques are to be used

such as Fletcher-Reeves etc., see (Press, 2007), one

must resort to a trick, whereby N

(j)

is deliberately

given a sufficiently high value and it is left to the

height variables c

k

(j)

to emphasize and eventually

eliminate one or the other of the Gaussian shapes.

Even if this trick works, there is always the risk of

being trapped in a local minimum.

Both problems can be overcome simultaneously

by using a local search technique such as Simulated

Annealing, for instance, see (Press, 2007) and

(Rayward-Smith, 1996).

It is important to note that for each input dataset

MiRRyx

mn

ii

,...,,),( ∈×∈

(11)

there is a representation (8) which approximates the

response variables to any desired degree of

precision, the exact proof of which is very technical

and will be omitted here. The proof follows along

the following lines, however: For each response

variable one begins with M shapes, each as high as

the corresponding response variable and located

right at the corresponding input point, with an

arbitrary shape matrix. The shape matrices are then

narrowed down consecutively until for each shape,

the impact of remote shapes is small enough to

satisfy the precision requirement.

3.3 A Note on Overfitting

Like any approximation problem on the real line, it

is necessary to limit the risk of overfitting by

checking the goodness of fit of the minimization

routine on a validation set of points, which are not

used in tuning the model parameters. This task is

currently in progress between the authors.

GENERATING MULTIDIMENSIONAL RESPONSE SURFACES FROM PROCESS DATA - Finding Optimal Set

Points for Machine Control

399

4 FINDING THE OPTIMAL

POINT ON THE RESPONSE

SURFACE

In contrast to (Ribeiro, 2010) the analysis described

in the present paper considers only one response

variable, which determines the optimal operating

point, while more than one response variable may

appear in the constraints.

This step will be analyzed under the two

different scenarios of unconstrained and constrained

optimization.

4.1 Unconstrained Optimization

Assume that one arbitrary response variable

},...,1{* mj ∈

(12)

is to be maximized, i.e.

)(*)(

**

xfMaxxf

j

Rx

j

n

∈

=

(13)

Two special cases must be considered. In case 1

one assumes that N

(j)

=1. Then, due to the positive

definiteness of the shape matrices as required above

and the monotonicity of the natural logarithm,

maximizing f

j*

(x) with respect to x is equivalent to

minimizing

(*) (*) (*)

11 1

(): ( ) ( )

jT j j

xx Ax

αμ μ

=− −

(14)

which yields the simple result

*)(

1

*

j

x

μ

=

(15)

In case 2, i.e. whenever N

(j)

>1, one must either

use a non-linear search technique with several

randomized starting points or a local search

technique. In view of (15), a plausible choice for the

starting point may be

∑

∑

=

=

=

*)(

*)(

1

*)(

*)(

1

*)(

0

j

j

N

k

j

k

j

k

N

k

j

k

c

c

x

μ

(16)

There is a variety of such search techniques, as

can be seen in (Press, 2007) and (Speyer, 2010), for

example. However, simple application of the first

order necessary conditions of any optimal point to

f

j*

(x), i.e.

0)(

*

=

∇ xf

j

(17)

yields, along with (8), the following equation:

)(*)(

1

xbxHx

jj

−

=

(18)

with

)()(

1

)()(

)(

1

)(

)()(

)(

)(

)()()(

)(

)()()(

:)(

:)(

j

k

j

k

N

k

xAx

j

kj

N

k

j

k

xAx

j

kj

Aecxb

AecxH

j

j

k

j

k

T

j

k

j

j

k

j

k

T

j

k

μ

μμ

μμ

∑

∑

=

−−−

=

−−−

=

=

(19)

Observing that in (18) the right hand side

depends on x as well, one may try to find an iterative

expression with

...3,2,1

)(*)(

)1(1)1()(

=

=

−−−

k

xbxHx

k

j

k

j

k

(20)

hoping, for the time being, that H

j

(x) is invertible

and (20) represents a contracting map. (20) may be

generalized to the case of constrained optimization

using the Lagrange function or a penalty term. In

any case observe, that it bears a certain resemblance

to the quadratic programming problem.

4.2 Constrained Optimization

As a representative of the multitude of potential

constrained optimization problems assume that one

must maximize a particular response variable j*

while all the other ones are to stay within a certain

upper limit, which amounts to solving the following

minimization problem:

*}{},...,1{,)(

))((

,0

*

jmjfxf

xfMin

jj

j

Rx

n

−∈≤

−

∈

(21)

Introducing a slack variable

1m

j

R

ξ

−

∈

(22)

one easily sees that solving (21) is equivalent to

solving a non-linear minimization problem with the

following Lagrangian:

∑

−∈

−−

+

−

=

*}{},...,1{

,0

*

²))((

))(();(

jmj

jjjj

j

xff

xfxL

ξλ

λ

(23)

see (Speyer, 2010). Finding a solution to (23) with a

derivative based non-linear minimization technique

may be attempted by a large scale Sequential

Quadratic Programming Problem such as described

in (Gill, 2005), for instance.

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

400

However, in this situation local search heuristics

can be used again by noting that the objective

function -f

j*

(x) can be augmented by a penalty

function which assumes increasingly high values, if

the constraints

*}{},...,1{,)(

,0

jmjfxf

jj

−∈≤

(24)

are violated. The smallest such penalty function can

then be used in the solution.

5 APPROACHING THE

OPTIMAL POINT ON THE

RESPONSE SURFACE

Assume that, at a certain time

,...}3,2,1{,* ∈Δ= ltlt

(25)

throughout operation of the process under

consideration, the process state is equal to

n

Rx ∈

~

(26)

with

*

~

xx ≠

(27)

indicating operation under sub-optimal conditions. It

is then important to find a sequence of control

variables

ww

RuRu ∈∈

τ

,...,

1

(28)

for some

,...}3,2,1{∈w

(29)

and some

,...}3,2,1{∈

τ

(30)

5.1 Deterministic Case

Here one assumes that

*),(

...

),(

~

1

111

xuxxx

uxxx

xx

ttt

ttt

t

==

=

=

−+++

++

ττττ

(31)

Assume there is a cost

γ

(x

t+k-1

,u

k

) attached to the

transition

1

,,{1,...,}

tk k tk

xuxk

τ

+− +

→∈

(32)

The total transition cost is then given by

∑

=

−+

=

τ

τ

γ

1

11

),(:),...,,(

k

kktt

uxuuxC

(33)

As long as a transition law as given in (31) can be

found, (33) can be - again - minimized using either

non-linear minimization or local search.

5.2 Stochastic Case

Assume that the transition from x

t+k-1

to x

t+k

under

the control u

k

, k=1,2,...,

τ

takes place in a stochastic

manner such that the distribution density of x

t+k

is

given by a density

1

(; , ):

nw n

tk k

gzx u R R

+

+−

→

(34)

The expected cost under the control policy u

1

,...,u

τ

is

given by

dzuxzguuzC

uxuuxC

t

R

tt

n

),;(),...,,(

),(),...,,(

12

11

∫

+

+=

τ

τ

γ

(35)

The optimal policy u

1

*,...,u

τ

∗

leading to the minimal

expected cost C*(x

t

,u

1

*,...,u

τ

*) satisfies the

Bellman equation

}*),;()**,...,,(*

*),({

*)*,...,,(*

12

1

*

1

1

dzuxzguuzC

uxMin

uuxC

t

R

t

Ru

t

n

w

∫

+

=

∈

τ

τ

γ

(36)

see (Bhattacharya, 2009). The Bellman-equation can

be solved by means of the classical dynamic

programming approach and - again - by local search

techniques such as Simulated Annealing.

6 EXAMPLE

The problem considered in this example consists in

solving efficiency related optimization problems for

an input file with n = 8 independent variables and m

= 2 response variables. The two response variables

considered are power output and NO

x

emissions. M

= 4560 records were available. The data correspond

to a gas turbine in a French power plant. All of the

signals have been normalized to values between 0.0

and 1.0 each.

As a constrained optimization problem Power

output (response variable 1) will be maximized

while a series of constraints, partly referring to gas

inflow - one of the control variables - and partly

referring to NO

x

emissions (response variable 0) will

GENERATING MULTIDIMENSIONAL RESPONSE SURFACES FROM PROCESS DATA - Finding Optimal Set

Points for Machine Control

401

be imposed. It will be shown that the data contained

in the input file, when filtered with respect to those

constraints, already exhibit some variance in

response variable 1, without the smoothing effect

brought about by response surface modelling.

6.1 Input Data

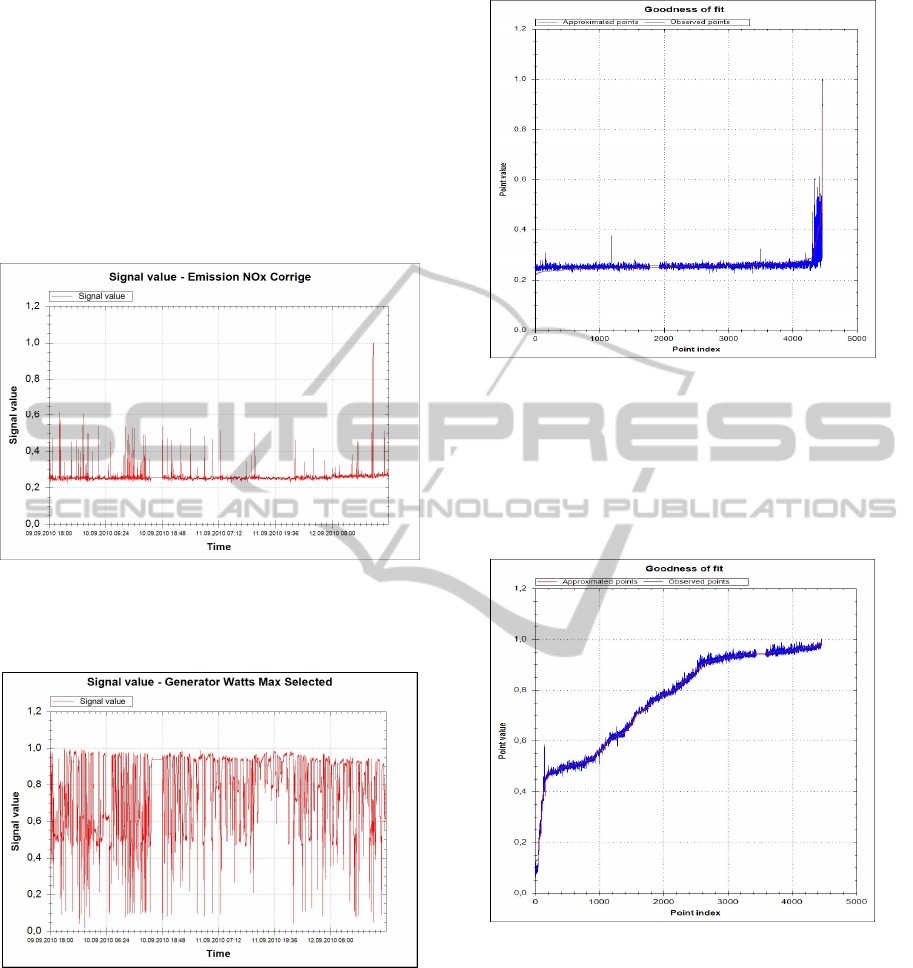

Figure 3 shows the time trajectory of the NO

x

emissions throughout the time period under

consideration:

Figure 3: NO

x

emissions - Time Trajectory.

Figure 4 shows the time trajectory of the power

output:

Figure 4: Power output - Time Trajectory.

6.2 Results

Results for this example are given for steps 1 and 2

only. Developing optimum control policies is

ongoing research at this time.

6.2.1 Approximation

Figure 5 shows the goodness of fit for NO

x

emissions as a result of the approximation:

Figure 5: NO

x

emissions - Goodness of Fit.

Please note that - for ease of comparison - the

approximated points have been ordered increasingly

with respect to size and that the corresponding input

values, i.e. those with equal input variables have

been juxtaposed accordingly. Figure 6 shows the

goodness of fit for the power output:

Figure 6: Power output - Goodness of Fit.

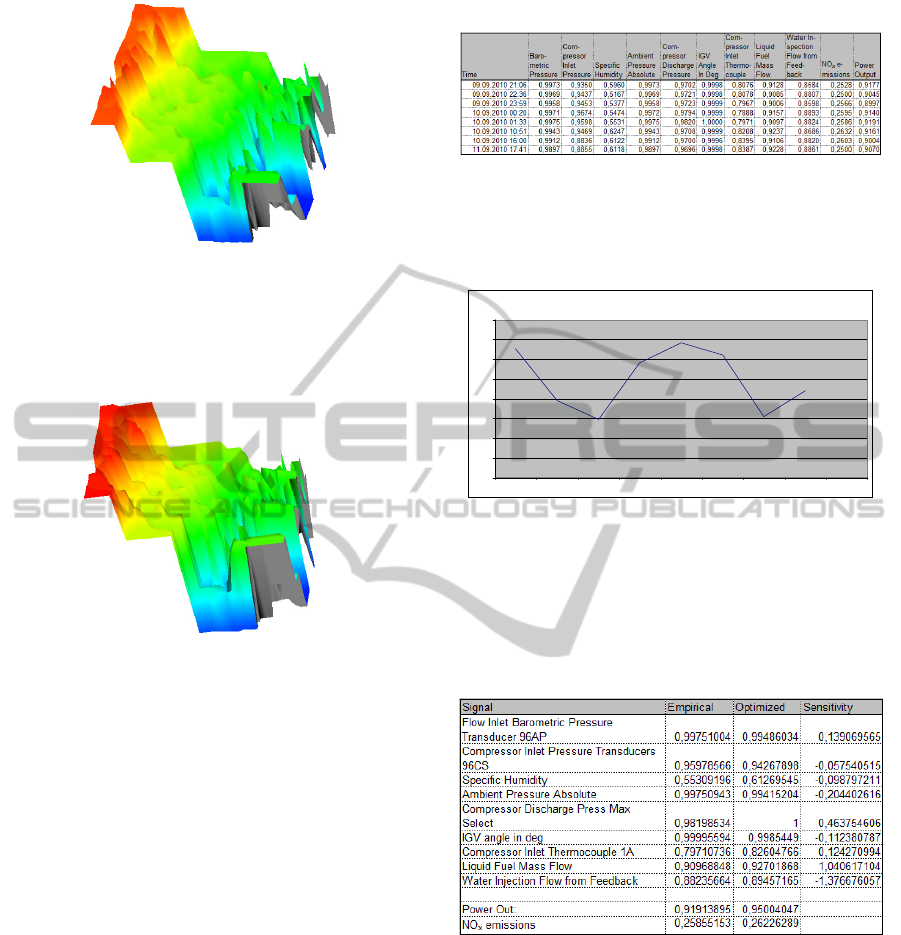

Figure 7 shows a three-dimensional representation

of the empirical power output as contained in the

input data as a function of the input variables 0 and

1 (Barometric pressure and Compressor inlet

pressure, see below), whereby all the remaining

input variables have been set equal to their

respective midpoint between minimum and

maximum:

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

402

Figure 7: Three-dimensional representation of empirical

power output with respect to control variables 0 and 1.

Figure 8 is the analogous representation with the

empirical power output replaced by its theoretical

counterpart obtained from approximation:

Figure 8: Three-dimensional representation of theoretical

power output with respect to control variables 0 and 1.

The good visual agreement between figures 7 and 8

is another view on the goodness of fit as shown in

figure 6.

6.2.2 Efficiency Maximization

Optimization Problem

The problem considered was to maximize Power

output under the following constraints:

Compressor Discharge Pressure >= 97% of

Maximum

NO

x

emissions <= 40% of Maximum

IGV guide angle >= 99,90% of Maximum

Liquid Fuel Mass Flow <= 93% of

Maximum

Water Injection flow <= 89,4% of

Maximum

Input Data Filtered with Respect to Constraints

Table 1 shows the subset of input data resulting

from filtering the records with the constraints as

shown above:

Table 1: Input data filtered with respect to constraints.

Table 1 reveals that already within the filtered

dataset power output shows a variance of roughly

2% with respect to the maximum value of 1.0,

keeping the normalized range of values in mind, as

illustrated in figure 9:

Power Output

0,885

0,89

0,895

0,9

0,905

0,91

0,915

0,92

0,925

123456789

Figure 9: Variance in power output in the filtered dataset.

Optimization Results

Table 2 shows the mathematical solution to the

optimization problem stated above with respect to

both input variables and response variables:

Table 2: Optimization Results.

The following comments must be made in order to

properly interpret these results:

The column titled Empirical lists the values of

all the input variables corresponding to that

particular record in the filtered input file - see

table 1 - with maximum overall power output.

This goes along with an NO

x

emission value of

25.85 % of the maximum as shown in the

corresponding line and 91.91% of maximum

power.

The column titled Optimized lists the values of

the input variables corresponding to the solution

of the constrained optimization problem. It can

GENERATING MULTIDIMENSIONAL RESPONSE SURFACES FROM PROCESS DATA - Finding Optimal Set

Points for Machine Control

403

be noted that all of the constraints are satisfied

to a good degree of precision:

o Compressor Discharge Pressure = 100% >=

97% of maximum

o NO

x

emissions = 26,23% <= 40% of

maximum

o IGV angle = 99.85% <= 99.9% required

o Liquid Fuel Mass Flow = 92.70% of

maximum versus <= 93% required

o Water Injection flow = 89,45% of

maximum versus 89,4% required

Yet there is a theoretical increase in the Power

output of approximately 3.09%=95.00%-

91.91%. Comparison of the ratio of Power

output divided by Liquid Fuel Mass Flow

reveals an efficiency increase from the optimal

element in the filtered dataset to the

mathematical solution of the constrained

optimization problem of 1.43%.

The column titled Sensitivity is the partial

derivative of the Power Output with respect to

the input variable in question, averaged over the

input space using the sample of input data.

It must be noted that the solution to the

optimization problem must be verified against

the criteria of technological feasibility. For

instance, turbine inlet temperature must not

exceed a fixed value and no optimal operating

point must violate this additional constraint.

7 SUMMARY

The present paper presents a technique to generate

Gaussian response surfaces from high dimensional

data and shows how to use them to find optimal

operating points with respect to process

characteristics such as Power output, NO

x

-

emissions, gas inflow etc.

There are two sources of optimization to be

expected through an industrial application of such

surfaces:

• Finding true optima by removing noise in the

data and appropriate smoothing

• Consistently using those optima as set points

in the context of adaptive control.

From the authors' point of view, many of the topics

considered in this paper will be central to future

research in the power industry around the world,

such as

• Fast optimization techniques in finding the

response surfaces, using a combination of non-

linear and local search techniques

• Fast optimization techniques to find the optimal

points on the response surfaces

• Embedding the algorithms inside machine

control hardware and software to name just a

few.

ACKNOWLEDGEMENTS

Our thanks go to our co-workers Sebastian Feller,

Yavor Todorov and Dirk Pauli for valuable hints in

numerical optimization techniques and to Tina

Condon for careful proof reading.

REFERENCES

Bhattacharya, R. N., Waymire, E. C. 2009. Stochastic

Processes with Applications. Society for Industrial

and Applied Mathematics (SIAM), Philadelphia

Gill, P. E., Murray, W., Saunders, M. A. 2005. SNOPT: A

large Scale SQP Algorithm. SIAM Review 47 (2005),

99-131

Myers, R. H., Montgomery, D. C., Anderson-Cook, C. M.

2009. Response Surface Methodology, Process and

Product Optimization Using Designed Experiments.

Wiley, Hoboken (2009)

Oezer, E. A., Ibanoglu, S., Ainsworth, P. 2004. Expansion

characteristics of a nutritious extruded snack food

using response surface methodology. Eur. Food Res.

Technol. 218 (2004), 474-479

Press, H. W. et al. 2007. Numerical Recipes, The Art of

Scientific Computing. Cambridge University Press;

Cambridge, MA, USA

Rayward-Smith, V. J. et al. (Eds.) 1996. Modern Heuristic

Search Methods. Wiley, Chichester

Ribeiro, J. S., Teófilo, R. F., Augusto, F., Ferreira, M. M.

C. (2010). Simultaneous optimization of the

microextraction of coffee volatiles using response

surface methodology and principal component

analysis. Chemometrics and Intelligent Laboratory

Systems 102 (2010), 45-52

Speyer, J. L., Jacobson, D. H. 2010. Primer on Optimal

Control Theory. Society for Industrial and Applied

Mathematics (SIAM), Philadelphia

APPENDIX

Definition of c,

μ

and A:

}},...,1{},,...,1{,{:

)()(

mjNkcc

jj

k

∈∈=

}},...,1{},,...,1{,{:

)()(

mjNk

jj

k

∈∈=

μμ

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

404