DISCRETE EVENT SIMULATION FOR A COMPLEX HIGH

POWER MEDICAL SYSTEM

Oliver Heuermann

1

, Wolfgang Fengler

1

and Reinhard Langmann

2

1

Computer Architecture Group, Technische Universität Ilmenau, Ilmenau, Germany

2

Dept. of Electrical Engineering, FH-D University of Applied Sciences, Duesseldorf, Germany

Keywords: MLDesigner, Discrete event simulation, Analytical modeling, Reliability, Lifetime extension, High power

tubes, Klystron, Magnetron, Thyratron, Accelerator, x-ray tubes.

Abstract: This position paper describes research activities in the scope of targeted lifetime extension of components

which are used in medical devices and systems as well as in high energy physics. The considered medical

areas are mainly in the therapy field as well as kV-imaging diagnostics. The focus of the analysis of medical

machines and systems with high-power tubes is on the x-ray-radiation or rf-power performance. On this

occasion, the operational behaviour of such tubes is of special interest. In this paper a methodology will be

presented to examine the specific influence of service life-determining parameters. For the implementation

of the methodology a discrete event simulation is constructed using the realtime design tool MLDesigner

from MLDesign Technologies, Inc. Studies can be carried out with regard to the tube service life in different

components. The simulation shows that the targeted specific influence on the service life-determining

parameters can prolong useful service life of a high power tube.

1 INTRODUCTION

1.1 Motivation

As part of research work at the Computer

Architecture Group of the Technical University

Ilmenau (Technische-Universität-Ilmenau) the

default behavior of high-power tubes used in

medical equipment is investigated. The focus of this

research work aims on the development of new

business and application models for service life

extension of equipment in medical technology. To

develop appropriate additional sensors and condition

monitoring concepts, it is especially necessary to

provide a detailed look at the life-defining

parameters. With the help of modeling a realtime

discrete event simulation, the theoretical

assumptions of the research work, meaning, that by

means of a targeted control of service life-

determining the parameters, the whole useful service

life of high power tubes can be extended essentially,

will be investigated. The expected outcome of this

investigation is the consolidation of the theoretical

assumptions by means of an appropriate physical

experiment. The implementation of all required

information about the tube specific life-defining

parameters will improve the uptime of high power

medical systems.

1.2 Context

Functions in a medical system (eg radiotherapy

equipment, particle therapy, computed tomography,

mammography and angiography equipment) use, for

diagnosis or treatment, high-power tubes such as

klystrons, magnetrons, thyratrons, x-ray tubes, and

linear accelerators. The flow of diagnostic and

therapeutic applications is to be modeled and

investigated by means of a simulation. An

investigation of the relationship between the

loadprofile of a system and the service life of a tube

used in that system is possible.

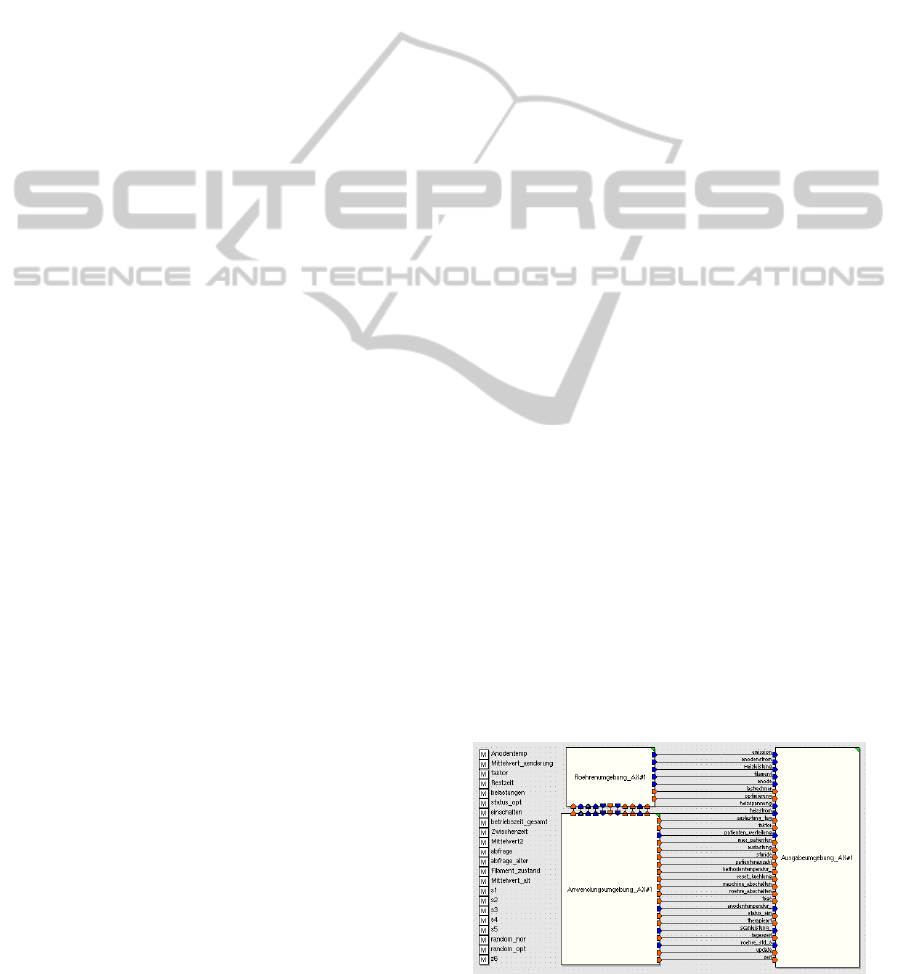

Partial models for hardware and software of the

control system as well as of the electronic and

electromechanical components are necessary.

Exemplary models of high tubes are established and

inserted into the simulation system (Figure 1).

Partial models are to be interchangeable (see also

Section 2.1, Figure 6) for use in simulations for

different application fields. In Figure 1 a typical

structure of a high-power tube-driven medical

system is shown.

395

Heuermann O., Fengler W. and Langmann R..

DISCRETE EVENT SIMULATION FOR A COMPLEX HIGH POWER MEDICAL SYSTEM.

DOI: 10.5220/0003458503950400

In Proceedings of 1st International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2011), pages

395-400

ISBN: 978-989-8425-78-2

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

Figure 1: MLDesigner simulation structure overview.

It is necessary to establish a basic tube model for the

simulation tool MLDesigner (MLDesign Technologies,

Inc. 2007), as well as the implementation of

predefined algorithms and methods for evaluation of

the tube-data (Heuermann, 2006). The tube data

used for the simulation model consist of a tube-

specific set of transfer characteristic curves like

heater curve (filament voltage and current), uP

(relation between filament power and cathode

current at a given tension), efficiency, gain, electron

beam focussing currents, current density with a

given emitter material and -dimension at a certain

tension as well as specific cathode activation

schedules to convert carbonates to oxide and

evaporation rates (see for example Figure 5 and

corresponding equation (1)). The required tube data

set has to be measured for each tube, digitized,

approximated and can then be used to build a tube

simulation model.

The structure of the system model is done in

several phases. The first priority is the development

of a basic tube (realized in the block “Tube”, Figure

1 and the equal to the block

“Roehrenumgebung_AX#1” in Figure 6), complying

with a typical x-ray tube, just the way it is used in

most cases in practice. Based on these results of the

modeled tube, an optimized design is created, in

which the predetermined factors affecting service

life-determining parameters are changed selectively.

By a direct comparison of the two models, with and

without optimization, a very accurate statement on

the expected life of such a tube for a certain

loadprofile is possible (Wippler, 2007, Krestel,

1988).

2 BACKGROUND

The life of vacuum tubes, used to produce radiation

(reception, screening, treatment and therapy) in the

medical technology, is determined to a large extent

by the emission of the cathode. During the period of

usability, in all type of tubes, directly as well as

indirectly, heated cathodes, and “cold” emitting

cathodes, a reduction of the electron emitting

material can be noticed (eg filament evaporation rate

and barium evaporation rate). Some of the service

life-determining parameters for the vacuum tubes

used in medical technology are as follows:

X-ray/Carbon nano tubes:

• anode roughening, anode heat capacity,

filament evaporation rate, scan-seconds

load (load profile), temperature, timing,

arcing

They have a finite, but not in all applications

reliable, predictable service life and must be

replaced by the facility to ensure availability.

High Power Tubes:

• cathode roughening, barium evaporation

rate, beam-seconds load (load profile),

temperature, gascomposition/vacuum

quality, ion back-bombardement, timing,

arcing

They have a finite, but unpredictable service life and

must be replaced at short notice by the facility to

ensure availability (Heuermann, 2010).

In the field of x-ray tubes, there are procedures

for lifetime prediction known, e.g. used in high

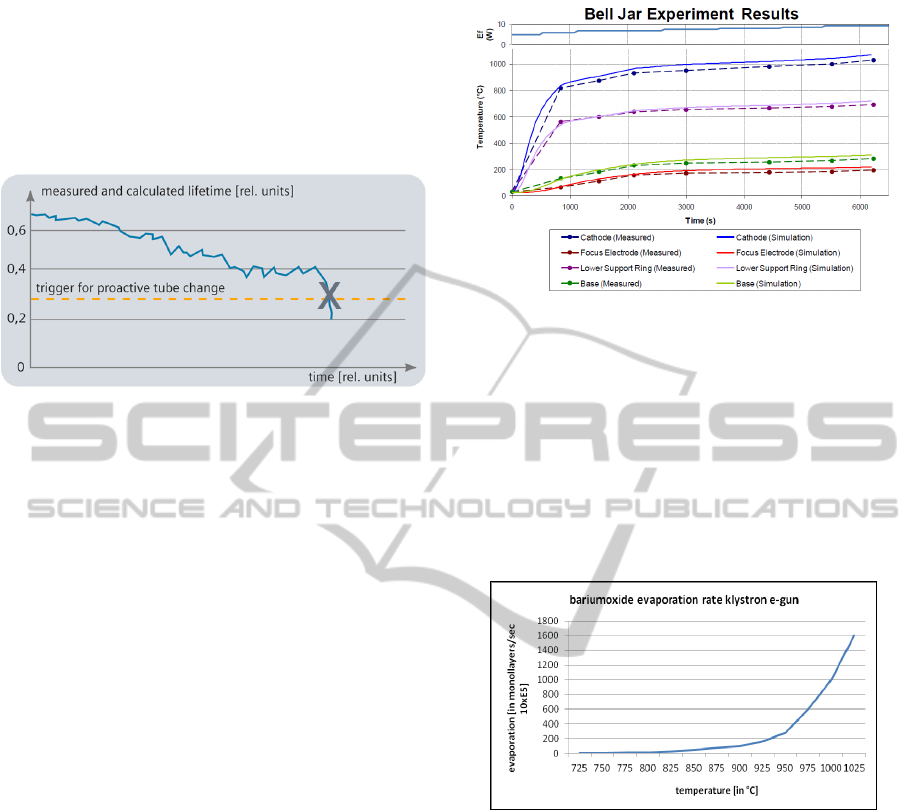

resolution CT-systems (Figure 2). The analysis of

input vectors, taking into account disturbance

vectors, generates output vectors. These output

vectors do reliably produce predictable lifetime

calculations with high confidence. In prior art

solutions mostly the condition monitoring is

restricted to the view from the “outside” on the

physical behaviour of the tube (Heuermann, 2006,

2007).

Figure 2: TubeGuard@CT structure overview.

In the field of high power tubes, usually the

resistance of the heater coil is measured. With the

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

396

knowledge of the used materials and the dimensions,

a thermal model can be created and the cathode

surface temperature of the direct heated tungsten

filament can be calculated. The emitter deterioration

(Figure 3) is based on sensor data of tube current

and filament current (Siemens Guardian Programm,

2007).

Figure 3: Measurement of emitter deterioration.

This procedure is used for the calculation of the

cathode surface temperature, from which the

tungsten evaporation rate is dependent. The results

are limitedly usable for the cathode but not

sufficiently accurate for calculating the anode

surface temperature.

Many disturbance vectors, such as tube-stray

distribution, time dependant varying parameters of

the tube itself, and different ambient temperatures of

the object to be considered, alter the thermal balance

of the system, which is used for the calculation. As a

result, a heating scheme materializes that does not

match the actual existing surface temperature. As an

example (Figure 4) a thermal investigation done on

an e-gun is presented. The simulation was performed

by the manufacturer of the e-gun with a

COSMOS/M model. Cathode is 40°C, other points

20°C higher in the specific tube model. This results

in a shorter predicted service life. On the other hand,

if the model does not reflect the real thermal balance

the cathode temperature could be much higher. As

an example for the given dimensions of the used e-

gun, back-heating as a cause of ion-back-

bombardement (beam but no RF: 50°C, beam and

RF: 110°C) adds 60°C to the cathode surface.

As an example of the importance of accurate

surface temperature estimation, the effects in a

klystron will be explained as follows:

For a nominal surface temperature given with

890° C, production of only 50° C more temperature

on the surface results in twice as high barium

evaporation (Figure 5 and corresponding equation

(1)). The same is true for all types of high-power

tubes (klystron, magnetron, thyratron, accelerator),

which use barium enriched materials as an electron

Figure 4: Mismatch between simulated and measured

temperatures in an e-gun assembly.

emitter in the gun because of the low work function.

This released barium is deposited on the cold

spots in the tube and provides gradually a reduction

of dielectric strength in the tube. The result is a high

voltage low impedance breakthrough (so called

arcing) (Heuermann, 2007, 2010).

f(x) = 2 E-08 x

5

– 8 E-05 x

4

+ 0,116 x

3

-

84,73 x

2

+ 30547 x – 4 E+06

(1)

Figure 5: Example of evaporation rate vs. temperature.

Researchers working on that topic, also

published solutions like continuously measuring the

µP (micro perveance) and keeping the cathode

current to 98% of the nominal value (Wright,

Oiessen, 2000). Another solution is to implement

thermo-couples in the cathode surface structure

(Noguchi, 1996).

These solutions represent the state of the art in

the field of condition monitoring for electron tubes.

The usual practice today is that tubes, depending on

the type (x-ray, klystron, magnetron, linac,

thyratron), are assigned to according maintenance

contracts, which stipulate an exchange at a certain

time. It is the top priority of the equipment

manufacturers, to avoid tube-failures of this manner

from the very beginning. However, there is no

possibility to ensure a complete avoidance of

DISCRETE EVENT SIMULATION FOR A COMPLEX HIGH POWER MEDICAL SYSTEM

397

incidents. This is why, in so called unavoidable

circumstances, one would like to have at least a big

enough lead time, to ensure the exchange can be

made before there is a downtime of a system.

3 SIMULATION

The hospital-specific diagnostic and treatment

requirements are implemented into the simulation

environment. The daily routine of a clinic is

considered in the simulation, as well as a statistically

spread patient number, the load profile given by

logging files recorded over months will give all

necessary operating points. In a first step, manually

selected load profiles are used, the interface for on-

site recorded load profiles (.tua files = tube history

records) is in work.

Particularly interesting is the implementation of

the "optimization". The calculation of residual life is

based on the fact that all calculated life-critical

values are afflicted with an error reflected from

practise of about + -15%. This is due to

manufacturing tolerances of the tube and its

environmental factors. The thermal balance

calculated with the knowledge of the geometries and

materials does not show the correct value for the

surface temperature of the anode plate or the cathode

surface. The "optimization" deals with the

simulation exactly as before, but with a smaller

error: + -2%. This error is the assumed total residual

error of the measurement chain (pyrometer,

operational amplifiers, AD-converter) to measure

the surface temperature (Heuermann, 2010).

Creating a discrete event simulation, which is

extended and detailed as well as driven by real load

profiles from customer sites, enables reliable

investigations. The work has shown that

MLDesigner (MLDesign Technologies, Inc. 2007) is

the right tool for the reconstruction of the technically

physical processes within a medical system.

MLDesigner offers the possibility to use Markov-

Chains for the network theorem based system

(queuing networks with parallel and serial service

units) and probability tools like Poisson-distribution

as well as random generators for the patient arrivals.

During observation, it soon becomes clear that

the topic is a classic optimization problem. It is a

balancing act between maximized service life (carry

out the exchange as late as possible), and realizing

the avoidance of potential downtime. A statement of

this quality on the life of a high-performance tube

can not be given to this day in a satisfactory manner.

The existing studies and investigations are only

estimates and approaches. The complex relation-

ships and calculations within such a tube are seen

analyzed and evaluated from the outside of the tube

(Wippler, 2009, Heuermann, 2006).

The underlying research work pursues a

fundamentally new approach. This means a direct

view on the processes within the tube, instead of just

estimating. This allows examining the condition of

the tube much more in detail, with the result that the

statements on the processes are significantly more

related to reality.

A simple example is the surface temperature of

the cathode. So far, the temperature is calculated

according to complex procedures. Despite all

precision and complexity of observation, the result is

still estimation. The idea of the research works

however is just to measure the surface temperature

of the cathode. Thus, it is possible to respond to

changes almost immediately. The model to be

developed will shed light on whether it is precisely

this optimization, that will be prove decisive for the

substantial extension of the economic life of a high

power tube.

The realization of this comparison is carried out

by two simulation models. The basic model

corresponds to the current usage of high power

tubes, ie without any optimizations. Based on that

first developed basic model, a model extension is

designed. This serves a direct comparison between

the basic and extended model. These extensions

include the optimizations as discussed. Thereafter,

the data of the two simulation runs can be compared.

With the optimization, a service life extension

should be observed under normal circumstances. In

the simulation a very flexible block structure was

realized: An adaptive application environment (rep.-

rates, cathode/anode current, filament power,

patients/h etc.), a flexible exchangeable tube model

block and a load block which reflects the required

energy (e.g. 23MV, 21MeV, 160keV ect.) within an

individual diagnostic- or treatmentplan was

developed (Heuermann, 2007, 2010).

Figure 6: Encapsulated simulation environment for

angiography.

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

398

4 SIMULATION RESULTS

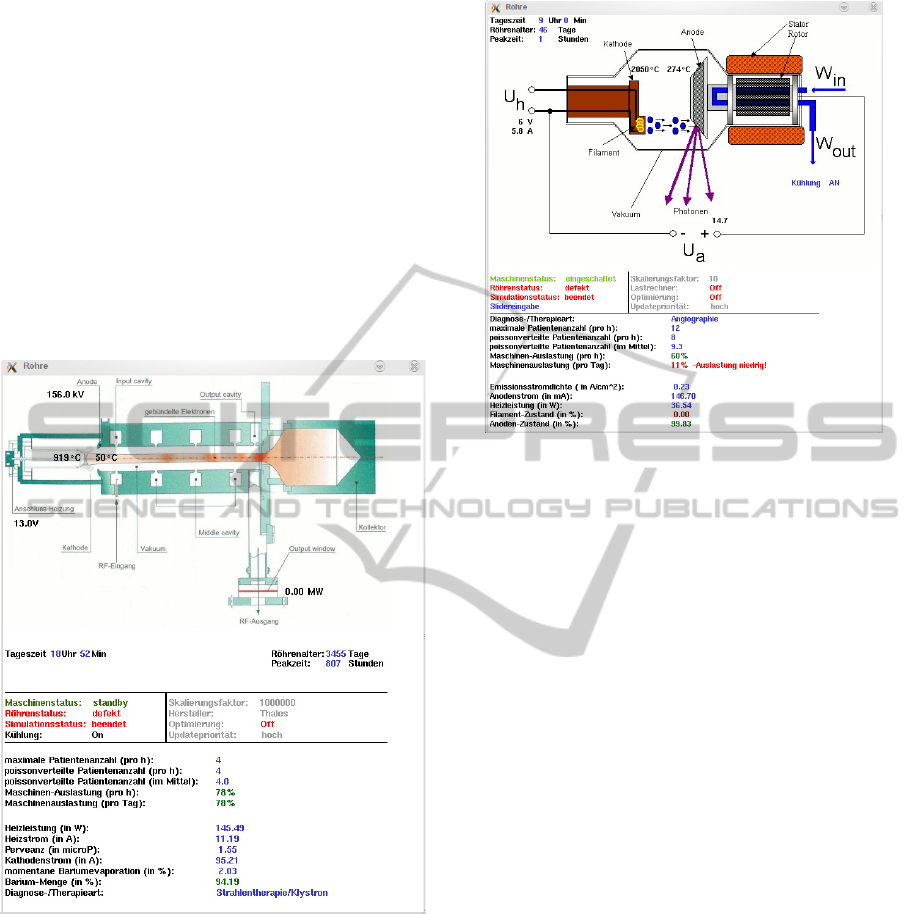

The simulation run for a klystron (Figure 7) and a x-

ray tube (Figure 8) shows patient count per hour,

statistically spread over one day, machine load

profile, actual condition of the gun and the anode.

The optimization option was off. Within the

optimization option two specific calculations will be

used. Once the exact cathode surface temperature

and second the gas pressure inside of the tube. Both

parameters will give the control system the most

significant service life-determining parameters. The

rate of change of µP and ion-back-bombardement

will indicate how fast the cathode is loosing

emission (Heuermann, 2007, 2009, 2010).

Figure 7: Simulation run example for a klystron.

Simulation result for 21MeV treatments (7,5MW

peak pulse power within 7µs beam-on-time) with 12

working hours, 260 working days, 4 patients per

hour, 13 minutes patient changing time:

Real beam on time: 807 hours

Useful service life: 3455 days in total results in

13,29 years

Reason for failure: end of life condition µP <= 1,56

reached

Figure 8: Simulation run example for a x-ray tube.

Simulation result for angiography diagnostic,

(15kW peak beam power within 10 sec. scantime)

with 12 working hours, 260 working days, 8 patients

per hour, 5 minutes patient changing time:

Real beam on time: 1 hour

Useful service life: 46 days in total

Reason for failure: heater overcurrent caused broken

filament

5 CONCLUSIONS

In the field of high-power tubes there is a large

development potential regarding service life

management and condition monitoring services to be

found.

A targeted control of the service life-determining

parameters extends the life of high-power tubes. As

proof of a life extension, a simulation model is used,

which provides information about the behavior of

service life-critical parameters. Results produced by

the simulation model are transferable to reality and

can be used in a practical implementation. The

simulation shows that a targeted control of service

life-determining parameters influences the overall

lifetime of a tube. In a next step, real load profiles

recorded at customer sites will drive the tube model.

These load profiles reflect the daily routine in a

hospital with the individual patient distribution and

their diagnostic and therapy schedules and, as a

result, the real tube load. This novel approach will

improve the uptime of medical systems. First results

from single x-ray-tube systems (CT, Angiography,

DISCRETE EVENT SIMULATION FOR A COMPLEX HIGH POWER MEDICAL SYSTEM

399

Fluoroscopy and Mammography) show that in case

of direct heated cathodes the predictive maintenance

works well. In case of multiple tube systems like

radiation therapy machines, at least three high power

tubes are used in one system, the proposed specific

methods for life extension of equipment and systems

in medical devices will increase the uptime

dramatically.

REFERENCES

Krestel, Erich, 1988. Bildgebende Systeme für die

medizinische Diagnostik. Berlin und München:

Siemens Aktiengesellschaft, ISBN: 3-8009- 1505-7,

1988.

Wippler, Denny, 2009. Konzeption, Design, Codierung

einer Simulation auf Basis des Simulationstools

MLDesigner zur Untersuchung einer

medizintechnischen Anlage. Diploma thesis,

Technische Universität Ilmenau, 2009.

Heuermann, Oliver, 2006. Lebensdauermanagement-

systeme in medizintechnischen Geräten und Systemen.

White paper, Erlangen, 2006.

Heuermann, Oliver, 2007. Electrical Parameters. White

paper, Erlangen, 2007.

Heuermann, Oliver, 2010. Röhre, insbesondere

Elektronenröhre, mit Mitteln zur Messung der

Elektrodentemperatur und Schutz hierfür. Patent,

Siemens AG: DE 10 2007 062 054 B4, 2010.

Heuermann, Oliver, 2009. Lernverfahren und Steuerung

für Röntgenröhren mit Multikathoden auf der Basis

von Feldemission. Patent application, Siemens AG:

2009P12684 DE, 2009.

Siemens Guardian Program, 2007. Siemens Guardian

Program Including TubeGuard for SOMATOM

Definition systems. Flyer, Siemens AG, 2007.

Noguchi, Ryoji, 1996. Active measurement of cathode

surface temperature. Patent, Sony Corp:

JP000010116566AA, 1996.

Wright, Edward L., Oiessen, Eric A., 2000, An adaptive

heater voltage algorithm and control system for

setting and maintaining a vacuum electron device.

Patent, Comm and Power Ind Inc (US):

US000006456009B1, 2000.

MLDesign Technologies, Inc., 2007. MLDesigner

Documentation. 2130 Hanover St, Palo Alto, CA

94306 (USA): 2007.

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

400