BUSINESS PROCESS MODELING AND SOA IN INDUSTRIAL

O&M APPLICATION DEVELOPMENT

David Hästbacka, Petri Kannisto and Seppo Kuikka

Department of Automation Science and Engineering, Tampere University of Technology

P.O. Box 692, FI-33101 Tampere, Korkeakoulunkatu 3, Tampere, Finland

Keywords: BPM, SOA, Application development, Orchestration, Operation and Maintenance, Industry.

Abstract: While striving to increase profits in global competition, companies are trying to improve efficiency and

reduce costs by outsourcing and focusing on their core functions. For operation of industrial plants this often

results in provision of services even for high-priority activities such as maintenance. Integration of external

information systems and service providers to business processes and information workflows brings new

challenges to application development in order to support introduction of maintenance services as efficiently

as possible. This paper discusses the approach of applying business process modeling and service-oriented

concepts to development of supporting software applications. Business process modeling is proposed for

describing service interactions and information flows, and to function as a foundation for the application

development. To satisfy required flexibility in changing business environments, the applications represented

as services are composed into executable process workflow orchestrations using standard Internet

technologies. To validate the approach a scenario consisting of a condition monitoring process and an

environment footprint estimator is presented.

1 INTRODUCTION

Operating models in manufacturing and process

industries have evolved in such a way that industrial

companies have to concentrate on their primary

production related functions in order to stay

competitive and profitable in the global

environment. This has led to provision of services

for non-core activities in the quest to improve

efficiency and reduce costs by outsourcing and

relying on services from business partners.

Operation and maintenance (O&M) of industrial

plants involves operative production and

maintenance of devices and systems as a whole.

Maintenance is an important factor in achieving high

utilization and productivity, and its activities depend

highly on operating processes and production

schedules. For task co-ordination, asset management

and sharing of mutually important data becomes

even more important when services of external

service providers are being used. This information is

required in performing the service or produced as a

result of it.

Unfortunately, a lot of this information exchange

is still transferred manually between enterprises, i.e.

from person to person or by email. Development of

applications to support O&M tasks is complicated

and the developed applications are challenging to

maintain due to heterogeneity among technologies

and practices. The work processes should be taken

into account for information exchange requirements,

and management of work processes and resources in

service collaborations should also be considered.

Our previous work in the area of Web service

technologies and O&M have shown inefficiencies in

the development of O&M applications. In order to

provide applications that better support operations in

distributed service environments, the degree of

automation in development has to increase. This

paper presents an approach based on business

process modeling (BPM) and utilization of service-

oriented architecture (SOA) in development of

applications to support O&M services. With process

modeling a mutual understanding of services and

information flows between participants can be

achieved. These models are then essential in

implementing the software applications that support

activities in the distributed environment.

SOA is an important facilitator in loosely

coupled information system integration and is well-

suited for cross-enterprise integration. The

277

Hästbacka D., Kannisto P. and Kuikka S..

BUSINESS PROCESS MODELING AND SOA IN INDUSTRIAL O&M APPLICATION DEVELOPMENT.

DOI: 10.5220/0003507202770285

In Proceedings of the 13th International Conference on Enterprise Information Systems (ICEIS-2011), pages 277-285

ISBN: 978-989-8425-55-3

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

autonomy and composability of services in SOA

provide means for management of service processes

and rapidly changing business environments.

To validate the approach, two different kind of

executable business processes were implemented to

illustrate integration of O&M activities and data

gathering. The first process is an activity triggering

condition monitoring process while the

environmental footprint estimator is used for

aggregating data to be used in decision support. The

results and findings of the implementations are

presented as well as examined for future research.

Section 2 presents background and related work

in the area of O&M in industry, BPM and SOA

advances. Section 3 presents the approach based on

business process modeling of O&M activities in

application development, and the service-oriented

aspects of information systems implementing

executable processes. The condition monitoring and

environmental footprint estimator processes are

presented in section 4, and the paper is concluded

with future work in section 5.

2 BACKGROUND AND RELATED

WORK

2.1 O&M in Industry

Current industrial manufacturing practices have

evolved into efficient and rationalized operation

processes. Utilization of expertise and supporting

services from various service providers has

increased as the emphasis of manufacturing is

focused more on core competencies. This has

resulted in extensive use of services, and in many

cases, from a large number of service providers.

Maintenance is an important supporting activity

that has been increasingly outsourced in

manufacturing and process industry. Levery (1998)

states that maintenance of productive assets is

outsourced for specialist maintenance where the

expertise is not available in-house or when repetitive

routine work is performed. He continues that

between these there are tasks, where maintenance

requirements cannot be defined clearly or be related

to certain assets of parts of the production process,

that require knowledge of in-house maintenance and

production process related information.

There are many different types of maintenance

strategies used that all require a lot of planning of

both preliminary schedules and tasks to be executed.

Whether it is reactive maintenance, in case of a

sudden failure, or a scheduled preventive

maintenance operation, the tasks need to be

allocated to an unambiguous location in the plant

hierarchy. In addition to the plant model, also

previous incidents and operations are of relevance

when planning and executing the work.

As condition based maintenance is becoming

general this brings another valuable source of

information that is used in planning of maintenance

operations. Condition monitoring systems can

provide notifications and trigger events for starting

required maintenance tasks either in advance or

when a sudden failure occurs.

2.2 Towards Service Systems

Process device manufacturers have shown growing

interest in providing after-sales services for their

devices, e.g. maintenance throughout the lifecycle.

Auramo et al. (2004) have analyzed a process

equipment supplier shifting its operation from

selling equipment and services to offering long-term

partnerships, and taking more responsibility of the

operations of the customer. The authors argue that

the supplier’s role as a co-producer of value results

in increased operational efficiency while

simultaneously providing better service to the

customer. Baines et al. (2007) reviewed the state-of-

the-art in the integrated combination of products and

services and concluded that provision of services

requires understanding of how customers value the

service and how products, technologies and

operations support this value offering.

Managing the resulting service network requires

administration similar to in-house processes.

However, as work practices may differ, it is more

challenging to integrate and, for instance, ensure

sufficient communication and information exchange.

It is characteristic to a service network that the

business environment may change, i.e. when service

providers are replaced or a new participant enters the

network. Introducing the new circumstances requires

flexibility in adapting the processes accordingly.

This requirement is especially challenging from an

information systems integration point of view due to

the various data exchanges required in the actual

services performed.

2.3 Information Exchange

Straightforward access to maintenance data and

related information systems is of significant value in

planning, conducting and reporting maintenance

activities. Information on running operations is

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

278

constantly accumulated and stored in various

systems. Maintenance related information is

typically stored in enterprise resource planning

(ERP) and manufacturing execution systems (MES).

However, with more sophisticated control systems,

i.e. DCS and PLC systems - and intelligent field

devices with condition monitoring features, for

instance - the diversity in integrations is increasing.

In addition, there can be other information sources,

e.g. provided by device vendors or authorities, that

are of relevance in maintenance operations.

Environmental aspects, for instance, are becoming

more important for sustainable production and there

are external data sources providing reference data

that can be used in assessments.

In organizationally and geographically

distributed business environments it should be of

mutual interest to have access to up-to-date data in

order to make the most of existing information and

to be able to receive and provide the services as

efficiently as possible. It is still quite common that

information is not shared automatically between

information systems as part of the operations, and

data required for the tasks need to be gathered

manually and reported after completion.

E-maintenance is a term used for software

platforms and integration of physical processes with

enterprise tools. In the PROTEUS initiative the aim

was to create a software platform to support web

based e-maintenance practices using Internet

technologies and middleware (Szymanski et al.,

2003; Bangemann et al., 2006). Business process

integration to the platform has also been considered

by Hausladen & Bechheim (2004). They state that

for successful integration the workflow must be

defined clearly and that the processes must be stable

and not change on short term perspective in order to

be implemented on the platform.

Viinikkala et al. (2005) have discussed the use of

value added Web services to enhance O&M

information management. In their approach, they

propose a service framework using Web Service

technology to address the challenges of information

flow and integrated plant operations. The value

added services are categorized based on complexity

and the added value of O&M information.

Zeeb at al. (2008) have considered Web services

for providing well-defined interfaces to support

communication in maintenance procedures. In their

approach on the LOMS platform, a maintenance

procedure is modeled as a workflow and Web

service based technologies with service templates

used for creating services. However, BPEL was not

used due to DPWS compliancy issues.

Hutchinson et al. (2007) state that there are, in

general, significant challenges when trying to

integrate services from different sources and

migrating existing systems to service oriented

computing. In the research, they identified typical

architectural mismatches and suggest that a

migration process addressing these challenges

should include detailed business process analysis as

well as architectural analysis.

3 DEVELOPMENT APPROACH

BASED ON BPM AND SOA

The approach to be presented emphasizes the role of

business process modeling of services when

developing applications that support the service, e.g.

in maintenance. A business process oriented

approach supports operations driven development

and process models are used to steer the

implementation of respective software applications.

The other important aspect is service-orientation

in the supporting IT infrastructure in order to

facilitate exchange of data required in and produced

as a result of services. Service-oriented architecture

in information systems enables aligning applications

with the business processes and not vice versa.

3.1 Plant Lifecycle Management

Plant lifecycle management stands for all the

information related to a plant throughout its lifecycle

from early design, construction, operation and

maintenance to disposal and recycling. As a concept

it integrates the logical plant to the physical and the

technical model. In practice, this is integration of

schemata and diagrams from e.g. the manufacturing

process design, mechanical models for construction,

e.g. CAD, and information systems such as ERP,

MES and DCS.

The emergence of the so called digital factories

enable extended utilization of information produced

in all lifecycle phases. Ideally, all activities are

defined and the outcome of all tasks is recorded in

the plant wide model. The plant information model

then becomes an almost equally important asset as

the physical plant which it logically represents.

A logical plant information model is beneficial

for plant operations, and especially for services

performed by external service providers. The

challenges of managing mutual information in

distributed service networks can be met with open

systems and standardization to make integration of

BUSINESS PROCESS MODELING AND SOA IN INDUSTRIAL O&M APPLICATION DEVELOPMENT

279

applications easier. For example, allocating

maintenance activities to assets, such as devices and

equipment in a plant, can be specified if open and

standardized access to the plant model can be

provided for the service providers.

Despite standardization efforts, such as ISO

15926-1 (2004) and its other parts, there is still

diversity in plant information model descriptions.

Therefore, service integration platforms should not

restrict models or data, and instead provide tools that

are versatile for developing the needed applications.

3.2 Business Process Modeling of

Services with BPMN

Managing activities in a distributed service network

requires careful specification of responsibilities and

interactions between participants. Traditionally

modeling of business processes has been used as a

tool to represent processes of an enterprise for

analysis and process improvement. More recently,

partly due to the process thinking paradigm, BPM

has been used to present interweaved activities in

complex business scenarios.

In contrast to many other approaches for

application development in O&M and related

services, lean management of processes and

flexibility required in business environments of

today should, according to our opinion, be

emphasized. Applications that support O&M

activities in services are required in order to enable

efficient operation, and BPM can assist in specifying

required interactions and information flows.

Especially when operations are distributed and tasks

of different service providers are interweaved, the

benefits of process modeling are evident.

First of all, business process modeling is

documentation and understanding of how operations

are being carried out. When we understand how our

processes work, identify who is involved and how

activities flow we can improve our way of working.

Often it is easy to improve efficiency by removing

manual work with automated information systems.

Modeling of business processes using a notation

providing mutual understanding enables

specification of operations and tasks on a suitable

level for the participants involved. BPM can be used

to clarify the responsibilities and workflows in

outsourced maintenance service scenarios. In

addition to tasks, also information flows between

participants and required resources can be described.

Business Process Modeling Notation (BPMN) is

a standard notation for describing business process

interactions and information flow (OMG, 2009). The

graphical notation intends to be both intuitive and

expressive for modeling of various types of

processes. The diagrams consist of pools

representing participants and inside them tasks

represent activities. Tasks are connected by arrows

indicating process flows and may include loops,

sequences, conditions and alternative paths. Tasks

connected between pools represent communication

or events that in turn can affect the process.

3.3 Executable Processes - WS-BPEL

BPM diagrams present processes on an abstract level

and are primarily intended for human interpretation.

Efficiency of business processes can be improved by

automation and implementation as executable

processes integrating various information systems.

For operation and maintenance services it

provides the following benefits:

• Automation of laborious processes and

routine activities that can be defined clearly

• Processes can be executed periodically or

started as a result of an event

• Activities can be automatically documented

for future reference and analysis

Executable processes can be controlled by

humans, include decision making based on

conditions or utilize external services or composite

processes that provide the required control and

decision making. Although automation is preferred,

human participation in some form may often be

required to perform the correct operations.

In addition to programmatic system integration

approaches, there are platforms and technologies for

creating executable processes. For example, WS-

BPEL (OASIS, 2007) as well as many commercial

proprietary solutions provide means for managing

workflow between systems with e.g. Web services.

By orchestrating Web services, for example, it is

possible to create programmatically executable

business processes by composition of services.

WS-BPEL is a standardized, XML-based

language for describing service orchestrations by

linking Web service interactions and message flows.

A WS-BPEL process can be composed inside

another process and the process itself can be invoked

as any other Web Service due to its standard WSDL

interface description.

The executable processes can be implemented

manually based on the abstract process descriptions.

However, with the use of standard notations

including sufficient data in the models, much of the

work can be eased, and executable processes can

even be automatically generated. Some

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

280

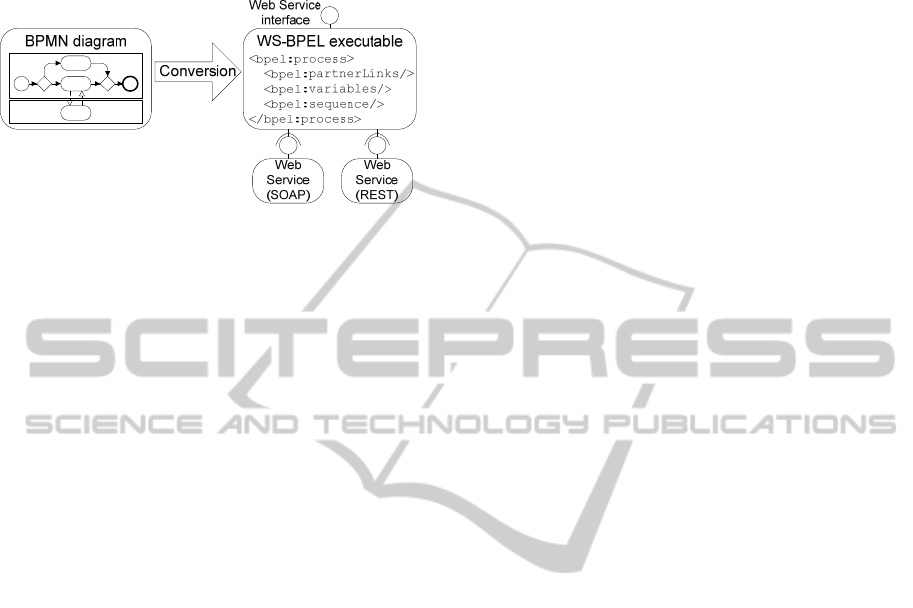

transformations, for example mapping of certain

BPMN structures to corresponding WS-BPEL

elements, can be done automatically (see figure 1).

Figure 1: Abstract BPM diagrams are used as a basis for

creating executable processes based on Web Service

technology.

Advanced tools for specifying executable

processes, e.g. in WS-BPEL, not only take

implementing processes from a programming

construct level to a more expressive level, but also

bring reconfigurability to the process management.

WS-BPEL processes can be used to invoke services,

control execution flow and data management using a

declarative approach. Reconfiguration is especially

useful in O&M business processes when the

business environment changes and processes need

updating. For example, a maintenance service

provider integrating a new service to plant

operations might only need small modifications to

an existing business process template, e.g. new data

mappings and information routing.

Integration of systems requires well-defined

interfaces and available services. Additionally, it is

also important to have the data accessible in a

machine-interpretable format preferably based on

acknowledged standards. Ideally, the specification of

automatic business processes mitigates to composing

reusable service units and connecting information

flows into executable processes.

3.4 SOA and XML Based Technologies

to Facilitate Integration

In distributed environments, such as operation and

maintenance of industrial plants, there are many

partners involved with various information systems

that would require integration in order to fully

support the use of external services. When required

information in maintenance tasks is transferred

manually, it is often lost for future reference and

analysis. If integration was flexible and systems

were designed open, information exchange between

participants could be significantly improved.

SOA characterizes assets as service components

that for the O&M application development domain

offer the following benefits:

• Application development in a business

process driven manner

• Flexible applications suitable for dynamic

business environments

• A foundation for integrating and managing

data from various applications and sources,

both horizontally and vertically

• Integration of operations and services of

business partners and service providers

SOA provides many advantages of which

especially abstraction, reusability and composability

are of interest in O&M application development.

Abstraction of the inner logic of a service promotes

contract based development of interfaces, i.e.

standardization, and obliges interactions to focus on

information flows. Reuse of service components or

service encapsulated legacy systems justify

expensive development efforts and provides means

to integrate systems also in the future.

System integrations are challenging due to

heterogeneity in both technologies and data

representations. Modern information systems such

as many enterprise resource planning and

maintenance information systems offer integration

options using Web service and XML technologies.

Where legacy systems are needed, migrations to

SOA using wrappers can be used to expose data and

functionality as services. However, requirements for

implementing and integrating services are not

limited to data access, but more importantly to its

format and semantics. As different standards and

practices are used, it is important for the application

development method to support management of

various contents with, for example, middleware or

XML transformations such as XSL and XQuery.

When information systems involved in the

process are available as services, they can be

programmatically invoked, and a process flow

between activities can be established. The

supporting message processing and transformations

required can also be included and controlled e.g.

from WS-BPEL orchestrations. Human interaction

can be implemented through input in existing tools

or new interfaces for acknowledgment, acceptance

or denial of actions in service processes.

3.5 Service Composition

Service based operation is composition by nature.

From a plant operations perspective its main process

is production. The main process consists of sub

BUSINESS PROCESS MODELING AND SOA IN INDUSTRIAL O&M APPLICATION DEVELOPMENT

281

processes and is supported with activities that are

related to the core functions. Similar to composing

operational services, such as maintenance work, also

the related processes in information systems can be

composed to support the provided service.

Figure 2 illustrates the outline of business

processes, service interfaces and applications. The

top level in the figure models actual business

processes, i.e. the interactions and tasks performed

in daily operations on an abstract level of detail.

In order to create applications that either fully

automate or support O&M processes, an approach

based on SOA can be applied. The orchestration

service layer represents an implemented, executable

business process supporting and corresponding to

the actual maintenance work processes. The

orchestration is a composition controller that links

services into workflows through a process service

model. An orchestration can therefore also link other

orchestrations into compositions.

The service interface layer can be divided, in

addition to orchestration services, to business

services and application services. Business services

represent business logic and business models of

maintenance service activities whereas application

services provide reusable functions for processing

data in various application environments. In addition

to these, utility and adapter services are typically

required to support the service compositions.

Business

service layer

Application

service layer

Application

layer

Orchestration

service layer

Service

interface

layer

Business

process layer

Figure 2: Vertical alignment of business processes, service

compositions, services and applications. Erl (2006).

The composition of services based on business

processes in a top-down manner enables

development of applications that support actual

business processes. When systems and applications

are seen as services, process compositions can be

created in a flexible manner satisfying the

requirements of changing business demands in

O&M services. The layered approach also enables

service providers to implement their processes in

their own way, and in turn utilize other service

providers while still maintaining interoperability.

4 EXPERIMENTAL RESULTS

In this study, two business processes were created

using the chosen technologies. The first example is a

condition monitoring process that collects condition

information from devices. The second process is an

environmental footprint estimator for approximating

the environmental load a device causes during its

lifetime. The business processes can be used

together; if the condition monitoring process

indicates a need for a device replacement, different

device candidates can be compared using the

footprint estimator.

4.1 Development and Execution

Environment

The software used to develop and run executable

business processes in this study is Intalio BPMS. It

provides tools for modeling business processes and

their interaction with Web services in BPMN. Intalio

BPMS can partially convert BPMN diagrams to WS-

BPEL and execute the resulting processes. There is

both a free and a commercial edition available.

Intalio BPMS has been used for managing

clinical workflows (Nugrahanto & Morrison, 2008)

and modeling of banking related business processes

(Mpardis & Kotsilieris, 2010). Martin & Bagnoud

(2009) used it in a case in which the interoperation

of different business process platforms was tested.

Jallow et al. (2010) introduced a requirements

change management system for building industry.

In this study, BPMN is used to model the

business processes. Based on these models service

orchestrations are then created as executable WS-

BPEL processes. WS-BEPL interacts with services

using WSDL documents describing both SOAP and

HTTP interfaces, including also REST resources.

4.2 Condition Monitoring

The condition monitoring business process retrieves

the condition information from the devices of one

manufacturer. There are three main problems. First,

there has to be a means to find out which devices

have been supplied by the manufacturer. Second,

there has to be a way to find a device so that its

condition information can be retrieved (the device

network is dynamic so it can change any time).

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

282

Third, there has to be a means to integrate the

devices to business processes.

The first problem is solved by using a plant

information model. It can provide the serial numbers

of the devices of a manufacturer. The second

problem is solved by using a service to provide the

endpoints of devices according to their serial

numbers. The third problem, integration, is solved

by using a technology called DPWS (Devices Profile

for Web Services; Nixon et al., 2009).

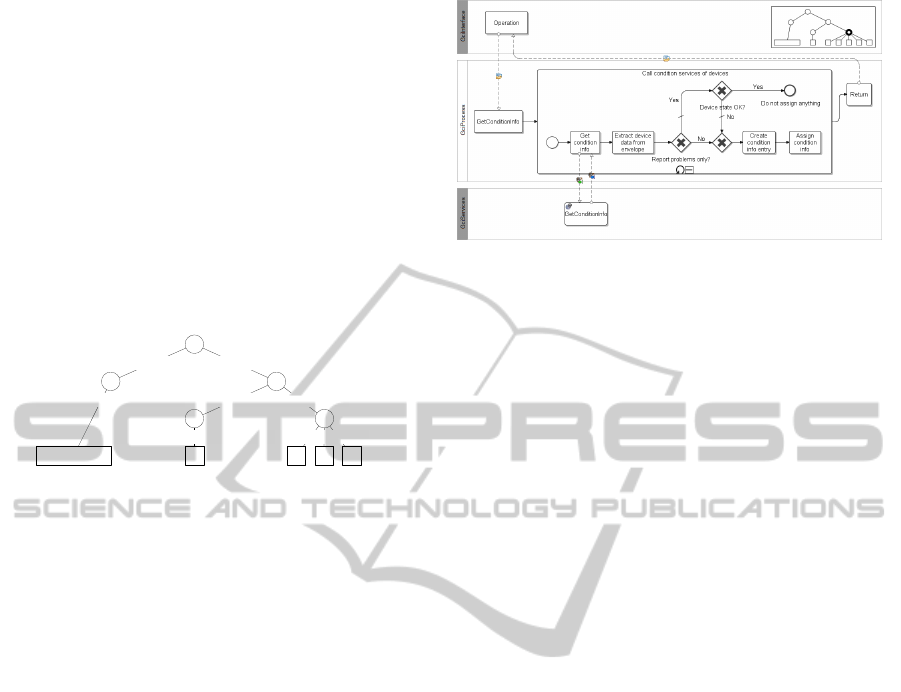

The architecture of the condition monitoring

service is presented in figure 3. Squares represent

DPWS devices, circles are business processes and

the rectangle represents the plant information model.

GetConditionInfoBySerialNr

GetConditionServiceEndpoints

GetEndpoints

(DPWS)

GetConditionInfo

(DPWS)

GetConditionInfo

Plant information

model

ConditionInfoOfManufacturersDevices

GetSerialNrsOfManufacturer

Figure 3: Composition of hierarchical processes in the

condition monitoring example.

There are two types of DPWS services in the

hierarchy. GetEndpoints takes device serial numbers

as its input and finds the endpoints of the

corresponding devices. GetConditionInfo provides

the actual condition information for devices.

There is a total of five business processes. When

ConditionInfoOfManufacturersDevices is called, it

calls GetSerialNrsOfManufacturer that uses the

plant information model to retrieve the serial

numbers of the devices delivered by the chosen

manufacturer. Then, GetConditionInfoBySerialNr is

called. It calls GetConditionServiceEndPoints to

retrieve device endpoints according to device serial

numbers. Now that device endpoints are known,

GetConditionInfoBySerialNr retrieves condition

information from the devices by calling

GetConditionInfo. Finally, the return value is

returned to ConditionInfoOfManufacturersDevices

which shall further return it to its caller.

Figure 4 demonstrates the use of BPMN and

describes the flow of the GetConditionInfo business

process. The business process retrieves the condition

information of each device given in its input.

Depending on the input of the business process,

either the condition information of all the devices or

only the condition information of devices with

problems is assigned to the return value. To achieve

this, conditional execution paths are used.

Figure 4: BPMN presentation of the GetConditionInfo sub

process that requests and processes data from devices.

4.3 Environmental Footprint Estimator

The environmental footprint estimator estimates the

emissions output of devices during their lifetime

based on consumption of specific resources. For

example, comparing consumption of electricity in

alternative devices can give an estimate of emissions

that can be taken into account in decision making.

As there may be hundreds of emissions caused by a

production process, the relevant resources consumed

are chosen by the user when the business process is

started. The emissions from only one resource are

calculated at a time; if a device consumes more than

one resource, the business process is run once for

each resource. To enable the comparison of different

devices, the business process can process several

consumption amounts at a time.

A public European Union based environmental

database (ELCD, 2010) is used to provide

information about the emissions caused in resource

production. If the duration of device life and its

consumption of resources are known, it is possible to

estimate the footprint of the equipment or device by

using reference data from the database.

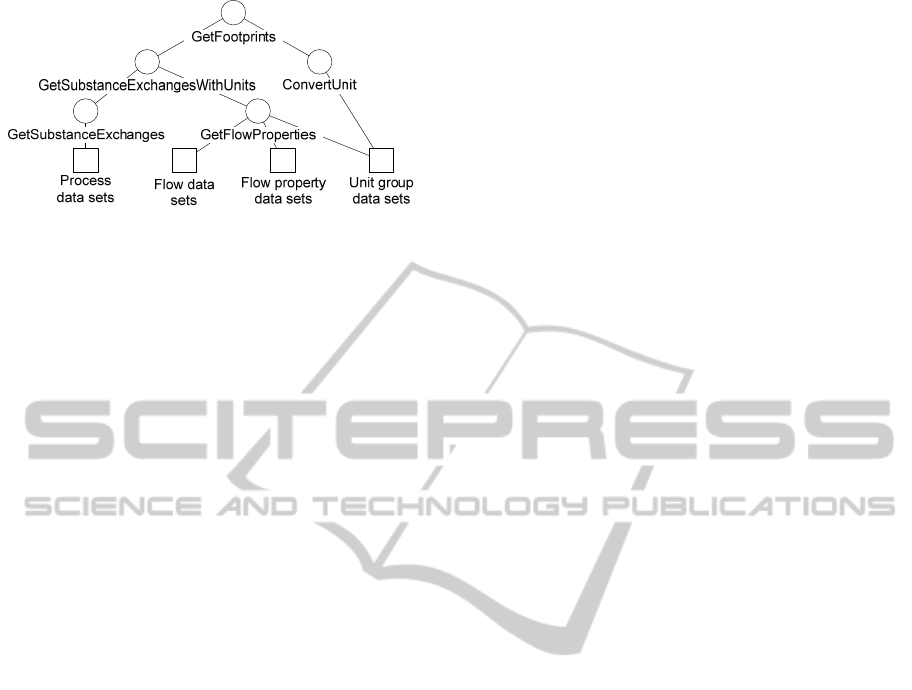

The architecture of the business process is

presented in figure 5. It is a hierarchy that consists of

business processes (circles) and environmental data

resources (squares). The environmental data is

provided in XML format, which facilitates

integration to WS-BPEL business processes.

There are four XML document resources in the

hierarchy. Process data sets provide the reference

amounts of emissions caused by the production of

one resource. To retrieve the units of emissions,

three additional data sets must be retrieved for each

emission: flow, flow property and unit group.

BUSINESS PROCESS MODELING AND SOA IN INDUSTRIAL O&M APPLICATION DEVELOPMENT

283

Figure 5: Composition of processes as services that are

used in gathering environmental footprint estimation data.

There are five business processes in the

hierarchy. GetFootprints calls GetSubstance-

ExchangesWithUnits to retrieve the reference

amounts and the reference units of the emissions of

one production process. To perform that,

GetSubstanceExchangesWithUnits uses two other

business processes. GetSubstanceExchanges

retrieves the reference amounts of emissions from a

process data set, and GetFlowProperties retrieves

the related reference unit by utilizing flow data sets,

flow property data sets and unit group data sets.

Once the reference emissions are known, there may

be a need for unit conversions by ConvertUnit.

4.4 Future Refinement and Research

The examples illustrate how a plant information

model, including engineering data from design, can

be utilized in maintenance services. Because the

condition monitoring process is fully automatic, it

can be executed periodically and trigger events of

assessing the maintenance need or replacement of a

device. The environmental footprint estimator

process, on the other hand, is invoked manually and

can be used to gather data to support decision

making e.g. in choosing new equipment.

In order to improve the examples the condition

monitoring process could, either automatically or by

human operator acceptance, invoke processes such

as device inspections or ordering of maintenance

services. The devices being monitored might also

have different maintenance service providers

requiring either separate processes or additional

logic in looking up the service provider.

The condition monitoring example could also be

upgraded to use a standard message exchange

format. A good candidate for this would be the Open

Systems Architecture for Condition-Based

Maintenance (OSA-CBM; MIMOSA, 2006) that is

intended for transferring information in a condition-

based maintenance system.

Regarding processes in general, and especially

automation and event-driven execution, the WS-

Notification standard family (Graham et al., 2004) is

interesting. WS-Notification provides a topic-based

publish/subscribe pattern for registration to events of

interest that could be used to implement event-

driven process execution. Beneficial to service

compositions in real business environments and

characteristic to the pattern is dynamic registration

to the data source and separate messages to

registered subscribers.

In the long run, the emergence of Semantic Web

technologies opens up new possibilities especially in

classification of information and applying reasoning

to further automate processing and workflow. Also

as further standardization in the O&M domain is

needed the importance of semantics is increasing.

5 CONCLUSIONS

In efforts to make industrial plant operations more

efficient, maintenance among other operations has

been outsourced. Integration of mutually valuable

information could improve service collaboration by

giving the service provider more insight in providing

the service and the customer in receiving it.

Especially in distributed service networks,

information on maintenance operations and

maintenance history is shared inefficiently partly

due to laborious integrations that would be required.

In our opinion, application development should take

business processes and information exchange

requirements better into consideration when

designing new applications and integrating

information systems. An operation driven O&M

application development approach suitable for

services can be achieved with business process

modeling and implementation based on SOA. The

approach presented is a top-down development

approach that enables business demands and service

operations to steer the application development. For

technologies and migration of existing information

systems, a standards based service-oriented

approach is suggested for providing service

interfaces for data exchange and service

composition.

The experiments indicate that business process

modeling with BPMN and integration of O&M

application services using WS-BPEL provides

means for composing services efficiently while

maintaining the required flexibility and

reconfigurability of services. The approach probably

also saves time compared to traditional

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

284

programming approaches, and promotes

standardization of data, application interfaces and

operation practices.

An interesting future research topic from a

services point of view is management of service

collaborations where more details and participants

are involved. This, as well as previously presented

challenges, call for standardization to aid in

integration of services and information systems.

Also advances in the use of intelligent agents,

utilization of technologies of the Semantic Web, and

the increased capabilities of plant floor devices

provide interesting research topics in the future.

REFERENCES

Auramo, J., Tanskanen, K., Småros, J., 2004. Increasing

Operational Efficiency Through Improved Customer

Service: Process Maintenance Case, International

Journal of Logistics: Research and Applications,

Volume 7, Issue 3, September 2004, pages 167 - 180.

Baines, T, Lightfoot, H, Evans, S, Neely, A, Greenough,

R, Peppard, J, Roy, R, Shehab, E, Braganza, A,

Tiwari, A, Alcock, J, Angus, J, Bastl, M, Cousens, A,

Irving, P, Johnson, M, Kingston, J, Lockett, H,

Martinez, V, Michele, P, Tranfield, D, Walton, I,

Wilson, H, 2007. State-of-the-art in product-service

systems, Proceedings of the Institution of Mechanical

Engineers, Part B: Journal of Engineering

Manufacture, Volume 221, Issue 10, 2007, pages

1543-1552. doi: 10.1243/09544054JEM858

Bangemann, T., Rebeuf, X., Reboul, D., Schulze, A.,

Szymanski, J., Thomesse, J-P, Thron M., Zerhouni, N.

PROTEUS--Creating distributed maintenance systems

through an integration platform, Computers in

Industry, Volume 57, Issue 6, E-maintenance Special

Issue, August 2006, Pages 539-551, ISSN 0166-3615,

doi: 10.1016/j.compind.2006.02.018.

ELCD, 2010. ELCD core database version II. European

Commission, DG Joint Research Centre - Institute for

Environment and Sustainability. Available:

http://lca.jrc.ec.europa.eu/lcainfohub/datasetArea.vm

Erl, T., 2006, Service-Oriented Architecture: Concepts,

Technology & Design. Prentice Hall, Pearson PTR,

760 p. ISBN: 0131858580

Graham, S., Niblett P., Chappell, D., Lewis, A.,

Nagaratnam, N., Parikh, J., Patil, S., Samdarshi, S.,

Sedukhin, I., Snelling, D., Tuecke, S., Vambenepe,

W., Weihl, B., Publish-Subscribe Notification for Web

services (WS-Notification whitepaper), version 1.0,

2004.

Hausladen, I, Bechheim, C., E-maintenance platform as a

basis for business process integration, 2nd IEEE

International Conference on Industrial Informatics,

2004. INDIN '04. pp. 46-51, 26-26 June 2004.

Hutchinson, J., Kotonya, G., Walkerdine, J., Sawyer, P.,

Dobson, G., Onditi, V., 2007. The Challenge of

Evolving Existing Systems to Service-Oriented

Architectures, 5th IEEE International Conference on

Industrial Informatics. INDIN’07. Vol. 2, pp.773-778,

23-27 June 2007.

Intalio BPMS. Available: http://www.intalio.com/bpms

ISO, 2004. 15926-1 Industrial automation systems and

integration — Integration of life-cycle data for process

plants including oil and gas production facilities —

Part 1: Overview and fundamental principles. ISO

Standards.

Jallow, A. K., Demian, P., Baldwin, A. N. & Anumba, C.

J., 2010. An Integrated Requirements Management

System for Construction Projects. International

Society for Computing in Civil and Building

Engineering (ISCCBE).

Levery, M., 1998. Outsourcing Maintenance - A Question

of Strategy, Engineering Management Journal , vol.8,

no.1, pp.34-40, Feb 1998.

Martin, S. & Bagnoud, L., 2009. A Case Study of

Business Process Interoperability in a Logistics

Supply Chain Environment. In Lecture Notes in

Business Information Processing, 2009, Volume 17,

Part 8. Springer.

MIMOSA, 2006. Open Systems Architecture for

Condition-based Maintenance (OSA-CBM) Primer,

August 2006, Machinery Information Management

Open Standards Alliance.

Mpardis, G. & Kotsilieris, T., 2010. Bank Loan Processes

Modelling Using BPMN. In DESE 2010,

Developments in E-systems Engineering. IEEE.

Nixon, T., Regnier, A., Driscoll, D. & Mensch, A., 2009.

Devices Profile for Web Services Version 1.1. OASIS.

Nugrahanto, S. & Morrison, I., 2008. A Design Science

Approach to Modelling and Facilitating Clinical

Workflow and Decision Making. In HIC 2008,

Australia's Health Informatics Conference. Health

Informatics Society of Australia Ltd (HISA).

OASIS, 2007. Web Services Business Process Execution

Language (WS-BPEL) Version 2.0, OASIS Standard.

OMG, 2009. Business Process Model and Notation

(BPMN) Version 1.2. OMG specification.

Szymanski, J., Bangemann, T., Thron, M., Thomesse, J.-

P., Reboeuf, X., Lang, C., Garcia, E., PROTEUS - a

European initiative for e-maintenance platform

development, 9th IEEE International Conference on

Emerging Technologies and Factory Automation.

ETFA'03. Vol. 2, pp. 415- 420, 16-19 Sept. 2003.

Viinikkala, M., Jaakkola, V-P., Kuikka, S., Value Added

Web Services for Industrial Operations and

Maintenance. 7th International Conference on

Enterprise Information Systems, 2005, ICEIS’05. pp.

361-365, 25-28 May 2005.

Zeeb, E., Priiter, S., Golatowski, F., Berger, F., A Context

Aware Service-Oriented Maintenance System for the

B2B Sector, 22nd International Conference on

Advanced Information Networking and Applications -

Workshops, 2008. AINAW 2008. pp.1381-1386, 25-28

March 2008.

BUSINESS PROCESS MODELING AND SOA IN INDUSTRIAL O&M APPLICATION DEVELOPMENT

285