DEVELOPMENT OF A SCHEDULING MODULE WITHIN AN

INTEGRATED SOLUTION FOR THE EVALUATION OF PROCESS

VARIANTS

Tim Neumann, Daniel Kretz, Joerg Militzer and Tobias Teich

University of Applied Sciences Zwickau, Dr.-Friedrichs-Ring 2a, 08058 Zwickau, Germany

Keywords:

Proposal preparation, Scheduling, Genetic algorithm, Manufacturing, Process variant.

Abstract:

The success or failure of small and medium sized enterprises (SME) is related to the handling of factors

like individual customer demands, price pressure and the probability to deliver at the required date and time.

Often such SME’s are on the market for single-part or small-series production and want to be supplier for

larger companies. Therefore, the decision makers of their customers have to investigate potential suppliers

due to these mostly interrelated criteria. To increase these known factors during the proposal preparation is

one possibility to enhance the market position of the SME. Thereby, a consideration of different variants of

manufacturing a product and the premature investigation of resources and their capacities is necessary. Within

the scope of this paper is introducing a conceptional framework for the evaluation of different process variants

to manufacture a product. Thereby, we are using genetic algorithms to optimize and evaluate process variants

including the necessary resources and their capacitive use in an evaluated period. Additionally, we want to

introduce our prototypical implementation.

1 INTRODUCTION

The process planning is a significant phase after the

product design in product lifecycle for the success or

failure of a small and medium sized enterprise (SME).

Especially in the branch of single-part or small-series

production in industrial engineering is the process

planning responsible for the improvement of criteria

like individual customer demands, price pressure and

the probability to deliver at the required date and time.

Therefore, it is necessary to think about these factors

and their dependencies as soon as possible. One pos-

sibility to reach an enhancement is the consideration

of different ways for manufacturing a product, the

premature investigation of resources which possibly

could be used and their capacity, during the proposal

preparation.

Currently, discombobulated application land-

scapes and heterogenic systems are preventing an ef-

ficient, integrated and automated product develop-

ment. Therefore, it is indispensable to use the poten-

tial of an integrated solution of Computer Aided De-

sign (CAD), Computer Aided Manufacturing (CAM),

Computer Aided Process Planning (CAPP) and Enter-

prise Resource Planning (ERP).

We are developing a integrated solution which

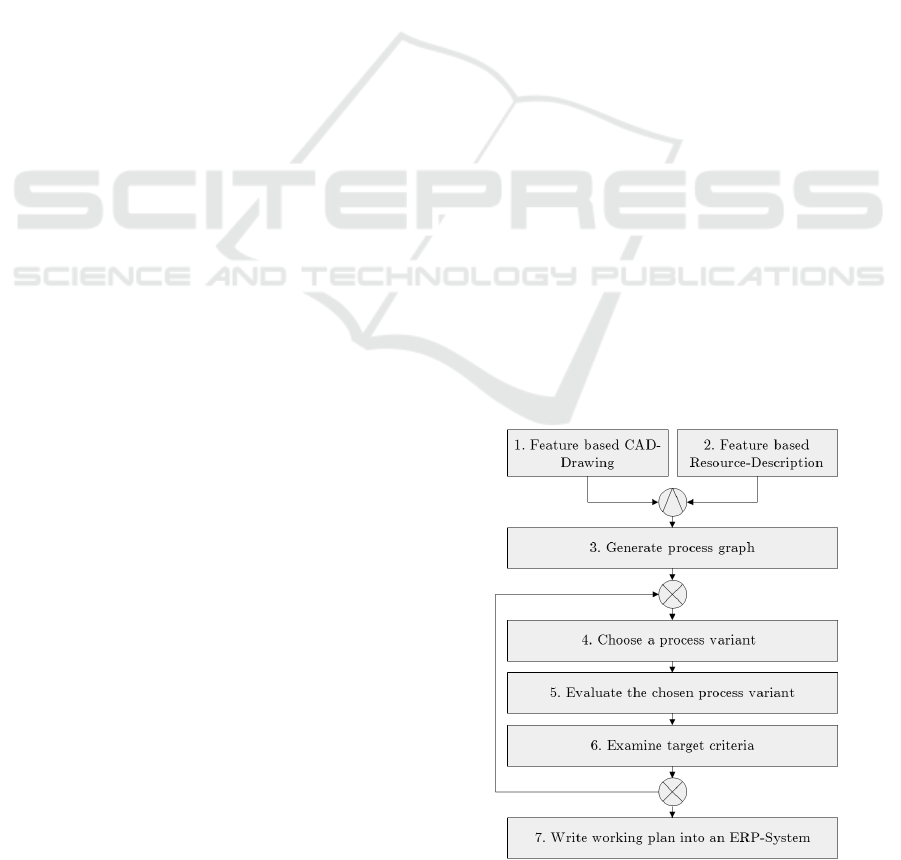

Figure 1: Structure of the parts.

consists of seven fundamental process steps, as il-

lustrated in figure 1. First, there is a feature based

CAD drawing of a requested part. Thereby, a fea-

ture is an object for the description of parts and their

geometrical, functional and technological properties

393

Neumann T., Kretz D., Militzer J. and Teich T..

DEVELOPMENT OF A SCHEDULING MODULE WITHIN AN INTEGRATED SOLUTION FOR THE EVALUATION OF PROCESS VARIANTS.

DOI: 10.5220/0003531103930398

In Proceedings of the 8th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2011), pages 393-398

ISBN: 978-989-8425-75-1

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

(Ehrlenspiel et al., 2005). To realise this definition we

utilise the STEP application protocol (AP) 224 from

ISO 10303 (International Organization for Standard-

ization, 2006). Next to the feature based CAD draw-

ing, we implemented a feature based resource de-

scription which describes suitable machines and other

resources as well as the features in the CAD draw-

ing. This provides the ability to determine e.g. set-up

times or accruing costs. We extract the master data

for these resources from an ERP system.

With these two prerequisites we provide the pos-

sibility to generate a process graph in the third block.

This graph includes all feasible variants for the pro-

duction of the requested part and therefore consid-

eres geometrical, functional and technological cor-

rectness. Thereby, it maps the expertise of a process

planner to support the decision process and it is re-

sponsible for determining suitable manufacturingpro-

cess variants which could be utilized for the produc-

tion of the part or assembly.

After generating the process graph we have to

choose a single process variant for the upcoming eval-

uation in the fourth block. Therefore we utilize ge-

netic algorithms (GA) for scheduling and hence the

evaluation of this process variant.

In the sixth step we examine the target criteria. If

they are not met or not satisfying, we return to the

fourth part and select another process variant. If all

target criteria are met, or satisfying, we can continue

with the process and submit the selected process vari-

ant as a working plan into the ERP system in a last

step.

Within this paper we want to introduce the

scheduling problem for the evaluation of a process

variant. Afterwards we describe our genetic algorithm

and its characteristics. After the theoretical concept

we want to give a introduction to our software archi-

tecture of the whole integrated solution. This section

is followed by our conclusion.

2 SCHEDULING PROBLEM

Amongst other things, placed orders and their deliv-

ery dates are different input information which we re-

quire for the scheduling process. These orders are

not production orders, they are just placed orders we

need to deliver. Additionally, we need information

about available resources and their capacitive utiliza-

tion. This information represents fixed production or-

ders within an evaluated period. Finally we need in-

formation about the initially transferred process vari-

ant. This process variant consists of the parts list and

the sequential working plan. The specification to se-

quential working plans based on the viewing at com-

ponent level.

For this consideration we have defined a own

scheduling problem that will be explained and clas-

sified as follows. For this reason we want to refer to

the definition implemented by Graham et al. (Gra-

ham, R.L. ; Lawler, E.L. ; Lenstra, J.K. ; Rinnooy

Kan, A.H.G., 1979) and T’kindt (T’kindt and Billaut,

2006).

Basically, n jobs (J

j

| j = 1, ..., n; n ∈ N)

should be produced on m machines (M

i

| i =

1, ..., m; m ∈ N). Additionally is defined, that the

number of operations O is divided into o

jk

(k | k =

1, ..., l; l ∈ N) operations. This implies that o

jk

is

the k

th

operation of job j. Therefore, it is defined,

that every job J

j

with J

j

∈ J consists of a sequence

of k operations (o

jk

). Consequently is o

jk

≺ o

j(k+1)

.

Hence, we define that the k

th

operation of the job has

to be executed before its successor.

For each step within the manufacturing pro-

cess, a number of applicable machines M

jk

⊂ M is

assignable. Depending on the chosen machine M

i

,

each operation determines different production (exe-

cution) times p

jki

. This is a derivation from the basic

definition and describes the production time p

jki

as

time for the production of operation k of job j on ma-

chine i. We also define, for each machine distinct cost

rates. We declare the cost rate for each time unit and

machine as c

i

.

Viewing at component level implies another devi-

ation. The base definition defines a due date for each

job as d

j

. We have modified this definition to assign

due dates only to jobs without any successor. Thus,

we address the component at the top level of the part

list. Accordingly, this associates the requested part.

Additionally, our approach supports the mapping

of divergences and convergences in the production

process. Figure 2 illustrates this aspect.

Figure 2: Example structure.

This example assume, that the jobs J

5

and J

6

are

placed orders within the evaluated period. Accord-

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

394

ingly, the jobs J

1

to J

4

map the part list of these two

products. Each level of the part list represent the se-

quential working plans. Finally we assume, that job

J

8

represents the requested product.

The final aspect of our scheduling problem defini-

tion is the grouping of jobs. This approach results in a

more balanced selection of jobs during the scheduling

process. Hence, we define that jobs which are directly

or indirectly related to other jobs belong to a common

group.

After the definition of the scheduling problem, we

want to classify the discussed problem. Therefore, we

use the common α | β | γ-classification.

Within this classification we can categorize all

known scheduling problems. Thereby α describes the

machine environment, β the job characteristics and γ

the optimality criteria. For our previously introduced

scheduling problem we define the following classifi-

cation:

GMPM, m | prec, d

j

, p

j

∈ [p

j

; p

j

], recrc | GP

The first parameter α describes the machine en-

vironment. Because of their restrictions, classifica-

tions types like P for identical parallel machines, Q

(uniform parallel machines), R (heterogeneous par-

allel machines), F (Flow-Shop problems), O (Open-

Shop problems) and finally J (Job-Shopproblems) are

not applicable for our problem definition. Certainly,

the classification into Job-Shop problems is similar

to our problem definition, but it does not fit exactly.

In fact we only have an partial assignment between

operations and machines. Therefore we need a gen-

eralized classification. Hence, we have identified our

problem as a ”General Shop Multi Purpose Machines

Scheduling Problem” (GMPM). The second informa-

tion in this field is m and is related to the amount of

machines, which is unknown but fixed.

The second parameter β describes the job char-

acteristics. To reflect the previously explained

predecessor-successor relationships between jobs as

well as operations, we use prec (precedence con-

traints). This definition is also very general and in-

cludes special cases. Next to the definition of the job

structure, we have defined that d

j

describes the infor-

mation about due dates. Furthermore, we have de-

fined the limits of production time p

j

∈ [p

j

; p

j

].

The finally given information of our classification

is recrc (recirculation). This indicates that a single

job can be produced repeatedly on one machine.

The last parameter of the α | β | γ-classification is

the optimality criteria γ. As we mentioned initially,

more than a single fact is responsible for the success

or loss of a company. Consequently we require to uti-

lize multi criteria optimisation. In fact, there are dif-

ferent multi criteria optimisation approaches possible

(Loukil et al., 2005). We have selected the goal pro-

gramming approach as introduced by T’kindt and Bil-

laut (T’kindt and Billaut, 2006). This is reasoned by

the fact that we can define main goals, like reducing

selling prices by comparing accruing costs or reduc-

ing deviations from due dates by comparing comple-

tion times. This multi criteria optimisation will also

be the basis for the fitness evaluation in the genetic

algorithm.

3 GENETIC ALGORITHM

Genetic algorithmsare often used for solving schedul-

ing problems. The relatedness between the de-

fined scheduling and the job-shop scheduling prob-

lem leads towards occupying with genetic algorithms

(Syswerda, 1991).

The basics of genetic algorithms are developed by

Holland (Holland, 1975) and De Jong (Jong, 1975). A

illustration of the procedure of the genetic algorithm

in generally gives (Vnyi, 2004).

First, we have to initialize a random population of

solutions. We apply a serial genetic algorithm. Fur-

thermore we use the generational replacement as de-

scribed by (Holland, 1975). This means that one gen-

eration of solutions is completely replaced by their

offspring. Additionally to the generational replace-

ment we are using elitism to retain the best solutions.

The performance of a GA depends on an effec-

tive problem representation. Thereby, problem rep-

resentation is an encoding of the actual optimization

problem into structures of individuals. Within the en-

coding process we have to ensure that required infor-

mation is completely mapped into an individual and

avoid invalid solutions.

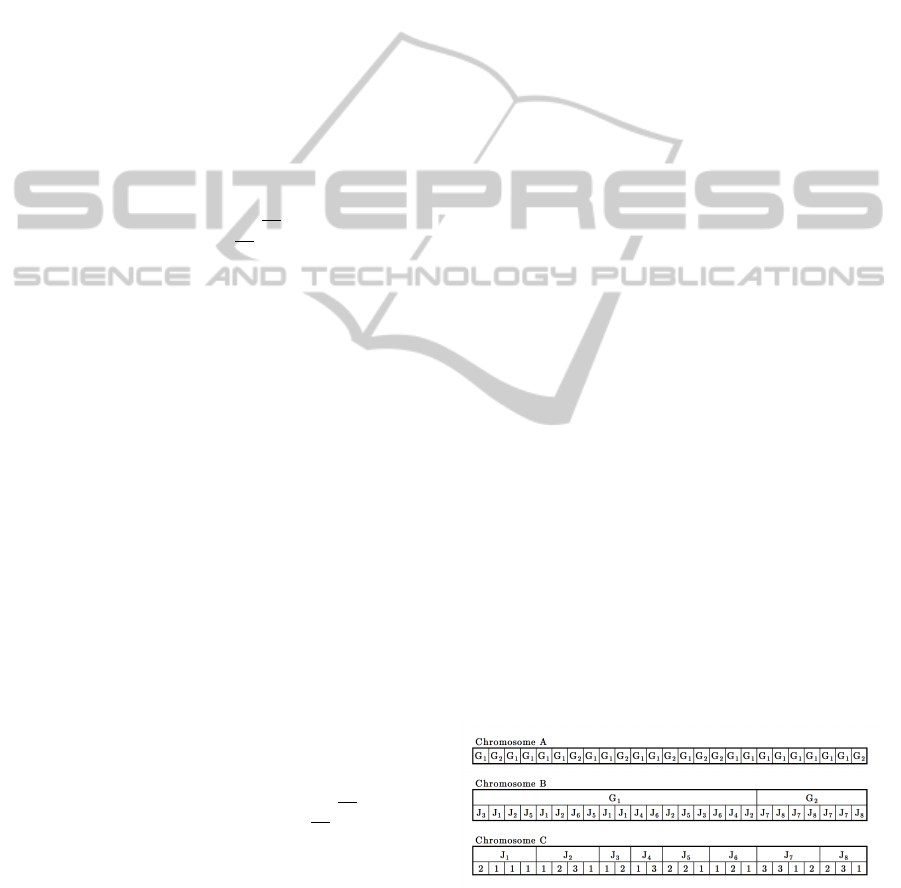

We have decided to develop a multi chromosome

individual with operation-based representation (Gen

and Cheng, 1997). To give an example, we have il-

lustrated a multi chromosome structure in figure 3 in

reference to our example graph.

Figure 3: Example individual.

Thereby, chromosome A represents a permutation

of groups. The Chromosome B consists of a permu-

tation of jobs. Finally, with chromosome C we want

to select a resource for each operation. As you can

DEVELOPMENT OF A SCHEDULING MODULE WITHIN AN INTEGRATED SOLUTION FOR THE EVALUATION

OF PROCESS VARIANTS

395

see it is not a permutation of elements. Furthermore,

we utilise an integer chromosome which represent an

index of the selected machine or resource from a re-

source set. Every chromosome evolves independently

from each other.

To compare the individuals we have to decode and

calculate a fitness value. The decoding process of the

individualsis an iterativeprocess, beginning at the left

side of the individual.

The first step is the selection of the first element

of chromosome A. Referring to the illustrated exam-

ple individual the first element of chromosome A is

G

1

. Therefore, we retrieve the first job from chromo-

some B, which is part of group G

1

. Additionally this

job has to be executable which means either there are

no predeceeding jobs or they are all already executed

completely. After the selection of the job we need to

identify the next executable operation and an assigned

machine from chromosome C. The index in the ele-

ments of chromosome c indicates the machine selec-

tion from a given set of assignable resources. Now,

we have decoded one individual for the first time. We

continue the decoding process for the next element in

chromosome A in the same way. Consequently, we

have to repeat this process for each element in chro-

mosome A. After the last element we get a table with

a complete planning sequence.

With such a table and the addition of machine ca-

pacity utilisation in the evaluated period we can de-

velop a new machine utilisation plan. This is neces-

sary because the pure processing time does not pro-

vide an evaluation of the solution quality.

On the one hand there is a solution with lesser to-

tal production time, but with a displacement of com-

pletion dates after the due dates. On the other hand,

there could be a solution with an enormous increased

total production time, but with a displacement of the

completion times before the due dates.

Accordingly, for our algorithm we have selected

the minimisation of the maximum weighted lateness

L

ω

max

which is an result of two different kinds of late-

ness, the earliness E

j

= max{0, d

j

−C

j

} and the tardi-

ness T

j

= max{0, C

j

− d

j

}. Thereby, C

j

addresses the

completion date and d

j

the due date of a job. Further-

more it is possible that the minimisation of earliness

is more important than the minimisation of tardiness.

So we have defined the weighted lateness L

ω

max

:

L

ω

max

=

n

∑

j=1

(ω

E

E

j

+ ω

T

T

j

)

Additionally to this value we have to evaluate

the minimisation of the maximum production costs

K

M

(p

jki

; c

i

). This is an attempt to multi criteria

optimisation of goal programming. We derive due

dates and accruing costs of our products and we can

compare them to our completion dates and the prices

which have to be achieved.

To improve our solution we have to search better

solutions within the solution space. Thereby, genetic

operators help to improve our individuals. First of all,

we have to define and determine these basic opera-

tors like the selection, the recombination operator and

finally the mutation operator.

Before the recombination of some individuals, we

have to select parent individuals. This is done by the

selection operator (Nissen, 1997). Currently our al-

gorithm applies the tournament selection. Thereby

we chose a number of individuals for a tournament.

This number depends on the size of the population re-

duced by the number of elitists and the percentage of

elements we want to select for the tournament. The

fittest individual within the tournament group is se-

lected as a parent. To determine the second parent,

we repeat this approach. With the two selected par-

ents we can continue with the recombination. This

procedure shall be continued until we have selected

the required number of parents.

Recombination as the second operator is deemed

to be the central operator in the algorithm. Because of

the different kinds of chromosomes in one individual

we have to separate the individual for the recombina-

tion.

Chromosome A and B are permutation chromo-

somes. This chromosome type requires specialised

crossover operators. In our case we use the partially

mapped crossover(PMX) (Ting et al., 2010). This op-

erator is characterised by the preservation of genetic

sequences without destroying the permutation char-

acter. Accordingly, it is possible, that good sequences

are achieved.

Chromosome C is an integer chromosome and

therefore, we have to use another specialised

crossover operator. There are two basic operators.

First, there is the uniform crossover (Syswerda, 1989)

and second the N-Point-Crossover (Gwiazda, 2006).

At the moment the decision which of these two pos-

sible crossover operators we are implementing is not

made.

In addition to the recombination we use muta-

tion operators. These are useful to established a bal-

ance between exploitation and exploration (Weicker,

2007).

Before starting with the mutation we haveto deter-

mine a global or overall mutation rate reveals whether

a chromosome is mutated or not. Additionally to this

we have to define the local mutation rate which deter-

mines the probability of applying mutation operators

and influences the strength of mutation in the genetic

algorithm.

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

396

Given the fact that there are two different chro-

mosome types we also need specialised mutation op-

erators e.g. to preserve the permutation in chromo-

some A and B. To permute A and B we randomly se-

lected different procedures for mutation. Therefore,

we have forced to implement four different meth-

ods like Position-Based mutation, Order-Based muta-

tion, Scramble-Based mutation or the Swap mutation

(Syswerda, 1991). This concept supports the idea of

parallelism in the algorithm.

The integer chromosome C is mutated by the ad-

joining mutation (Michalewicz, 1999).

With this last operator we are at the beginning of

the procedure. For the next generation of individu-

als this algorithm has to be repeat until the stopping

criterion is reached.

In the following section we want to introduce a

implementation of this algorithm in our integrated so-

lution.

4 IMPLEMENTATION

The developed and introduced framework for the

evaluation of process variants is part of an integrated

system. For this system we have presented a process

structure in the first section of this paper. Now we

want to introduce our implementation of this struc-

ture. Therefore, we have drafted a five tier architec-

ture which reflects the different abstraction layers of

our final software solution

The lowest level is the persistence layer. This

layer is responsible to keep all information for differ-

ent application states permanently. This data is saved

on storage devices within files or databases.

For the integration and collaboration of the par-

ticular modules we define the communication layer.

This layer provides access to the permanent required

and accruing data of the persistence layer. Addition-

ally, it is basis for the exchange of logical program

data during runtime. The communication layer pro-

vides also the ability to handle the other modules

e.g. to invoke succeeding processing functions or to

provide state information about executed calculations

and their results.

We define the application layer in the third tier. In

detail it consists of four particular modules that con-

sequently represent the implemented components of

the program and algorithms. In the AP 224 CAD

module CAD drawings are modelled. This module

is necessary to instantiate the feature based product

model. The second one is the process variants mod-

ule. Thereby, we develop a system, that generates

different suitable process variants to manufacture the

requested part. Thereby, it maps the expertise of a

process planner to support the decision process. The

process variants are extended by the resource module.

This contains information about assignable resources

and their abilities which provides the ability to deter-

mine e.g. set-up times or accruing costs. Finally on

this layer there is the scheduling module which is dis-

cussed within this paper.

For the implementation of the genetic algorithm in

the scheduling module we are utilizing an optimiza-

tion framework called EvA2(Unversity of Tuebingen,

). EvA2 offers a huge range of heuristics including

evolutionary algorithms. The reason for using EvA

is quite obvious. EvA includes a library for the GA

procedure that we have already discussed in this pa-

per. The graphical user interface (GUI) of EvA pro-

vides a solution for an easy parametrization of the

genetic algorithm. Another advantage of this frame-

work is the integration of a visualization of the own

optimization procedure. To implement our defined

problemwe have mapped our problem into an abstract

scheme. After the problem definition we have adapted

the problem representation for EvA2. In addition to

the problem definition and representation we haveim-

plemented the fitness evaluation. EvA2 uses these

definitions in the genetic algorithm. We only had

to implement specialized operators like the partially

mapped crossover. Consequently, we do not have to

worry about the handling of the genetic algorithm.

The required data is extracted from an ERP system,

in our case SAP. For the data exchange we need an

interface to send and receive master and transaction

data to or from an external application. SAP offers a

solution for the data exchange between the ERP sys-

tem and the APO (Advanced Planner and Optimizer).

This is called the SAP Core Interface (CIF). Addition-

ally to the CIF we use the SAP Java Connector (SAP

JCo). This is a middleware which supports the devel-

opment of SAP connected Java applications includ-

ing incoming and outgoing ABAP calls. These ABAP

calls are received and sent by a Java server and pro-

cessed e.g. in the scheduling module. Therefore, we

had to find, interpret and simulate all required outgo-

ing and incoming function calls to use the containing

data in the external scheduling module. Furthermore,

we have to run the function calls in the SAP system to

load the results from the scheduling module into the

ERP system.

Therefore, the fourth layer is the control layer

which avoids the isolation of processes which are run-

ning within our application modules. Additionally,

this layer controls and coordinates the entire planning

process and states of the particular modules.

The fifth layer is the presentation layer which rep-

DEVELOPMENT OF A SCHEDULING MODULE WITHIN AN INTEGRATED SOLUTION FOR THE EVALUATION

OF PROCESS VARIANTS

397

resents the user interface for the interaction between

users, especially designer, as well as mechanical en-

gineers, and the application modules.

5 CONCLUSIONS

Within the scope of this paper we have introduced a

concept for a scheduling module to evaluate process

variants in the proposal preparation using an genetic

algorithm. Therefore we have explained our problem

definition and classification α | β | γ - classification

and its rules for the scheduling problem. Thereby, we

derived the using of a very general classification and

we did not exclude any specialised definition.

Afterwards, we discussed the genetic algorithm to

schedule a process variant and the workload in a com-

pany within a defined evaluation period. For this we

use the widespread problem representation of the op-

eration based representation. In a first version we de-

veloped a sequential genetic algorithm. With a more

complex problem definition it is possible or necessary,

that we are forced to use other structures like a paral-

lel genetic algorithm. Within this definition we also

introduced the the genetic operators selection, recom-

bination and mutation.

The last section explained our software architec-

ture and the implementation for the discussed proce-

dure within a scheduling module. This includes the

description of the five tier architecture and especially

for the scheduling module the EvA2 framework. Ad-

ditionally we have explained the data exchange be-

tween the ERP system and the developed application.

Future work includes tests of the algorithm, its

configuration and its efficiency. Therefore we have to

use established benchmarks or we have to develop a

own benchmark. This should include different scenar-

ios for a wide range of different cases. Furthermore,

we have to develop an extended version of the optimi-

sation program. This version should include the test

results and changes of the algorithm configuration.

REFERENCES

Ehrlenspiel, K., A.Kiewert, and Lindemann, U. (2005).

Kostengnstig entwickeln und konstruieren - Kosten-

management bei der integrierten Produktentwicklung.

Springer, Berlin, 5th edition.

Gen, M. and Cheng, R. (1997). Genetic algorithms and en-

gineering design. Wiley series in engineering design

and automation. Wiley & Sons Inc.

Graham, R.L. ; Lawler, E.L. ; Lenstra, J.K. ; Rinnooy Kan,

A.H.G. (1979). Optimization and approximation in

deterministic sequencing and scheduling. A survay.

Annals of Discrete Mathematics 5. Gabler.

Gwiazda, T. D. (2006). Genetic Algorithms Reference -

Crossover for single-objective numerical optimization

problems, volume Volume I. Thomas Gwiazda.

Holland, J. (1975). Adaption in natural and artificial Sys-

tems, volume 5th edition printed in 1998. MIT Press.

International Organization for Standardization (2006). Ap-

plication Protocol: Mechanical product definition for

process planning using machining feature. Industrial

automation systems and integration - Product data rep-

resentation and exchange, Part 224. Beuth, Geneva,

3rd edition.

Jong, K. D. (1975). An Analysis of the Behavior of a Class

of Genetic Adaptive Systems. University of Michigan.

Loukil, T., Teghem, J., and Tuyttens, D. (2005). Solving

multiobjective production scheduling problems using

metaheuristics., volume 161 of European Journal of

Operational Research. Elsevier Ltd.

Michalewicz, Z. (1999). Genetic algorithms + data struc-

tures = evolution programs. Springer Verlag.

Nissen, V. (1997). Einfhrung in Evolutionre Algorithmen.

Vieweg.

Syswerda, G. (1989). Uniform crossover in genetic algo-

rithms. Proceedings of the third international confer-

ence on Genetic algorithms. Morgan Kaufmann Pub-

lishers Inc.

Syswerda, G. (1991). Schedule optimization using genetic

algorithms. Handbook of genetic algorithms.

Ting, C.-K., Su, C.-H., and Lee, C.-N. (2010). Multi-parent

extension of partially mapped crossover for combi-

natorial optimization problems, volume 37 of Expert

Systems with Applications. Elsevier Ltd.

T’kindt, V. and Billaut, J.-C. (2006). Multicriteria Schedul-

ing - Theory, Models and Algorithms, volume 2nd.

Springer Verlag.

Unversity of Tuebingen. http://www.ra.cs.uni-tuebingen.de/

software/EvA2/ - accessed on 29.01.2011.

Vnyi, R. (2004). Object oriented design and implementa-

tion of a general evolutionary algorithm. Conference

for Genetic and Evolutionary Computation - GECCO

2004.

Weicker, K. (2007). Evolutionre Algorithmen, volume 2.

Teubner Verlag.

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

398