FINDING THE BEST GRASPING POINT IN OBJECT

MANIPULATION TASKS

A Comparison between GA and PSO Methods

Hamed Mesgari, Farzad Cheraghpour

Dep. of Mechanical Engineering, K.N. Toosi University of Technology, Vanak Square, Tehran, Iran

S. Ali A. Moosavian

Dep. of Mechanical Engineering, K.N. Toosi University of Technology, Vanak Square, Tehran, Iran

Keywords: Optimization, Performance index, Object manipulation, Robotic manipulator, Grasping, Particle Swarm

Optimization, Genetic Algorithm.

Abstract: Grasp planning is one of the most interesting subjects of object manipulation tasks in robotics and the

development of grasp methods would be affected the robot performance. One of the most important subjects

which is discussed in grasp planning, especially in industrial applications, is optimal grasp planning and

finding the best grasping point. So it is important to find the best grasping point that the manipulator contact

with object. In this paper, the MAG performance index, which is designed for object manipulation tasks,

would be used for two different types of objects which are manipulated in the predefined path. Particle

Swarm Optimization (PSO) and Genetic Algorithm (GA) methods would be used to maximize this index

and find the best grasping point and finally compared with each other. The results show that in faster object

manipulation tasks, the GA method is more suitable than PSO method. Since in accurate object

manipulation tasks, the PSO method is preferred to GA method.

1 INTRODUCTION

Object manipulation is defined as the translation or

change in objects orientation by robot manipulators.

For a translation task, robot manipulator moves a

body by exerting appropriate joint forces and torques

after contacting with that. For object manipulation,

we can define several goals, e.g. turning a switch,

opening a door, polishing a surface, translation of a

vehicle engine in a production line, etc. One of the

most important things which are studying in object

manipulation is how body and robotic arms are

relating. This process is called grasp.

A good grasp must have several properties which

categorized in five principal groups, i.e. force

closure, equilibrium, stability, dexterity and dynamic

response (Hester et al., 1998). Thus an index must

be used to satisfy these grasp properties. Several

researches had been done on grasp planning in two

last decades. Some non-dimensional indices are

defined to evaluate grasp function. In one vision

(Cheraghpour et al., 2009), grasp principal

properties are classified into three main groups. In

the first group, the indices choose the appropriate

grasping points on object, which shows itself in

equations by grasp matrix, represent the kinematics

parameters of robot arm and grasped object. In the

second group, the indices choose the appropriate

configuration of robotic arm. Since there are several

responses for accessing of a robot arm to a point in

work space by calculation of inverse kinematics, the

answer must satisfy kinematics specifications like

dexterity and move capabilities. In the third group,

the indices are related to kinetics of robot

manipulator and grasped body after grasp process

and during the manipulation.

In other vision (Byoung et al., 2001), other non-

dimension indices are presented which included

other grasp properties like stability grasp index,

uncertainty grasp index, maximum force

transmission ratio index, task isotropy index and

stiffness mapping-based grasp isotropy index. With

199

Mesgari H., Cheraghpour F. and Ali A. Moosavian S..

FINDING THE BEST GRASPING POINT IN OBJECT MANIPULATION TASKS - A Comparison between GA and PSO Methods.

DOI: 10.5220/0003532001990204

In Proceedings of the 8th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2011), pages 199-204

ISBN: 978-989-8425-75-1

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

these in mind, Multi Aspect Grasp (MAG)

performance index (Cheraghpour et al., 2009) is

chosen to evaluate the grasp quality for object

manipulation in the predefined task.

Numerical solution methods are powerful tools

which can be used to solve problems, especially in

nonlinear problems numerical methods are more

suitable and useful than analytical solutions. Among

all these methods, Particle Swarm Optimization

(PSO) method and Genetic Algorithm (GA) are used

so widely in solving problems (Mannepalli et al.,

2010). These methods, especially PSO method, are

developed so widely in recent years (Kaviani, Fathi,

Farokhnia and Ardakani, 2009). Besides, PSO and

GA method are so fast and easy to use and their

results are so trustworthy (Martinez et al., 2009).

In this paper, Particle Swarm Optimization

(PSO) method and Genetic Algorithm (GA) would

be used to find the best grasping point of two

different objects according to maximizing the MAG

performance index and the results would be

compared with each other.

2 THE MAG INDEX

The Multi Aspects Grasp (MAG) performance index

is defined as (Cheraghpour et al., 2009):

0

12 3

max max

1

1

f

t

ii

N

ii

t

DP

M

AG W C W W dt

tDP

⎡⎤

⎛⎞

=++−

⎢⎥

⎜⎟

Δ

⎢⎥

⎝⎠

⎣⎦

∫

(1)

where t

0

and t

f

denote initial and final times of

simulation respectively, ∆t= t

f

- t

0

, weighting factors

W

1

, W

2

and W

3

are defined to put different

emphasizes on each term. In Eq. 1 C

N

is defined as

the inverse of condition number of grasp matrix, i.e.

G:

(

)

()

min

max

N

G

C

G

σ

σ

=

(2)

Also, the term D is related to move ability of robotic

arm and defined as:

(

)

**

det

T

D

JJ=

(3)

where J

*

denotes the Jacobian matrix which maps

robotic arm joints velocity space to grasped object

center of gravity velocity. Finally, the term P is

related to power consumption of robotic actuators

and defined as:

.

.

T

P

dt dt

θτ

⎡

⎤

=

⎢

⎥

⎢

⎥

⎣

⎦

∫∫

(4)

Note that in Eq. 1 the terms D

max

and P

max

denoted

the maximum values of D and P respectively in the

predefined task.

3 PSO METHOD

Particle Swarm Optimization (PSO) is a global

optimization method which is presented first by

Russell and Kennedy in 1995 (Atyabi et al., 2009).

PSO is a search method which is inspired from the

group behavior of animals like birds and fishes. The

main advantageous of PSO over other optimization

methods is the plenty existence of particles. Besides,

in nonlinear problems derivations of performance

index are so sophisticated whereas PSO is needless

of performance index derivations which made this

method so useful in solving nonlinear problems.

In this method, every particle is the representative of

problem solution which is moving in the search

space until approaches to the best position. At

starter, the position and velocity of every particle are

chosen randomly and then the value of particles is

calculated based on a merit criterion by moving in

the response space. Thus all particles accelerated

toward the best solution of problem step by step.

There is a memory is PSO which can save the best

position gained by every particle in P

i

and the best

position gained by all particles in P

g

during

simulation and in every step, i.e. iteration. The

velocity of particles is corrected by random

coefficient in the direction of these two positions.

This fact is shown by constraints Eq. 5 and Eq. 6 and

Figure (1):

11 2 2

(1) () ()() ()()

ii ii gi

vt wvtcRPtxt cRPtxt

→→→→ →→

⎛⎞⎛

⎞

+= + − + −

⎜⎟⎜

⎟

⎝⎠⎝

⎠

(5)

Where v

i

and x

i

are position and velocity of i-th

particle respectively, R

1

and R

2

are random

coefficients between 0 to 1 and c

1

and c

2

are

arbitrary constants. Parameter t denoted the

calculation step. Thus the new position of particles is

calculated as:

(1) () (1)

iii

xt xt vt

→→→

+

=++

(6)

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

200

Figure 1: Principle of PSO method and the process of

achieving to new position.

The term inertia weight w in Eq. 5 is declined

linearly with time:

()

()

12 2

max

max

iter t

www w

iter

−

=−× +

(7)

where w is inertia weight, w

1

and w

2

are the initial

and final inertia weights respectively, t is the

iteration step and maxiter is the termination

iteration. The inertia weight term control the

effectiveness of one step back velocity on the

solution finding task.

4 SIMULATION

4.1 Robotic Manipulator

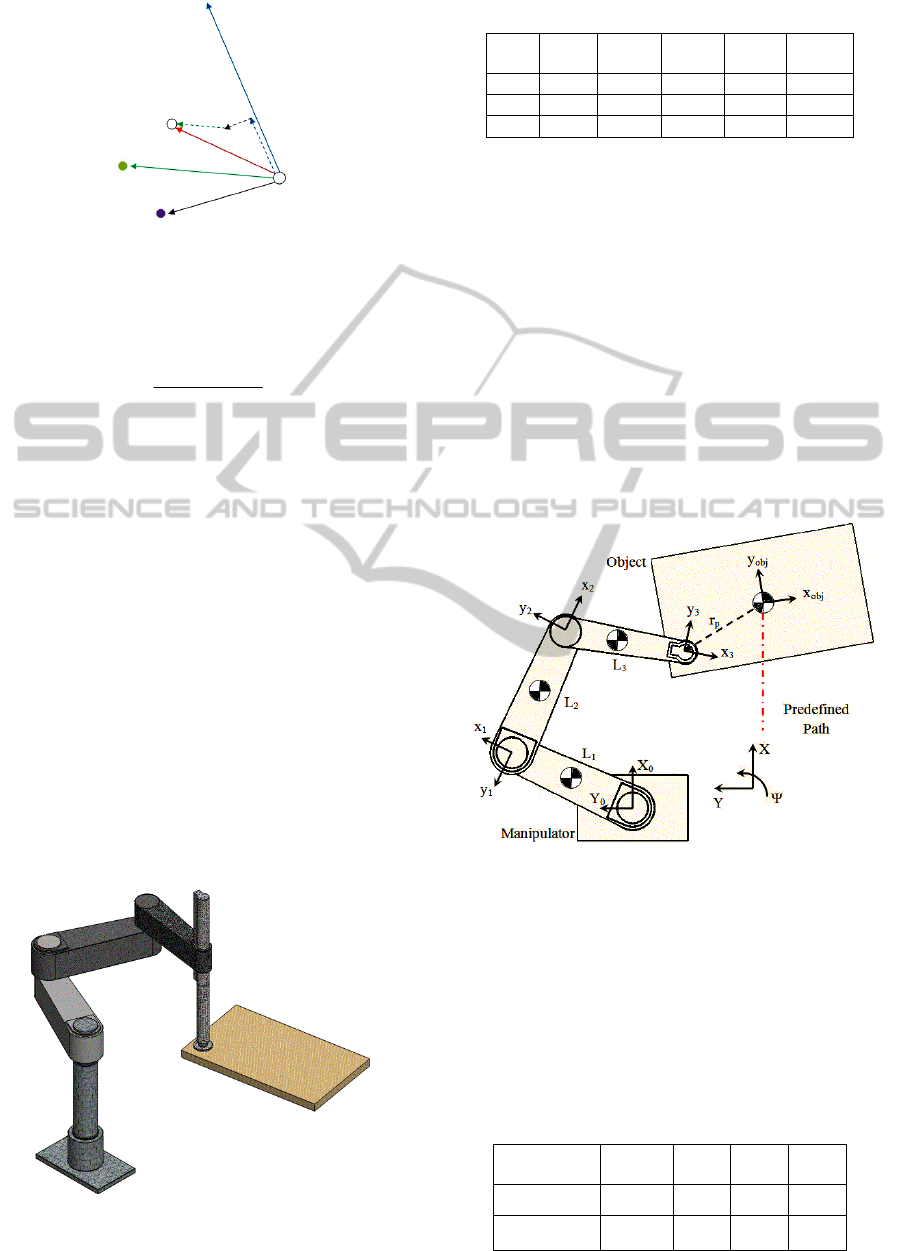

Figure (2) shows a robotic manipulator performing

the object manipulation task, i.e. moving the object

through the predefined path. The system includes a

RRR manipulator. The inertial and geometrical

parameters of manipulator arms are shown in Table

(1). Note that the unit of I

xx

, I

yy

and I

zz

in Table (1) is

kg.m

2

.

Figure 2: The SCARA type manipulator grasps a

rectangular object.

Table 1: Manipulator inertial and geometrical parameters.

zz

I

y

y

I

x

x

I

m[kg] L[m] Link

0.539 0.524 0.13017.41.041

0.539 0.524 0.13017.41.042

0.192 0.212 0.015 6.1 0.92 3

4.2 Task

The task is moving the object on the straight line

along X-axis. Joints trajectory are quintic functions

as follows (Craig, 2005):

2345

012345

0

()

() 1

() 10

5(sec)

f

Xtaatatatatat

Yt

t

t

ψ

=+++++

=

=

=

(8)

The predefined path, grasping point coordinates with

respect to object center of mass and also the DH

coordinates of each link of the manipulator are

shown in Figure (3).

Figure 3: Predefined path for object center of mass in a 2D

task, the position of grasping points with respect to C.G.

of object and DH coordinates.

The grasp is supposed to be solid, i.e. the object

orientation cannot change with respect to the End-

Effector. The MAG index is calculated for two types

of objects, i.e.

1.25 0.55

mm

×

rectangular (No.1) and

20.3

mm

×

long bar (No.2). The inertial parameters

of objects No.1 and No.2 are shown in Table (2).

Table 2: Grasped objects inertial parameters.

zz

I

y

y

I

x

x

I

m [kg] Object No

3.4612.9030.56522.27 1

6.6266.4830.14919.44 2

x

i

(t)

x

i

(t+1)

P

i

P

g

v

i

(t)

FINDING THE BEST GRASPING POINT IN OBJECT MANIPULATION TASKS - A Comparison between GA and PSO

Methods

201

Note that the unit of I

xx

, I

yy

and I

zz

in Table (2) is

kg.m

2

.

Also weighting factors W

1

, W

2

and W

3

in Eq. 1 are

supposed to be equal, i.e. all the terms have the same

importance in object manipulation task.

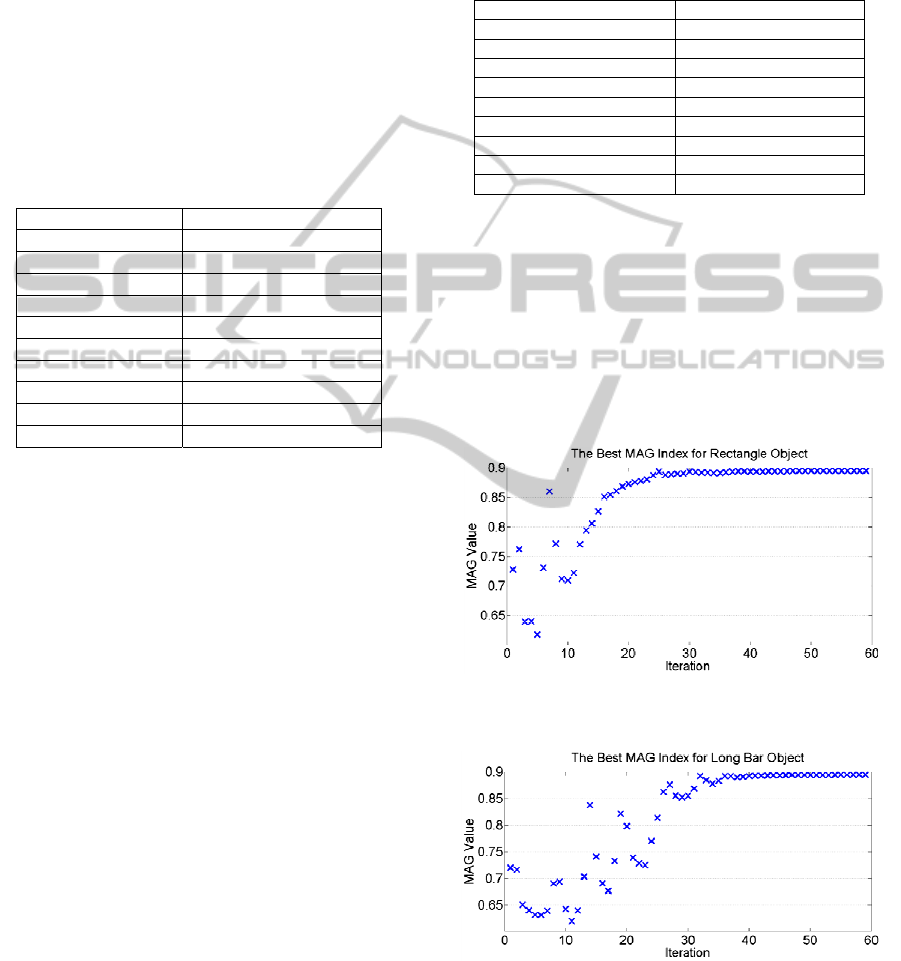

4.3 PSO Method Parameters

We developed a program for calculation of MAG

index from object surface points which is coded in

MATLAB program. Basic PSO parameters which

are illustrated in Eq. 5, Eq. 6 and Eq.7 are shown in

Table (3) (Shi and Eberhart, 1999).

Table 3: Basic PSO parameters.

Parameters Objects No.1 and No.2

V

max

1

V

min

0

x -

y -

c

1

1.4

c

2

1.4

w

1

0.4

w

2

0.9

Agents 20 particles

Elimination time 60 iterations

where V

max

and V

min

are the upper and lower

boundary values of initial velocity respectively, x

and y are initial values of grasping points position

with respect to object center of mass which are

randomly selected on the object surface, c

1

and c

2

are fixed constants in Eq. 5, w

1

and w

2

are the initial

and final inertia weights respectively used in Eq. 7

(Samanta and Nataraj, 2009), agents and elimination

time are the number of particles which search in

response space and the total iterations needed to

converge the answers respectively which are

obtained heuristically (Atyabi et al., 2009). Note that

agents are the representatives of the problem

solution, i.e. the best grasping points of object which

maximize the MAG index.

4.4 GA Parameters

We use MATLAB Genetic Algorithm toolbox to

maximize MAG index and find the position of the

best grasping point. In the toolbox, MAG index and

the geometrical dimensions of object are selected as

fitness function and inputs respectively. The

simulation parameters are shown in Table (4).

Generation and population size are obtained

heuristically, i.e. more generation and population

size values do not make any differences is results

and these are the minimum values that results

needed to be converged. Since there is no constraint

in problem, mutation function is selected as

constraint dependant. Other parameters are selected

according to their definition (Goldberg, 1997).

Table 4: GA parameters.

Parameters Object No.1 and No.2

Population size 20

Fitness scaling function Rank

Selection function Stochastic uniform

Crossover fraction 0.8

Crossover function Scattered

Mutation function Constraint dependant

Generation 40

Migration fraction 0.2

Migration interval 20

5 RESULTS AND DISCUSSION

The results of MAG index value obtained from PSO

method for rectangular (No.1) and long bar (No.2)

objects are shown in Figure (4) and Figure (5). The

results show that the MAG value for both

rectangular and long bar object is about 89 percent

for the best grasping point.

Figure 4: MAG index value for the best grasping point for

rectangular object calculated by PSO method.

Figure 5: MAG index value for the best grasping point for

long bar object calculated by PSO method.

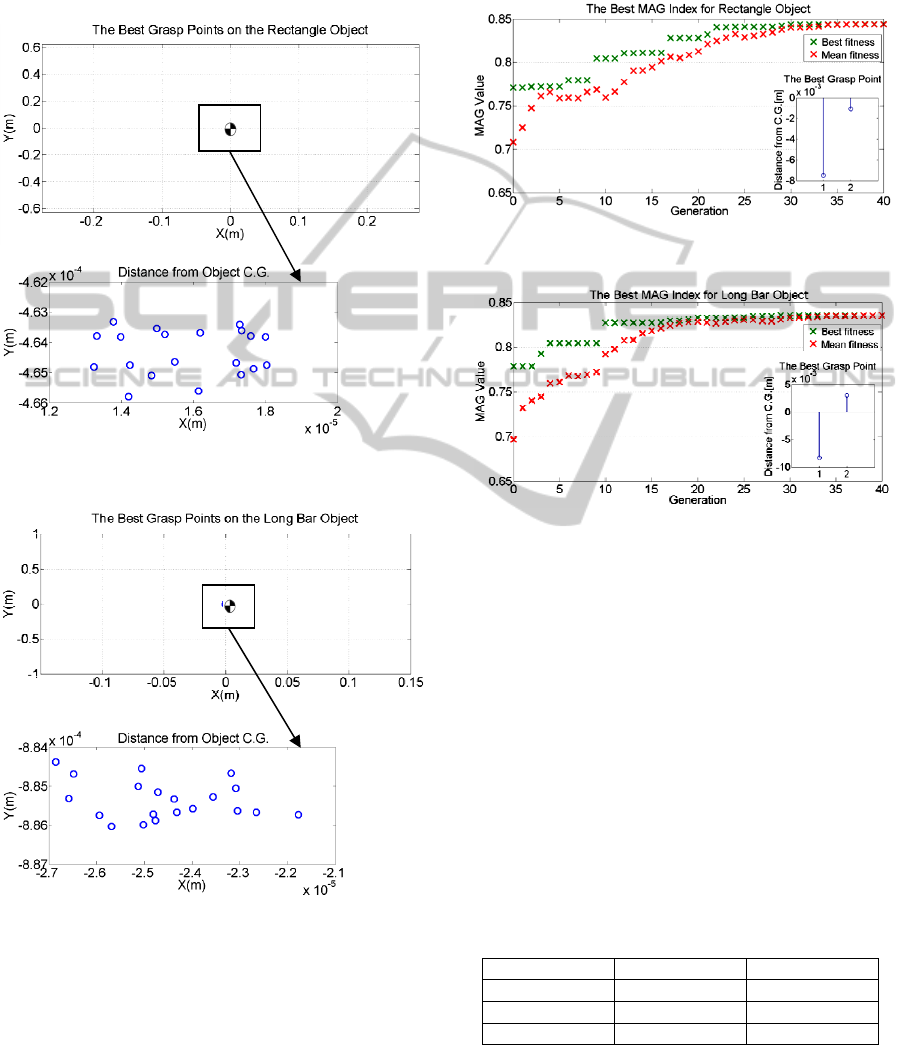

The best grasping points of objects obtained from

PSO method are shown in Figure (6) and Figure (7).

The results show that the best grasping points are

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

202

closed to object center of gravity. It is analytically

proved that the best grasping point must be closed to

the object center of gravity, i.e. the maximum MAG

performance index value is belong to the best

grasping point which is the object center of gravity

(Cheraghpour et al., 2010).

Figure 6: The best grasping points for rectangular object

calculated by PSO method and their magnified positions.

Figure 7: The best grasping points for long bar object

calculated by PSO method and their magnified positions.

The results obtained from GA for object No.1 and

object No.2 are shown in Figure (8) and Figure (9).

The results show that MAG index value for

rectangular and long bar object are about 84 and 83

percent respectively for the best grasping point

which is closed to object center of gravity

(Cheraghpour et al., 2010).

Note that in Figure (8) and Figure (9), 1 and 2

represented the x and y coordinates of grasping point

position respectively which are measured from

object center of gravity.

Figure 8: MAG index value for the best grasping point for

rectangular object calculated by GA method.

Figure 9: MAG index value for the best grasping point for

long bar object calculated by GA method.

The results show that maximum MAG index value

which is obtained from PSO method is more than

GA method, i.e. MAG index value obtained from

PSO method for both object NO.1 and object NO.2

is 89 percent whereas MAG index value obtained

from GA for object NO.1 and object are 84 and 83

percent respectively for the grasping point which is

closed to object center of gravity. Besides, the best

grasping point obtained from PSO method is closer

to object center of gravity than the result of GA one.

Also, program processing times on an Intel CPU

2.8 GHz for GA and PSO method are shown in

Table (5).

Table 5: A comparison between approximated processing

time of GA and PSO methods.

time (sec) time (sec)

Method object No.1 object No.2

PSO 236 238

GA 150 152

The Table (2) shows that GA is converging faster

than PSO method, i.e. processing time of GA is less

than PSO method.

FINDING THE BEST GRASPING POINT IN OBJECT MANIPULATION TASKS - A Comparison between GA and PSO

Methods

203

6 CONCLUSIONS AND FUTURE

WORK

In this paper, MAG performance index is selected to

evaluate grasp quality of object manipulated in the

predefined path. Two numerical solution methods

were used and compared with each other. Particle

Swarm Optimization (PSO) method and Genetic

Algorithm (GA) were used to maximize this index

and find the best grasping point for object

manipulation in the predefined task. Two different

kinds of objects were used as the case studies. The

results show that the maximum value of MAG index

obtained from PSO method is more than maximum

value which is obtained from GA one. Besides, both

methods show that the best grasping point is closed

to object center of gravity, which was analytically

proved. Also the results of GA method are

converged faster than PSO method but with different

accuracies, i.e. PSO method had more accurate

results than GA one. Therefore, in faster object

manipulation tasks, the GA method is more suitable

than PSO method. Since, in accurate object

manipulation tasks, the PSO method is preferred to

GA method.

In the future, we would like to do this procedure

for unsymmetrical objects. Also for spatial and

wheeled mobile manipulators (WMM), which has

the geometrical constraints of object and the

manipulator is more sophisticated, the problem

could be more interesting. For online problems, e.g.

facing to a new object, soft computing methods like

neural networks, fuzzy logic and neuro-fuzzy would

be used and compare.

REFERENCES

Hester, R., Cetin, M., Kapoor, Ch,. Tesar, D., 1998. A

criteria-based approach to grasp synthesis, The

University of Texas at Austin.

Cheraghpour, F., Moosavian, A., Nahvi, A., 2009.

Multiple Aspect Grasp Performance Index for

Cooperative Object Manipulation Tasks. IEEE/ASME

International Conference on Advanced Intelligent

Mechatronics, IEEE Press.

Byoung, H., Sang-Rok, O., Byung-Ju, Y., Hong, S., 2001.

Optimal Grasping Based on Non-Dimensionalized

Performance Indices, Proceedings of the 2001

IEEE/RSJ. IEEE Press.

Mannepalli, S., Dutta, A., Saxena, A., 2010. A multi-

objective GA based algorithm for 2D form and force

closure grasp of prismatic objects, Int. Journal of

Robotics and Automation.

Kaviani, A. K., Fathi, S. H., Farokhnia, N., Ardakani, A.

J., 2009. PSO, an effective tool for harmonics elimination

and optimization in multi-level inverters, 4th IEEE

Conference on Industrial Electronics and

Applications, ICIEA 2009, IEEE Press.

Martinez, R., Castillo, O., Aguilar, L., 2009. Optimization

of interval type-2 fuzzy logic controllers for a

perturbed autonomous wheeled mobile robot using

genetic algorithms, Elsevier Press.

Atyabi, A., Phon-Amnuaisuk, S., Chin Kuan, H., 2009.

Applying Area Extension PSO in Robotic Swarm,

Springer Science and Business Media, Springer Press.

Craig, J., 2005. Introduction to Robotics; Mechanics and

Control, Addison-Wesley Publishing, 2nd edition.

Shi, Y., Eberhart, R., 1999. Empirical study of particle

swarm optimization, Proceedings of IEEE Congress

on Evolutionary Computation, Piscataway, NJ, USA,

IEEE Press.

Samanta, B., Nataraj, C., 2009. Application of particle

swarm optimization and proximal support vector

machines for fault detection, Published in Springer

Science and Business Media, LLC, Springer Press.

D. E. Goldberg, 1997. Genetic Algorithm in search,

Optimization, and Machine Learning, Prentice-Hall

International, Inc.

Cheraghpour, F., Moosavian, A., Nahvi, A., 2010. Robotic

Grasp Planning by Multiple Aspects Grasp Index for

Object Manipulation Tasks, Proceeding of ICEE2010,

Isfahan University of Technology.

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

204