BEAM TRAJECTORY CONTROL OF THE FUTURE COMPACT

LINEAR COLLIDER

G. Balik

LAPP, Université de Savoie, CNRS/IN2P3, Annecy-le-Vieux, France

A. Badel

3

, B. Bolzon

2

, L. Brunetti

1

, B. Caron

3

, G. Deleglise

1

, A. Jeremie

1

R. Le Breton

3

, J. Lottin

3

, L. Pacquet

1

1

LAPP, Université de Savoie, CNRS/IN2P3, Annecy-le-Vieux, France

2

CERN-European Organization for Nuclear Research, Geneva, Switzerland

3

SYMME-Polytech Annecy Chambéry, Université de Savoie, Annecy-le-Vieux, France

Keywords: Adaptive algorithm, Disturbance rejection, Least-squares algorithm, Optical feedback, Parameter

optimization, Vibration control.

Abstract: The future Compact Linear Collider (CLIC) currently under design at CERN (European Organization for

Nuclear Research) would create high-energy particle collisions between electrons and positrons, and

provide a tool for scientists to address many of the most compelling questions about the fundamental nature

of matter, energy, space and time. In accelerating structure, it is well-established that vibrations generated

by the ground motion constitute the main limiting factors for reaching the luminosity of 10

34

cm

-2

s

-1

. Several

methods have been proposed to counteract this phenomena and active vibration controls based on the

integration of mechatronic systems into the machine structure is probably one of the most promising. This

paper studies the strategy of the vibration suppression. Active vibration control methods, such as optimized

parameter of a numerical compensator, adaptive algorithm with real time control are investigated and

implemented in the simulation layout. The requirement couldn’t be achieved without the study of active-

passive isolation able to damp high frequency ground motion. Thus, a pattern of a potential active/passive

isolation has been proposed opening up prospects on the design of a future mechanical isolation.

1 INTRODUCTION

After the world’s largest particle accelerator LHC

(Virdee, T. S., 2010, The LHC project), the next

generation of accelerators is being designed. Among

them, the Compact Linear Collider CLIC is an

ambitious project that proposes colliding beams of

positrons and electrons.

The performance requirements of CLIC

challenge the stabilization and control system in a

number of areas. In order to achieve the required

luminosity of 10

34

cm

-2

s

-1

, two beams are accelerated

and steered into collision. Considering the desired

size of the beams (nanometer scale), the collision

will require a very low vertical motion of these two

beams all along the collider, and more specially

through the last two focusing magnets. This can be

done only by focusing and colliding the two separate

beams to nanometer spot sizes. Thus, it imposes

very tight constraints on the final focus (FF)

system’s alignment and stability.

The future CLIC composed of two arms of

approximately 17 km long facing each other will

accelerate beams at velocities near the speed of light.

Once accelerated with the required energy and

emittance (Assmann, R. W. et al., 28 July 2000)

through the main linac, a sophisticated beam

delivery system focuses the beam down to

dimensions of 1 nm RMS size in the vertical plane

and 40 nm horizontally. This requires the final focus

magnets to be stabilized to vibration amplitude of

less than 0.1 nm for oscillations above 0.1 Hz at the

interaction point (IP).

Given the tight specifications and hardware

limitations, ground motion mitigation is a real

challenge. This paper proposes a method to deal

with ground vibrations. A first part aims to design a

97

Balik G., Badel A., Bolzon B., Brunetti L., Caron B., Deleglise G., Jeremie A., Le Breton R., Lottin J. and Pacquet L..

BEAM TRAJECTORY CONTROL OF THE FUTURE COMPACT LINEAR COLLIDER.

DOI: 10.5220/0003534700970104

In Proceedings of the 8th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2011), pages 97-104

ISBN: 978-989-8425-74-4

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

filtering algorithm combining feedback control and

real time adaptive algorithm based on the

generalized least square algorithm. Next a study of

the global pattern of the isolation needed to achieve

the requirements is presented. This paper ends up

with numerical simulations and robustness test.

2 BEAM-BASED FEEDBACK

Once accelerated, the beam goes through a final

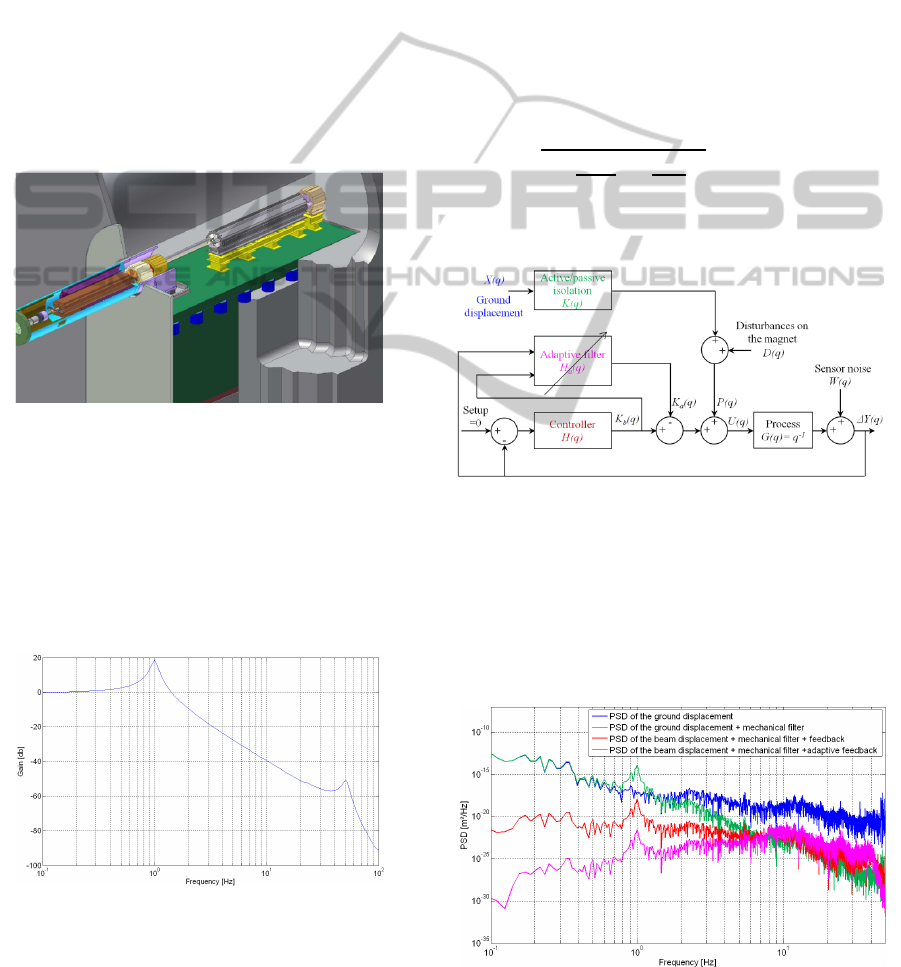

focusing magnet subject to disturbances (see fig. 1)

Stabilization of the beam can be obtained by using

the corrective capabilities of the beam components

by measuring the beam parameters (size, position…)

tanks to a Beam Position Monitor (BPM) (not

represented) and acting on the beam with a kicker.

The frequency range in which this is possible is

given by the beam repetition rate. For CLIC, this

rate is 50Hz (which means that the beam is

composed of a serial of trains separated from each

other in time by 20 ms). This configuration imposes

that the beam cannot be corrected above several Hz.

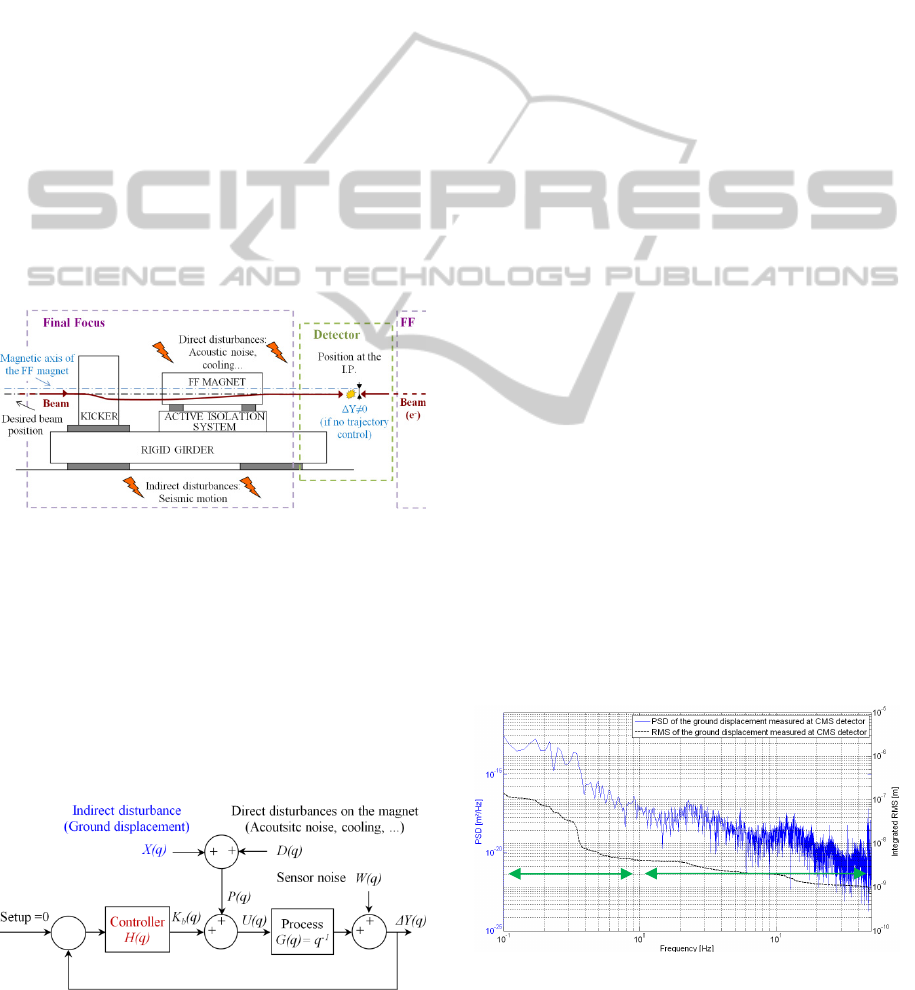

Figure 1: Final focus scheme.

As ground motion is still at a detrimental level

until about 50-100Hz, depending on the site, it needs

to be corrected by mechanical means. Thus, this

magnet stands on an active-passive support designed

to reduce ground motion vibrations.

The proposed control framework is composed of

a feedback loop where the controller (H) defines the

dynamical behaviour of the system. The structure of

this control is given in figure 2 (The backward shift

operator is denoted q

-1

).

Figure 2: Scheme of the beam trajectory control.

The disturbance (X) is the mechanical excitation

from ground motion (see part 2.1) which is also the

disturbance felt by the magnets (Other sources of

disturbances are neglected as their contribution to

the beam motion is supposed to be insignificant

compared to the ground motion itself). (P) is finally

the disturbance felt by the magnet.

The transfer function between the mechanical

displacement of this magnet and the beam can be

modeled by a constant matrix (equal to 1 in the

model as it is considered as a uniform rigid

structure). Finally the noise of the sensor (W) is

added to the displacement of the beam.

The action (K

b

) meant to reduce the motion of

the beam (or the offset between the two beams at the

interaction point) is done by a kicker. The obtained

displacement of the beam is proportional (equal to 1

in the following model) to the injected current of the

kicker. The dynamic of the system is due to the

frequency of the beam train, so the process can be

treated as a first approach as a delay at a sampling

period equal to 0.02 s.

This scheme allows to design a controller (H)

that performs optimally (depending on the PSD of

the ground motion) to minimize the integrated RMS

displacement of the beam.

2.1 The Ground Motion

For this study, the reference is the measured motion

in the tunnel of the Large Hadron (LHC) at CERN

and more precisely, the ground motion where is

located the Compact Muon Solenoid (CMS)

calorimeter (The CMS Collaboration, 2008). Figure

3 represents the PSD and the integrated RMS of the

ground motion measured at CMS thanks to a

geophone (Güralp CMG-6T calibration: ±12.5 mm

s-1, Frequency range: [0.033-50] Hz, sensitivity:

2x998 V s m

-1

, resolution: 0.05 nm between 4 Hz

and 50 Hz) (Güralp Systems Limited, Inc.)

Figure 3: PSD and integrated RMS of the ground motion

measured at CMS.

Cultural

noise

Earth

motion

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

98

Considering the limited bandwidth of the

geophones, simulations have been computed in the

frequency range [0.1-50] Hz instead of [0-∞[. Note

that the limitation at 50 Hz has no impact on the

results as the PSD decreases significantly with

frequency above this frequency.

The PSD of the natural ground motion is a steep

function of frequency which falls off as 1/f

4

. Several

peaks can be observed, related to machinery and

structural resonances. Such peaks appear as steps in

the integrated R.M.S. PSD is particularly useful,

because it allows to calculate the total RMS (Root

Mean Square) displacement in any frequency band

(or indeed over the whole frequency range

measured) by integrating the displacement PSD and

taking the square root.

2.2 Design of a Classical Controller

The required specifications impose to lower the

integrated RMS(0). The controller has to provide

real-time computation. Considering the process and

the previous requirements, the structure of the

controller has been chosen to be the following:

(

)

=

+

+

1+

+

Higher order structures of the controller have

been tested but it didn't result in a significant gain

compared to the complexity of the feedback control.

Considering the previous scheme (fig.2), the closed

loop transfer function taken into account is the

transfer function between the beam displacement

and the disturbance X (also called sensitivity transfer

function):

(

)

=

Δ

X

=

1+

Note that as G is a pure delay, the effect, in term

of amplitude of the closed loop on sensor's noise

disturbance W (or any direct disturbance D) is the

same as for the ground motion disturbance P.

2.3 Optimization of the Controller

The method to lower the RMS(0.1Hz) of is the

following:

• Estimation of the PSD of the measured ground

motion signal,

• Scanning the parameter space of the controller,

• For each of these combinations, if the parame-

ters give a stable closed loop transfer function

F, then:

• Computation of the PSD of the obtained output

using:

•

(

)

=

|

(

)|

.(

(

)

)

• Computation of the integrated RMS ,

• Selection of the parameters' set of the

controller that gives the minimum RMS (0).

As these parameters obviously depend on the

PSD of the input disturbance (P), if this signal is

changed in terms of PSD, then the optimization will

produce another set of parameters.

The transfer function F between the ground

motion disturbance and the output depends

obviously on these parameters. In the optimized

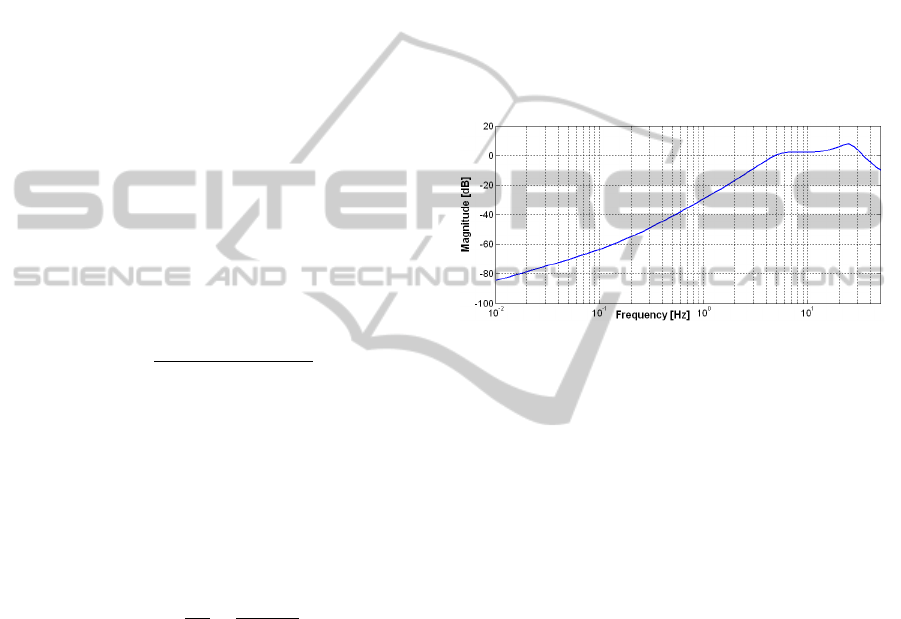

case, the next plot represents its transfer function:

Figure 5: Sensitivity transfer function magnitude.

However, the sensitivity transfer function F has

an important property:

|

()

|

= 0

/

with

=2

This formula obtained from Bode's sensitivity

integral (Mohtadi, C., 1990, Bode's integral theorem

for discrete-time systems) induces that lowering

effects of disturbances at low frequencies will

increase effects of disturbances at high frequencies

(also called “water bed effect”).

2.4 Simulation Results

The following simulation has been computed by

injecting a sample of the ground motion disturbance.

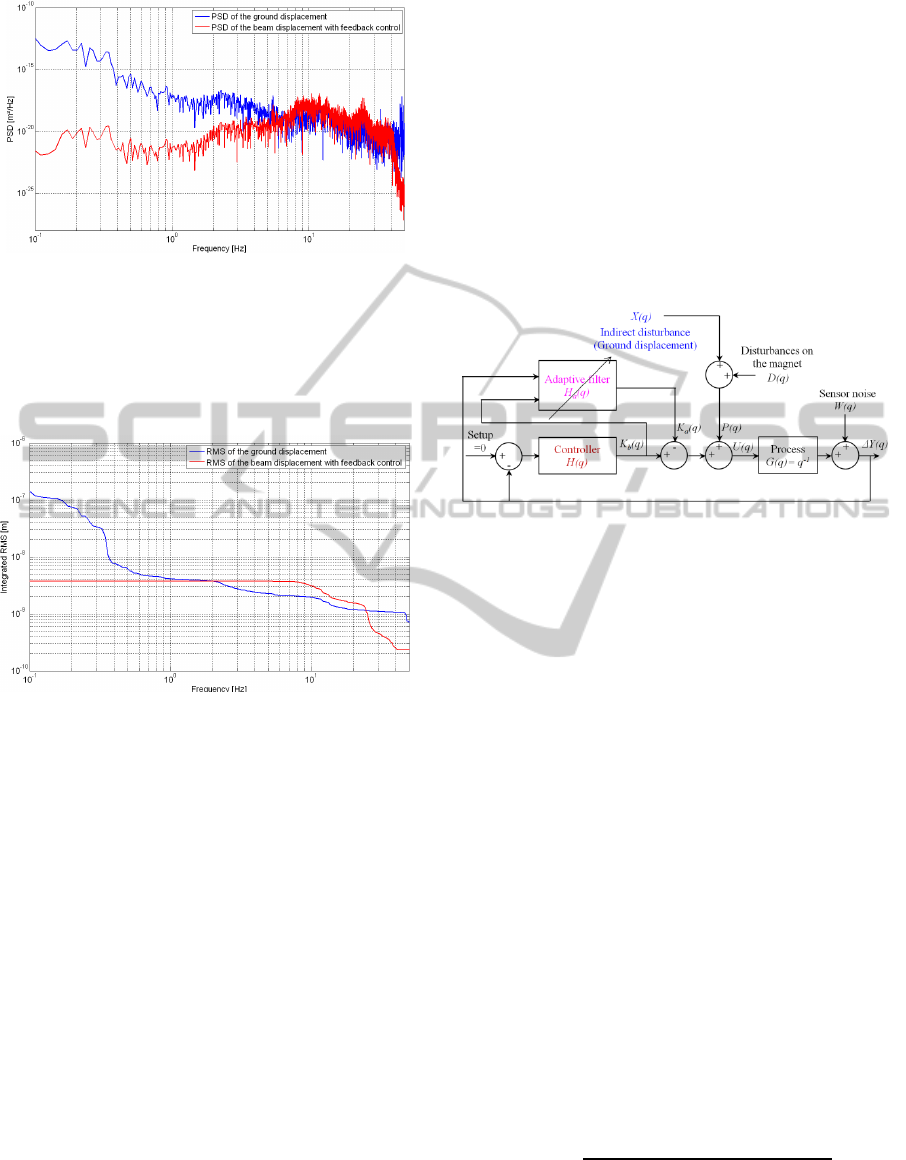

No other noise has been considered. Figures 5 and 6

represent the PSD and the integrated RMS

displacements obtained by simulation with the

optimized feedback control loop:

BEAM TRAJECTORY CONTROL OF THE FUTURE COMPACT LINEAR COLLIDER

99

Figure 5: PSD obtained with feedback control.

The plot above shows mainly two things; first of

all, the controller is able to correct the beam

trajectory to compensate effect of ground motion

between [0-6] Hz. Then after 5-6 Hz, it will increase

ground motion.

Figure 6: Integrated RMS obtained with feedback control.

This amplification after 6 Hz has bad

consequences for the integrated RMS which rises to

almost 4 nm.

Because of the sample time of the process, the

feedback is efficient in a very limited frequency

bandwidth [0-5] Hz. It implies that the integrated

RMS at 5 Hz of the disturbance P has to be the

lowest possible, and that one cannot do better than

this value by the means of a feedback control. It is

thus necessary to consider a complementary solution

able to filter the ground motion vibrations as much

as possible. This study will be the topic of part 4.

3 FEEDBACK AND ADAPTIVE

ALGORITHM STRATEGY

This strategy is most likely used when the sources of

disturbances are unknown or variable in time, which

is the case in this study. The dynamical behavior of

the system is defined by the feedback loop, and an

adaptive algorithm changes the command of the

process to minimize the prediction error. The

ordinary least-squares method may lead to biased or

non-consistent estimates of system parameters in the

presence of noise. The bias problem may be solved,

for example, by using the generalized least-squares

method. In the generalized least-squares method, a

digital filter is used to filter the observed input-

output data.

3.1 Design of the Adaptive Filter

The control scheme is the following:

Figure 7: Adaptive feedback control scheme.

This control uses the prediction-error to

reconstruct and cancel out the disturbance. This

scheme is by nature non-linear as it is composed of

two interlinked loops. To avoid such a complex

study, a general adaptive command structure defined

by Landau's stability theorem (Landau, I. D., Zito,

G., 2006, Digital Control Systems) has been used. In

practice the estimation scheme is needed to be

iterative, allowing the estimated model to be updated

at each sample interval as new data become

available. The generalized least square algorithm

estimates the parameters h of the filter H

a

by

minimizing the following least square criteria:

(

)

=

()

²

This Algorithm uses the prediction error:

(

)

=

(

)

−

(

)

(

−1

)

(balanced with a forgetting factor λ) made on the

estimation to compute the next set of the parameters:

ℎ

(

)

=ℎ

(

−1

)

+

(

)

(

)

using the Kalman gain:

(

)

=

(

−1

)

()

1+

(

)

(

−1

)

()

and the Ricatti equation:

(

)

=

(

−1

)

−λ

(

)

(

)

(

−1

)

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

100

3.2 Simulation Results

Figure 8 and 9 show the obtained performance using

this configuration.

Figure 8: PSD obtained with adaptive feedback control.

The PSD plot shows that this adaptive scheme

has allowed to considerably decrease the power of

the ground motion displacement in the bandwidth

[0-5] Hz. It also has the drawback to increase the

amplification after 5 Hz leading to an integrated

RMS worse than with feedback only.

Figure 9: Integrated RMS obtained with feedback and

adaptive control.

Previous observations with optimized feedback

and adaptive control show that the residual

integrated RMS displacement at 0.1 Hz of the beam

displacement is mainly due to the integrated RMS at

5 Hz of the motion of the magnet support. Above

that frequency, the control is not efficient. The

strategy consists in adding active/passive isolation

under the magnet which steers the beam. It has to

attenuate the ground motion vibration from 5 Hz

which means that the resonance frequency of this

mechanical structure has to be below 5 Hz. Similar

concepts have already been developed in the

research and industrial field (Braccini, S. et al.,

2005), (Ellison, J. et al., 2001, Passive vibration

control of airborne equipment using a circular steel

ring).

4 ACTIVE/PASSIVE ISOLATION

To avoid luminosity loss the vertical position of the

magnets must be stabilized to 0.1 nm RMS for

frequencies of 0.1 Hz and above. This will be

achieved by the previous adaptive feedback

controller and a passive pre-isolator, complemented

by an active isolation system. The characteristic of

this whole isolation system is determined by

simulation in the next part.

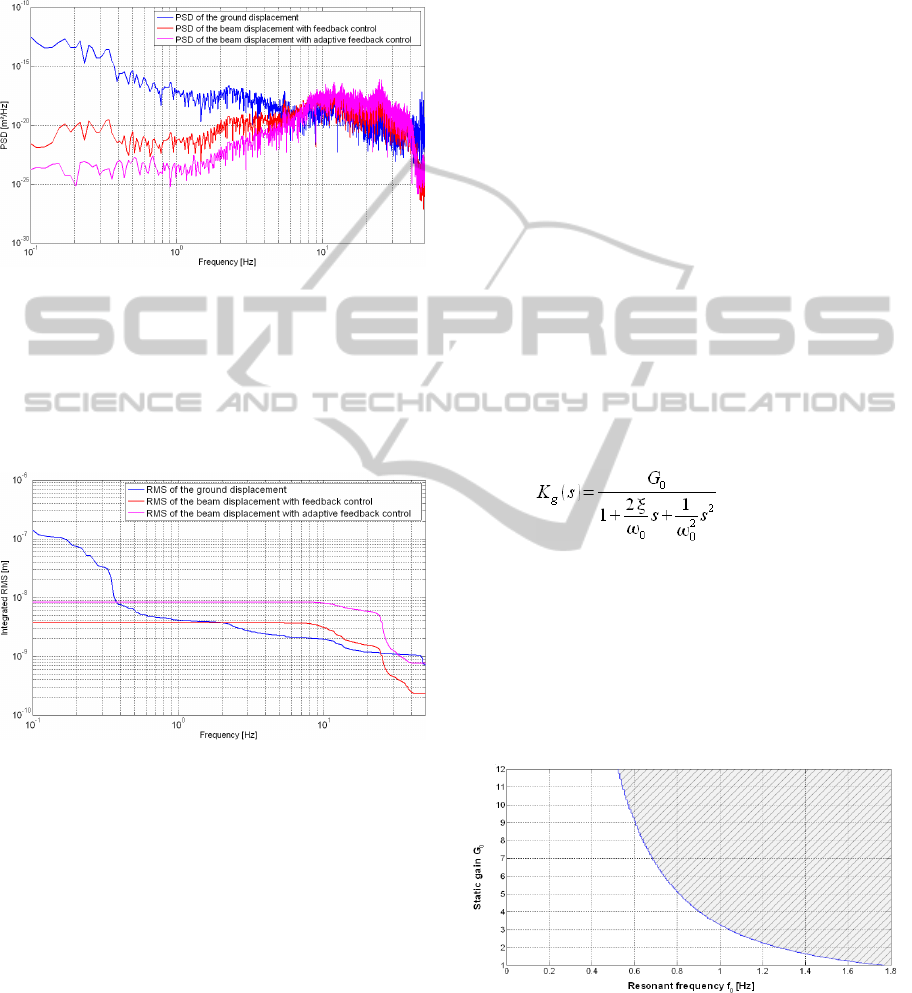

4.1 Pattern of the Mechanical Support

This part aims to establish a pattern of the

mechanical support needed between the ground and

the beam to reach the specifications of 0.1 nm. This

transfer function should be representative of a

typical mechanical support dynamical behavior.

Thus, it has been modeled by the following 2

nd

order

low-pass filter:

with ω

0

=2πf

0

This scheme implied to optimize the controller

for each combination (f

0

, G

0

), until an eventual

solution allows to reach the specifications (The

mechanical filter modification imply a modification

of the input disturbance (P) and a re-optimization of

the controller, see part 3.2). The body of the

combinations (f

0

, G

0

), see figure 10, constitutes the

pattern of the desired active-passive isolation

dynamic.

Figure 10: Pattern of the active-passive isolation dynamic.

The area under the curve represents the body of

the combinations (f

0

, G

0

). The simulation showed

that this pattern is independent of the damping ratio

ξ in the range [0.005 0.7]. This results from the

BEAM TRAJECTORY CONTROL OF THE FUTURE COMPACT LINEAR COLLIDER

101

extremely high efficiency of the adaptive feedback

control in low frequencies.

This pattern is actually used for a more detailed

study of a mechanical support design. This support

will be efficient enough to achieve the desired

performances.

4.2 Passive Isolation

The ground micro-seismic motion at frequencies

above 4 Hz, either natural or generated by

machinery, can be effectively reduced by a passive

mechanical low-pass filter currently being designed

(Ramos, F., Dynamic analysis of the FF magnets

pre-isolator and support system). In this scheme, the

whole system sits on a big massive support; the pre-

isolator:

Figure 11: Layout of the pre-isolator, with the concrete

mass supporting the two final focus magnets.

The two magnets are supported by rigid girders

that are fixed on top of a massive concrete block,

weighing about 80 tons and resting on several

springs (in blue in Figure 11) whose rigidity is tuned

in order to have a vertical resonance of the whole

assembly at 1 Hz. The transfer function of this

mechanical filter is given figure 12:

Figure 12: Transfer function of the pre-isolator.

Ground motions at frequencies above 1 Hz are

reduced by a factor f

2

up to the first internal resonant

mode, which can be tuned to be in the bandwidth 30

– 50 Hz. The system is designed to provide a

reduction of the RMS vertical displacement from

about 3 to 0.1 nm at 4 Hz and it has to work in

combination with the active stabilization (i.e.

adaptive feedback control plus an eventual

combination with an active/passive isolation).

4.3 Mechanical Support Consideration

The study of the design of such an active support is

not the topic of this paper. Its behavior (described

part 4.2) has been modelised by a product of two

second-order low-pass filters (K

1

and K

2

, K=K

1

.K

2

)

with resonance frequencies f

1

= 1 Hz and f

2

= 50 Hz

and damping ratios ξ

1

= 0.05 and ξ

2

= 0.075.

,

(

)

=

1

1+

2

,

,

+

1

,

²

with

=2

This dynamic has been implemented in the next

simulations (see figure 13)

Figure 13: Feedback and adaptive control scheme with

active/passive isolation simulation.

4.4 Results

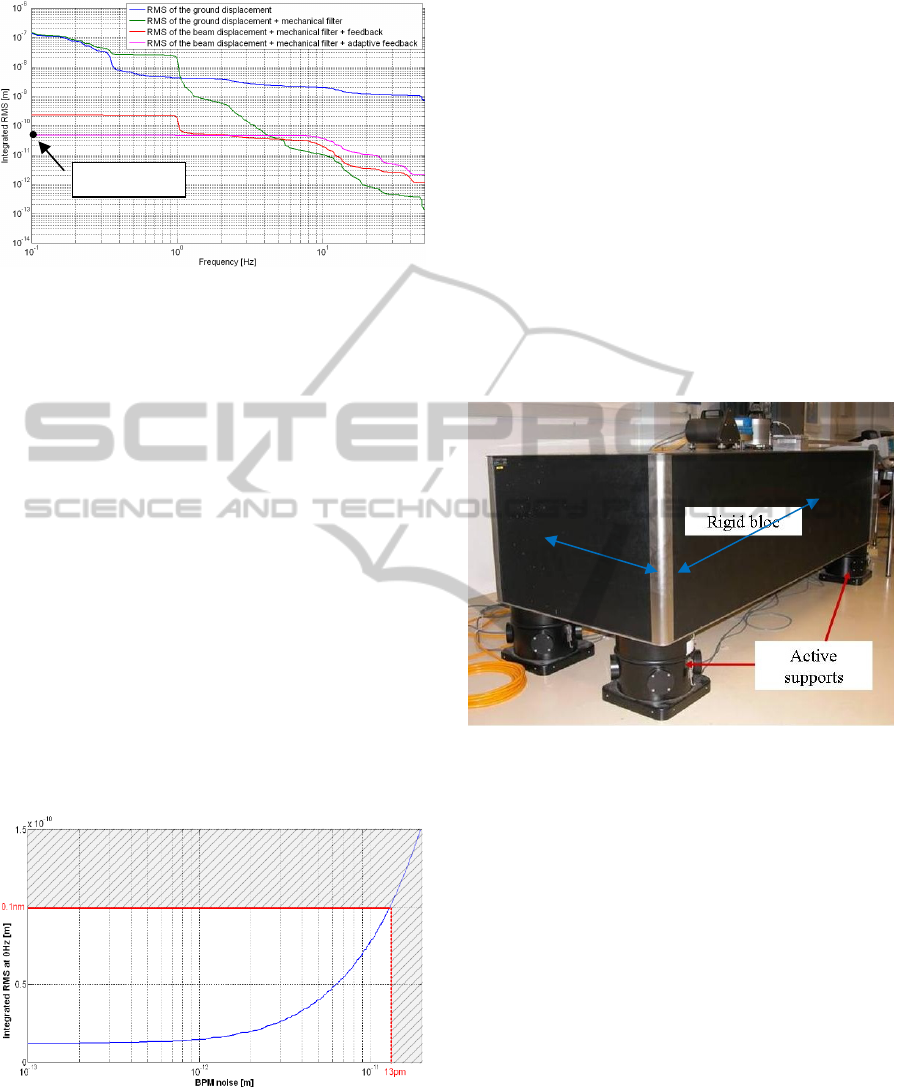

The following plots represent the simulation results

of the feedback and adaptive control obtained when

filtering the ground motion by the pre-isolator’s

transfer function.

Figure 14: PSD obtained with adaptive feedback control

and mechanical filter.

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

102

Figure 15: Integrated RMS obtained with adaptive

feedback control and pre-isolator.

The simulation shows that this strategy

combining passive isolation to damp fast motion of

the ground and feedback loop coupled with an

adaptive algorithm which deals with slower motions

is able to reach an integrated RMS at 0.1 Hz of

4.60e

-11

m.

The previous study is based on a model of the

real system currently under development.

Considering the current project status, it was thus

necessary to make several assumptions and to

arbitrarily fix certain parameters.

4.5 Robustness

The goal here was to observe the influence of the

sensor’s noise on the control’s behavior. Figure 16

shows the variation of the integrated RMS

displacement of the beam versus the noise of the

BPM (represented by a white noise (W) added to the

measured displacement).

Figure 16: Variation of the integrated RMS displacement

at 0.1 Hz versus BPM noise.

The level of sensor’s noise is crucial for a good

performance of the control. It cannot exceed 13 pm

integrated at 0.1 Hz to respect the specifications. As

the BPM gives an indirect measurement (amplified

image of the position by 10

5

), the BPM’s noise has

to be < 1.3 µm integrated RMS @ 0.1 Hz. This

result has to be taken into consideration in the design

of this monitor and will certainly be one of the

strategic requirements.

4.6 Perspective

Previous results could even be improved by

combining the previous passive isolation with active

isolation systems. A study of the different

commercial solutions (Redaelli, S., 2003, Thesis)

aimed to select the most efficient one on the market

for this type of application. The selected solution is a

TMC table with STACIS feet (TMC Company,

2002), also described in (Geffroy, N. et al,

Mechatronics 2008), see figure 17:

Figure 17: TMC table with STACIS feet.

This product is able to manage vibrations at a

sub nanometer scale. However, given the tight

tolerances, and the cost of such a product, a

dedicated solution is being developed. This system

includes four piezoelectric actuators and four

capacitive sensors. Such a system is potentially

suitable to be handled by three degrees of freedom

algorithm controlling the vertical motion and the two

associated rotations.

5 CONCLUSIONS

In this paper we have presented our methodology of

the stabilization of the future Compact Linear

Collider. Considering that the imposed tolerances

(integrated RMS (0.1) at the interaction point has to

be lower than 0.1 nm) are considerably lower than

the natural ground motion (a few micrometers),

these requirements are very challenging and were

4.60e

-11

m

2,50

m

1

m

BEAM TRAJECTORY CONTROL OF THE FUTURE COMPACT LINEAR COLLIDER

103

never achieved in the past. This article has

represented a mechanical setup and a dedicated

control approach which allows to obtain a very low

vertical displacement of the beam at the interaction

point of about an integrated RMS (0.1) of 0.046 nm.

In order to perform these results, the strategy was to

carry out a study on an innovative control which is

very efficient in low frequencies. This algorithm is

composed of a combination of a feedback obtained

thanks to a parametric study and an adaptive control

based on the generalized least-squares method. This

method was tested in simulation with a

representative model of the system and with real

measurement of the ground motion. Next, a pattern

of the dynamic of the required mechanical damping

structure, needed to filter the vibrations above a few

Hertz has been established for the purpose of a

further development. To validate this study,

simulation test with a mechanical support have been

performed, and robustness tests as well in order to

take into account the prediction errors of the

mechanical system model and to estimate the

acceptable maximal sensor noise. The study opens

up perspectives for the construction of an active-

passive isolation support as well. Thus, a massive

support is currently being studied and a dedicated

active isolation integrating vibration sensors,

piezoelectric actuators and an appropriate

instrumentation is being designed.

ACKNOWLEDGEMENTS

The research leading to these results has received

funding from the European Commission under the

FP7 Research Infrastructures project EuCARD,

grant agreement no.227579. The authors wish to

express their thanks to D. Schulte, J. Pfingstner and

K. Artoos from C.E.R.N., for this project and fruitful

collaboration.

REFERENCES

Virdee, T. S., 2010, The LHC project: The accelerator and

the experiments, Nuclear Instruments and Methods in

Physics Research A, doi:10.1016/j.nima.2010.02.142.

The CMS Collaboration, 2008, The CMS experiment at

the CERN LHC, Journal of Instrumentation.

Assmann, R. W. et al., 28 July 2000, A 3 TeV e+ e–

Linear Collider Based on CLIC Technology, CERN

European Organization for Nuclear Research.

Goldman, S., 1999. Vibration Spectrum Analysis, Indus-

trial Press, ISBN 978-0-8311-3088-6.

Güralp Systems Limited, Inc.

Mohtadi, C., 1990, Bode's integral theorem for discrete-

time systems, IEEE proceedings. Part D. Control

theory and applications vol. 137, no2, pp. 57-66.

Landau, I. D., Zito, G., 2006, Digital Control Systems:

Design, Identification and Implementation,

Communications and Control Engineering.

Ellison, J. et al., 2001, Passive vibration control of

airborne equipment using a circular steel ring, Journal

of Sound and Vibration, Volume 246, Issue 1, Pages

1-28.

Ramos, F., Dynamic analysis of the FF magnets pre-

isolator and support system, to be published.

Braccini, S. et al., 2005, Measurement of the seismic

attenuation performance of the VIRGO Superattenua-

tor, Astroparticle Physics 23 557–565.

TMC Company, 2002, TMC STATIS 2000 Stable Active

Control Isolation System, User’s manual, Document

P/N 96- 26690-02 Rev. D.

Geffroy, N., Brunetti, L., Bolzon, B., Jeremie, A., Caron,

B., Lottin, J., Active stabilization studies at the sub-

nanometer level for future linear colliders. Mechatro-

nics 2008.

Redaelli, S., 2003, Stabilization of Nanometer-Size

Particle Beams in the Final Focus System of the

Compact LInear Collider (CLIC), Thesis, Lausanne.

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

104