ITERATIVE LEARNING CONTROL APPLICATION

TO A 3D CRANE SYSTEM

Radu-Emil Precup, Florin-Cristian Enache, Mircea-Bogdan Rădac

Dept. of Automation and Appl. Inf., “Politehnica” University of Timisoara, Bd. V. Parvan 2, 300223 Timisoara, Romania

Emil M. Petriu

School of Information Technology and Eng., University of Ottawa, 800 King Edward, Ottawa, ON, K1N 6N5, Canada

Claudia-Adina Dragoş, Stefan Preitl

Dept. of Automation and Appl. Inf., “Politehnica” University of Timisoara, Bd. V. Parvan 2, 300223 Timisoara, Romania

Keywords: 3D crane system, Cascade Learning, Design approach, Iterative Learning Control.

Abstract: This paper deals with the application of an Iterative Learning Control (ILC) structure to the position control

of a 3D crane system in the crane position control problem. The control system structure involves Cascade

Learning (CL) built around control a loop with a frequency domain designed lead-lag controller. The

parameters of the continuous-time real PD learning rule as lead-lag controller are set such that to fulfil the

convergence condition of the CL process. A set of real-time experimental results concerning a 3D crane

system laboratory equipment is offered to validate the new CL-based ILC structure.

1 INTRODUCTION

The gantry crane systems are important in many

industrial applications including the 3D crane

systems as representative Multi Input-Multi Output

(MIMO) systems. Some current control approaches

related to 3D crane systems reported in the literature

deal with the combination of time-optimal control

and of visual feedback (Yoshida and Tabata, 2008),

PID controllers with friction compensation

(Westerberg et al., 2008), inertia theorem-based

nonlinear controllers (Chang and Chiang, 2008),

nonlinear tracking control structures (Chwa, 2009),

feed-forward and input-shaping techniques

(Kaneshige et al., 2009), sliding mode control

(Pisano et al., 2010) or gain scheduling techniques

(Cuenca et al., 2011).

Iterative Learning Control (ILC) is based on the

fact that the performance indices (overshoot, settling

time, etc.) of control systems executing repetitively

the same tasks can be improved using previous

experiments, referred to also as cycles or iterations,

in the control system operation. Several learning

rules are implemented in ILC structures that are built

around the control system whose performance is

improved (Bristow et al., 2006; Ahn et al., 2007; Xu

et al., 2009).

This paper gives a new solution to the crane

position control problem dedicated to a 3D crane

system laboratory equipment that models industrial

gantry crane systems (Inteco, 2008). Our control

system structure involves Cascade Learning (CL)

(Xu et al., 2009) built around a control loop with a

frequency domain designed lead-lag controller. The

parameters of the continuous-time real PD learning

rule as lead-lag controller are set such that to fulfil

the convergence condition of the learning process in

the CL-based control system structure. The

convergence condition guaranteed by our ILC

structure is an inequality that employs a frequency

domain calculated H

∞

norm.

This paper suggests two contributions with this

regard. First, a new control system structure based

on the combination of lead-lag control and ILC is

suggested. Second, real-time experimental results

are included to validate our new control system

structure.

117

Precup R., Enache F., R

ˇ

adac M., Petriu E., Drago¸s C. and Preitl S..

ITERATIVE LEARNING CONTROL APPLICATION TO A 3D CRANE SYSTEM.

DOI: 10.5220/0003537301170122

In Proceedings of the 8th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2011), pages 117-122

ISBN: 978-989-8425-74-4

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

The two contributions of this paper are important

and also advantageous with respect to the current

literature in the field because they ensure the simple

design of both the lead-lag controller and the

learning rule. Frequency domain approaches are

used in this context.

This paper is structured as follows. The process

models are presented in the next section. Section 3

focuses on the design of the new control system

structure. A set of real-time experimental results is

given in Section 4 to validate the new CL-based ILC

structure. The conclusions are given in Section 5.

2 PROCESS MODELS

It is accepted that the state variables of the MIMO

state-space model of the process are (Chen et al.,

2008; Inteco, 2008)

1

x

– the distance of the cart

from the centre of the rail,

10

x

– the initial condition

for

1

x

,

2

x

– the speed of the cart on the direction of

1

x

,

3

x

– the distance of the rail with the cart from

the centre of the construction frame,

4

x

– the speed

of the rail with the cart on the direction of

3

x

,

5

x

–

the acute angle between the lift-line of the payload

and the rail,

6

x

– the angular speed that corresponds

to

5

x

,

7

x

– the acute angle between the lift-line of

the payload and the vertical line,

8

x

– the angular

speed that corresponds to

7

x

,

9

x

– the length of the

lift-line, and

10

x

– the speed of the lift-line.

The control signals in the process model are

1

u

,

2

u

and

3

u

that correspond to the PWM duty cycles

applied to the DC motors that actuate the system on

the axes

1

x

,

3

x

and

9

x

, respectively. The three axes

1

x

,

3

x

and

9

x

are referred to as follows the x-axis,

the y-axis, and the z-axis, respectively.

The nonlinear state-space equations of the

process in the 3D crane system are expressed in (1)

if no disturbance are considered and zero initial

conditions are considered for all state variables

excepting

1

x

by the transformation of the equations

given in (Chen et al., 2008; Inteco, 2008).

Therefore the MIMO state-space model of the

process and the parameter values, obtained from the

first-principle model of the process, are given as

follows in (1) and (2), respectively:

),sgn()]sgn(

)[(sin)]sgn([

)]sgn()[sin()sin()]sgn(

)[(sin)(sin]1

)(cos)(sin)(sin)[cos(

)sin()cos()sin()(sin

)cos()cos()sin()(sin

)]sgn()[cos(

,

)],sin(/[

)]sgn()[cos(/

2/)]sgn()[cos()sin(

)]sin(/[)cos()(sin

)](sin/[)cos()sin(

,

,/2

/)]sgn()[cos(

)sin(

/)]sgn()[sin()cos(/

)]sgn()[(sin)cos()sin(

/])cos()sin()(sin

)cos()sin()sin()cos(

)sin()[cos()cos(/)cos(

)sin(/)sin()]sgn([

,

,)sin(

)sin()]sgn([

)sin()sin()sgn(

,

,)cos()]sgn(

)[cos()sgn(

,

101039

2

61010

35

2

1101031

4427510

1037

2

5

2

23

5

2

17

2

5

2

27

532775

2

2175515

2

9

2

8221510

109

59

4427910

891010377

25

2

9377

2

2

135

22

927728

87

9106

910103551

9442759

101037

2

55

2

2

93551337

2

55232752

151759

2

85

3952216

65

37

5232210103

7524424

43

35131110

103512212

21

xTxTxxxTx

TxxTxT

xTxTxxx

TxTxxu

xxxx

xkuxxx

kuxxxkx

xxxTxTxx

xx

xx

xTxTxxx

xxxTxTxx

xxuxx

kxxuxxkx

xx

xxx

xxTxTxx

xxTx

Txxx

xTxTxxx

xuxxkux

xxkuxxk

uxkxxxxx

xxxxTxTx

xx

ux

xkukxTxT

xxxTxTx

xx

uxkukxT

xTxxTxTx

xx

szsz

sz

sx

sz

sy

sx

sz

sz

sx

sz

sy

sz

sx

sz

sy

−−+−⋅

−μ+−−μ+

++⋅

−−μ+−

μ−μ−⋅

+⋅

−−⋅

++=

=

++⋅

−−−⋅

μ+μ⋅

μ−=

=

−

−−μ−

++

−−⋅

μ+μ+⋅

μ−−

+⋅

+−−=

=

⋅

μ++−−⋅

μ−−−=

=

μ++−

−μ−−−=

=

(1)

.8333.20

,4935.6 ,4903.1 ,3535.217

,3263.26 ,5242.11

,8258.129 ,0336.16

,8636.49 ,1431.0 ,4156.0

3

21

32

121

=

===

==

−==

=

=

μ

=

μ

sz

sysx

T

TTT

TT

kk

k

(2)

The controlled output, y, can be one or more of

the state variables

1

x

,

3

x

,

5

x

,

7

x

and

9

x

, and the

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

118

choice of the state variables depends on the control

problem that is solved. The state variables

1

x

,

3

x

are

involved as controlled outputs in the crane position

control problem, and the state variables

5

x

,

7

x

and

9

x

are involved as outputs in the anti-swing control

problem. With this regard the process with the state-

space equations given in (1) is a nonlinear MIMO

system.

Several approaches can be used to simplify the

nonlinear process model presented in (1) and (2).

The strongest simplification is based on accepting

that only the forces on the three axes

1

x

,

3

x

and

9

x

affect the movement of the system. The zero initial

conditions result in the definition of the three

transfer functions

)(sH

x

,

)(sH

y

and

)(sH

z

:

)],1(/[)(/)()(

)],1(/[)(/)()(

)],1(/[)(/)()(

39

23

11

sTsksusxsH

sTsksusxsH

sTsksusxsH

zzz

yyy

xxx

+==

+==

+

=

=

(3)

where

x

k

,

y

k

and

z

k

are the process gains, and

x

T

,

y

T

and

z

T

are the process time constants. The least-

squares identification based on real-world input-

output data measured from the laboratory equipment

leads to the following parameter values (Enache,

2010):

.s 0408.0 ,1019.0

,s 0379.0 ,2747.0

,s 0587.0 ,2939.0

==

==

=

=

zz

yy

xx

Tk

Tk

Tk

(4)

The three transfer functions defined in (3) (with

the parameters in (4)) can be viewed as three Single

Input-Single Output (SISO) processes. Three SISO

control loops can be designed, but the control

systems design should account for the model

simplification and for the interactions between the

three control loops. The effects of these interactions

cannot be neglected when control structures for

9

x

are designed.

The ILC-based control system structure designed

in the next section is dedicated to the x-axis and to

the y-axis, i.e., it controls

1

x

and

3

x

, respectively,

using the process transfer functions

)(sH

x

and

)(sH

y

. However, the experimental results to be

presented in Section 4 were conducted for the real-

world process.

3 CONTROL SYSTEM

STRUCTURE

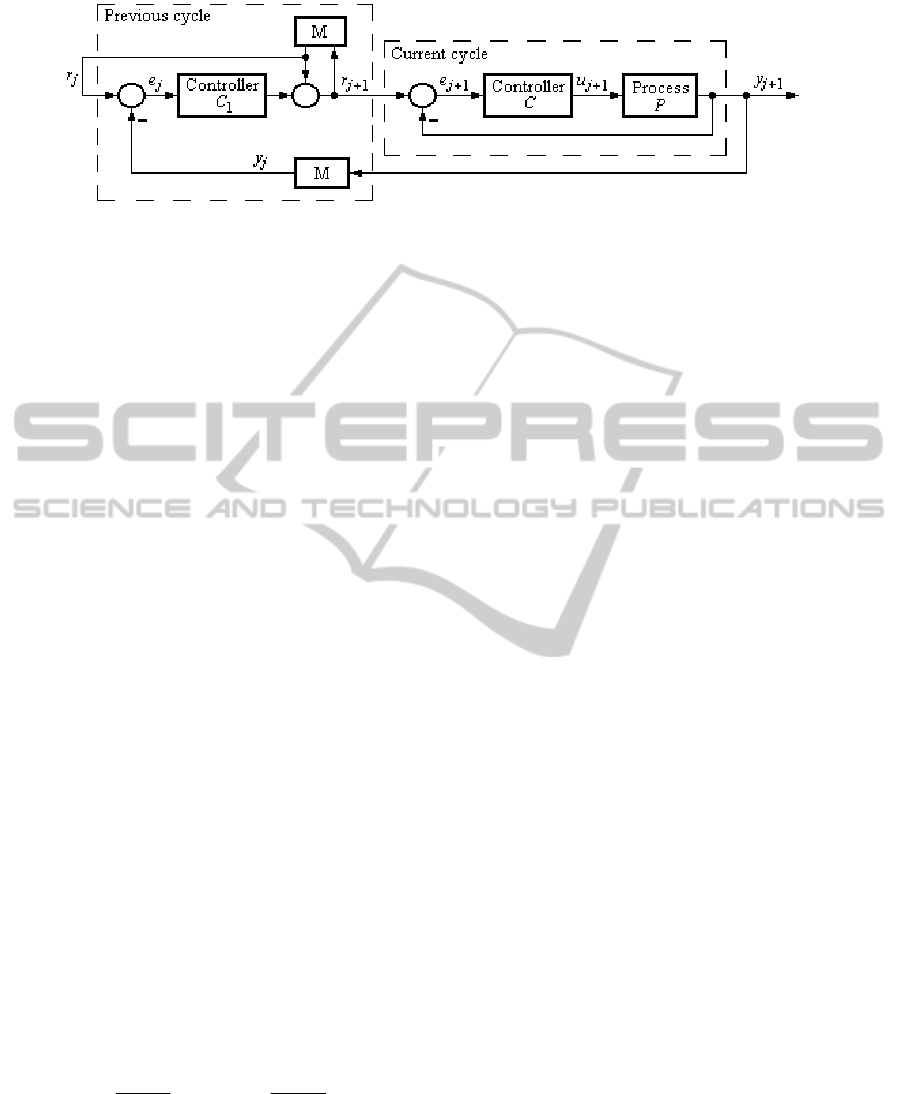

The ILC-based control system structure with CL is

are presented in Figure 1, where r is the reference

input, y is the controlled output,

y

r

e −=

is the

control error, u is the control signal, M is the

memory block, the subscript j indicates the cycle

(experiment) index, C and C

1

are the transfer

functions of the controllers with the argument

omitted for simplicity, and P is the process transfer

function. The current control loop is characterized

by the controller with the transfer function C, the

reference input

j

r

and the index

1+j

. The

controller with the transfer function C

1

is referred to

also as the learning rule. The disturbance inputs are

not included in Figure 1 as in many situations they

are not repetitive. That is the reason why they were

not applied in the real-time experiments.

If the error at the first cycle

0

e

is finite and

nonzero,

}0{\

0

Re

∈

, the convergence condition for

the learning process in the ILC-based control system

structure is

10 ,

1

<γ<∈∀γ≤

∞

+

Ni

e

e

i

i

,

(5)

where the parameter

γ

determines the convergence

speed, and the following general notation and

frequency domain calculation are used for the H

∞

norm

|)(|sup ω=

Ω∈ω

∞

jGG

,

(6)

with

1

2

−=j

, and

baba

ω<ω≤ω

ω

=

Ω

0 ],,[

– the

frequency range of interest that contains the

frequencies

ω

of the controllers. The convergence

of the learning process is guaranteed because (5)

results in

∞→→γ≤

∞∞

iee

i

i

as 0

0

.

(7)

Using the control system structure in Figure 1,

the convergence condition can be transformed into

1

1

1

1

<γ≤

+

−

∞

CP

CCP

.

(8)

The design approach consists of the following

design steps based on frequency domain designs:

Step 1. Carry out a frequency domain design to tune

the parameters of the controller with the transfer

function C that belongs to the control loop in the

ITERATIVE LEARNING CONTROL APPLICATION TO A 3D CRANE SYSTEM

119

Figure 1: ILC-based control system structure with CL.

current cycle. The value of the phase margin is

imposed to ensure not only stable control system in

the current cycle that guarantees a finite

0

e

but also

acceptable performance indices of this control

system which is subject to performance

improvement by ILC.

Step 2. Set the value of the parameter

γ

and

carry out a frequency domain design that employs

(6) to tune the parameters of the controller with the

transfer function C

1

that belongs to the control loop

in the previous cycle. The parameters of C

1

are

tuned such that to fulfil the condition (8).

4 REAL-TIME EXPERIMENTAL

RESULTS

Our design approach is tested through experiments

on a 3D crane system laboratory equipment (Inteco,

2008) to validate it for the two ILC-based control

system structures presented in the previous section.

Our experimental setup consists of a rail moving

along the frame, a cart moving on the rail, and a

payload being shifted up and down.

The ILC-based control system structure controls

separately the x-axis and the y-axis, i.e., it controls

1

x

and

3

x

, respectively, using the process transfer

functions

)()( sHsP

x

=

and

)()( sHsP

y

=

,

respectively, defined in (3). The two steps of the

design approach use the lead-lag controllers and the

real PD learning rules with the transfer functions

)(sC

and

)(

1

sC

, respectively:

sT

sT

ksC

sT

sT

ksC

d

c

b

a

c

+

+

=

+

+

=

1

1

)( ,

1

1

)(

11

,

(9)

where

c

k

and

1

k

are gains, and

a

T

,

b

T

,

c

T

and

d

T

are time constants.

The two steps of the design approach were

applied such that to obtain the same parameter

values for both processes, i.e., both axis, x and y.

This simplification is possible because of the

inequality-type convergence condition (8). The

frequency domain approaches applied in the two

steps of the design approach resulted in the

parameter values

.s 07.0 ,s 01.0

,s 1 ,5.1 ,1.0

1

===

=

=

=

cdb

ac

TTT

Tkk

(10)

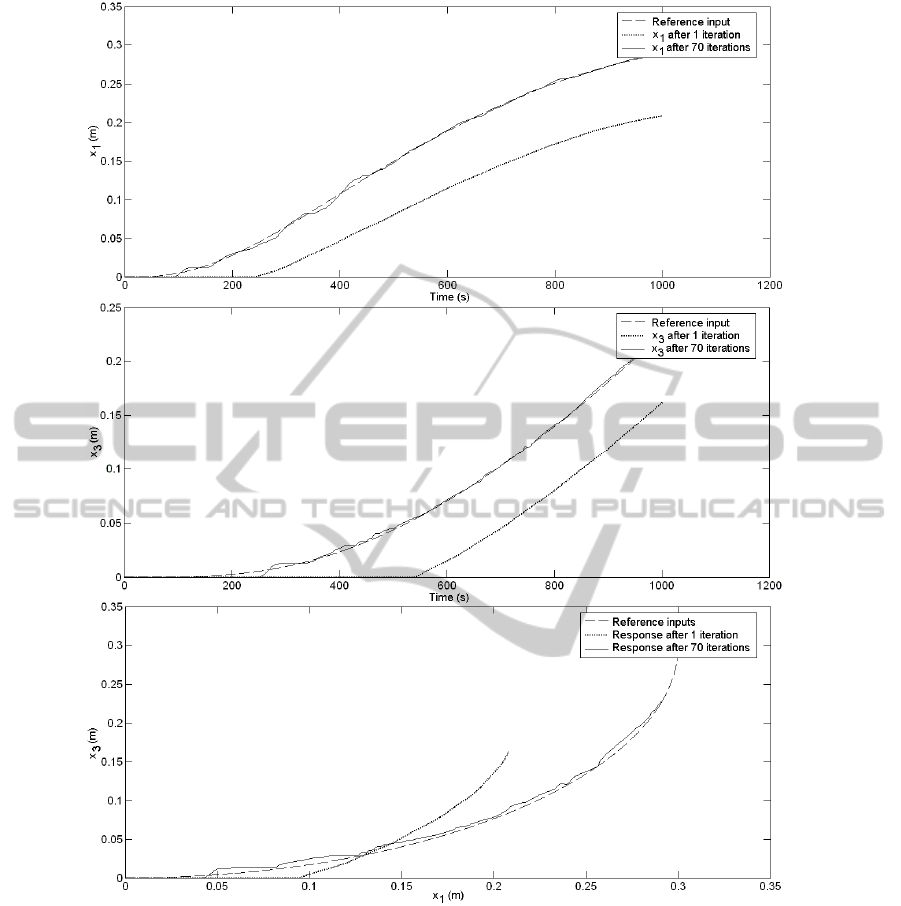

A part of the real-time experimental results is

presented as follows for reference inputs

j

r

that

characterize an arc of a circle in the (

1

x

,

3

x

) plane,

referred to also as the xy plane. The results are

expressed as the responses of

1

x

and

3

x

as

controlled outputs (i.e., they play the role of

1+j

y

according to Figure 1) after one iteration and after

several iterations. The system responses of the ILC-

based control system structure with CL are presented

in Figure 2. The results prove the strong control

system performance improvement with respect to

the first cycle (experiment). A good tracking

performance is ensured.

5 CONCLUSIONS

This paper has suggested an ILC-based control

system structure that involves CL. The combination

with PD controllers and learning rules and

application to the position control of a 3D crane

system laboratory equipment is convenient because

this equipment allows the application of repeatable

reference inputs and initial conditions over the

cycles (iterations) of the ILC learning processes.

Our design approach is important as it ensures

the serious improvement of the control system

performance indices (overshoot, settling time, etc.)

in the system responses with respect to the reference

input. However the disturbance rejection is not

carried out since we used PD controllers.

Our continuous-time design approach is justified

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

120

Figure 2: Experimental results: the system responses after 1 and after 70 iterations for the ILC-based control system

structure with CL.

because of its simplicity in the design. Therefore it is

applicable to other nonlinear processes in various

fields (Cottenceau et al., 2001; Horváth and Rudas,

2004; Škrjanc et al., 2005; Johanyák et al., 2006;

Bellomo et al., 2008; Bernard and Tichkiewitch,

2008; Derr and Manic, 2008; Vaščák, 2009). The

only constraint concerns the repeatability of the

inputs and of the initial conditions related to the

control systems.

Future research will be focused on the

application of our ILC-based control structures to

the z-axis crane position control problem and to the

anti-swing control problem. The extensions to

discrete-time control system structures are aimed.

ACKNOWLEDGEMENTS

This work was partially supported by the UEFISCDI

of Romania, and by the strategic grant POSDRU

6/1.5/S/13 (2008) of the Ministry of Labour, Family

and Social Protection, Romania, co-financed by the

European Social Fund – Investing in People.

ITERATIVE LEARNING CONTROL APPLICATION TO A 3D CRANE SYSTEM

121

REFERENCES

Ahn, H.-S., Moore, K. L., Chen, Y., 2007. Iterative

Learning Control. Robustness and Monotonic

Convergence for Interval Systems. Berlin, Heidelberg,

New York: Springer-Verlag.

Bellomo, D., Naso, D., Babuška, R., 2008. Adaptive fuzzy

control of a non-linear servo-drive: theory and

experimental results. Engineering Applications of

Artificial Intelligence. 21, 846-857.

Bernard, A., Tichkiewitch, S. (Eds.), 2008. Methods and

Tools for Effective Knowledge Life-Cycle-

Management. Berlin, Heidelberg, New York:

Springer-Verlag.

Bristow, D. A., Tharayil, M., Alleyne, A. G., 2006. A

survey of iterative learning control. IEEE Control

Systems Magazine. 26, 96-114.

Chang, C.-Y., Chiang, K.-H., 2008. The nonlinear 3-D

crane control with an intelligent operating method. In

Proceedings of 2008 SICE Annual Conference. Tokyo,

Japan, 2917-2921.

Chen, W., Wu, Q., Tafazzoli, E., Saif, M., 2008. Actuator

fault diagnosis using high-order sliding mode

differentiator (HOSMD) and its application to a

laboratory 3D crane. In Proceedings of 17

th

World

Congress of the International Federation of Automatic

Control. Seoul, Korea, 4809-4814.

Chwa, D., 2009. Nonlinear tracking control of 3-D

overhead cranes against the initial swing angle and the

variation of payload weight. IEEE Transactions on

Control Systems Technology. 17, 876-883.

Cottenceau, B., Hardouin, L., Boimond, J.-L., Ferrier, J.-

L., 2001. Model reference control for timed event

graphs in dioids. Automatica. 37, 1451-1458.

Cuenca, Á., Salt, J., Sala, A., Piza, R., 2011. A delay-

dependent dual-Rate PID controller over an Ethernet

network. IEEE Transactions on Industrial Informatics.

7, 18-29.

Derr, K., Manic, M., 2008. Wireless based object tracking

based on neural networks. In Proceedings of 3

rd

IEEE

Conference on Industrial Electronics and Applications

(ICIEA 2008). Singapore, 308-313.

Enache, F.-C., 2010. Iterative learning control-based

control solutions. Applications to a 3D crane

laboratory equipment. B.Sc. Thesis, Department of

Automation and Applied Informatics, “Politehnica”

University of Timisoara, Timisoara, Romania.

Horváth, L., Rudas, I. J., 2004. Modeling and Problem

Solving Methods for Engineers. Burlington, MA:

Academic Press, Elsevier.

Inteco Ltd, 2008. 3D Crane, User’s Manual. Krakow,

Poland: Inteco Ltd.

Johanyák, Z. C., Tikk, S., Kovács, S., Wong, K. K., 2006.

Fuzzy rule interpolation Matlab toolbox - FRI toolbox.

In Proceedings of 15

th

International Conference on

Fuzzy Systems (FUZZ-IEEE’06). Vancouver, BC,

Canada, 1427-1433.

Kaneshige, A., Miyoshi, T., Terashima, K., 2009. The

development of an autonomous mobile overhead crane

system for the liquid tank transfer. In Proceedings of

2009 IEEE/ASME International Conference on

Advanced Intelligent Mechatronics (AIM 2009).

Singapore, 630-635.

Pisano, A., Scodina, S., Usai, E., 2010. Load swing

suppression in the 3-dimensional overhead crane via

second-order sliding-modes. In Proceedings of 11

th

International Workshop on Variable Structure Systems

(VSS 2010). Mexico City, Mexico, 452-457.

Škrjanc, Blažič S., Agamennoni, O. E., 2005.

Identification of dynamical systems with a robust

interval fuzzy model. Automatica. 41, 327-332.

Vaščák, J., 2009. Using neural gas networks in traffic

navigation. Acta Technica Jaurinensis, Series

Intelligentia Computatorica. 2, 203-215.

Westerberg, S., Manchester, I. R., Mettin, U., La Hera, P.,

Shiriaev, A., 2008. Virtual environment teleoperation

of a hydraulic forestry crane. In Proceedings of 2008

IEEE International Conference on Robotics and

Automation (ICRA 2008). Pasadena, CA, USA, 4049-

4054.

Xu, J.-X., Panda, S. K., Lee, T. H., 2009. Real-time

Iterative Learning Control. Design and Applications.

Berlin, Heidelberg, New York: Springer-Verlag.

Yoshida, Y. Tabata, H., 2008. Visual feedback control of

an overhead crane and its combination with time-

optimal control. In Proceedings of 2008 IEEE/ASME

International Conference on Advanced Intelligent

Mechatronics (AIM 2008). Xi’an, China, 1114-1119.

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

122