MODELING AND SIMULATING A NARROW TILTING CAR

Salim Maakaroun, Wisama Khalil, Maxime Gautier and Philippe Chevrel

Institut de Recherche en Communication et Cybernétique de Nantes, 1 rue de la Noe, Nantes 44321, France

Keywords: Intelligent Transportation Systems, Modelling, Simulator, Robotics, Tilting car.

Abstract: The use of an electrical narrow tilting car instead of a large gasoline car should significantly decrease traffic

congestion, pollution and parking problem. The aim of this paper is to give an approach to develop a

dynamic model for narrow cars. This model can be used to simulate their behaviours and evaluate tilt

control systems. The approach is based on considering the vehicle as a multi-body poly-articulated system

and the modelling is carried out using the robotics formalism based on the modified Denavit-Hartenberg

geometric description.

1 INTRODUCTION

The idea behind narrow tilting car research is to

develop a vehicle used in urban transportation

having the advantages of motorcycle and passenger

car. This will reduce the size of the vehicle such that

it can be operated on reduced size lanes thereby

increasing the effective capacity of highways. In

order to maintain its stability, the vehicle should tilt

while cornering, to compensate the effect of lateral

acceleration and remain in its trajectory. Moreover

the use of electric motors with a group of batteries is

the most earth friendly technology.

In the literature, many works have been

published on the topic of tilting narrow vehicle.

Karnopp and Fang (Karnopp, 1992) were the first to

suggest a leaning into the turn similar like

motorcyclist’s one. Karnopp, Hibbard and So

(Hibbard, 1992. So, 1997) studied the tilt angle

required and the dynamics of such a vehicle. But

few people talked about the global dynamic model

of a four wheel tilting car. Rajamani, Gohl and

Alexander (Gohl, 2006) developed a dynamic model

of a three wheel vehicle which has four degrees of

freedom including lateral and tilt dynamics. All

these models don’t take into account the dynamics

of the suspensions, the vertical dynamic and the

study was on a simplified model called bicycle

model. Therefore to model a complex system in 3D

motion, many methods can be used. Kiencke

described his model with 4 individual co-ordinate

systems (Kiencke, 2000) while Rajamani with 6 co-

ordinate system (Rajamani, 2006). We claim that it

is preferable to proceed in a systematic method of

geometrical description, based on the modified

Denavit-Hartenberg parameterization (Khalil, 1986).

The last was applied on a two wheeled vehicle

model with suspensions (Maakaroun, 2011). This

description allows to automatically calculate the

symbolic expression of the geometric, kinematic and

dynamic models by using a symbolic software

package SYMORO+ (Symbolic Modelling of

Robots) (Khalil, 1997). Moreover, the dynamical

model can be calculated numerically using

programming software as Matlab, C++. This

formulation leads to a minimum set of equations

where the constraint equations for the mechanical

system are automatically eliminated.

This paper concentrates on developing a global

dynamic model for a narrow tilting car “Lumeneo

Smera “ (Lumeneo, 2003) by applying methods used

in robotics. Since the structure of the Smera is

complex and contains loops, this approach can

elaborate systematically the symbolic equations of

motion and makes the implementation of the

dynamic model very easy. This method is described

and applied on the car in section 2. Then Kinematics

and dynamics models are given in section 3 and 4.

Finally, simulation results are illustrated and

commented and conclusions are done.

2 GEOMETRIC DESCRIPTION

OF THE CAR

2.1 Robotic Representation of a

Multi-body System

The car is considered as a mobile tree-structured

229

Maakaroun S., Khalil W., Gautier M. and Chevrel P..

MODELING AND SIMULATING A NARROW TILTING CAR.

DOI: 10.5220/0003538102290235

In Proceedings of the 8th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2011), pages 229-235

ISBN: 978-989-8425-75-1

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

multi-body system composed of n bodies (links)

where the chassis is the mobile base and the wheels

are the terminal links.

The links are numbered

consecutively from the base to the terminal links.

Each body C

j

is connected to its antecedent C

i

(i=a(j)) with a joint that represents an elastic or rigid

translational or rotational degree of freedom. The

symbol

a(j) denotes the link antecedent to link j, and

consequently a(j) < j .A body can be virtual or real;

the virtual bodies are introduced to describe joints

with multiple degrees of freedom like ball joint or

intermediate fixed frames. The frame R

i

(O

i

, x

i

, y

i,

z

i

)

which is attached to the body C

i

is defined as

following:

The z

i

axis is along the axis of joint i, the u

j

axis

is defined as the common normal between z

i

and z

j

.

The x

i

axis is along the common normal between z

i

and one of the succeeding z axis, where link i is the

antecedent of link j and the origin O

i

is the

intersection of z

i

and x

i

.

The homogeneous transformation matrix

i

T

j

between

two consecutive frames R

i

and R

j

is expressed as a

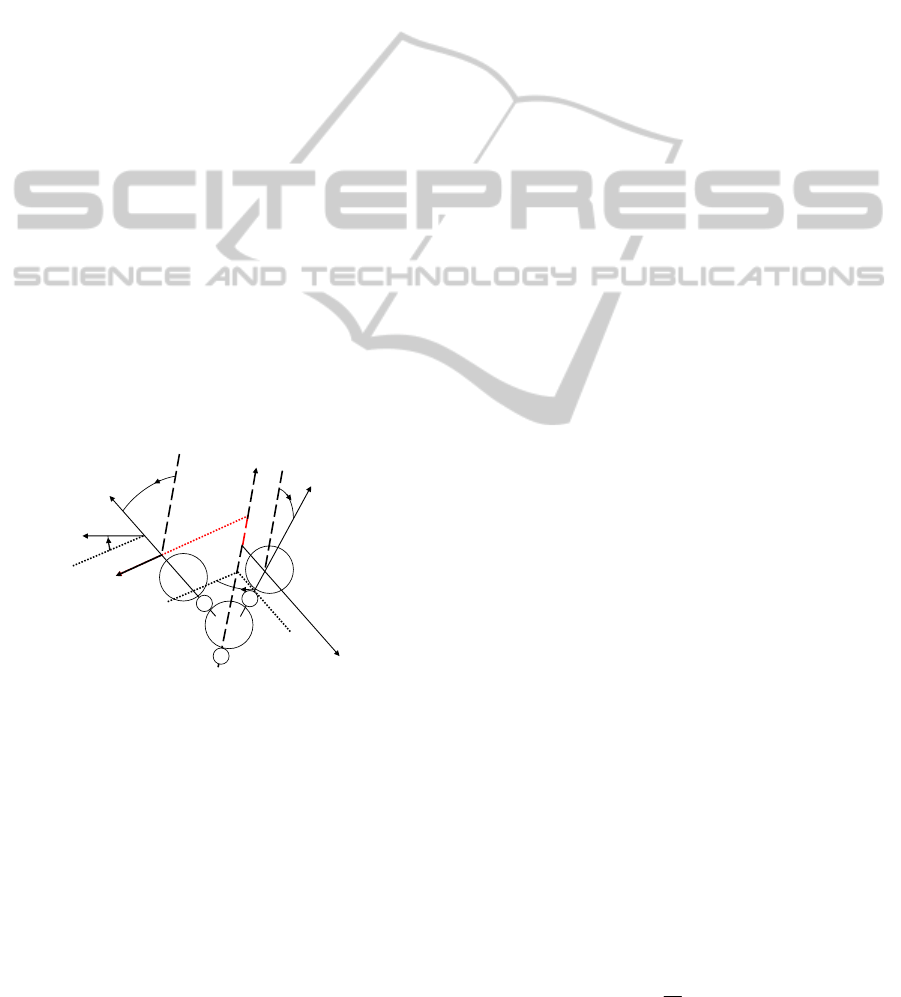

function of the following six parameters (Figure 1):

• γ

j

: angle between x

i

and u

j

about z

i

• b

j

: distance between x

i

and u

j

along z

i

• α

j

: angle between z

i

and z

j

about u

j

•d

j

: distance between z

i

and z

j

along u

j

• θ

j

: angle between u

j

and x

j

about z

j

• r

j

: distance between u

j

and x

j

along z

j

z

j

z

i

z

k

z

i

u

j

x

j

d

j

b

j

O

i

C

i

C

j

C

k

x

i

=u

k

α

j

r

j

θ

j

α

k

γ

j

Figure 1: Geometric parameters.

The generalized coordinate of joint j is denoted by

q

j

, it is equal to r

j

if j is translational and θ

j

if j is

rotational. In (Figure 1), since x

i

is taken along u

k

,

the parameters γ

k

and b

k

are equal to zero. We define

the parameter σ

j

= 1 if joint j is translational and σ

j

=

0 if joint j is rotational. If there is no degree of

freedom between two frames that are fixed with

respect to each other, we take σ

j

=2. In this case, the

time derivative of q

j

is zero.

2.1 Application for the Tilting Car

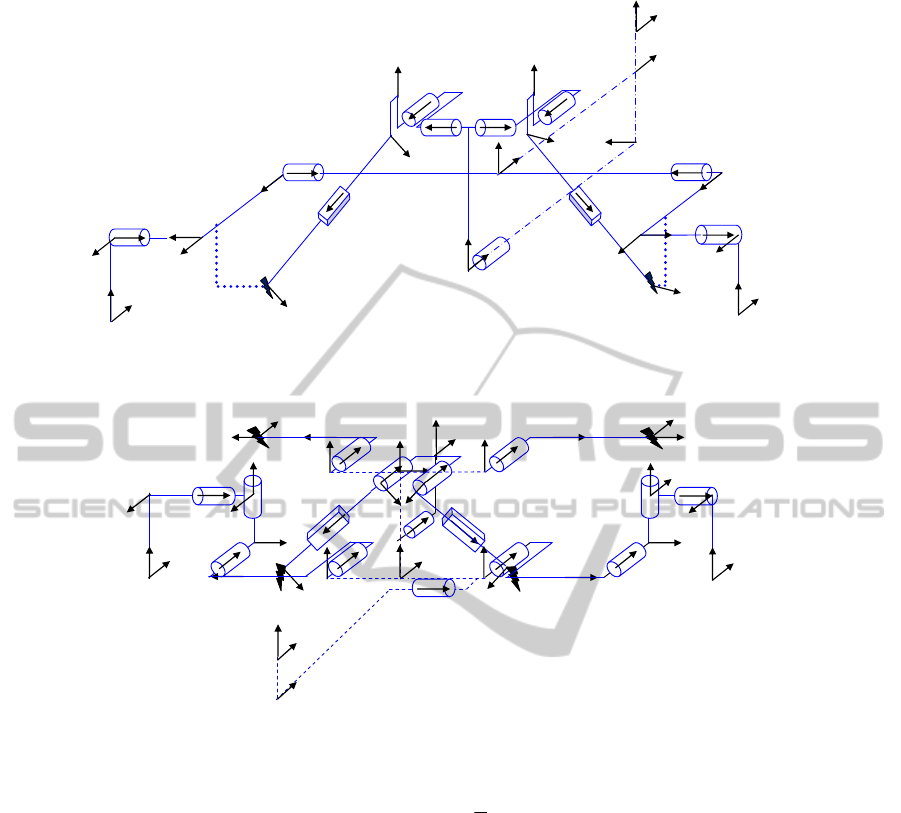

The model of the Smera (Figure 2): is composed of

19 real bodies (Lumeneo, 2003) connected by 24

joints. Thus it contains 6 closed Kinematic loops:

- C

1

is the chassis

- C

2

and C

13

are two mechanical parts called “lyre”

which have a rotational movement around the

longitudinal axis of the chassis. C

2

is actuated by

an electrical motor which controls the roll of the

vehicle.

- C

5

and C

8

are the rear driving wheels.

- C

3

, C

6

and C

14

, C

15

are respectively the rear and

the front suspensions of the vehicle.

- C

4

and C

7

are the rear arms that connect the

chassis to the rear wheels.

- C

11

and C

18

are the front steering wheels.

- C

9

, C

10

and C

12

and the chassis constitute a

parallelogram which carries the hub of the left

front wheel.

- C

16

, C

17

and C

19

constitute with the chassis a

parallelogram which carries the hub of the right

front wheel;

The Kinematic closed loops are defined as follows:

- LP1 is composed of C

1

, C

2

, C

3

and C

4

- LP2 is composed of C

1

, C

2

, C

6

and C

7

- LP3 is the left parallelogram; it is composed of

C

1

, C

9

, C

10

and C

12

- LP4 is composed of C

1

, C

9

, C

13

and C

14

- LP5 is the right parallelogram composed by C

1

,

C

16

, C

17

and C

19

- LP6 is composed of C

1

, C

13

, C

15

and C

16

Let R

f

be a fixed reference frame attached to the

ground. In robots manipulator, C

0

is fixed with

respect to R

f

. In case of mobile system C

0

is taken

fixed with the chassis frame.

So according to MDH description and

SYMORO+, the structure is defined as a robot with

a mobile base by considering C

1

attached to C

0

via a

blocked joint.

The inertial parameters of this base are

those of C

1

and the speed and the acceleration are

then the ones of the chassis described in his own

frame. The chassis motion is described with Euler

coordinates (Cartesian) while all the other links are

described with the generalized Lagrangien

coordinates (joints). The body C

1

with a location ζ

(i.e. position & orientation) gives the system posture

in the frame R

f

. The movement of the chassis in this

mixed Euler-Lagrangien model is given by:

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎣

⎡

=

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎣

⎡

=

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎣

⎡

=

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

,,

z

y

x

z

y

x

z

y

x

V

V

V

V

ω

ω

ω

ω

ω

ω

ω

ω

It is to be noted that:

1

1

1

1

1

1

1

1

VV

dt

d

V ∧+=

ω

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

230

Where

1

V

1

= [

1

V

x1

1

V

y1

1

V

z1

]

T

are respectively the

longitudinal, lateral and vertical translational speed

of the chassis.

C

19

C

18

C

17

C

16

C

7

C

8

C

6

C

3

C

2

C

4

C

5

C

13

C

10

C

11

C

9

C

12

C

14

C

15

C

1

Figure 2: Multi-body description of the Smera.

All the joints which connect the various bodies

are revolute joints except the joints on both sides of

the rear suspensions and the joints below the front

hubs are respectively spherical and cardan joints.

The suspensions are represented by prismatic

flexible joints.

The rear Lyre is motorized, and all the joints can

be calculated in terms of this actuated joint, by

resolving the geometric equations of each loop. The

resolution of these equations was validated

experimentally (Maakaroun, 2010).

The modelling of a complex structure which

contains multiple loops is carried out by opening

each loop in order to obtain, an equivalent tree

structure system. The opened joints are chosen

among the non-motorized (passive) joints.

Loops LP1, LP2, LP3, LP4, LP5 and LP6 are

opened as shown in figure 3.

According to this description, the vehicle motion is

completely described by the vector q of the 36

generalized coordinates:

[]

T

pa

qqq =

;

[

]

T

aa

q

ξξ

=

;

pp

q

ξ

=

ξ[1x6] is the posture of the chassis ( position &

orientation)

[]

'17'108518111514632

qqqqqqqrrrq

a

=

ξ

ξ

a

is the vector of the actuated and independent

joints.

[]

21 ppp

ξξξ

=

[]

97''2'24''2'21

qqqqqqq

ddggp

=

ξ

[]

'13'131319171612102 dgp

qqqqqqqq=

ξ

ξ

p

is the vector of the passive joints angular position.

- q

2g’

, q

2g’’

, q

2d’’

, q

2d’’

, q

13g’

and q

13d’

are the

angular positions of the revolute joints linked by

the suspensions,

- q

9

, q

10

, q

12

, q

16

, q

17

and q

19

are the angular

positions of the parallelograms,

- q

4

and q

7

are the angular positions of the rear

arms. The revolute axes of the two drive motors

are coincident with the ones of these joints.

- q

5

, q

8

, q

11

and q

18

are the angular positions of the

four wheels with respect to their revolute axis,

- q

10’

and q

17’

are the steering angles.

- r

3

, r

6

, r

14

and r

15

are the length of the

suspensions. They are calculated from the

dynamic model.

- q

2

is the angular position of the rear motorized

lyre and q

13

is the angular position of the front

lyre.

It is to be noted that the frame i is the antecedent of

frame i

’

which is the antecedent of frame i

’’

.

3 KINEMATIC CONSTRAINTS

3.1 Rear Train

Since the loops LP1 and LP2 are opened in spherical

joints, we can conclude respectively that the

translational velocity of the frame R

5

and R

11

are

equal from both sides of the opened joints with

respect to the base frame.

[

]

[]

TT

ddgg

qqqJqqqqqq

63217''2'24''2'2

=

(1)

The derivative of the above equation gives:

[

]

[]

163217''2'24''2'2

YqqqJqqqqqq

TT

ddgg

+=

J

1

is the jacobian matrix (6x3) between the velocities

of the rear train articulation.

-

[

]

T

qqqJY

63211

=

;

11

J

dt

d

J =

3.2 Front Train

The first and second derivate of the geometric

equations of Loops LP3, LP4, LP5 and LP6 gives:

(Maakaroun, 2010)

[

]

UJqqqqqqqqq

T

dg 2'13'131319171612109

=

[

]

22'13'131319171612109

YUJqqqqqqqqq

T

dg

+=

(2)

- J

2

is the jacobian matrix (9x5) between the

MODELING AND SIMULATING A NARROW TILTING CAR

231

velocities of the front train articulation and the

angular velocities of the chassis.

-

[]

T

T

qqU

631

1

ω

=

;

22

J

dt

d

J =

-

[]

T

T

qqU

631

1

ω

=

;

UJY

22

=

;

By combining the equations obtained in section 3-A

and 3-B, we can elaborate the relation between the

velocities of the active, passive joints and the

translational, angular velocities of the chassis.

[]

[

]

[]

[]

YqJqYVJ

qJqVJ

ap

T

a

TT

p

ap

T

a

TT

p

+=⇒+=

=⇒=

ξωξ

ξωξ

1

1

1

1

1

1

1

1

(3)

⎥

⎦

⎤

⎢

⎣

⎡

=

)69(2)86(2)39(

)86(1)66(

0)5:4(:,0)3:1(:,0

00

xxx

xx

JJ

J

J

[]

T

TT

YYY

21

=

4 DYNAMIC MODEL

4.1 Dynamic Parameters

For each real link there are 14 standard dynamic

parameters (Gautier, 1990) composed of 10 standard

inertial parameters:

- J

j

= [XX

j

XY

j

XZ

j

YY

j

YZ

j

ZZ

j

]: The six

components of the inertia matrix of link j given in

the frame R

j

,

- MS

j

= [MX

j

MY

j

MZ

j

]: the three components of

first moment of link j around the origin of the

frame j,

- M

j

: the mass of link j

For each actuated joint j, we introduce:

- I

aj

as the total inertia of the rotor of motor and

the drive transmission.

- F

vj

, F

sj

as the viscous and coulomb friction

parameters.

For a flexible joint, we define:

- K

j

as the stiffness of the joint j

4.2 External Forces

The external forces applied to the car, which have

the most significant impact on vehicle dynamics, are

the contact forces between the ground and the tires.

These external forces can be modelled using the

magic formula of Pacejka (Pacejka, 2002), estimated

or measured at the center of the wheels by using

dynamometric wheels. Aerodynamic forces also

have an effect on the vehicle behaviours, particularly

at high speed (> 90 Km/h).

4.3 Euler-Lagrange Dynamic Model

The mixed Euler-Lagrange model is obtained from

two recursive equations using recursive calculations

of Newton-Euler algorithm in the following way

(Khalil, 2002):

In the first (forward) recursive, we calculate the total

forces and moments on each link. Then in the

second (backward) recursive equations, we calculate

the forces f

j

and moments m

j

exerted on body C

j

by

its antecedent C

i

.

The inverse Dynamic model (IDM) of the tree

structure with a mobile base can be written as:

),,,,,,,(

),,,,,,()(

KFFgfqqqf

KFFgfqqHqqA

vse

vsearar

p

a

=

+=

⎥

⎦

⎤

⎢

⎣

⎡

Γ

Γ

(4)

- A

ar

is the inertial matrix of the system

- H

ar

is the vector of centrifugal, Coriolis,

gravity and generalized efforts terms.

-

[

]

T

p

T

a

TT

Vq

ξξω

1

1

1

1

=

-

[

]

T

p

T

a

TT

Vq

ξξω

1

1

1

1

=

;

-

⎥

⎦

⎤

⎢

⎣

⎡

=

pppa

apaa

ar

AA

AA

A

;

⎥

⎦

⎤

⎢

⎣

⎡

=

p

a

ar

H

H

H

Since the joint velocities and accelerations are

expressed in the terms of the independent actuated

variables, and the torque of the passive joints is

equal to zero, the IDM of the closed chain structure

will be:

)(

ppppapa

T

apapaaa

p

T

am

HqAqAJHqAqA

J

+++++=

Γ+Γ=Γ

(5)

By using equations (2) and (3), the above equation

can be written as:

mamm

HqA

+

=

Γ

(6)

Where:

)( JAJAJJAAA

pp

T

pa

T

apaam

+++=

)(

p

T

pp

T

apam

HJDAJDAHH +++=

The matrix A

ar

can be calculated by the algorithm of

Newton-Euler, by noting from the relation (4) that

the ith column is equal to Γ:

)0,0,0,0,0,,0,()(:,

iar

uqfiA

=

(7)

u

i

is the unit (n x 1) vector, whose elements are

zero except the ith element which is equal to 1.

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

232

x

1

z

1

u

1’

u

2

z

7

z

7’’,

z

8

x

7’’,

x

8

x

7

x

8’

z

8’

x

7’

z

7’

z

2

x

2

z

2g’

z

2d’

z

2g’’

z

2d’

x

2g’

x

2g’’

z

3

x

3

z

4

x

4

x

4’

z

4’

z

4’,

z

5

x

5

x

5’

z

5’

x

1’

z

1’

x

2d’

x

6

z

6

Figure 3: Geometric description of the rear train.

z

17’’,

z

18

z

1

x

1

u

1’’

z

ch

z

18’

x

18’

x

17’’,

x

18

z

17’

x

17’

x

17

z

17

x

16

z

10’’,

z

11

z

11’

x

11’

x

10’’,

x

11

x

9

z

10

x

10’

z

10’

x

10

z

16

z

9

z

19’

x

19’

z

12’

x

12’

z

19

x

19

z

12

x

12

z

14

z

15

x

15

x

14

z

13

x

13

, x

13

’

u

16’

u

9’

u

12

u

19

z

13’

z

13d’

z

13g’

x

13g’

x

13d

’

z

1’’

, x

1’’’

x

1’

x

ch

z

1’’’

Figure 4: Geometric description of the front train.

The calculation of the vector H

ar

can be obtained

with the Newton-Euler method, by noting that H = Γ

if:

),,,,,0,,( KFFgfqqfH

vsear

=

(8)

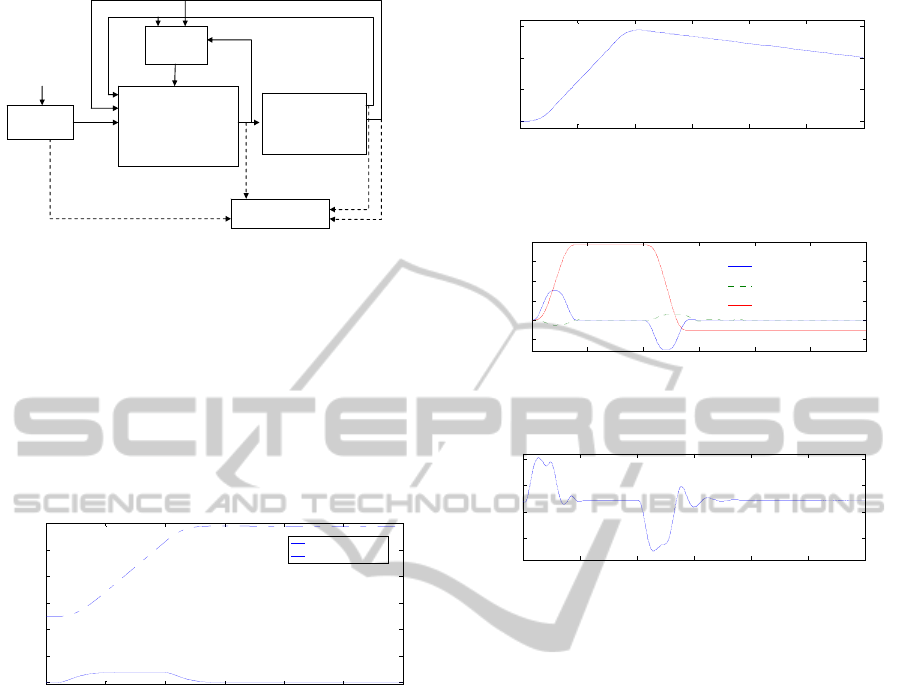

5 SIMULATOR

To predict the behaviours of the vehicle, we made a

simulator by using the dynamic model obtained from

the equation of Newton-Euler. The simulator

architecture is described in figure 5.

5.1 Direct Dynamic Model with

Constraints

To keep the tires in contact with the ground, we

must add four constraints to the dynamic model.

Therefore, the vertical velocity and acceleration of

the contact tire/road with respect to the reference

frame must be equal to zero.

[

]

0

)3(18)3(11)3(8)3(5

''''

=Φ=

a

T

ffff

qVVVV

(9)

[

]

0

)3(18)3(11)3(8)3(5

''''

=Φ+Φ=

aa

T

ffff

qqVVVV

d

t

d

(10)

Equation (13) becomes:

λ

T

mam

HqA Φ++=Γ

Where:

- λ is the lagrangien multiplier vector

- Φ

T

λ represents the vector of the efforts

transmitted by joints to respect the

constraints.

And the direct dynamical model that gives the joint

accelerations as a function of joint positions,

velocities torques, and external wrenches (forces and

moments) will be:

][

0

)(

1

)44(

mm

x

T

tm

a

H

qA

q

−Γ

⎥

⎥

⎦

⎤

⎢

⎢

⎣

⎡

Φ

Φ

=

⎥

⎦

⎤

⎢

⎣

⎡

−

λ

(11)

MODELING AND SIMULATING A NARROW TILTING CAR

233

t

q

t

q

t

q

Direct

Dynamical

Model

Integrators

+Transformation

matrix

External

Wrenches

Visualization

Trajectory

Scenario

Desired

Torques

Figure 5: Simulator architecture.

6 SIMULATION

Two scenarios are considered. In the first, the

vehicle is subject to a traction torque applied on the

rear wheels which generate an acceleration phase

then a decelerating one as shown in Figure 6. The

trajectory is a straight line with initial velocity of 5

m/s.

0 5 10 15 20 25 30

0

2

4

6

8

10

12

Time (s)

Longitudinal Velocity (m/s)

and acceleration of c.g(m/s2)

Velocity

Acceleration

Figure 6: Longitudinal velocity and acceleration of c.g.

In the second the vehicle is subject to a desired

steering torque to follow the trajectory of Figure 7.

However, to maintain the stability, the bicycle must

tilt into the corner such that the resultant force of the

lateral acceleration and the weight of the vehicle is

along the vertical axis of the vehicle (So et al 1997).

The desired tilt angle will be the roll of the bicycle

and it will be equal to:

)/(tan

1

1

gV

x

f

des

ψθ

−

=

(12)

In order to get that, a simple PD controller is

used to stabilize the roll dynamics to the desired tilt

angle (Figure 8). The controller’s output represents

the required tilting torque applied on the rear lyre to

stabilize the vehicle (Figure 9).

0 10 20 30 40 50 60

0

5

10

15

x longitudinal distance (m)

y laterral distance (m)

Figure 7: Trajectory of c.g in the horizontal plan.

0 5 10 15 20 25 30

-0.2

0

0.2

0.4

0.6

Time (s)

Roll,Yaw &

steering Angle (rd)

steering angle

Roll angle

Yaw angle

Figure 8: Trajectory of c.g in the horizontal plan.

0 5 10 15 20 25 30

1.5

1.55

1.6

1.65

Time (s)

Lyre angle (rd)

Figure 9: Rear Lyre motorized angle.

7 CONCLUSIONS

This paper presents the dynamical model of a

narrow tilting car where the structure is complex.

Future works consists on, simulating more scenarios

as high speed, considering aerodynamic forces,

elaborating robust control strategies to avoid

external perturbation and maintain the stability of

the vehicle.

REFERENCES

Karnopp, D., Fang C. 1992. Simple model of steering

controlled banking vehicles, ASME Dynamics Systems

and Control Division (DSC), 44, pp. 15-28.

Hibbard, R., Karnopp, D., 1992, The dynamics of small,

relatively tall and narrow tilting ground vehicle ASME

Dynamics Systems and Control, 52, pp. 397-417.

So, S. G., Karnopp, D., 1997, Active dual mode tilt control

for narrow ground vehicle, Vehicle System Dynamics

journal, vol 27, pp 19-36, 1997.

Hibbard, R., Karnopp, D., 1992, Optimum roll angle

behavior for tilting ground vehicles, ASME Dynamics

Systems and Control Division (DSC),vol 44, pp. 237.

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

234

Gohl, J. and al, 2006 Development of a Novel Tilt

Controlled Narrow Commuter Vehicle, CTS,

Minnesota.

Rajamani, R., 2006, Vehicle dynamics and control,

Springer.

Kiencke., U, Nielsen, L., 2000, Automative Control

Systems for Engine, Driveline and Vehicle. New York:

Springer-Verlag.

Khalil, W., Kleinfinger, J., 1986, A new geometric

notation for open and closed loop robots, IN Proc.

IEEE on robotics and automation, pp. 1174- 1180,

San Francisco, CA, USA.

Khalil, W., Creusot D., 1997, Symoro+: A system for the

symbolic modelling of robots, Robotica, vol. 15, no. 2,

pp. 153–161.

Khalil, W. and Dombre, E., 2002, Modeling, Identification

and Control of Robots. London: Hermès Penton.

Lumeneo, www.lumeneo.fr.

Maakaroun, S., Khalil, W. and al., 2010, Geometrical

Model of a New Narrow Tilting Car, In Proc. 15th Int

Conf. on Methods and Model, in Automation and

Robotics, Miedzyzdroje, Poland.

Maakaroun, S., Khalil, W. and al., 2011, Modeling and

Simulation of a Two wheeled vehicle with suspensions

by using Robotic Formalism, In Proc. 18th IFAC

World Congress, Milan, Italy.

Gautier, M., Khalil, W., 1990, Direct calculations of

minimum set of inertial parameters of serial robots,

IEEE Trans. On Robotics and Automation, Vol. RA-

6(3), p. 368-373.

Pacejka, H. B., 2002, Tyre and Vehicle Dynamics,

Oxford, U.K.: Butterworth-Heinemann.

Canudas deWit, P and al, 2003, Dynamic friction models

for road/tire longitudinal interaction, Veh. Syst. Dyn.,

vol. 39, no. 3, pp. 189–226.

So, S., Karnopp, D., 1997, “Active dual mode tilt control

for narrow ground vehicles”, Vehicle System

Dynamics, vol. 27 pp. 19-39.

MODELING AND SIMULATING A NARROW TILTING CAR

235