ANOMALY DETECTION IN PRODUCTION PLANTS

USING TIMED AUTOMATA

Automated Learning of Models from Observations

Alexander Maier, Oliver Niggemann, Roman Just, Michael J¨ager

Institut Industrial IT, OWL Universitiy of Applied Sciences, Lemgo, Germany

Asmir Vodenˇcarevi´c

Knowledge-Based Systems Research Group, University of Paderborn, Paderborn, Germany

Keywords:

Parallelism structure, Behavior model, Timed automata, Anomaly detection, Model-based diagnosis.

Abstract:

Model-based approaches are used for testing and diagnosis of automation systems (e.g. (Struss and Ertl,

2009)). Usually the models are created manually by experts. This is a troublesome and protracted procedure.

In this paper we present an approach to overcome these problems: Models are not created manually but

learned automatically by observing the plant behavior. This approach is divided into two steps: First we learn

the topology of automation components, the signals and logical submodules and the knowledge about parallel

components. In a second step, a behavior model is learned for each component. Later on, anomalies are

detected by comparing the observed system behavior with the behavior predicted by the learned model.

1 INTRODUCTION

Model-based diagnosis uses a model of a production

plant to compare the predictions of the model to ob-

servations of the running plant. If there arises a dif-

ference between the simulation of the model and the

running plant, an anomaly is signaled.

The bottleneck in model-based diagnosis is the

modeling aspect. Usually, this is done manually by

experts who know the plant in detail. After each plant

modification, this work has to be repeated.

In this paper, we present a method for the anomaly

detection (part of model-based diagnosis) for produc-

tion plants using probabilistic deterministic timed au-

tomata (PDTA) as behavior models. But in contrast

to usual approaches, these automata are not created

manually but are learned automatically based on ob-

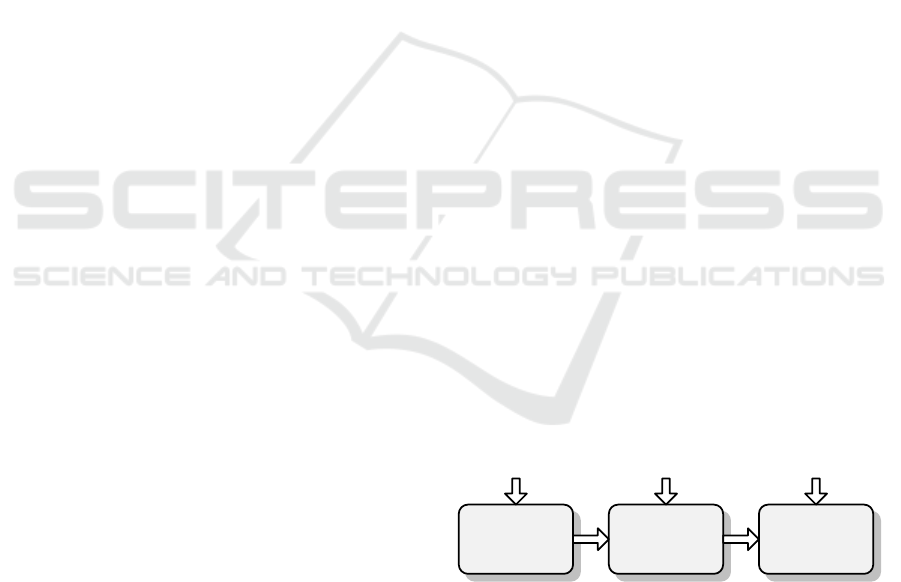

servations from the plant. Figure 1 shows our 3-step

toolchain for the anomaly detection:

The first step is learning the topology of the au-

tomation system: Learning the behavior of parallel,

asynchronous components is hard unless this paral-

lelism structure is known beforehand. E.g. learning

the timing behavior of 2 asynchronous components,

each comprising 1000 states, is hard when the paral-

lelism structure is unknown; obviously up to 1000000

1. Learning

parallelism

structure

2. Learning

behavior

model

3. Anomaly

detection

Local neighbor

information for

each device

observations observations

Figure 1: Our toolchain for the anomaly detection.

states may be learned.

No data analysis can reveal this parallelism struc-

ture. But for the special case of plant signals, the plant

structure often mirrors the components’ parallelism.

And this resembles the topology of the automation

system, i.e. the topology of IO devices. So in order to

learn the parallelism structure, learning the topology

of the automation system is often a good approxima-

tion. Further details are given in section 2.1.

In the second step, for each component, a behavior

model is learned automatically on basis of recorded

plant observations. Section 2.2 gives more details to

the model formalism and the learning algorithm.

In the third step anomalies are detected: During

runtime of the production plant, we compare the out-

put of the model simulation with observations of the

production plant. Typical anomalies in this paper are

363

Maier A., Niggemann O., Just R., Jäger M. and Voden

ˇ

carevi

´

c A..

ANOMALY DETECTION IN PRODUCTION PLANTS USING TIMED AUTOMATA - Automated Learning of Models from Observations.

DOI: 10.5220/0003538903630369

In Proceedings of the 8th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2011), pages 363-369

ISBN: 978-989-8425-74-4

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

timing deteriorations or changed signal values. This

is discussed in section 3 in detail.

2 LEARNING BEHAVIOR AND

PARALLELISM STRUCTURE

In order to learn the overall model, we first have to

identify the parallelism structure and finally learn the

behavior model for each component individually.

2.1 Learning Parallelism Structure

As mentioned above, the topology of the automation

system is used to approximate the parallelism struc-

ture. This parallelism structure decomposes the over-

all model into parallel components—for which se-

quential behavior models can be learned.

We use AutomationML (AutomationML, 2010)

as an exchange format to store the topology of the

automation system—and therefore of the parallelism

structure. This parallelism structure includes infor-

mation like the IO devices, Programmable Logical

Controllers (PLCs) and communication networks.

For some types of communication networks, the

topology of the automation system can be identified

automatically. In this paper, the PROFINET standard

is used as an example.

123.11…

123.11…

123.11…

Step 1: IP addresses are

collected (using DCP)

Step 2: Local neighborhoods are

found (using LLDP and SNMP)

Step 3: Identical

nodes are merged,

forming the

topology

Figure 2: Topology Learning Principle.

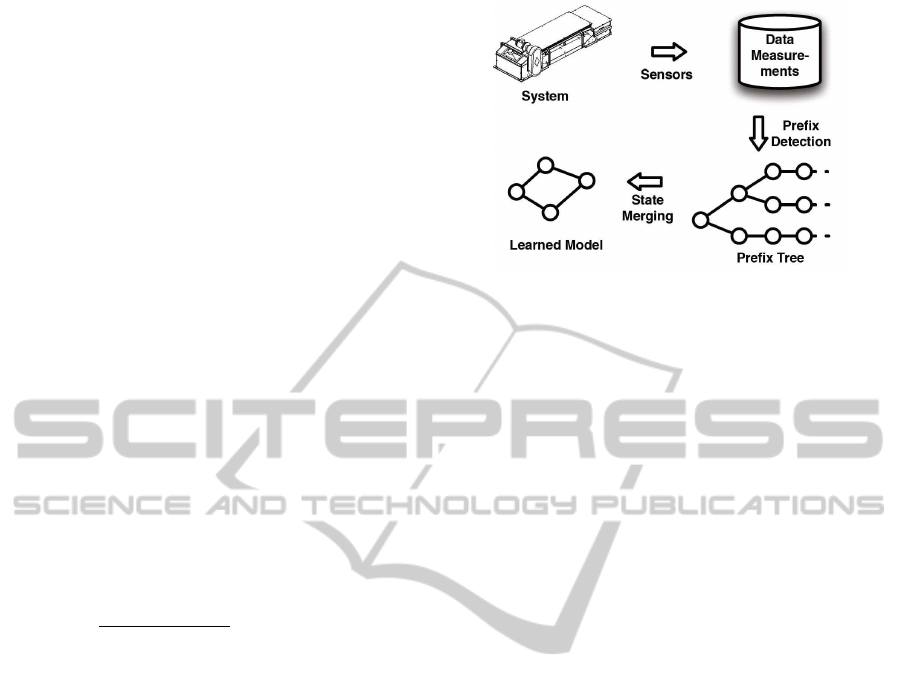

The learning procedure is organized in three steps

(see figure 2): (i) First we collect all IP addresses

in the network, using the DCP standard. As result

we’ve got an unsorted collection of all participants

in the network. (ii) In the next step we look for lo-

cal neighborhoods for each node. In a PROFINET

network each device offers network related data, like

local and neighbor information in its own database,

called LLDP-MIB. This information is accessible via

the SNMP protocol, by addressing each device in the

network directly. Collecting local and neighbor infor-

mation of each network participant leads to raw data,

describing single autonomous nodes. (iii) Based on

these gathered data sets, a topology map can be cre-

ated, by merging each individual node based on the

assignment of neighbor information to local data of

other nodes.

In the following, a parallelism structure and its

components are defined formally; the definition here

is especially tailored for the purpose of model learn-

ing.

Definition 1 (Component). A component C is de-

fined by a behavior function b

C

: R × {0,1}

m

→

{0,1}

n

,n,m ∈ N is a function over m input variables

and over time and it returns n output variables.

The reader may note that we assume a global time

base and a deterministic, discrete system; from this it

follows that the order of all value changes are prede-

fined, i.e. a component behaves sequentially.

So far, we do not distinguish between components

describing plant modules, PLCs, or network devices.

While such classifications are necessary from a do-

main point of view, a general formalism for learning

models should abstract from such classifications.

A parallelism structure is now created by connect-

ing several components:

Definition 2 (Parallelism Structure). A parallelism

structure M is defined as a tuple < C ,z > where

C = {C

0

,.. .,C

p−1

} is the set of components and z :

C ×N →C ×N maps an output variables of one com-

ponent onto the input variable of another component.

I.e. z(C

i

,k) = (C

j

,l) connects the k’s output vari-

able of C

i

with the l’s input variable of C

j

.

Finally we have to learn the behavior model for

each component. The following section gives more

details about the used formalism and the learning al-

gorithm.

2.2 Learning Behavior Model

In general, model-based diagnosis can use any kind

of behavior models. However, the quality of diagno-

sis depends on the used modeling formalism and the

prediction abilities of the models. In the following,

we give some requirements to this formalism for the

use case of anomaly detection for production plants.

State based Systems. Production plants mainly show

a state based behavior, i.e. the system’s state is pre-

cisely defined by its current and previous discrete IO

signals.

Usage of Time. Since actions in automation plants

are mostly depending on time, the formalism has to

consider it as well.

Probabilistic Information. Here, the behavior mod-

els describe the previous, recorded plant behavior. So

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

364

unlike in specification models, behavior probabilities

must be modeled.

Timed Automata are well suited for the require-

ments from above. A large number of variants of au-

tomata exist. Here we use a timed, probabilistic au-

tomaton where the timing is expressed as a relative

time span.

In contrast to traditional automata, the formalism

here is simplified to ease the learning task: First of

all, we allow only for relative timing, e.g. transitions

may not refer to a global time base.

Definition 3 (Timed, Probabilistic Automaton). An

automaton is a tuple A = (S, S

0

,F,Σ, T,δ,Num),

where

• S is a finite set of states, S

0

∈ S is the initial state,

and F ⊆S is a distinguished set of accepted states,

• Σ is the alphabet. For a component, Σ equals the

set of events.

• T ⊆ S ×Σ×S gives the set of transitions. E.g. for

a transition hs,a,s

′

i, s,s

′

∈ S are the source and

destination state and, a ∈ Σ is the trigger event.

• A function Num : T →N counts the number of ob-

servations in which a transition has been used in

the system’s past. Num can be used to compute a

transition probability p for a transition (v,w) ∈T:

p(v, w) =

Num(v,w)

∑

((v,w

′

)∈T)

Num(v,w

′

)

.

• A transition timing constraint δ : T →I, where I is

a set of intervals. δ always refers to the time spent

since the last event occurred. It is expressed as

a time range or as a probability density function

(PDF), i.e. as probability over time.

Learning Probabilistic Deterministic Timed Au-

tomata

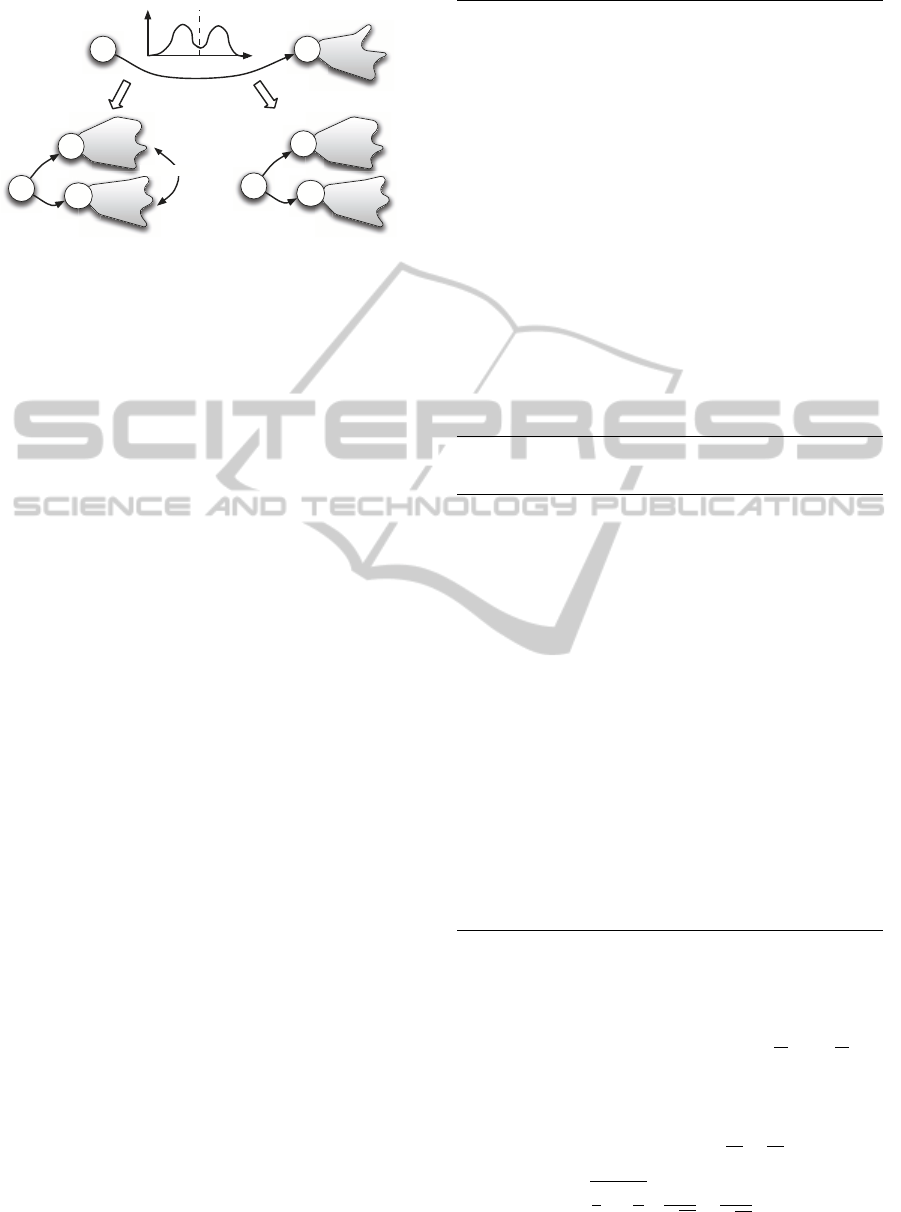

Learning behavior models–i.e. automata–for se-

quential components follows the methodology from

figure 3: First of all, all relevant data is measured

from the system. For this, the system is observed dur-

ing several production cycles. The resulting observa-

tion sequences (recorded events and time stamps) are

stored in a database.

In a next step, common prefixes of such data se-

quences are identified. I.e. for the first cycle, the se-

quence of events is stored in form of an event list.

Then for each following cycle, common prefixes with

a previous event sequence are identified; if the actual

sequence derives at some point, the result is an event

tree. The final result is a prefix tree (prefix tree accep-

tor, PTA) which models all observation sequences in

a dense form—dense because common sequences are

stored only once.

Now, similar states of the prefix tree are merged.

The result is an automaton which models the system.

Figure 3: The general learning methodology.

Our algorithm (Bottom Up Timing Learning Al-

gorithm, BUTLA) for learning the behavior models

differs to the existing algorithms in two points:

1. Bottom-up merging order: We use a bottom-up

merging strategy, i.e. we start with the final (leaf)

states and go up to the starting state in a breadth-first-

like manner. This eliminates the need for recursive

compatibility checks of the sub-trees. This has two

advantages: (i) the algorithm shows a better runtime

behavior and (ii) the resulting automaton resembles

better the real plant behavior.

This bottom-up strategy works best if all leafs of

the prefix trees correspond to final states or to the

same states in a cyclic process. Here, the new algo-

rithm applies domain specific knowledge: For mea-

surements of plants, it is normally no problem guar-

anteeing this constraint.

2. Different time learning operation: Here, we use a

different heuristic to learn the correct timing informa-

tion at the transitions:

(i) First of all, timing is expressed by means of

probability density functions instead of time interval;

this allows for a much preciser model of the timing.

(ii) At the core of transition timing learning lies

one decision: Should a transition with an event e be

split into two transitions with different timing infor-

mation? Unlike other approaches, we base our deci-

sion on the timing information itself, not on the sub-

tree resemblance; figure 4 shows an example:

s

0

and s

1

are two states in an automaton, the transi-

tion timing is a statistic for the transition occurrences

in the past and is expressed as a probability density

function (shown next to the transition).

Using Verwer’s approach, the transition would

only be split (new states s

′

1

and s

′′

1

) if the new result-

ing sub-trees are different. The motivation is that dif-

ferent states should define different successive behav-

iors, i.e. sub-trees.

But looking at figure 4, a split could be justified

just on the basis of probability density functions: Ob-

ANOMALY DETECTION IN PRODUCTION PLANTS USING TIMED AUTOMATA - Automated Learning of Models

from Observations

365

P

t

5

s'

1

s''

1

Subtree

Subtree

incompatible

[0,2]

(2,9]

s

0

s

1

s

0

Subtree

Subtree

s'

1

s''

1

[0,5]

(5,9]

s

0

Traditional

Approach

New

Approach

Subtree

Figure 4: A different timing learning approach.

viously the density function is created by two overlap-

ping Gaussian distribution. So it can be presumed that

two different technical processes have created the cor-

responding event—i.e. here again we apply domain

specific knowledge. And different processes must be

modeled as different states, because only then can the

learning algorithm associate transitions with the cor-

rect timing. And only such a precise timing associ-

ation allows for a correct separation between correct

and erroneous behavior (anomaly detection).

Our algorithm BUTLA is shown in figure 5 and can

be described as follows: First of all, a prefix tree is

created (step 1). Then, compatible states are merged

in a bottom-up order (steps 2); how state compatibil-

ity is defined will be explained later on. If the PDF

describing a transition timing is multi-modal (i.e. is

the sum of several independent processes, see also

figure 4), the transition is split (step 3). Each of the

new states created by the split gets a copy of the orig-

inal sub-automaton (the function Num must be re-

computed).

BUTLA uses a function compatible to check

whether two states can be merged (see figure 6): The

idea is similar to ALERGIA’s approach (see section

4), only that we compare in-going and not out-going

transitions and that no recursive sub-tree comparisons

are needed.

First of all, several additional variables are needed

in figure 6: The number of occurrences of an out-

going transition for a specific state and a specific event

(f (a,v), step 1), the number of occurrences of in-

going and out-going transitions for a specific state

(f

in/out

, step 2-3) and the number of measurement se-

quences which end in a specific state (f

end

, step 4).

If the f

end

s for two states (in relation to f

in

) are too

different (see function compatible below), they are

not merged (step 6). Similarly, if for any event a the

corresponding f(a,∗)s are too different (in relation to

f

in

), the states are also not merged (step 7).

In step 8, it is checked whether two transitions,

that might be merged, have too different timing con-

straint PDFs. This is done to prevent later unneces-

Given:

(1) Discrete componentC, its function b

C

, its events E

(2) Measurements S = {S

0

,...,S

n−1

} where S

i

= (E ×

R)

p

, p ∈ N is one sequence of p events over time (i.e. one

measurement or one scenario).

Result: C’s function b

C

defined by an automaton

(1) Build prefix tree A = (S, S

0

,F,Σ,T, δ, Num) based on S .

A is a timed, probabilistic automaton according to definition 3

(2) for all v, w ∈ S in a bottom-up order do

(2.1) if compatible(v, w) then

(2.1.2) merge(v, w)

end for

(3) for all v in a top-down order do

(3.1) for all out-going transitions e of v do

(3.1.1) if transition timing δ(e) is multi-modal then

(3.1.1.1) split(e)

end for

end for

Figure 5: Automata learning algorithm BUTLA.

Given: v, w ∈S

Result: decision yes or no

(1) f(a, v) :=

∑

e=(∗,a,v)∈T

Num(e), v ∈ S, a ∈Σ where

∗ is an arbitrary element

(2) f

in

(w) :=

∑

e=(∗,∗,w)∈T

Num(e), w ∈ S

(3) f

out

(v) :=

∑

e=(v,∗,∗)∈T

Num(e), v ∈ S

(4) f

end

(v) := f

in

(v) − f

out

(v), v ∈ S

(5) d(a,v) :=

∑

e=(∗,a,v)∈T

δ(e) where the sum denotes the

adding of two PDFs

(6) if fractions-different( f

in

(v), f

end

(v), f

in

(w), f

end

(w))

(6.1) then return false

(7) for all a ∈Σ do

(7.1) if fractions-different( f

in

(v), f (a,v), f

in

(w), f (a,w))

(7.1.1) then return false

(8.1) if PDFs-different(d(a, v),d(a, w)) then

(8.1.1) return false

end for

(10) return true

Figure 6: Comparison algorithm compatible.

sary splits; the function PDF-different can be imple-

mented using the well-known R

2

test.

To compare whether two fractions

f

0

n

0

and

f

1

n

1

are

significantly different (function fractions-different),

we use the Hoeffding Bound:

different(n

0

, f

0

,n

1

, f

1

) :=

f

0

n

0

−

f

1

n

1

>

r

1

2

log

2

α

1

√

n

o

+

1

√

n

1

where 1−α,α ∈ R is the probability of the decision.

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

366

3 ANOMALY DETECTION

For diagnosis, we use the discrete probabilis-

tic deterministic timed automaton (PDTA) A =

(S,S

0

,F,Σ, T,δ,Num) as defined in definition 3.

Therefore, the behavior can be defined as a path

through the automaton as follows.

Definition 4 (Path through Automaton). Let A =

(S,S

0

,F,Σ, T,δ,Num) be an automaton. A path P

through the automaton is defined as a list of sequen-

tial transitions P ⊆ T

∗

.

Definition 5 (Observation). An observation of the

plant is defined as o = (a,t), where

• a ∈ Σ is the trigger event in the plant and

• t is a relative time value (relative to the last signal

change).

The learned automaton is now used to detect

an unusual behavior (an anomaly) in an automation

plant. During runtime we observe the running au-

tomation plant and simulate the identified model in

parallel. Then we compare the simulation outputs

with the observations from the running system. If

there arises any difference, an anomaly (error) has oc-

curred.

Figure 7 shows the algorithm for detecting an

anomaly. Following types of anomalies can be de-

tected using this procedure:

Functional Errors. In a current state exits no event

(i.e. changing signal value) for a certain signal (sen-

sor/actuator). E.g. while filling a bottle the next event

should be ”bottle full” but for some reason the filling

stops (event: ”stop filling”).

For every observed event it is checked whether-

its symbol corresponds to one of the possible outgo-

ing events in the current state (line 2.2a). An error

is found when no transition with the observed event

exists, i.e. if the observed path is not equal to one

possible simulated path in the automaton.

Timing Errors. A timing error occurs when the sig-

nal changes correctly, but the timing range doesn’t fit.

E.g. if the filling of the bottle should take between

four and five seconds, an anomaly would be found,

when this takes less than four or more than five sec-

onds. Since we often don’t have hard time limits, it’s

useful to work with distribution functions. In this case

we can return the probability of the failure.

For every observed event it is checked whetherthe

time of the observed event fits into the time range or

doesn’t differ more than a predefined deviation from

the expected value. This is done in line 2.2b.

Probability Errors. Taking the probabilities into

consideration more complex and gradual errors can be

Given:

(1) Probabilistic Deterministic Timed Automaton (PDTA) A =

(S, S

0

,F,Σ,T, δ, Num) (according to definition 3)

(2) O = (o

1

,...,o

k

), o

i

is an observation according to definition

5

(3) α: a predefined value for the probability deviation

(4) Num

′

: T → N, ∀e ∈ T : Num

′

(e) = 0

Result: localized anomaly (if there exits one) otherwise ’OK’

Algorithm:

(1) s := S

0

// beginning with initial state

(2) for i := 1 to k do // iterate over all observations

(2.1) o

i

= (a,t) // observation with symbol and time

(2.2a) if exists e ∈ T with e = (s,a,s

′

) // check symbol

(2.2b) and t ∈ δ(e) then // check times

(2.2.1) Num

′

(e)++ // update observed occurrences

(2.2.2) if p

Num

′

(e) − p

Num

(e) > α then

(2.2.2.1) return anomaly

(2.2.3) s := s

′

// go to next state

(2.3) else

(2.3.1) return anomaly

(2.4) end if

(3) end for

(4) return OK

Figure 7: Algorithm for anomaly detection.

detected when the probabilities in the observed sys-

tem diverge from the probabilities in the model. E.g.

while checking the filling of a bottle, 95% of the bot-

tles are filled correct and 5% wrong. Here it would be

an anomaly, if the observed probability exceeds this

usual value.

In line 2.2.2 it is checked whetherthe probabil-

ity for taking the chosen transition doesn’t vary too

much. The occurrences of each event in the real plant

are counted and the probabilities are recalculated after

each occurrence (line 2.2.1). For the check we need

α as additional parameter for the allowed tolerance.

If the probability exceeds this tolerance, an error is

detected.

4 STATE OF THE ART

4.1 Parallelism Structure

From a model learning perspective, a parallelism

structure subdivides the overall system into parallely

working components. I.e. a parallelism structure

defines a (hierarchical) set of interconnected com-

ponents where components work in parallel (usu-

ally asynchronously) and each individual component

shows a sequential behavior only. In plants, such se-

quential components often correspond to one techni-

ANOMALY DETECTION IN PRODUCTION PLANTS USING TIMED AUTOMATA - Automated Learning of Models

from Observations

367

cal device such as a robot, a conveyor belt, a reactor,

or a PLC (programmable logic controller).

Currently there exists no algorithm to identify a

parallelism structure by only using observations in an

automation system.

4.2 Behavior Model

The Finite State Machine/ Automaton (FSM) is one

of the most established modeling formalism. Based

on the initial FSM different types for different cases

were developed(e.g. non-deterministic, timed, proba-

bilistic, hybrid). An overview to the main formalisms

can be found in (Kumar et al., 2010). Petri nets also

allow modeling discrete behavior and are used e.g. by

(Cabasino et al., 2007).

There exist already several algorithms for learning

an automaton by using observations. In general, there

is a distinction between online and offline algorithms.

Online algorithms allow to ask for new patterns dur-

ing runtime while offline algorithms have to deal with

a given set of examples. The best known and one of

the first online algorithm is Angluin’s L* (Angluin,

1987).

Offline algorithms use a prefix tree to collect and

combine all recorded observations. MDI (Thollard

et al., 2000) and ALERGIA (Carrasco and Oncina,

1999) are two offline algorithms which learn a PDFA.

They use only positive examples, i.e. no failure mea-

surements. MDI uses a global criterion to check the

compatibility of two states. After each merging step

the old automaton and the new one are compared. If

the similarity measure exceeds a predefined value, the

new automaton is kept, otherwise rejected. ALER-

GIA uses a local criterion to check the compatibility.

Before merging two states, the Hoeffding Bound is

used to measure the similarity of these states. If these

states are similar enough, they are merged.

Verwer already presented different algorithms for

identifying timed automata (Verwer, 2010). Some of

them use as well negative as positive examples. To

include timing information Verwer introduced a split-

ting operation which splits a transition if the resulting

subtrees are different enough.

4.3 Model-based Diagnosis

Model-based diagnosis using discrete automata was

firstly introduced by Sampath et al. (Sampath et al.,

1994). They use a discrete deterministic (untimed)

automaton. This approach was applied for diagnosis

e.g. in (Hashtrudi Zad et al., 2003). In some other

contributions this approach is extended to the usage

of timed automata (e.g. in (Tripakis, 2002)).

Lunze et al. also work intensively with model-

based diagnosis based on timed discrete-event sys-

tems (e.g. (Lunze et al., 2001) (Supavatanakul et al.,

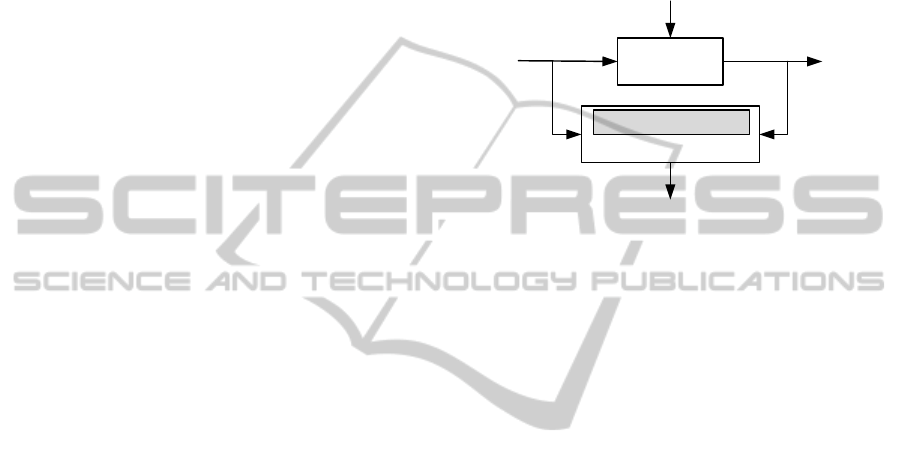

2006)). The main idea is to create a discrete-event

model which corresponds to the discrete-event sys-

tem and afterwards compare their outputs (see figure

8). If a failure occurs in the system, the diagnostic al-

gorithm detects a difference and suggests the failure

which occurred in the system.

Discrete-event

system

Diagnostic Algorithm

V

W

Discrete-event model

f

f

Figure 8: Diagnosis of dynamic systems (Supavatanakul

et al., 2006).

5 CASE STUDY

This chapter includes an exemplary use case for the

formalisms described below. For this case we use an

exemplary plant which is used to transport and pro-

duce bulk material e.g. transport corn an produce pop-

corn. This model factory comprises several modules

to store, carry and produce the bulk material. The

model factory is controlled by a PLC and the mod-

ules are connected using PROFINET.

Using the methodology from chapter 2.1 we dis-

covered the plant topology and detected the two IO-

modules. These are used for the parallelism struc-

ture. Therefore in the following two automata were

learned; one for each module.

A datalogger observes the network traffic on a

mirrored port and analyses the profinet frames. For

further usage the extracted process data (recorded

events and the time stamps) is stored in a database.

Using these observations a prefix tree was created for

each component. The PTA of the first module con-

tains 26 states, the second one 3611 states.

Then we learned the behavior model as timed au-

tomaton (according to definition 3) for each compo-

nent using the algorithm described in figure 5. The

final automaton contains 17 states (8 states in mod-

ule 1, 9 states in module 2). This corresponds to a

compression rate of 99.5%.

Finally, to test the anomaly detection, we caused

some failures in the plant. Combining all signal out-

puts from the components we compared the signal

values observed in the running plant with the outputs

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

368

of the simulation. Here we used the datalogger in the

plant again, but in context of a real-time analysis. The

network traffic (profinet frames) are analyzed and af-

ter each change of a signal our anomaly detection tool

gets a message with the signal, its value and the times-

tamp.

In some first experiments we inserted 17 different

failures. Using the algorithm from figure 7, we were

able to detect 88% of the failures correctly. In the

remaining 12% we were able to detect the error, but

the error cause wasn’t identified correctly.

Although we were able to detect most of the er-

rors (at least the failures which were enforced by our-

selves), we encountered a problem: Sometimes a cor-

rect behavior was recognized as an error. This hap-

pens because we are not able to learn the completely

correct behavior model. For this we would need an

infinite number of recorded test samples. To prevent

this, it is possible to enrich the recorded observations

e.g. by using a normal distribution and create addi-

tional samples. Another possibility is to adapt the

model during runtime. For this we would need a su-

pervised learning algorithm which allows the plant

operator to add a path to the model. This issue is not

yet solved and should be addressed in future work.

6 CONCLUSIONS AND FUTURE

WORK

In this paper we presented an efficient method for

anomaly detection based on behavior models avail-

able as finite state machines/ timed automata. In con-

trast to usual approaches these models are learned

automatically by observing the running plant. We

presented an appropriate algorithm for learning this

model as timed automaton. Our learning process

comprises the learning of the parallelism structure (in-

cluding the plant topology). Finally we learn the be-

havior model in the formalism of timed automata for

each component.

The overall model is used for anomaly detection.

We showedthe differenttypes of anomalies which can

be detected using this approach and validated the us-

ability of this approach by giving some first experi-

mental results.

During the experiments we encountered the prob-

lem, that a model cannot be learned with accuracy

of 100%. To reach this, we would need an infinite

number of test samples. This means that in practice

sometimes a regular behavior is diagnosed as a fail-

ure. In future work the learned model should be en-

riched with empirical data or adapted during runtime.

In further work hybrid automata should be taken

into consideration. This will expand the expressive-

ness and the ability of finding an error reliably. Until

now there exists no appropriate learning algorithm for

the learning of hybrid automata.

REFERENCES

Angluin, D. (1987). Learning regular sets from queries and

counterexamples. Inf. Comp., pages 75(2):87–106.

AutomationML (2010). www.automationml.org.

Cabasino, M. P., Giua, A., and Seatzu, C. (2007). Identifi-

cation of petri nets from knowledge of their language.

Discrete Event Dynamic Systems, 17:447–474.

Carrasco, R. C. and Oncina, J. (1999). Learning determinis-

tic regular grammars from stochastic samples in poly-

nomial time. In RAIRO (Theoretical Informatics and

Applications), page 33(1):120.

Hashtrudi Zad, S., Kwong, R., and Wonham, W. (2003).

Fault diagnosis in discrete-event systems: framework

and model reduction. Automatic Control, IEEE Trans-

actions on, 48(7):1199 – 1212.

Kumar, B., Niggemann, O., and Jasperneite, J. (2010). Sta-

tistical models of network traffic. In International

Conference on Computer, Electrical and Systems Sci-

ence,. Cape Town, South Africa.

Lunze, J., Schr¨oder, J., and Supavatanakul, P. (2001). Di-

agnosis of discrete event systems: the method and an

example. In Proceedings of the Workshop on Princi-

ples of Diagnosis, DX’01, pages 111–118, Via Lattea,

Italy.

Sampath, M., Sengupta, R., Lafortune, S., Sinnamohideen,

K., and Teneketzis, D. (1994). Diagnosability of dis-

crete event systems. In 11th International Confer-

ence on Analysis and Optimization of Systems Dis-

crete Event Systems, volume 199 of Lecture Notes

in Control and Information Sciences, pages 73–79.

Springer Berlin / Heidelberg.

Struss, P. and Ertl, B. (2009). Diagnosis of bottling

plants - first success and challenges. In 20th Inter-

national Workshop on Principles of Diagnosis, Stock-

holm, Stockholm, Sweden.

Supavatanakul, P., Lunze, J., Puig, V., and Quevedo, J.

(2006). Diagnosis of timed automata: Theory and

application to the damadics actuator benchmark prob-

lem. Control Engineering Practice, 14(6):609–619.

Thollard, F., Dupont, P., and de la Higuera, C. (2000).

Probabilistic dfa inference using kullback-leibler di-

vergence and minimality. In Proc. 17th International

Conf. on Machine Learning, pages 975–982. Morgan

Kaufmann.

Tripakis, S. (2002). Fault diagnosis for timed automata. In

FTRTFT, pages 205–224.

Verwer, S. (2010). Efficient Identification of Timed Au-

tomata: Theory and Practice. PhD thesis, Delft Uni-

versity of Technology.

ANOMALY DETECTION IN PRODUCTION PLANTS USING TIMED AUTOMATA - Automated Learning of Models

from Observations

369