TRACKING CONTROL FOR

TWO-DIMENSIONAL OVERHEAD CRANE

Feedback Linearization with Linear Observer

Tam´as R´ozsa and B´alint Kiss

Department of Control Engineering and Information Technology, Budapest University of Technology and Economics

Magyar Tud´osok krt. 2, Budapest, Hungary

Keywords:

Overhead crane, Motion planning, Tracking control, Flatness, Feedback linearization, Taylor approximation,

Linear observer.

Abstract:

A possible way to control non-linear systems is the use of exact linearization and the application of a tracking

controller to ensure exponential decay of the error along the reference trajectory. In case of overhead cranes,

it can be used if the load coordinates (or alternatively the rope angles) are known which is not the case in real

applications, where the motor axis displacements are usually measured. This paper applies the linearization

techniques such that the calculations of unmeasured states are realized with an observer, which is constructed

for the linear approximation of the dynamics along the reference trajectory. Simulation results are provided to

prove the applicability of the concept.

1 INTRODUCTION

Cranes and other types of weight handling equip-

ment are used to carry heavy loads (Gustafsson, 1996;

D. Buccieri and Bonvin, 2005; Kiss and Mullhaupt,

1999). In many cases, the load is attached to the me-

chanical structure with a rope, so the load position

cannot be directly actuated and the resulting oscilla-

tory behavior may present serious difficulties to inex-

perienced human operators. This oscillatory nature of

crane-like underactuated mechanical systems makes

them a popular benchmark application in control en-

gineering. Several tracking and sway elimination al-

gorithms are proposed in the literature (L´evine et al.,

1997; Marttinen et al., 1990; Neupert and Schneider,

2006; Overton, 1996; Hong et al., 1998), but many

of them are based on the knowledge of the load co-

ordinates (or alternatively the rope angles) which are

generally difficult to robustly measure in real applica-

tions.

The flatness property (L´evine, 2009) of the crane

models implies their feedback linearizability and it

can also be exploited for motion planning purposes.

We propose to apply a time-varying linear observer

to the linearized system dynamics along the reference

trajectory to determine the value of the unmeasured

state variables which need to be injected in the track-

ing feedback. The calculations and the simulation re-

sults will be presented on a simple, two-dimensional

overhead crane and they can be generalized for more

complex structures.

The remaining part of the paper is organized as

follows. Section 2 introduces some notations and

presents the dynamics of the two-dimensional over-

head crane. The tracking controller and the observer

design is presented in Section 3. Simulation results

of the trajectory behavior are shown in Section 4, and

our results are summarized in Section 5.

2 SYSTEM DYNAMICS

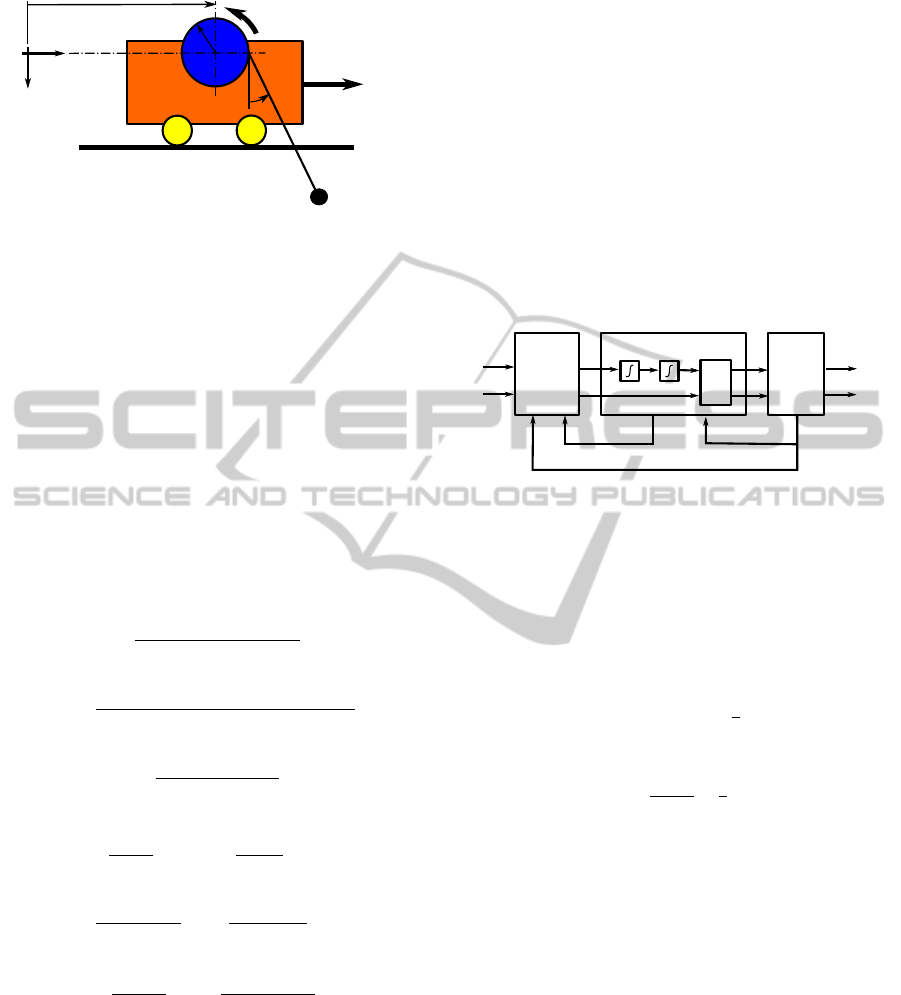

The two-dimensional overhead crane is illustrated in

Figure 1. The horizontal displacement of the cart with

mass M is denoted by R. The cart is actuated by a

motor delivering the force F which is considered to

be one of the input of the dynamics. The load with

mass m, having the coordinates (x

m

,z

m

) is accelerated

through a rope with the length of L, winched on a

drum of inertia J and radius ρ with a motor delivering

the torque T. The angle between the rope and the

vertical is denoted by θ. We assume no friction and

massless rope and due to the small value of ρ, we also

assume that the rope always connects to the winch at

point (R+ρ, 0). The resulting mechanical system has

427

Rózsa T. and Kiss B..

TRACKING CONTROL FOR TWO-DIMENSIONAL OVERHEAD CRANE - Feedback Linearization with Linear Observer.

DOI: 10.5220/0003539604270432

In Proceedings of the 8th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2011), pages 427-432

ISBN: 978-989-8425-74-4

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

Figure 1: The overhead crane.

three degrees of freedom so the dimension of the state

vector x is six. Several possible choices exist for x.

The non-linear system dynamics can be written in

the classical form (Isidori, 1995):

˙x = f(x) + g(x)u (1)

where x and u denote the state and input vectors, re-

spectively. Let us define

x =

h

R

˙

R

θ

˙

θ

L

˙

L

i

T

(2)

u =

h

F T

i

T

(3)

such that f and g read

f(x) =

˙

R

mJL

˙

θ

2

sinθ+mgJsinθcosθ

D

˙

θ

−

sinθ(Dg+mJL

˙

θ

2

cosθ)+mgJcos

2

θ+2D

˙

L

˙

θ

LD

˙

L

mMρ

2

(L

˙

θ

2

+gcosθ)

D

(4)

g(x) =

0 0

mρ

2

+J

D

mρsinθ

D

0 0

−

cosθ(mρ

2

+J)

LD

−

mρsinθcosθ

LD

0 0

−

mρ

2

sinθ

D

−

ρ

(

msin

2

θ+M

)

D

(5)

with

D = D(θ) = mMρ

2

+ mJsin

2

θ+ MJ. (6)

3 TRACKING CONTROL

In this section we present the linearizing and the

tracking controller first, then we give the details of

the observer design steps.

3.1 Stabilizing Feedback

It has been shown in (Fliess et al., 1993; L´evine et al.,

1997; Kiss and Mullhaupt, 1999) that the system

(1)–(5) with output

y =

h

1

(x)

h

2

(x)

=

R+ ρ + Lsinθ

Lcosθ

(7)

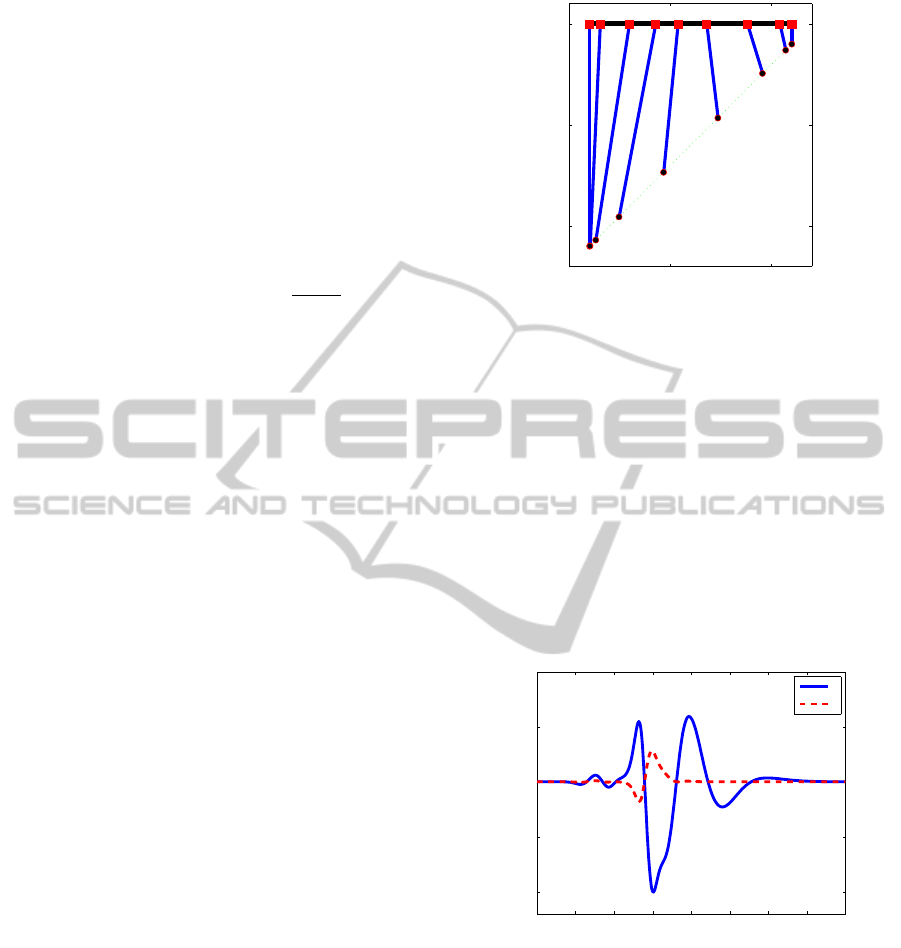

is differentially flat, which implies that the model is

feedback linearizable. The conception is shown in

Figure 2. Notice that the elements of the flat out-

put have been chosen as the Cartesian coordinates

(x

m

,z

m

) of the load.

!

!

"

Figure 2: Block diagram of the linearizing feedback.

Based on (Boustany and d’Andr´ea Novel, 1992),

the equations of the dynamic compensator are

F

T

= α(x) + β(x)

ξ

v

2

(8)

α(x) =

−mgsinθcosθ

mgρcosθ−

J

ρ

L

˙

θ

2

(9)

β(x) =

msinθ M

−

mρ

2

+J

ρ

J

ρ

sinθ

(10)

¨

ξ = v

1

(11)

Notice that ξ is the tension in the rope, divided by the

load mass.

Combining (1)–(6) and (8)–(11), the extended

state-space model can be written in the form

˙

˜x =

˜

f( ˜x) +

h

˜g

1

( ˜x) ˜g

2

( ˜x)

i

˜u (12)

with the new state and input vectors

˜x =

h

R

˙

R θ

˙

θ L

˙

L ξ

˙

ξ

i

T

(13)

˜u =

h

v

1

v

2

i

T

(14)

In fact, the new vector fields

˜

f, ˜g

1

, ˜g

2

read

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

428

˜

f( ˜x) =

˙

R

0

˙

θ

−2

˙

L

˙

θ−gsinθ

L

˙

L

L

˙

θ

2

+ ξ

˙

ξ

0

(15)

˜g

1

( ˜x) =

0

0

0

0

0

0

0

1

˜g

2

( ˜x) =

0

1

0

−

cosθ

L

0

− sinθ

0

0

(16)

This extended model can be exactly linearized with

static feedback which has the form (Isidori, 1995):

v

1

v

2

= A

−1

( ˜x) ·

x

(4)

m

z

(4)

m

− b( ˜x)

(17)

where A and b are calculated via Lie derivatives:

A( ˜x) =

L

˜g

1

L

3

˜

f

h

1

L

˜g

2

L

3

˜

f

h

1

L

˜g

1

L

3

˜

f

h

2

L

˜g

2

L

3

˜

f

h

2

(18)

b( ˜x) =

L

4

˜

f

h

1

L

4

˜

f

h

2

(19)

The resulting system is a decoupled linear system

˙x

′

= A

′

x

′

+ B

′

u

′

(20)

with

x

′

=

h

x

m

˙x

m

¨x

m

x

(3)

m

z

m

˙z

m

¨z

m

z

(3)

m

i

T

(21)

u

′

=

h

x

(4)

m

z

(4)

m

i

T

(22)

The elements of the new state vector x

′

can be ex-

pressed in coordinates of ˜x in (13). Note that the dif-

feomorphism is singular if

cosθ(gcosθ− ξ) = 0 (23)

One can easily design an additional feedback law for

the linear dynamics (20) which ensures the exponen-

tial decay of the tracking error, so that

e

(4)

x

+ k

x,3

e

(3)

x

+ k

x,2

¨e

x

+ k

x,1

˙e

x

+ k

x,0

e

x

= 0 (24)

e

(4)

z

+ k

z,3

e

(3)

z

+ k

z,2

¨e

z

+ k

z,1

˙e

z

+ k

z,0

e

z

= 0 (25)

are satisfied where

e

x

= x

m,ref

− x

m

(26)

e

z

= z

m,ref

− z

m

(27)

To determine the coefficients k

x,i

, k

z,i

, i = 0,1, 2,3,

several methods can be used, e.g., LQR and pole

placement techniques (Brogan, 1990).

3.2 State Observer

The previously proposed method assumes that the

state vector x in (2) is known. However, in real appli-

cations only motor positions can be easily measured,

i.e., R and L, but θ is difficult to determine.

We apply a linear state observer (Brogan, 1990)

for this purpose, calculating the first-order Taylor ap-

proximation of the non-linear model (1)–(5) for every

timestep along track. Simulationresults show that this

technique gives satisfactory result (see Section 4).

Introducing

¯x = x− x

0

(28)

¯u = u− u

0

(29)

¯y = y− y

0

(30)

the linear approximation of (1)–(5) at (x

0

, u

0

) can be

written as follows:

˙

¯x =

¯

A(x

0

,u

0

) ¯x+

¯

B(x

0

,u

0

) ¯u (31)

The matrices

¯

A and

¯

B are calculated via symbolic

derivation:

¯

A =

∂f(x,u)

∂x

(x

0

,u

0

)

(32)

¯

B =

∂f(x,u)

∂u

(x

0

,u

0

)

(33)

One can design a linear observer in the form

˙

ˆ

¯x =

¯

F(x

0

,u

0

)

ˆ

¯x +

¯

G(x

0

,u

0

) ¯y+

¯

H(x

0

,u

0

) ¯u (34)

where

ˆ

¯x denotes the estimation of ¯x, and

¯

F,

¯

G,

¯

H can

be chosen such that the estimation error ¯x−

ˆ

¯x decays

exponentially.

Since the matrices

¯

A,

¯

B,

¯

F,

¯

G,

¯

H depend on the op-

erating point, they are time-varying. Nevertheless,

they can be calculated off-line for every reference tra-

jectory which is important in real-time applications.

Note that this method also enables to design an

additional load estimator which ensures robustness

against unknown disturbances on the system input

channels, i.e., F and T. Laboratory experiments show

that this is an effective way to cancel friction forces.

TRACKING CONTROL FOR TWO-DIMENSIONAL OVERHEAD CRANE - Feedback Linearization with Linear

Observer

429

3.3 Motion Planning

It is expected to carry the load with zero velocity

and acceleration in the initial and final positions, so

any oscillations in these two points are to be avoided.

One can easily design a reference trajectory based on

polynomial approximation, which satisfies these con-

straints (L´evine, 2009).

In the two-dimensional overhead crane example,

the following expression can be used to calculate the

reference trajectory in x direction:

x

m

(t) = x

m,I

+ (x

m,F

− x

m,I

) ·

9

∑

i=5

a

i

t − t

I

t

F

− t

I

i

(35)

where t ∈ [t

I

,t

F

] and t

I

, t

F

denotes the time at the ini-

tial and final positions, respectively. The coefficients

a

i

are computed by solving a system of linear equa-

tions produced by the constraints mentioned above,

namely x

m

(t

I

) = x

m,I

, ˙x

m

(t

I

) = ¨x

m

(t

I

) = x

(3)

m

(t

I

) =

x

(4)

m

(t

I

) = 0 and x

m

(t

F

) = x

m,F

, ˙x

m

(t

F

) = ¨x

m

(t

F

) =

x

(3)

m

(t

F

) = x

(4)

m

(t

F

) = 0 In fact, the numerical values

of the coefficients are

a

5

= 126 a

6

= −420

a

7

= 540 a

8

= −315

a

9

= 70

(36)

The derivatives can be easily calculated as well. The

method in z direction is exactly the same as presented

for x.

There are some situations, for example if an ob-

stacle is present in the crane’s workspace, when other

type of path is required. According to (L´evine, 2009),

the geometry of the trajectory can be given by the

function

z

m

= z

m

(x

m

) (37)

where x

m

= x

m

(t) can be calculated using the polyno-

mial interpolation described by (35). Moreover, the

geometry can also be specified in the following form:

x

m

= x

m

(λ) (38)

z

m

= z

m

(λ) (39)

Here λ = λ(t) denotes the path parameter which can

also be calculated using (35).

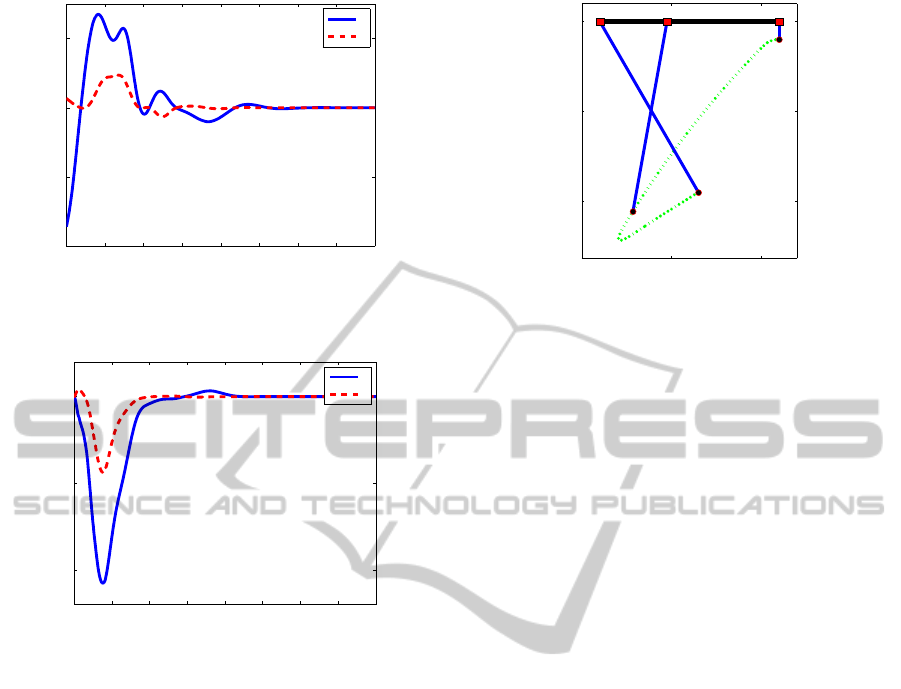

4 SIMULATIONS

This section shows simulation results based on the

methods described above. The parameters are given

as follows: m = 1kg, M = 3kg, J = 0.1kgm

2

,

ρ = 1.5cm, x

m,I

= 0.1m, z

m,I

= 1.1m, x

m,F

= 1.1m,

z

m,F

= 0.1m, T = 2s; sample time is set to 0.001s and

Figure 3: Illustration of the desired behavior.

the reference path is a straight line with a length of

1.41m. It is illustrated in Figure 3. Using pole place-

ment technique, the observer’s poles have been placed

equidistantly between −5 and −15, while the closed-

loop poles have been placed with the outer-loop con-

troller to −5.

In the first simulation the model was initialized

with the values of the reference trajectory. In this

case, Figure 4 shows the differences between the real

and estimated positions. One can see that the absolute

value of the highest error is 10

−4

m, which is totally

acceptable in most cases.

Figure 4: Estimation error in x and z directions.

On the other hand, if the initial states of the

crane model differ from the reference states, the

controller is still able to stabilize the system. Let

us consider some initial oscillation, i.e., θ

I

= π/20,

˙

θ

I

= −0.5rad/s. Theposition errorsareshown in Fig-

ure 5. The observer produces greater error here than

in the previous case, but the system still reaches the

equilibrium. Notice that initial error is also present

since the estimator starts from the reference initial

states.

Finally, Figure 6 shows the case when the ini-

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

430

Figure 5: Estimation error in x and z directions if the crane

model starts with an initial trajectory error.

Figure 6: Estimation error in x and z directions if both the

model and the observer start with the same initial state,

which is not the initial reference state.

tial states of the crane model differ from the refer-

ence states, but the observer’s states are also set to the

model’s initial states. It means that the initial error

is known so the observer can be initialized properly.

Thus, the initial estimation error is zero in this case.

The states have been modified to θ

I

= π/6,

˙

θ

I

=

−1rad/s. Although the load starts far from the ref-

erence path (in fact, the distance is 0.57m), the con-

troller stabilizes the system and the load is taken to

the desired location. Figure 7 illustrates the trajectory

in this situation.

5 CONCLUSIONS

We have presented the tracking controlproblem of the

two-dimensional overhead crane. A general approach

to solve it is using feedback linearization. It requires

the exact knowledge of the system states, however,

usually only two of the six states are measured. We

proposed a simple estimation method to calculate the

unmeasured states, which is based on the Taylor ap-

Figure 7: Trajectory in the case of high initial error.

proximation of the non-linear crane model. Simula-

tion results show that this approach gives satisfactory

result for small errors. Further research on this topic

might include stability analysis with parameter uncer-

tainties, and application to a laboratory equipment.

ACKNOWLEDGEMENTS

This work is connected to the scientific program of

the ”Development of Quality-Oriented and Harmo-

nized R+D+I Strategy and FunctionalModel at BME”

project. This project is supported by the New Hun-

gary Development Plan (Project ID: TMOP-4.2.1/B-

09/1/KMR-2010-0002). The work is partially sup-

ported by the Hungarian Scientific Research Fund un-

der grant OTKA K71762.

REFERENCES

Boustany, F. and d’Andr´ea Novel, B. (1992). Adaptive

control of an overhead crane using dynamic feedback

linearization and estimation design. In Robotics and

Automation, 1992. Proceedings., 1992 IEEE Interna-

tional Conference on, pages 1963–1968 vol.3.

Brogan, W. L. (1990). Modern Control Theory (3rd Edi-

tion). Prentice Hall.

D. Buccieri, P. M. and Bonvin, D. (2005). Spider-

carne: Model and properties of a fast weight handling

equipment. In Proceedings of the 16th IFAC World

Congress.

Fliess, M., L´evine, J., and Rouchon, P. (1993). A gen-

eralised state variable representation for a simplified

crane description. Int. J. of Control, 58:277–283.

Gustafsson, T. (1996). On the design and implementation

of a rotary crane controller. European J. Control,

2(3):166–175.

TRACKING CONTROL FOR TWO-DIMENSIONAL OVERHEAD CRANE - Feedback Linearization with Linear

Observer

431

Hong, K., Kim, J., and Lee, K. (1998). Control of a con-

tainer crane: Fast traversing, and residual sway con-

trol from the perspective of controlling an underactu-

ated system. In Proceedings of the ACC, pages 1294–

1298, Philadelphia, PA.

Isidori, A. (1995). Nonlinear Control Systems. Springer.

Kiss, B., L. J. and Mullhaupt, P. (1999). Modeling, flat-

ness and simulation of a class of cranes. Periodica

Polytechnica-Electrical Engineering, 43(3):215–225.

L´evine, J. (2009). Analysis and Control of Nonlinear Sys-

tems. Springer.

L´evine, J., Rouchon, P., Yuan, G., Grebogi, C., Hunt, B.,

Kostelich, E., Ott, E., and Yorke, J. (1997). On the

control of US navy cranes. In Proceedings of the Eu-

ropean Control Conference, pages N–217, Brussels,

Belgium.

Marttinen, A., Virkkunen, J., and Salminen, R. (1990).

Control study with a pilot crane. IEEE Trans. Edu.,

33:298–305.

Neupert, J., H. A. S. O. and Schneider, K. (2006). Trajec-

tory tracking for boom cranes using a flatness based

approach. In Proceedings of the SICE-ICASE Inter-

national Joint Conference, pages 1812–1816.

Overton, R. (1996). Anti-sway control system for cantilever

cranes. United States Patent, (5,526,946).

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

432