RESEARCH ON INNOVATION OF SHIPBUILDING SUPPLY

CHAIN MANAGEMENT BASED ON COMPLEXITY

ADAPTIVE SYSTEM

Gen Li, Chunlei Lv and Yifei Cheng

School of Economics and Mnanagement, Harbin Engineering University, Nantong Street, Harbin, China

Keywords: Shipbuilding supply chain management, Complexity adaptive system, Operational mode, Innovation.

Abstract: Because of the change of the whole operational environment, traditional methods could not reasonably be

used to settle the complicated problems which occur in shipbuilding supply chain management. Based on

complexity adaptive system theory, the paper first interprets the whole operational mode of shipbuilding

supply chain, then it establishes simulation model of shipbuilding supply chain according to Multi-Agent,

finally it puts forward some innovation directions in order to resolve complicated problems which emerge

from current shipbuilding supply chain management.

1 INTRODUCTION

Shipbuilding supply chain is a series of value-

increasing activities including original material

purchasing, conveyance, process, manufacturing and

productions arriving in ship owners, in fact it is a

function net chain structure which is filled with

logistics flow, fund flow, service flow, knowledge

flow and information flow thoroughly. Shipbuilding

supply chain management is a whole management

style which integrates supplier, manufacturers,

medium-sellers and buyers through logistics and

information flow (Ren and Zhao, 2008).

Under the premise that it quickly satisfies the

need of final users, shipbuilding supply chain must

have the ability to respond to the change of market

quickly and run perfectly from the whole supply

chain (Li, 2006). In the market environment which is

full of dynamic competition and cooperation

nowadays, the enterprises could belong to different

supply chains in the meantime. The competition

among enterprises actually has already converted

into the competition among different supply chains.

Under the competition situation above, the operation

environment of shipbuilding enterprises becomes

more complicated (Zhang, 2003). Enterprises should

re-examine their own operational modes from a new

aspect. They also should allocate resources and make

strategic decisions from the greater thinking space

and the area space. The paper explains the

complicated phenomenon and resolves complicated

problems of shipbuilding supply chain management

basically with the help of complexity adaptive

system theory.

2 CHARACTERISTICS AND

RELATED MODELS OF CAS

Complex adaptive system was put forward by John

Holland (USA) when the institute of Santa Fe was

10 years old in 1994. The fundamental thought of

CAS is that: because the agents will interact with

themselves and environment, they will change

themselves and also change the environment.

2.1 Fundamental Characteristics of

CAS

The core thought of CAS is “adaption creating

complexity”, it can say that it is a leap in

understanding system motion and evolving

regulation. Its characteristics will be discussed as

follows (Chen, 2001).

First, the agent is an active and live agent. This is

the key differentiation of CAS from other systems.

This characteristic makes it able to effectively be

applicable to economic, social, ecological

complicated system etc. But other methods are more

difficult to deal with these areas.

389

Li G., Lv C. and Cheng Y..

RESEARCH ON INNOVATION OF SHIPBUILDING SUPPLY CHAIN MANAGEMENT BASED ON COMPLEXITY ADAPTIVE SYSTEM.

DOI: 10.5220/0003568803890395

In Proceedings of the 13th International Conference on Enterprise Information Systems (NMI-2011), pages 389-395

ISBN: 978-989-8425-53-9

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

Second, the mutual influence and interaction

between the agent and environment (including

among the agents) is the main motive for the

evolution of the system. The former systems usually

put the internal attribute of agent into the initial

position, and they don’t emphasize on the interaction

between agent and environment (including among

agents). This makes CAS able to be used into

different areas where the characteristics of agents are

absolutely different, but there are many commons in

the correlation.

Third, it introduces the random factor, so it has a

stronger ability to describe and express.

Fourth, it contacts the macro view and the micro

view organically. It makes the change of agents

become the foundation of the change of the whole

system through the interaction between the agent and

environment (Tan and Dong, 2001).

Because of the above characteristics, CAS has

different functions and values compared with other

system methods

2.2 Main Models and Simulated Tool of

CAS

There are many methods to study CAS, but it has

more guiding significance from models and

simulated tool (Dong, 2006).

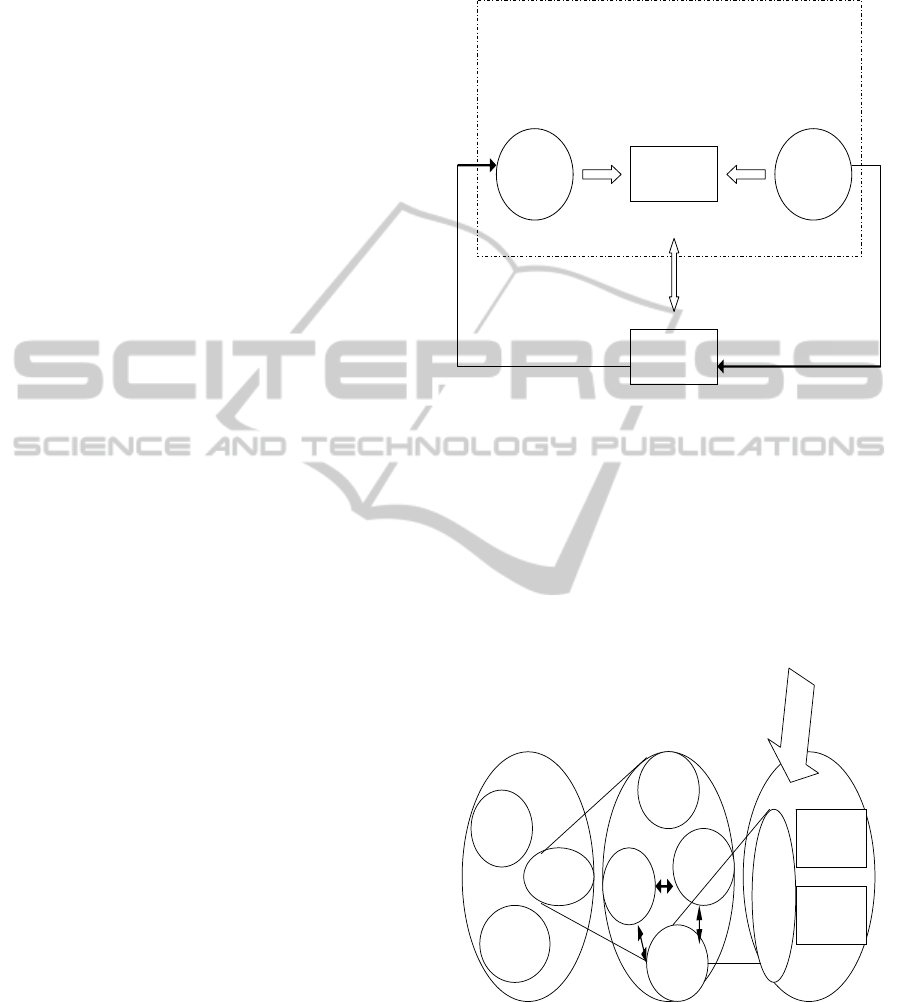

2.2.1 Stimulating-reaction Model

From the micro view level, it expresses the most

basic behaviour pattern of agent in each system with

the way of unity. The performance system of each

agent is composed of three parts such as a detector,

an effecter, a set of IF/THEN rule.

The detector is been used to accept external

incitement, the effecter is been used to make a

reaction, IF|THEN rule stipulates how to respond

towards different incitements, but it differs from

common sense which is 1 to 1 correspondence. In

order to simulate real world, this rule sets up many

kinds of choices and it contains contradiction,

conflict and disagreement. Based on genetic

algorithm, the agent can successfully compare and

choose rules, and it even yields new rules through

the procession of evolution. Figure 1 is stimulating-

reaction model as follows.

2.2.2 Echo Model

Based on micro stimulating-reaction model, it can

establish echo model which is macro mode of the

whole system. In this model, the agent has three

elementary parts: offensive label, defense label and

resource pool.

Adaptive agent

message message

detector effecter

a set of rule

environment

message message

Figure 1: Stimulating-reaction model.

The basic function of echo mode includes the

performance that an agent actively contacts with

other agents. In the meantime, it gives answers to

other agents towards their contacts, if they match

successfully, then they will exchange resources.

They will save and process resources in their inner

bodies; if the resources are enough and then they

will breed new agents. Under the control of echo

model, the system will be like figure 2 as follows.

Position1

Position2

position

3

Position

Agent2

Agent1

Agent3

Reso

-urce

p

ool

Offensive label

Defense label

Reso

-urce

Figure 2: Echo model.

2.2.3 Simulation Tool

Swarm is a simulated terrace. It is an experiment tool

to study CAS (Qiu, 2003). This simulated terrace is

used to carry out discrete event simulation. It has the

same characteristics as the general affairs simulation.

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

390

It adopts realizing method which is facing to object,

so in this terrace, it provides a whole set of database

which is the basic work what the researcher

completes in some simulated experiments. The

customer can realize many functions on the

foundation of these databases.

The majority of simulation procedures of Swarm

contain four types of objects: Model Swarm,

Observer Swarm, simulation agent and environment.

Model Swarm and Observer Swarm are subcategory

of Swarm category. Swarm category is the basic

structure piece of Swarm simulation. A Swarm is the

combination between a series of objects and

behaviour timetable that are caused by the objects.

Simulation agent usually inherits methods from

Swarm Object to provide support for memory and

management of speculation control. The different

simulation systems have different environment,

figure 3 is Swarm structure.

Model

Swar

m

Observer

Swar

m

Schedule Schedule

Space

Graph

Probe

Agent

Figure 3: The structure of Swarm.

3 ANALYSIS OF COMPLEXITY

AND ADAPTABILITY ON

SHIPBUILDING SUPPLY

CHAIN

3.1 The Source of Complexity of

Shipbuilding Supply Chain System

3.1.1 The INDEPENDENCE of Entities

Shipbuilding supply chain is network system that is

constituted by many comparatively independent

entities. Overall supply chain model and

optimization target don not exist. The management

of overall supply chain will be realized through

coordination among these comparatively

independent entities. Each enterprise in supply chain

has its own benefit and management mode and there

is no core place among these members. The change

of one enterprise will be affected by other enterprises

and this change will affect the change of other

enterprises. The whole shipbuilding supply chain can

constantly study, reorganize and perfect its layer

structure and functional structure (Choi and Dooley,

2003).

3.1.2 Turbulence and Indetermination of

Environment

Shipbuilding supply chain faces inside and external

environment that is full of turbulence and

indetermination. Ally and rival will change all the

time, and itself of shipbuilding supply chain also

adjusts in order to adapt to environment. Under this

circumstance, it is very important for the members in

shipbuilding supply chain to choose suitable

suppliers and dealers, join in the suitable supply

chain and valuate the efficiency and effect of supply

chain. But among the current researches and

applications towards shipbuilding supply chain, the

authors just see the supply chain and its environment

as a static state or very slowly changing object. They

usually adopt serial plan or control mode and over-

emphasize the stability of the colleague relationship,

so it lacks of enough adaptability and is very

difficult to adapt to the operation environment which

is changing rapidly.

3.1.3 Difference of Internal Structure

The pursuit of shipbuilding supply chain is

unobstruction and agility of logistics, information

flow, knowledge flow and capital flow. Because of

the different internal structure of shipbuilding supply

chain enterprise, the corresponding information

systems are not compatible. Shipbuilding supply

chain management is to integrate these distributed

and heterogeneous systems as a whole or

information sharing system, which is urgent problem

that needs to be resolved. But the current system is

mainly based on the traditional organization

management mode and do not really realize business

process integration from the scope of the entire

supply chain.

RESEARCH ON INNOVATION OF SHIPBUILDING SUPPLY CHAIN MANAGEMENT BASED ON COMPLEXITY

ADAPTIVE SYSTEM

391

3.2 Mechanism of Complexity of

Shipbuilding Supply Chain

3.2.1 Interaction and the Occurrence of

Emerging of Shipbuilding Enterprises

in the Supply Chain

The essence of emerging is the process from small to

big and from simple to complex. It is a kind of

interaction of before and after association. These

interactions and the system coming from the

interaction are nonlinear. The interaction is its center

and is more complex than the simple sum of

individual behaviour. The stable mergence

phenomenon could be an integral part of more

complex emergence phenomena.

3.2.2 Mutual Adaptation between the Agents

and Environment

The agents in the supply chain are the economic

entities which are those independent or half

independent. These agents have the supply and

demand relation that is full of competition,

cooperation and dynamic state etc. Operation unit,

business process, member’s enterprise, supply chain

system, the whole action environment constitute

agents in different layers. And each agent has its

own target, conduct strategy, internal structure and

existence motive.

These agents interact through gathering to expect

to continuously adapt to environment. Towards the

whole supply chain, there is no concentrated control

centre to guide the behavior of each agent, but the

whole supply chain is still in good order. Because

this activity and the repeated and mutual gathering

function with environment, which are basic move for

development and evolution of the whole supply

chain system.

3.2.3 Dynamic State and Non-line of

Shipbuilding Supply Chain

Modern enterprises exist in the environment which is

full of severe competition and indetermination.

Under CAS, although a shipbuilding enterprise

makes very small decision, it will largely influence

on related enterprises (Forrester, 1961). In the

meantime, environment also influences on modes,

various rules or standards of enterprises. The agent

will change its standard which indicates its ability to

adapt to environment because of the change of

mode, target appearance, basic function standard and

the ability to adapt to the environment etc.

3.2.4 Complexity of Shipbuilding Supply

Chain

The intertexture of positive and negative feedback

results in the complexity of supply chain and the

positive feedback exerts a great influence on the

system. Shipbuilding supply chain faces an

environment that is full of complexity, the random in

agent, which plays an important role in process that

system looks for various possibilities. Some

important whole characteristics come out in the

mentally dense and the random process.

3.2.5 Coordination of Shipbuilding Supply

Chain

On the one hand, how to manage and control the

logistics flow, information flow, knowledge flow,

the funds flow between suppliers and demanders and

availably lower inventory, accelerate turnover of

logistics and information flow, raise the efficiency of

circulates in enterprise production and commodity,

quickly respond to market opportunity, which

become urgently problems needing to be worked

out; On the other hand, because of market

competition which is turning worse, the pursue of

enterprises in the whole supply chain will result in

some antinomies. Enterprises should know that the

whole supply chain can achieve the state which is

called Pareto Optimality, but it can not achieve the

state of the optimization of every enterprise.

Therefore, an enterprise should understand how to

cooperate with the enterprises which are in upper

and lower class. This can make sure that the

efficiency of the whole logistics chain is the biggest

and the efficiency of the enterprise reaches the best

state (Chandra and Kumar, 2001).

4 SIMULATION MODEL FRAME

OF SHIPBUILDING SUPPLY

CHAIN ACCORDING TO

MULTI-AGENT

According to CAS, the paper adopts the software

terrace-SWARM which was developed by SFI in

order to establish the model for CAS. The Swarm

model defines the frame of model. With the help of

this frame, we can build simulation model based on

Multi-agent.

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

392

4.1 Introduction of Swarm Model

Swarm model can make the customer build up

his/her own application according to this frame; at

the same time, it considers factors such as the

characteristics of different agents, and the details of

space distribution, the characteristics of network

connections and so on. It mainly carry out

interaction towards a series of independent

individuals through independent affairs carry on

handing over to with each other, it will help study

behavior of the complicated system which is

composed of many agents.

Lin, FuRen and others have studied the process

restructuring strategies towards different orders

under the application of Swarm, the strategies have

affected on the performance of the whole supply

chain. They obtained ideal results (Lin and Shaw,

1998).

4.2 Simulation Model of Supply Chain

based on Multi-agent

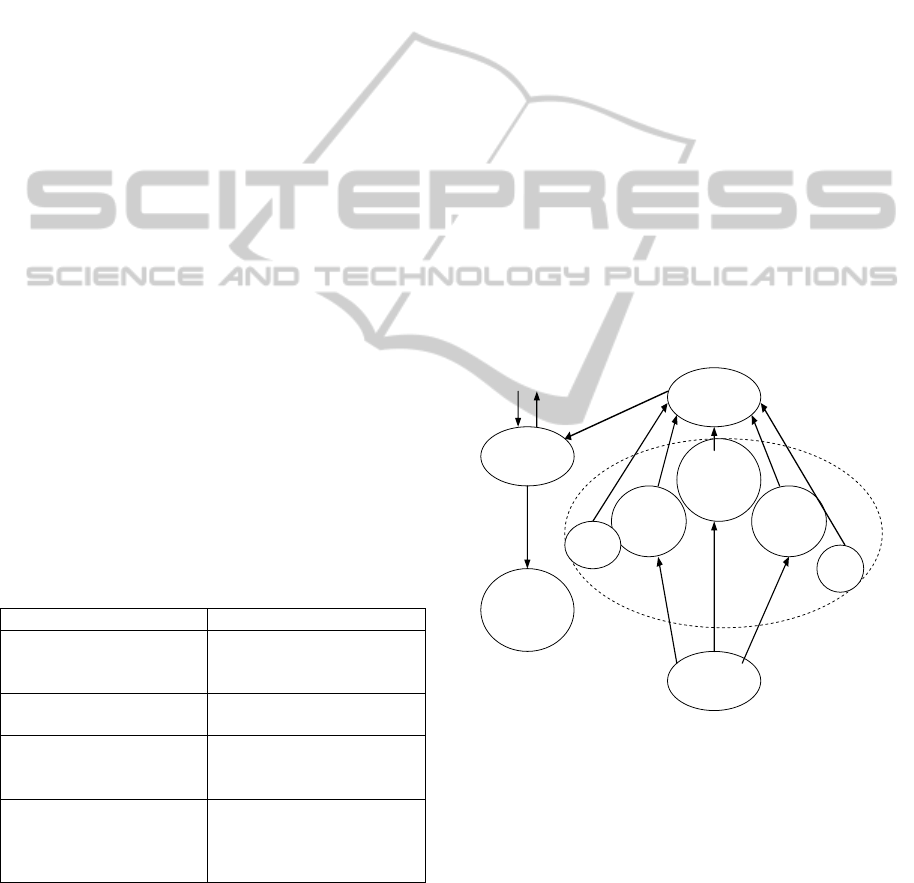

Table 1 shows mapping relationship between supply

chain model and Swarm model. We can see the four

similarities between them. These similarities are

very important for supply chain management.

According to this kind of corresponding relation, it

calls Swarm 21.1 class library in Jbuilder3.0

platform to build simulation model of supply chain

based on Multi-Agent (figure 4) shown. The

individual details are omitted for the limited length

of the paper.

Table 1: Mapping relationship between supply chain

model and Swarm model.

Supply chain model Swarm model

Different role agents in

different levels

A series of agents which

have different inner states

and behavior rules

Information interaction

among different agents

Information transmission

among different agents

Logistics flow and

machining process

The agent under discrete

event simulation and time

debugging triggering

The agents get the whole

supply chain

performance through

gathering and interaction

The performance of all

agents decides the whole

performance of system

In this simple model, system includes supplier

agent, manufacturer agent, customer agent, order

class and credit standing class, they are all

autonomic agents. Logistics, information, fund and

knowledge flows of the whole system will run under

demand pull. First, Model Swarm produces orders

and distributes orders for customers and the

customers consult price and delivery time from

manufacturers. Then manufacturers will inquire

supplier and supplier will quote in response. After

getting quotation, manufacturers will tell the

customers quotation and then the customers will

choose the best manufacturers. Similarly, the

manufacturers will also choose the best customers.

Finally, it will evaluate the credit of manufacturers

(suppliers) and update the prestige historical data.

5 RELATED STRATEGIES OF

SHIPBUILDING SUPPLY

CHAIN MANAGEMENT BASED

ON CAS

Supply chain is a CAS. Shipbuilding supply chain

management should fully consider the characteristics

of CAS and adjust management mode and theory.

We can put forward suggestions as follows (Wu,

2006).

SC_Observer

Observer

Swarm

Supply chain

Swarm

Manufacture

Agent

Supplier

A

g

ent

Customer

A

g

ent

Credit

Order

Figure 4: Simulation model of shipbuilding supply chain

management.

5.1 Self-management towards

Adaptability

Supply chain is a self-adaptive system, if one

enterprise wants to develop in the market; it need set

up a self-management thought. On the one hand, it

should coordinate with other enterprises in supply

chain; on the other hand it should pay attention to

itself-management. The kind of self expresses the

choices of “internal mode”.

RESEARCH ON INNOVATION OF SHIPBUILDING SUPPLY CHAIN MANAGEMENT BASED ON COMPLEXITY

ADAPTIVE SYSTEM

393

When the inner and outer environment is

changed, the shipbuilding enterprises should rapidly

readjust their goal and fundamental structure and

establish a rapid reaction mechanism for them to

change and optimize their own product

characteristics, management process, production

method, enterprise culture, even employee career

development. Meanwhile, supply chain network is

self-organization. Shipbuilding enterprises should

actively adjust their position in the supply chain and

reorganize themselves quickly according to the

dynamic change of the environment.

5.2 Paying Special Attention to

Adjustment of the Internal Model

Shipbuilding supply chain pursues the condition of

Pareto Optimality, this shows that enterprises in the

whole supply chain are unable to maximize their

own goals and interests. Based on this, the

enterprises need to establish their own

characteristics, such as product and service,

management, technology, enterprise culture and so

on, in order to meet diverse and dynamic market

demand. Under the optimization of the whole supply

chain, the enterprise realizes the target and

maximized benefit.

5.3 Strengthening the Management of

“Flow”

Towards supply chain management, we should do

well in managing logistics, information, knowledge

and fund flows among enterprises or between

enterprise and external environment. First, the

enterprises should realize that only they transmit

“flow” completely among themselves, it will be

possible for them to enhance their adaptive and anti-

risk ability. Enterprises should closely cooperate in

functional layer, operational layer and flow layer etc,

then eliminate the bottleneck of whole supply chain,

and raise the whole operation performance of supply

chain; Secondly, the enterprise shall establish

information system and strengthen the ability to

exchange information with external environment in

order to make enterprises effectively complete the

production plan and in or out goods scheduling.

Through this process, the enterprises can avoid

unnecessary waste.

5.4 Paying More Attention to Micro

Management

The good or bad operation performance of the enter-

prise depends largely on the national or social

policies and laws. The enterprise must recognize the

supply chain type which it is located in and

determine its strategic position in the shipbuilding

supply chain reasonably. Through the research, the

paper finds that the evolution and development of

the supply chain system is a collective dynamic

process. This can change strategic errors of some

enterprises that they blindly position themselves in

“core position” of supply chain. Only they clearly

establish strategic concept, they can reasonably

allocate resources and realize the target.

5.5 Establishing the Concept of

Continuous Learning

Shipbuilding supply chain system is the complex

adaptive system that has the ability to learn, which

means that supply chain is in change every minute,

including the change of external environment and

internal management pattern of the enterprise. Only

enterprises have the ability to learn fast, they can

deal with business environment which is changed

fast. Therefore, enterprises in shipbuilding supply

chain must establish the concept of learning

successively and make themselves become learning

organizations.

6 CONCLUSIONS

Shipbuilding supply chain is a CAS, so we need to

convert thinking mode and use the methods provided

by complexity science. Based on shipbuilding supply

chain operational mode of CAS, it can be more

objective to describe the behavior of complexity

system and provide more scientific operational

strategies of shipbuilding supply chain for policy

makers; Meanwhile, the paper puts forward the

corresponding innovation strategies of shipbuilding

supply chain management, such as self-management

toward adaptability; paying special attention to

adjustment of the internal model; strengthening the

management of “flow”; paying more attention to

micro management and establishing the concept of

continuous learning, which can reasonably interpret

complex phenomenon and resolve problems in

current shipbuilding supply chain. For the limited

time, simulation model of shipbuilding supply chain

hasn’t been simulated through the computer, which

will be the research direction in the future.

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

394

REFERENCES

Choi, T. Y., & Dooley, K. J., 2001. Supply networks and

complex adaptive systems: control versus emergence.

Journal of Operations Management, 351-366.

Chandra, C. & Kumar, S., 2001. Enterprise architectural

framework for supply-chain integration. International

Journal of Operation &Production Management,

21(4):461-475.

Chen, Y., 2001. Complex adaptive system theory and its

application: foundation, contents and implication.

Journal of Systemic Dial Entices, 9(4):35-39.

Dong, X., 2006. Research on enterprises’ innovation

system based on the CAS theory. Master Degree

Paper of Hebei Industry University, 10-14.

Forrester, J. W., 1961. Industrial Dynamics. Cambridge,

MA: MIT Press.

Lin, F., & Shaw, M. J., 1998. Reengineering the order

fulfilment process in supply chain networks. The

International Journal of Flexible Manufacturing

Systems, 197-229.

Li, B., 2006. Supply chain management lectures. Beijing:

electronic industrial press.

Qiu, S., 2003. Research on coordination theory, method

and application of complex adaptive systems, Doctor

Degree Paper of Tianjin University, 25-30.

Ren, W. & Zhao, H., 2008. Review of shipbuilding supply

chain management. Science Technology and

Engineering, 8(15):64-67.

Wu, J., 2006. Complex Adaptive System of Supply Chain

Management Strategy. Aerospace Industry

Management, 17-19.

Tan, Y., & Dong, H., 2001. Research on complexity

adaptive system theory and its application. System

Engineering, 19(5):1-6.

Zhang, T., 2003. Analysis and model of operation mode of

supply chain. System Engineering Theory and Practice,

8-9.

RESEARCH ON INNOVATION OF SHIPBUILDING SUPPLY CHAIN MANAGEMENT BASED ON COMPLEXITY

ADAPTIVE SYSTEM

395