A GENETIC ALGORITHM FOR SOLVING A PUBLIC SECTOR

SUSTAINABLE SUPPLY CHAIN DESIGN PROBLEM

Ernesto Del R. Santibanez-Gonzalez

Department of Computer Science, Federal University of Ouro Preto (UFOP), Ouro Preto, MG, Brazil

Henrique Pacca Luna

Computer Science Institute, Federal University of Alagoas (UFAL), Maceió, AL, Brazil

Geraldo Robson Mateus

Department of Computer Science, Federal University of Minas Gerais (UFMG), Belo Horizonte, MG, Brazil

Keywords: Sustainable supply chain, Green supply chain, Evolutionary computation, Genetic algorithms.

Abstract: This paper presents a novel mixed-integer 0-1 model (MIP) for solving a sustainable supply chain network

design problem that arises in the public sector. In our problem, we have to determine a fixed number of

facilities to be located at sites chosen from among a given set of candidate sites. Sustainable issues are

integrated into the model by reducing the greenhouse gas emissions produced by the transportation and the

operation of the facilities. We propose a simple genetic algorithm (GA) for solving this problem. In order to

validate our GA solutions we used GAMS to obtain optimal objective values on the MIP. Computational

results are very good for instances generated from a known OR test library.

1 INTRODUCTION

In 1987 the United Nations World Commission on

Environment and Development (UNWCED)

published Our Common Future Report. In this report

was defined sustainable development as

“development that meets the needs of the present

without compromising the ability of future

generations to meet their own needs”. This report

was a kick-off for a number of interdisciplinary

studies in the field of sustainability.

By 2020 the economic impact of climate change

in the world will reach 20% of the global GDP. The

man-made greenhouse gas emissions (GHG) are one

of the main causes of the climate change.

Considering the magnitude of the impact on the

global economy, the environment and the society,

many agencies of the government and international

institutions are taking actions to reduce and to

control the emission of GHG. The Kyoto

Agreement, signed by 35 countries, was one of the

pioneering intentions of reducing the emission GHG.

This agreement placed the target to reduce about

2012 the global emission of coal for an average of

5.4 % in relation to the levels of 1990. In this

respect, this paper focuses on how governments can

deploy supply chain networks for servicing people

while minimizing the costs of installation, operation

and transportation and, at the same time reducing the

GHG emissions.

There are principally two ways that the human

mind contributes to the emission of GHG:

production of energy (generation of energy) and

transport and logistics, apart from the deforestation.

Both are basic activities that every company as

every government agency realizes to satisfy end

costumers.

Governmental agencies and companies adopting

a friendly sustainable management are facing a

number of changes, from the strategy level till the

operational point of view, affecting their people and

impacting their business processes and their

technology. In this regard, as D. Simchi-Levi,

Kaminsky and E. Simchi-Levi (2007) pointed out,

“the strategic level deals with decisions that have a

222

Del R. Santibanez-Gonzalez E., Pacca Luna H. and Robson Mateus G..

A GENETIC ALGORITHM FOR SOLVING A PUBLIC SECTOR SUSTAINABLE SUPPLY CHAIN DESIGN PROBLEM.

DOI: 10.5220/0003588502220227

In Proceedings of the 13th International Conference on Enterprise Information Systems (ICEIS-2011), pages 222-227

ISBN: 978-989-8425-54-6

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

long-lasting effect on the firm. These include

decisions regarding the number, location and

capacities of warehouses and manufacturing plants,

or the flow of material through the logistics

network”. They established a clear link between

facility location models and strategic decisions of

supply chain management (SCM). Also,

governmental agencies and companies realized that

to be committed with sustainable practices could

imply changes in the criteria to design and to

manage supply chain. That is to say, in addition to

the costs of transport, operation and installation and

considerations on the level of service, the

sustainable models need to consider GHG emission

costs.

Supply chain design based on economic

consideration has been well covered in the literature.

On the other hand, the field of sustainable supply

chain design and management (SSCM) is quite new

(Seuring & Muller, 2008). The greatest benefits of

applying SCM are obtained by an extended analysis

including organizations upstream -closer to the raw

materials- and downstream -closer to the consumer-

of the supply chain and then back again so that the

unsold products are recycled. But, by extending the

focus, what this really does implies more

organizations, multiplying the relation between the

organizations and getting a more complex supply

chain (SC) to manage. Then the focus of the supply

chain management literature has been on dyadic

networks (supplier units-customer units) as we do in

this paper (Choi & Wu, 2009).

This paper proposes a genetic algorithm for

solving a supply chain network design problem that

arises in the public sector considering sustainable

constraints in the form of restrictions on the dioxide

carbon equivalent emissions. The authors are not

conscious of any article tackling the problem of

sustainability that arises in the location of such

public facilities as schools or hospitals. We present a

mixed-integer 0-1 facility location model who

allows to analyze the impact of restrictions in the

GHG emissions on the fixed and transportation costs

and in the location of facilities.

In this paper, in Section 2 is analyzed some

literature in connection with the problem. In section

3 is presented the mixed-integer 0-1 programming

model. In section 4, we discuss the genetic algorithm

implementation for solving the problem. In section 5

we provide some numerical results. Finally in

section 6 we give some conclusions of the work.

2 LITERATURE REVIEW

Above and beyond other aspects, there are

principally two kinds of questions related to the

sustainability. One of them is the emission of GHG.

For the production of a big quantity of GHG to

satisfy the present needs – for example, in the

processes of manufacture and distribution - we affect

the climate of a dangerous way that finally is going

to compromise the capacity so that future

generations could satisfy their own needs. In this

paper we focus on reducing the GHG emissions

caused by the operation of pubic facilities and the

transportation activities to satisfy the demand. We

model the problem of locating facilities in order to

satisfy a fixed demand, minimizing installation and

operating costs and constraining the GHG emissions.

Supply chain management (SCM) is being used

to address the problem of reducing the economic

impact of climate change generated by GHG

emissions. For the purpose of this paper, SCM is a

multidisciplinary management approach to master a

set of interacting organizations. These organizations

share different resources, products, services and

information, with the target to obtain competitive

advantages and to improve the profitability, both in

the individual form and in the collective form.

(Simchi-Levi et al., 2007). According to Choi and

Wu (2009), the focus of the literature of SC has been

in networks of dyadic (supplier firms – customer

firms) as we do in this work.

Disciplines integrating environmental practices

into the supply chain have been called in a number

of different ways. Some of them are: Sustainable

Supply Chain Management (SSCM) and, Green

Supply Chain Management (GSCM). Srivastava

(2007) did a careful review of the literature and he

showed that a wide frame of reference for GSCM

has not been sufficiently developed. Finally, he

defined GSCM as an integrated environment,

including product design, sourcing and selection of

material, manufacturing processes, delivery of the

final product to the consumers, and end-of-life

management of the product after its useful life. In

this paper, we do not make any distinction between

sustainable and green supply chain.

Mathematical modeling for designing

sustainable supply chain is attracting many

researchers to this field. But, according to Seuring

and Muller (2008), the field of sustainable supply

chain design and management (SSCM) is quite new.

In this work, the proposed model focuses on two

sustainable issues: economic and environmental

aspects of GHG emissions. On the other side, till

A GENETIC ALGORITHM FOR SOLVING A PUBLIC SECTOR SUSTAINABLE SUPPLY CHAIN DESIGN

PROBLEM

223

now much research has been done in the field of

private companies’ location theory. The authors are

not aware of any paper addressing the sustainable

problem that arises in the location of such public

facilities as schools or hospitals.

Hugo and Pistikopoulos (2004) developed a

multi-objective mixed-integer 0-1 model for

deciding location and capacity expansion of

facilities (plants), and transportation issues in a

given planning horizon. They maximize profit and

minimize the environmental impact of the plant

operations while satisfying the market demand for

products. They presented numerical results for a

small problem of 3 candidate plants, 3 customers, 2

products, 2 raw materials and 5 periods. In a later

work, Hugo and Pistikopoulos (2005) extended the

previous model and they reformulated the problem

as a stochastic programming model that can address

the decision-making process under uncertainty.

Ramudhin, Chaabane, Kharoune, and Paquet (2008)

proposed a mixed-integer 0-1 programming model

for the GSC design problem. Taking into account

environmental aspects, they analyzed the impact of

transportation, subcontracting, and production

activities on the design of a supply chain network.

The problem considers a three-echelon multi-

products supply chain network formed by a set of

suppliers, a set of subcontractors (plants), and a set

of costumer zones. The model integrates into the

objective function the total amount of GHG

emissions produced by transportation and production

activities, and determines the equivalent carbon

credits generated for different configurations of the

supply chain. The model is tested considering the

case of a steel product manufacturer with three

freight transportation modes, a product with two

semi finished products that are manufactured from

four parts, and at least two suppliers are competing

to supply each part. The model is first solved by

CPLEX Interactive Optimizer V10.0. The authors

also use Goal Programming to determine the best

trade-offs between two conflicting objectives: the

total logistics cost and carbon emissions. In

Chaabane, Ramudhin and Paquet (2010) is extended

the previous model considering life cycle assessment

(LCA) principles in addition to the traditional

material balance constraints at each node in the

supply chain. They proposed a multi-objective

mixed-integer 0-1 model to support sustainable

supply chain design over a long-term period of time.

The model distinguishes between solid and liquid

wastes, as well as gaseous emissions due to various

production processes and transportation modes. The

model is used to evaluate the tradeoffs between

economic and environmental objectives under

various cost and operating strategies for an

aluminum company. Finally, Diabat and Simchi-

Levi (2010), use a mixed-integer 0-1 programming

model including carbon emissions restrictions for

designing green supply chains. The problem is to

decide which plants and Distribution Centers (DCs)

to open, how the DCs are allocated to the plants, and

how the DCs distribute multiple types of products to

satisfy retailers’ demands. The objective is to

minimize the total facility opening and products

distribution costs subject to the total carbon emission

is not more than a predetermined emission cap. They

formulated the problem as a two-echelon multi-

commodity facility location problem with a carbon

emission constraint. They presented numerical

results for a 7 candidate plants, 18 candidate DCs,

63 retailers, and a single type of product. To solve

the instances, the authors use ILOG CPLEX 11.0

MIP solver in the GAMS modeling language.

The problem of locating facilities and allocating

customers is not new to the operations research

community and covers the key aspects of supply

chain design (Daskin, Snyder & Berger, 2005).

Simchi-Levi et al. (2007) establish a clear link

between location models and strategic SCM.

Altiparmak, Gen, Lin, and Paksoy (2006) pointed

out that this problem is one of “the most

comprehensive strategic decision problems that need

to be optimized for long-term efficient operation of

the whole supply chain”. Notice that, in Lai-Jun

Xiao-Ling and Zhongke (2009) a genetic algorithm

was used to solve a kind of facility location problem

on test networks with 10 potential facility sites and

30 demand points. In this paper we focus on the

sustainable supply chain design problem that arises

in governmental agencies, where you have to decide

the location of schools, hospitals, police stations, fire

stations, and so on, taking into account sustainable

issues.

3 PROBLEM FORMULATION

The sustainable supply chain network design

problem consists in deciding the number and

location of facilities, and the allocation of customers

to these facilities, minimizing the installation and

transportation costs integrated with GHG emissions

constraints. Our problem is uncapacitated by nature,

following most of the research on locating public

facilities, i.e., we do not restrict the capacity of the

facilities to service the demand. Our interest is to

analyze how service costs of governmental agencies

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

224

will be affected by sustainable restrictions. We

assume that GHG emissions come mainly from the

operation of the facilities and from the transportation

activities involved to service a fixed demand. We

suppose that GHG emissions are proportional to the

demand, i.e. population to be attended, and the travel

distance.

We introduce the following inputs and sets:

J = the set of demand nodes indexed by j

I = the set of candidate facility locations, indexed

by i

h

j

= demand at customer location j

∈

J

f

i

= fixed cost of locating a facility at candidate site i

∈

I

c

ij

= is the unit cost of supplying demand j

∈

J from

a facility located in i

∈

I

M = cardinality of J

α

i

= GHG emissions factor of a facility located at

candidate site i

∈

I

, in tons of CO

2

e per unit demand

β

ij

= GHG emissions factor per unit distance and per

unit demand between candidate facility site i

∈

I and

customer location j

∈

J, in tons of CO

2

e per km and

unit demand

and the following decision variables:

y

=

1

0 otherwise

x

ij

= is the fraction of the demand of j

∈

J supplied

from i

∈

I

The general supply chain design problem with

sustainable constraints ((GUSSCP) is defined by:

(

)

=

+ ℎ

(1)

:

= 1 ∀

(2)

≤

∀

(3)

ℎ

+

ℎ

≤

(4)

≥ 0 ∀ ,∀ (5)

0,1

∀ (6)

The objective function (1) minimizes the sum of

the installation facility costs and the demand-

weighted supplying costs. Constraints (2) warranty

that all demand is met. Constraints (3) warranty that

a demand node j must be allocated to a facility i

∈

I

already opened. Constraint (4) limits the total

Greenhouse Gas (CO

2

e) emissions to GHG.

Constraints (5) are non-negativity constraints and

constraints (6) are standard binary constraints.

Notice that, we would define the variables x

ij

∈

{0,1},

∀

i

∈

I,

∀

j

∈

J; however, the well-known

single assignment property of a related facility

location problem, warranties that a demand node j is

always serviced by only one facility. Regarding

constraints (3), when they are replaced by

constraints

≤

∀ ,∀ (3)

we got a stronger formulation for the problem, as

it was also discussed in a related facility location

problem (Cornuejols, Fisher & Nemhauser, 1977).

4 GENETIC ALGORITHM

IMPLEMENTATION

Genetic Algorithms (GAs) are a type of evolutionary

algorithms (EVA) used to solve a number of

combinatorial optimization problems. See for further

details the papers by De Jong and Spears (1989) and

Goldberg (1989). According to Osman and Kelly

(1996), an EVA is composed by five basic

components: (a) a genetic representation of solutions

to a problem; (b) a way to create an initial

population of solutions; (c) an evaluation function;

(d) genetic operators that alter the genetic

composition of children during reproduction and (e)

values for the parameters. In this section we briefly

describe these components and the GA

implementation for solving the GUSSCP problem.

In our implementation, each solution (individual)

to the problem is coded as a chromosome such that

each gene corresponds to a facility location decision

variable, taking value 1 if a facility is open and zero

otherwise.

The initial population of 100 individuals is

generated randomly. Then we recombine this initial

population and generate randomly two sets of 100

individual each. Each gene of the chromosome is

generated by a 0-1 uniform probability distribution.

Regarding the GHG emissions, this mechanism

could generate unfeasible solutions for GUSSCP, but

our strategy was to explore the behaviour of the

algorithm based on an initial population composed

of a number of unfeasible solutions. For our test

problems, the GA implemented in this way rapidly

generated a large number of unfeasible solution and

it obtained poorer solutions than the next approach

we will discuss it. In the second approach, after the

crossover and mutation operations, we introduce a

A GENETIC ALGORITHM FOR SOLVING A PUBLIC SECTOR SUSTAINABLE SUPPLY CHAIN DESIGN

PROBLEM

225

greedy-random procedure to generate to every

iteration of the GA at least 50% of feasible

solutions. Then our new population in every

iteration has at least 50% of feasible solutions. The

procedure is as follow: we generate a random

individual consisting of a number of facilities

opened/closed. Then based on the transportation

costs, we allocate the nearest client to each facility

opened. We do this till we get 50% of feasible

solutions for the new population. We replace

unfeasible solutions for the new ones obtained

through this procedure. Finally the best 100

individuals will be part of the new initial population

to start the main iteration of GA. As we can see later

in this paper, computational results are very good.

The fitness of a chromosome is calculated using

the objective function (1). To compute the first term

(installation costs) of (1) is straight forward from the

chromosome. To compute the second term

(transportation costs) of (1), we use a simple

procedure: for each customer we find its nearest

opened facility (minimal transportation cost). Then

we sum up both parts (installation and transportation

costs) to get the objective function value for each

individual of the population.

We use the standard genetic operators. The

crossover generates two new individual

(chromosome) exchanging the genetic material of

two (parental) individuals expecting that "good"

solutions can generate "better" ones. We selected

these individuals randomly from a two sets of

individuals, each set composed of 100 individuals as

described earlier. We do not limit the number of new

chromosomes generated by crossover. In this work

crossover probability (cross_p) is set to 0.7 (70%)

and we perform one-point crossover. The crossover

procedure is quite simple, we generate a random

value, if the cross_p value is greater than the random

value then we pick one individual from each set. We

generate another random value between one and the

number of potential facility sites, i.e, a cut point

dividing each individual (parent) into two segments.

The first child is created by combining the first

segment from the first parent and the second

segment from the second parent. The second child is

created from the first segment of the second parent

and the second segment of the first parent. The

mutation operator changes the value of a

chromosome with some small probability. In our

case, we get this probability to 0.1 (10%). The gene

in the chromosome is selected randomly and we

switch its value (0-1). We do not limit the number of

new chromosomes generated by mutation. The

selection operator is based on elitist selection,

favoring individuals of better fitness value to

reproduce more often than the worse ones when

generating the new population. In every iteration the

whole population (200 individuals) is ranked in a

non-decreasing order of the objective function value.

As we described earlier, feasibility of constraints (5)

is verified. In case there is lesser than 50% of

feasible solutions in the population, a greedy-

random procedure was implemented to generate new

(feasible) individuals. The best (100) solutions

passed to the next iteration.

In our case the total size of population is 200

individuals, and 100 of new individuals are

generated each iteration. We set the total number of

iteration to six.

5 COMPUTATIONAL RESULTS

The GA solution method for this problem was coded

and implemented by Scilab software. According the

sustainable supply chain literature discussed in

previous section, for testing our GA implementation

we generated 11 small size instances of GUSSCP.

These instances correspond to test networks up to 26

potential sites and up to 50 demand nodes taken

from the ORLIB (Beasley, 1996). As we do not

know in advance how well is going to perform the

GA, in order to validate our GA solutions we used

GAMS on integer linear programming model

described in section 3. Every test problem was

running 5 times and we present an average value in

Table 1. The optimal objective values were obtained

by GAMS. As we can see in Table 1, besides the

few number of iteration (6) used in our GA, the GAP

obtained is quite small. Both methods (GA and

GAMS) quickly converge on mentioned GUSCPS

instances and their running times are not reported.

The alpha (α) and beta (β) parameters were set to

one and two respectively. This was done to analyze

the behaviour of the algorithm and also to check

how the solution change when you penalty the

transportation GHG emissions. Total GHG

emissions were limited to values between 3,200.00

and 10,000.00 thousands.

We notice that, when you reduce the total amount of

GHG emissions permitted, and the number of

facilities remain free, the number of facilities to

open increase, also increasing the cost of the

solution but reducing the amount of GHG emitted by

the transportation component.

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

226

6 CONCLUSIONS

In this paper, we introduced a novel kind of

sustainable supply chain network design problem

with a GHG emission constraint. The problem

addressed the design of supply network arising

mainly in the public sector, where we need to satisfy

the demand for services like education and health

care locating a number of facilities. We limit the

GHG emissions generated by the facilities and the

transportation involved in servicing the customers.

The problem was formulated as a mixed integer 0-1

linear programming problem (MIP) and solved using

a genetic algorithm coded in Scilab. We conducted

an experimental study on instances of small sizes

taken from the ORLIB. In order to validate our GA

solutions we used GAMS to obtain optimal objective

values on the MIP. The genetic algorithm performs

very good considering we set a few number of

iterations. We observed that when you reduce the

total amount of GHG emissions permitted, and the

number of facilities remain free, the number of

facilities to open increase, also increasing the cost of

the solution but reducing the amount of GHG

emitted by the transportation component.

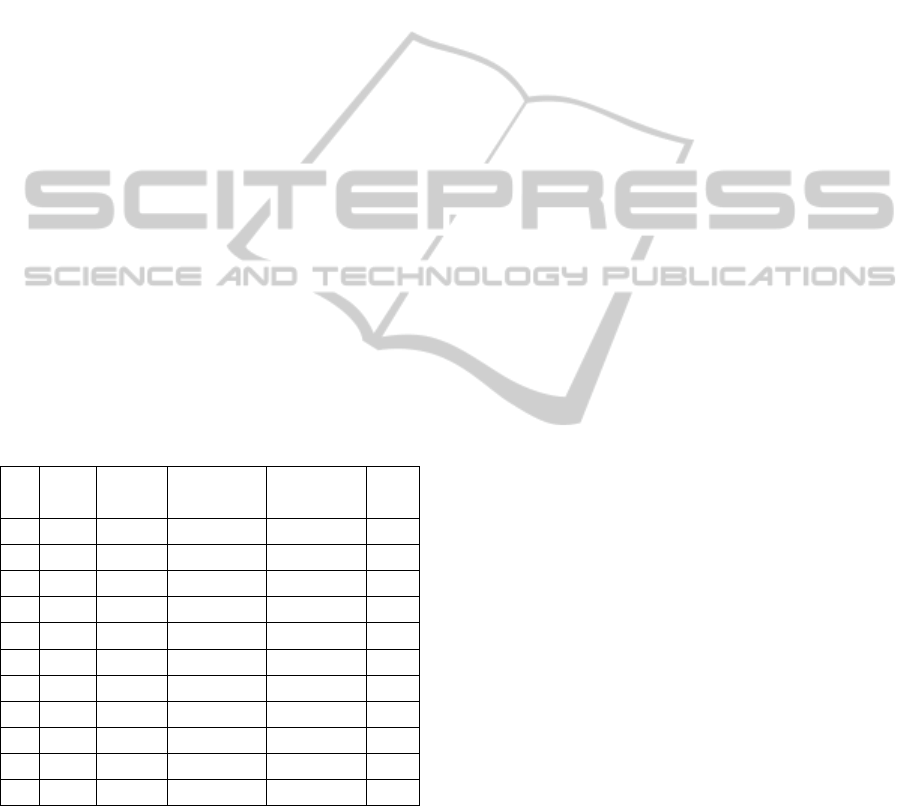

Table 1: Computational Results. First column indicates

number of problem instance; Fixed Costs in thousands; z*

is the optimal solution; z(GA) is the solution value

provided by GA.

#

Pr

Fixed

Costs

(th.)

Total

GHG

(mil.)

z* z(GA) GAP

(%)

1 25,0 10,0 1,746,347 1,775,425 1.7

2 17,5 10,0 1,727,848 1,731,842 0.2

3 12,5 10,0 1,700,236 1,700,841 <0.1

4 25,0 5,0 1,746,348 1,775,425 1.7

5 25,0 3,2 1,953,224 1,953,224 0.0

6 17,5 3,2 1,840,724 1,840,724 0.0

7 12,5 3,2 1,765,724 1,765,724 0.0

8 7,5 3,2 1,690,724 1,690,724 0.0

9 7,5 3,3 1,663,018 1,684,578 1.3

10 12,5 3,3 1,700.236 1,765,723 3.9

11 17,5 3,3 1,730,236 1,773,011 2,5

REFERENCES

Altiparmak, F., Gen, M., Lin, L. & Paksoy, T. (2006). A

genetic algorithm approach for multiobjective

optimization of supply chain networks. Computers &

Industrial Engineering, 51, 197–216.

Beasley, J. E. (1996). Obtaining test problems via Internet.

Journal of Global Optimization, 8, 429-433.

Choi T. Y. & Wu, Z. (2009). Taking the leap from dyads

to triads: Buyer–supplier relationships in supply

networks. Journal of Purchasing and Supply Mana-

gement, 15(4), p. 263-266.

Chaabane, A., Ramudhin, A. & Paquet, M. (2010).

Optimization and evaluation of sustainable supply

chains. In Proceedings of the 8th. International

Conference of Modelling and Simulation – MOSIM

2010. Tunisia.

Cornuejols, G., Fisher, M. L. & Nemhauser, G. L. (1977).

Location of bank accounts to optimize float: An

analytic study of exact and approximate algorithms.

Management Science, 23, 789–810.

Daskin, M. S., Snyder, L. V. & Berger, R. T. (2005).

Facility Location in Supply Chain Design. In A.

Langevin and D. Riopel (Eds.), Logistics Systems: De-

sign and Optimization (pp. 39-65). Kluwer.

De Jong, K. E. & Spears, W. M. (1989). Using Genetic

Algorithms to Solve NP-Complete Problems. In

Proceedings of the Third International Conference on

Genetic Algorithms (pp. 124-132). San Mateo, Cali-

fornia: Morgan Kaufmann.

Diabat, A. & Simchi-Levi, D. (2010). A carbon-capped

supply chain network problem. In Proceedings of

IEEE International Conference on Industrial

Engineering and Engineering Management 2009 (pp.

523-527). Piscataway, N.J.: IEEE.

Goldberg, D. (1989). Genetic Algorithms in Search,

Optimization and Machine Learning. Reading: Addi-

son-Wesley.

Hugo, A & Pistikopoulos, E. (2004). Environmentally

conscious process planning under uncertainty, In C.A.

Floudas & R. Agrawal (Eds.), Sixth international

conference on foundations of computer-aided process

design. Princeton: CACHE Corporation.

Hugo, A. & Pistikopoulos, E. (2005). Environmentally

conscious long-range planning and design of supply

chain networks. Journal of Cleaner Production:

Recent advances in industrial process optimization,

13(15), 1471-1491.

Lai-Jun, W., Xiao-Ling, S. & Zhongke. S. (2009). New

evolutionary Algorithm Applying to a Type of Facility

Location Problem. Information Technology Journal, 8

(4), 605-609.

Osman, I. H. & Kelly, J. P. (1996). MetaHeuristics:

Theory & Applications. Kluwer Academic Publishers.

Ramudhin, A., Chaabane, A., Kharoune, M. & Paquet, M.

(2008). Carbon market sensitive green supply chain

network design. In Proceedings IEEE International

Conference on IEEE (pp. 1093-1097). Singapore.

Seuring, S. & Muller, M. (2008). From a literature review

to a conceptual framework for sustainable supply

chain management. Journal of Cleaner Production,

16, 1699-1710.

Simchi-Levi, D., Kaminsky, P., and Simchi-Levi, E.,

2007. Designing & Managing the Supply Chain (3rd.

ed.). Boston, MA: McGraw-Hill/Irwin.

Srivastava, S., 2007. Green Supply-Chain Management: A

State-of-the-Art Literature Review. International

Journal of Management Reviews, 9(1), 53-80.

A GENETIC ALGORITHM FOR SOLVING A PUBLIC SECTOR SUSTAINABLE SUPPLY CHAIN DESIGN

PROBLEM

227